Cooling method used for improving steel coil quality

A cooling method and steel coil technology, which is applied in the field of steelmaking, can solve the problems of long residence time of hot coils at high temperature, and achieve the effects of improving the pickling speed, accelerating the cooling speed, and ensuring the quality of pickling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

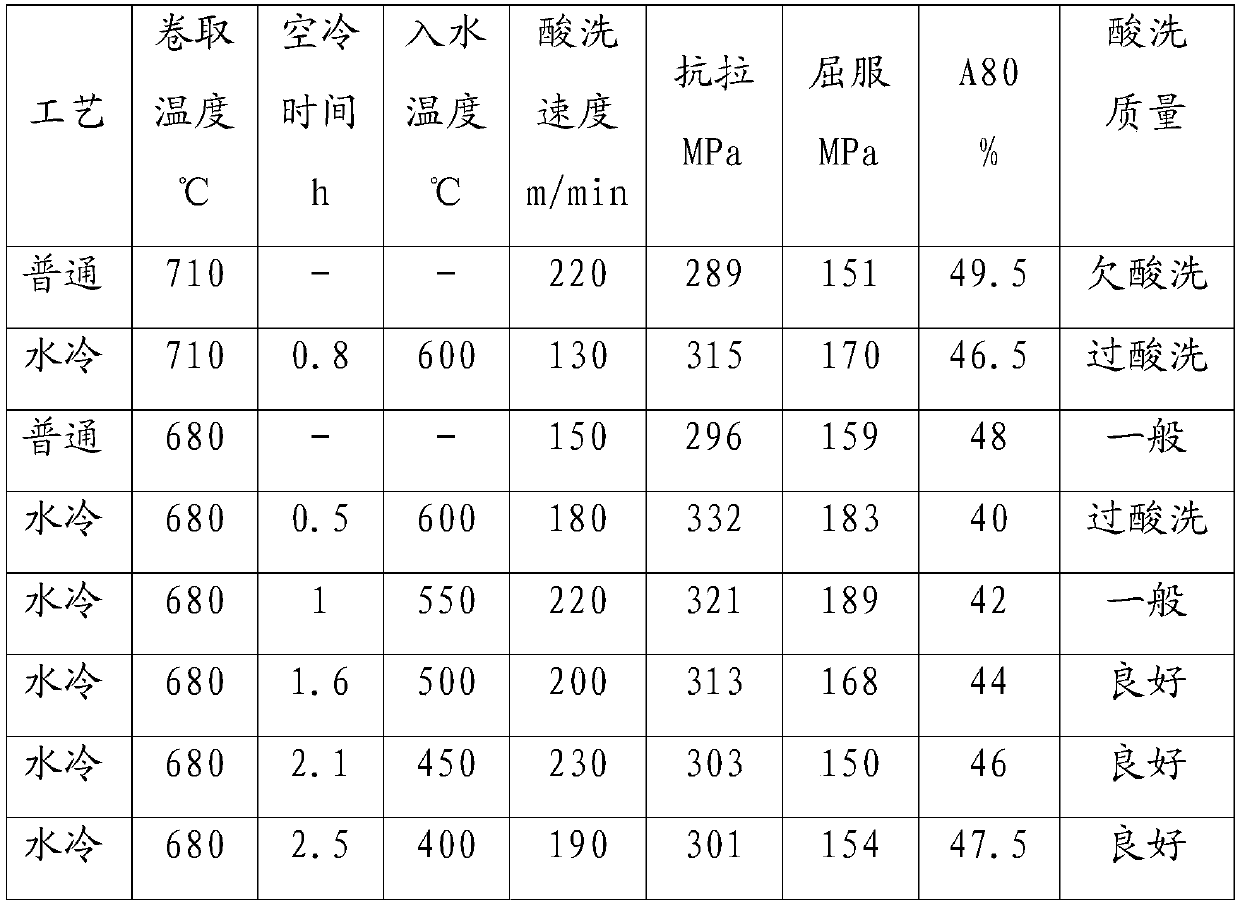

[0028] By providing a cooling method for improving the quality of steel coils, the embodiment of the present invention solves the technical problem of excessively long residence time of hot coils at high temperature in the prior art, realizes the guarantee of pickling quality, avoids excessive consumption of acid solution and ensures The technical effect of the stability of the surface quality of the hot coil.

[0029] The technical solution in the embodiment of the present invention is to solve the above-mentioned problems, and the general idea is as follows:

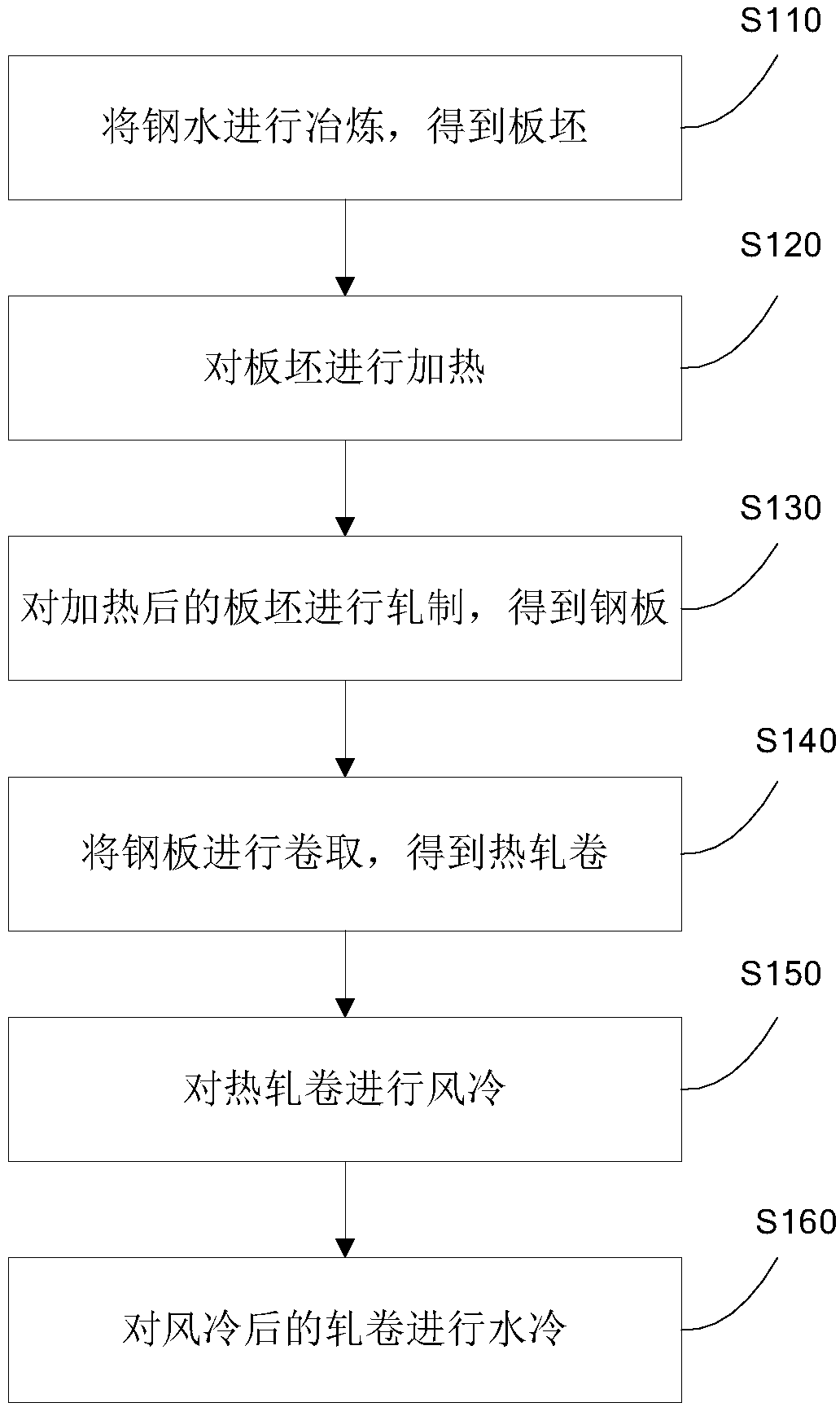

[0030] First smelt the molten steel to obtain a slab; then heat the slab; then roll the heated slab to obtain a steel plate; then coil the steel plate to obtain a hot-rolled coil; then wind the hot-rolled coil cold; finally water-cool the air-cooled rolled coils. Among them, the process of air cooling and water cooling is carried out in sequence, which speeds up the cooling speed, thereby solving the technical problem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com