Shock absorption and isolation rubber product steel plate cleaning device and cleaning method

A technology of rubber products and cleaning devices, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of large amount of dirt carried, hazards to operators, low cleaning efficiency, etc., and achieve high efficiency Thorough cleaning, avoiding rust and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

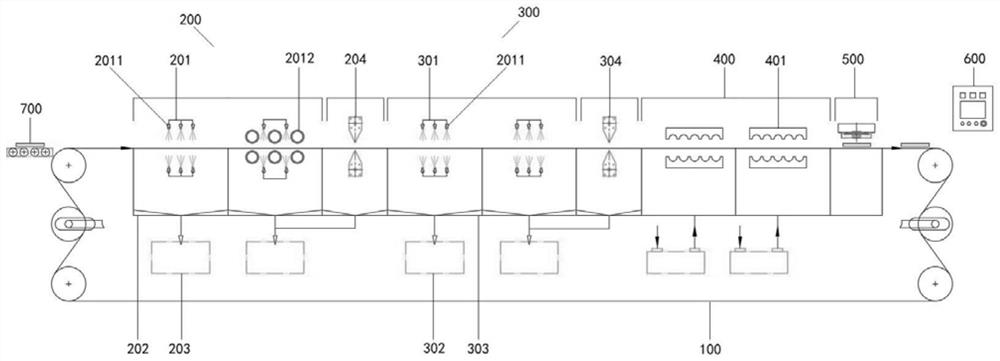

[0047] See Appendix Figure 1-3 , a shock absorption rubber products steel plate cleaning device, including:

[0048] Transmission unit 100, one end of which is the feeding end, one end is the unloading end; the transmission unit 100 is used to drive the steel plate workpiece 700 to move;

[0049] Along the transmission unit 100 transmission direction sequentially disposed solvent cleaning unit 200, clean water rinsing unit 300, hot air drying unit 400 and cooling unit 500, wherein:

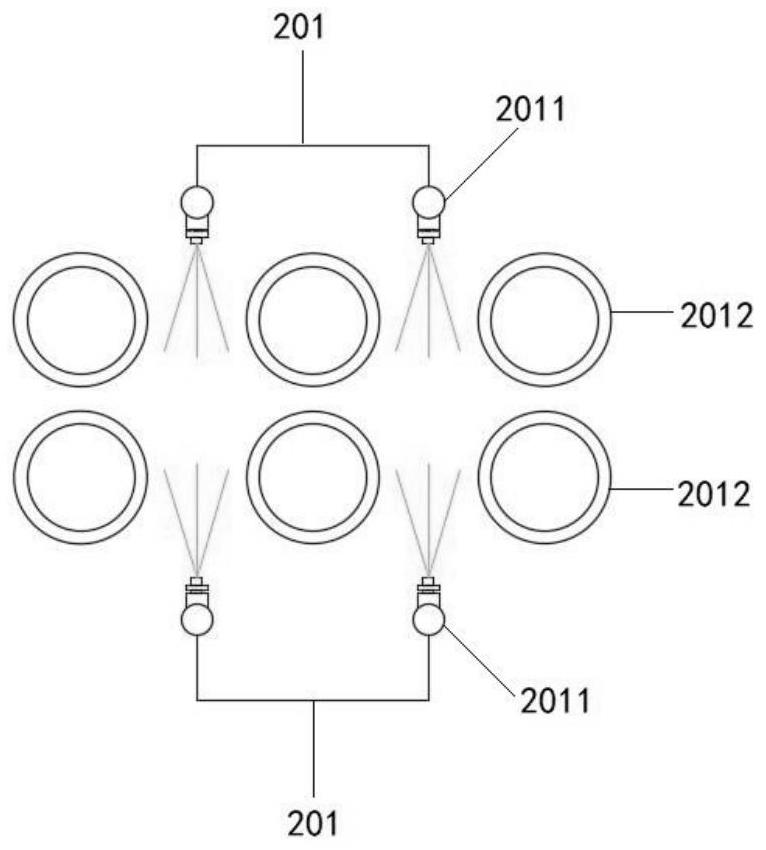

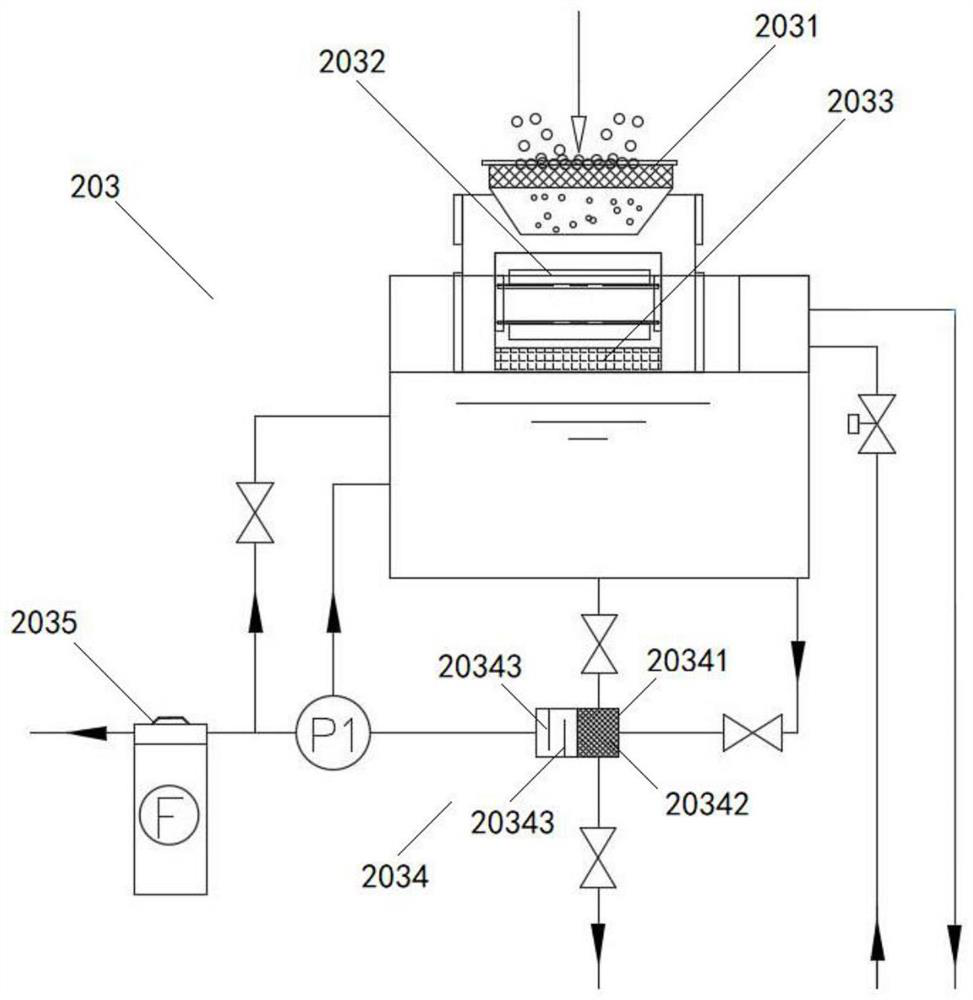

[0050] The solvent cleaning unit 200 is provided with at least one set, comprising a symmetrically disposed solvent spray pipe 201 on both sides of the upper part of the transmission unit 100, a solvent storage tank 202 disposed below the solvent spray pipe 201, a solvent filtration device 202 and a solvent spray pipe 201 connected to the solvent spray pipe 203 and a symmetrically disposed on both sides of the upper part of the transmission unit 100 and located after the solvent spray pipe 201 first a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com