Green phosphating anti-corrosion treatment liquid suitable for steel surface as well as preparation method and application of green phosphating anti-corrosion treatment liquid

A technology of anti-corrosion treatment and steel surface, applied in the direction of metal material coating process, etc., can solve the problem that the effect cannot meet the quality requirements, and achieve the effect of reducing sandblasting and rust removal operations, simple production process and promoting chemical reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

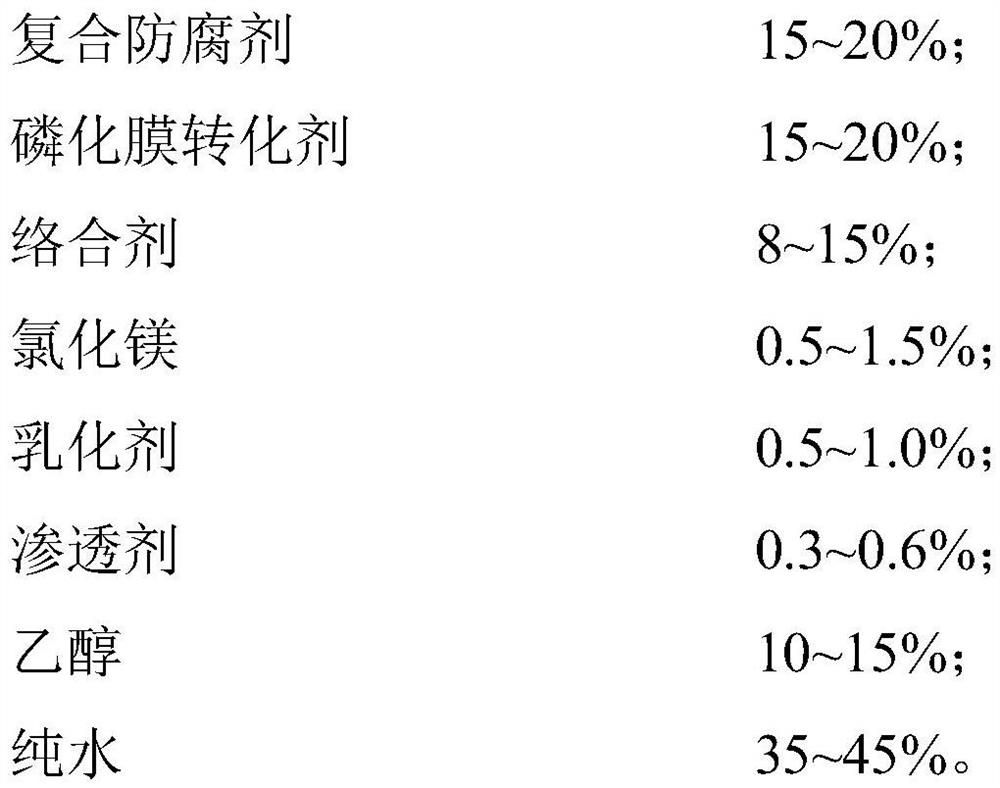

[0038] A green phosphating anticorrosion treatment solution suitable for steel surfaces, consisting of the following components by weight percentage:

[0039]

[0040] In weight percentage, the composite preservative is composed of the following raw materials: 60% water, 30% triethanolamine, 5% ammonium molybdate, 5% sodium molybdate;

[0041] The raw materials of the composite preservative are mixed, heated and stirred at 70-80° C. until the materials are completely dissolved and transparent, and the composite preservative is obtained.

[0042] In terms of weight percentage, the phosphating film converting agent is composed of the following raw materials: 66.67% phosphoric acid, 13% zinc dihydrogen phosphate, 11% zinc phosphate, 6% iron manganese phosphate, 3.33% zinc oxide;

[0043] The raw materials of the phosphating film converting agent are mixed, heated and stirred at 55-65° C. until the materials are completely dissolved and transparent, and the phosphating film con...

Embodiment 2

[0056] A green phosphating anticorrosion treatment solution suitable for steel surfaces, consisting of the following components by weight percentage:

[0057]

[0058] The raw materials and preparation of each component in this embodiment and the preparation and application of the antiseptic treatment solution refer to Example 1.

Embodiment 3

[0060] A green phosphating anticorrosion treatment solution suitable for steel surfaces, consisting of the following components by weight percentage:

[0061]

[0062] The raw materials and preparation of each component in this embodiment and the preparation and application of the antiseptic treatment solution refer to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com