Automatic dipping and extrusion machine

An all-in-one machine and extrusion mechanism technology, applied in the field of wave-absorbing material preparation, can solve problems such as low work efficiency, achieve the effect of convenient feeding, convenient feeding, and avoid rigid extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

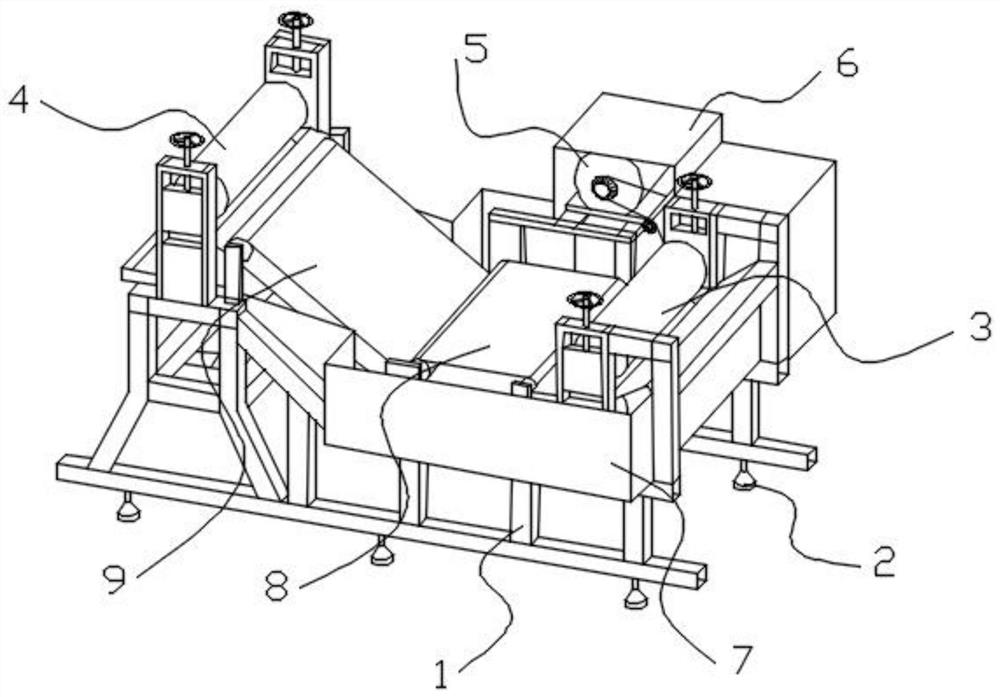

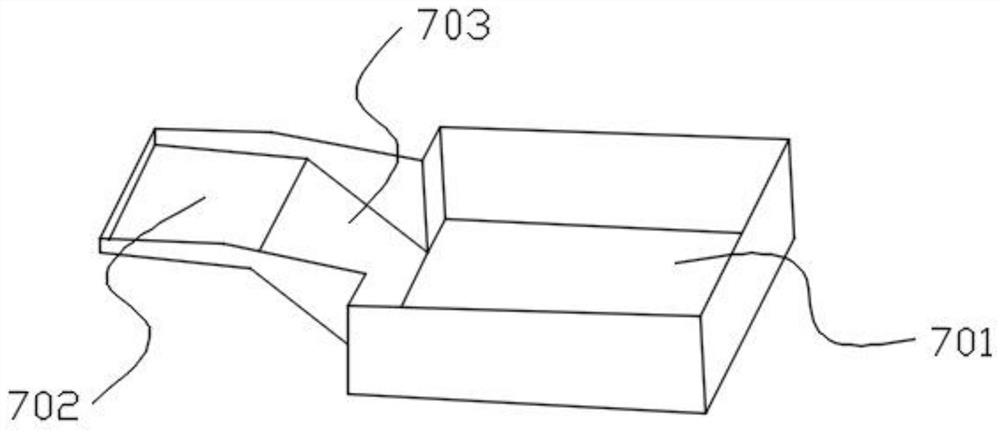

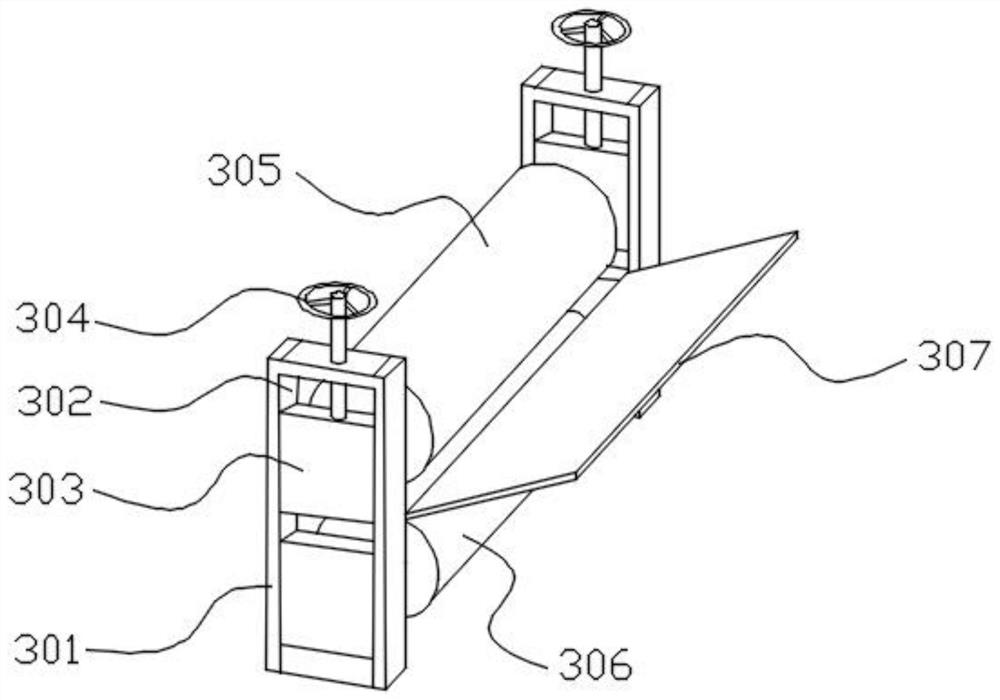

[0039] Such as figure 1 with Figure 5 As shown, an automatic impregnation extrusion machine includes a bracket 1 and a dipping pool 7 arranged on the bracket 1, and the two ends of the dipping pool 7 along the production line direction of the wave-absorbing material are dipping ends respectively. and the extruding end, the impregnation end and the extruding end of the impregnation tank 7 are respectively provided with an impregnation mechanism 3 and an extruding mechanism 4, and the inside of the impregnation pool 7 is provided with a connection impregnation mechanism 3 and an extruding mechanism The transmission mechanism of the mechanism 4, the drive motor 5 for driving the dipping mechanism 3, the extruding mechanism 4 and the transmission mechanism is also provided on the support 1, the drive motor 5 is provided with a protective cover 6, and the bottom of the support 1 is provided with a foot pad 2. Bracket 1 uses high-strength square steel to reduce weight, but the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com