Pickling treatment device and treatment method before epoxy powder spraying of steel pipe

A technology of epoxy powder and processing equipment, which is applied in the field of pipeline spraying, and can solve the problems that affect the effect of cathodic stripping resistance of the final coating and the steel pipe is easy to rust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

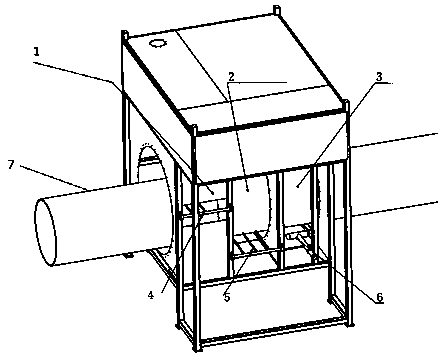

[0016] A specific implementation steps of pickling treatment before epoxy powder spraying of steel pipes:

[0017] Firstly, the steel pipe conveying device conveys the steel pipe 7 to the pickling bin 1 and sprays acid through the low-pressure acid spray pipe 4 for sufficient acid spray;

[0018] Secondly, after the steel pipe 7 has been sprayed with the above-mentioned acid liquid, it is then transferred to the high-pressure flushing chamber 2 by the steel pipe conveying device and fully cleaned with pure water to remove the residual acid liquid on the surface of the steel pipe 7;

[0019] Finally, the cleaned steel pipe 7 in the high-pressure flushing chamber 2 is transferred to the air-drying chamber 3 by the steel pipe conveying device and dried by the air-drying air knife assembly 6, that is, the pretreatment process is completed.

[0020] Pass the derusted steel pipe 7 through the steel pipe transmission device, first pass through the pickling chamber 1 for acid spraying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com