Environment-friendly steel pipe expanding extreme-pressure antirust emulsified oil as well as preparation method and application thereof

A technology of anti-rust emulsified oil and shaped steel pipes, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of no suitable working fluid, etc., achieve easy application and removal, uniform metal deformation, and reduce low friction to force and The effect of motivational demands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

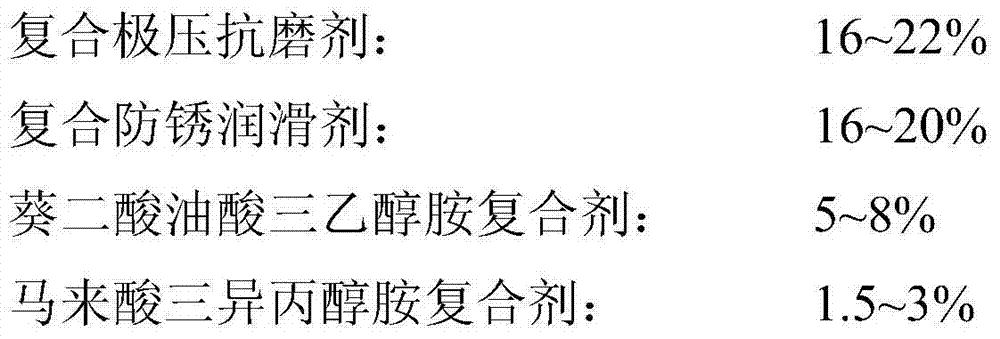

Examples

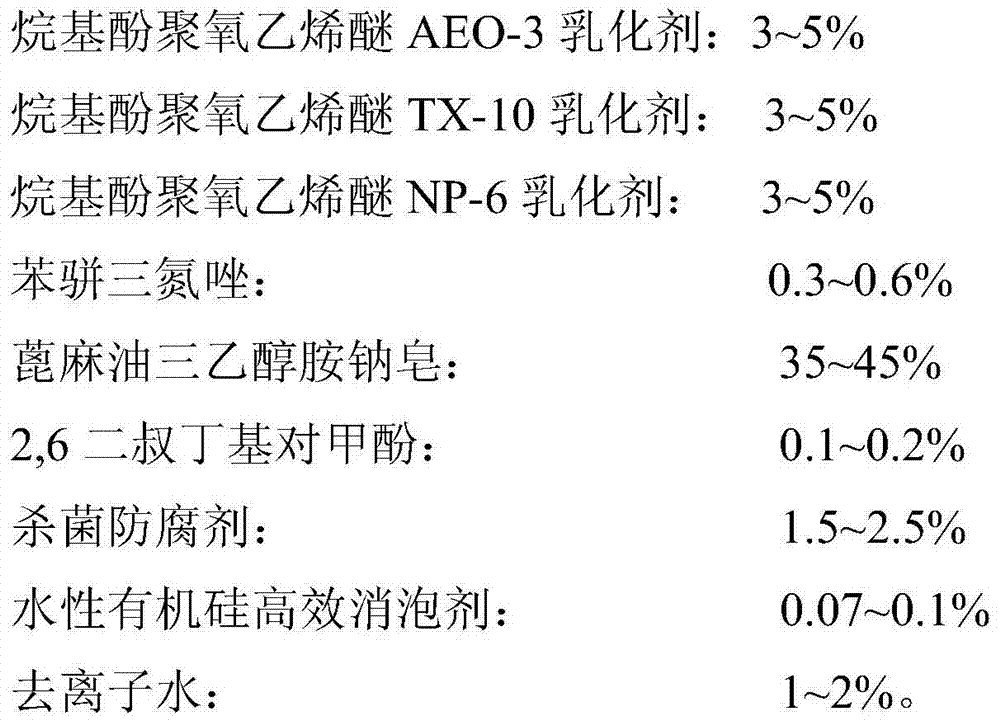

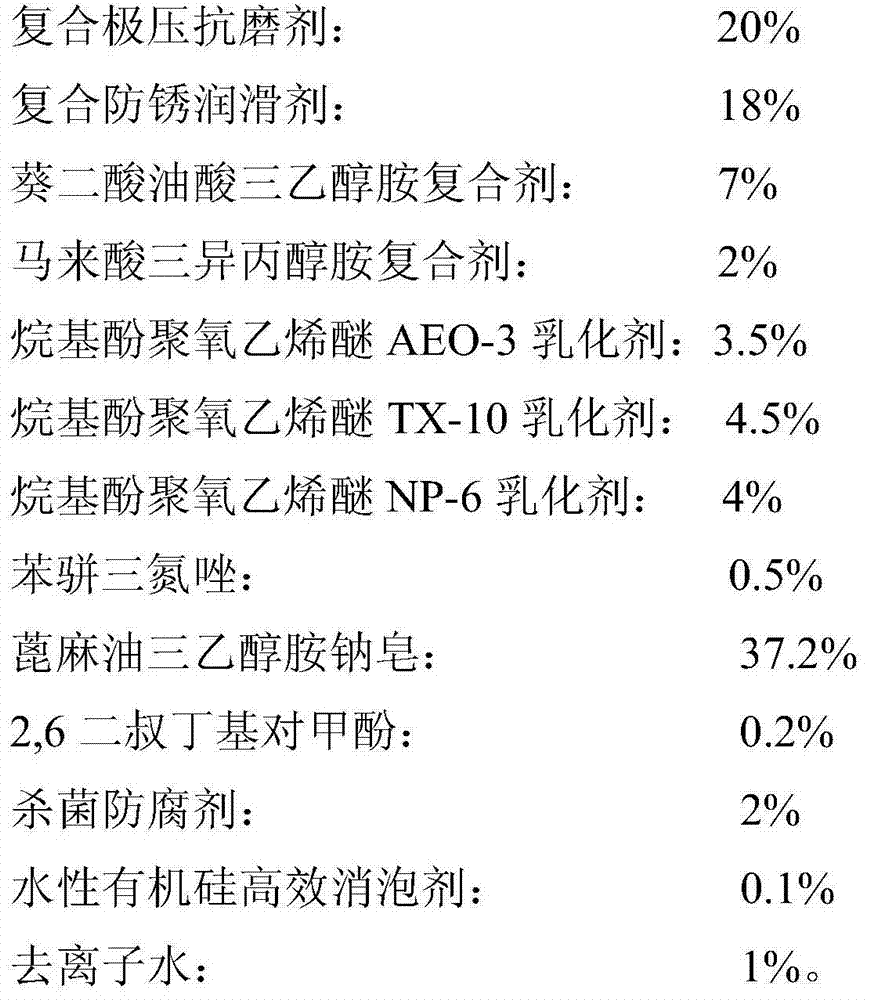

Embodiment 1

[0054] Composite extreme pressure antiwear agent is prepared by the following steps:

[0055] Add 35% chlorinated paraffin-52, 30% RC2526 additive, 15% sulfurized isobutylene, 10% sulfurized olefin cottonseed oil, 10% S-80 emulsifier into the reaction kettle, mix and heat up to 60-80°C, stirring continuously React for 30-60 minutes until the mixed material is completely dissolved and uniform to obtain a composite extreme pressure antiwear agent; the percentages mentioned are the percentages of each component in the total weight of the composite extreme pressure antiwear agent raw materials.

[0056] Composite anti-rust lubricant is prepared by the following method:

[0057] Add 44.44% sodium petroleum sulfonate, 44.44% alkanolamide 6501, 11.12% S-80 emulsifier into the reaction kettle, mix and heat up to 55-70°C, keep stirring for 30-60 minutes until the mixture is completely dissolved Until it is transparent, the composite antirust lubricant is obtained; the percentages ment...

Embodiment 2

[0069] The preparation methods of composite extreme pressure antiwear agent, composite antirust lubricant, sebacic acid oleic acid triethanolamine composite agent, maleic acid triisopropanolamine composite agent, and castor oil triethanolamine sodium soap are the same as in Example 1.

[0070] A method for preparing an environment-friendly steel pipe diameter-expanding extreme-pressure anti-rust emulsified oil, comprising the following steps:

[0071] (1) Add 0.5% deionized water, 3% alkylphenol polyoxyethylene ether AEO-3 emulsifier, 4.5% alkylphenol polyoxyethylene ether TX-10 emulsifier, 4% alkylphenol polyoxyethylene ether to the reactor Oxyethylene ether NP-6 emulsifier, heat up to 60-80°C, mix and stir for 30-60 minutes, add 0.3% benzotriazole, and stir until the mixture is completely dissolved and uniform, then cool down to 55-60°C;

[0072] (2) Add 16% compound extreme pressure anti-wear agent, 20% compound anti-rust lubricant, 8% sebacic acid oleic acid triethanolamin...

Embodiment 3

[0075] The preparation methods of composite extreme pressure antiwear agent, composite anti-lubricant, sebacic acid oleic acid triethanolamine composite agent, maleic acid triisopropanolamine composite agent, and castor oil triethanolamine sodium soap are the same as in Example 1.

[0076] A method for preparing an environment-friendly steel pipe diameter-expanding extreme-pressure anti-rust emulsified oil, comprising the following steps:

[0077] (1) Add 1% deionized water, 4% alkylphenol polyoxyethylene ether AEO-3 emulsifier, 5% alkylphenol polyoxyethylene ether TX-10 emulsifier, 4% alkylphenol polyoxyethylene ether to the reactor Oxyethylene ether NP-6 emulsifier, heat up to 60-80°C, mix and stir for 30-60 minutes, then add 0.5% benzotriazole, and stir until the mixture is completely dissolved, then cool down to 55-60°C;

[0078] (2) Add 21% compound extreme pressure anti-wear agent, 16% compound anti-rust lubricant, 6% sebacic acid oleic acid triethanolamine compound, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com