System and method for acid leakage treatment of acid tank and acid tank in cold rolling and acid rolling mill

A treatment method and acid tank technology are applied in the field of acid leakage treatment systems to achieve the effects of preventing the expansion of accidents, accelerating the rhythm of acid pouring, and ensuring the quality of pickling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

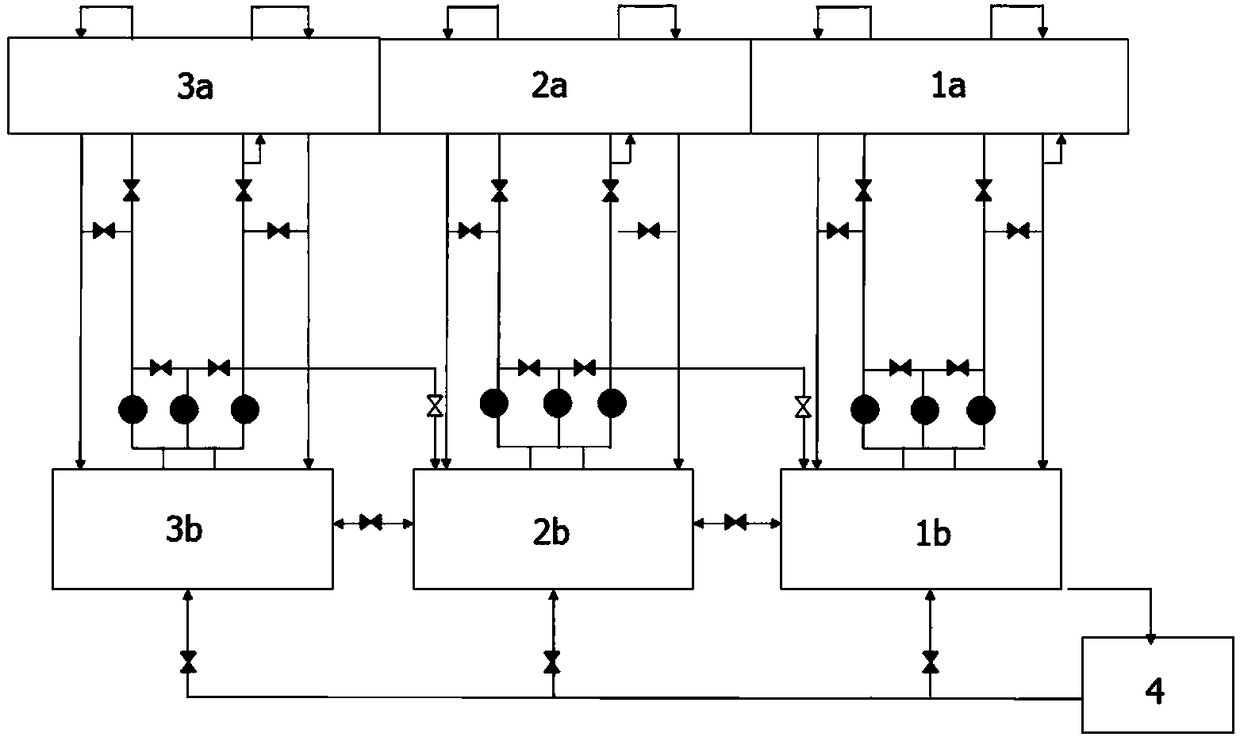

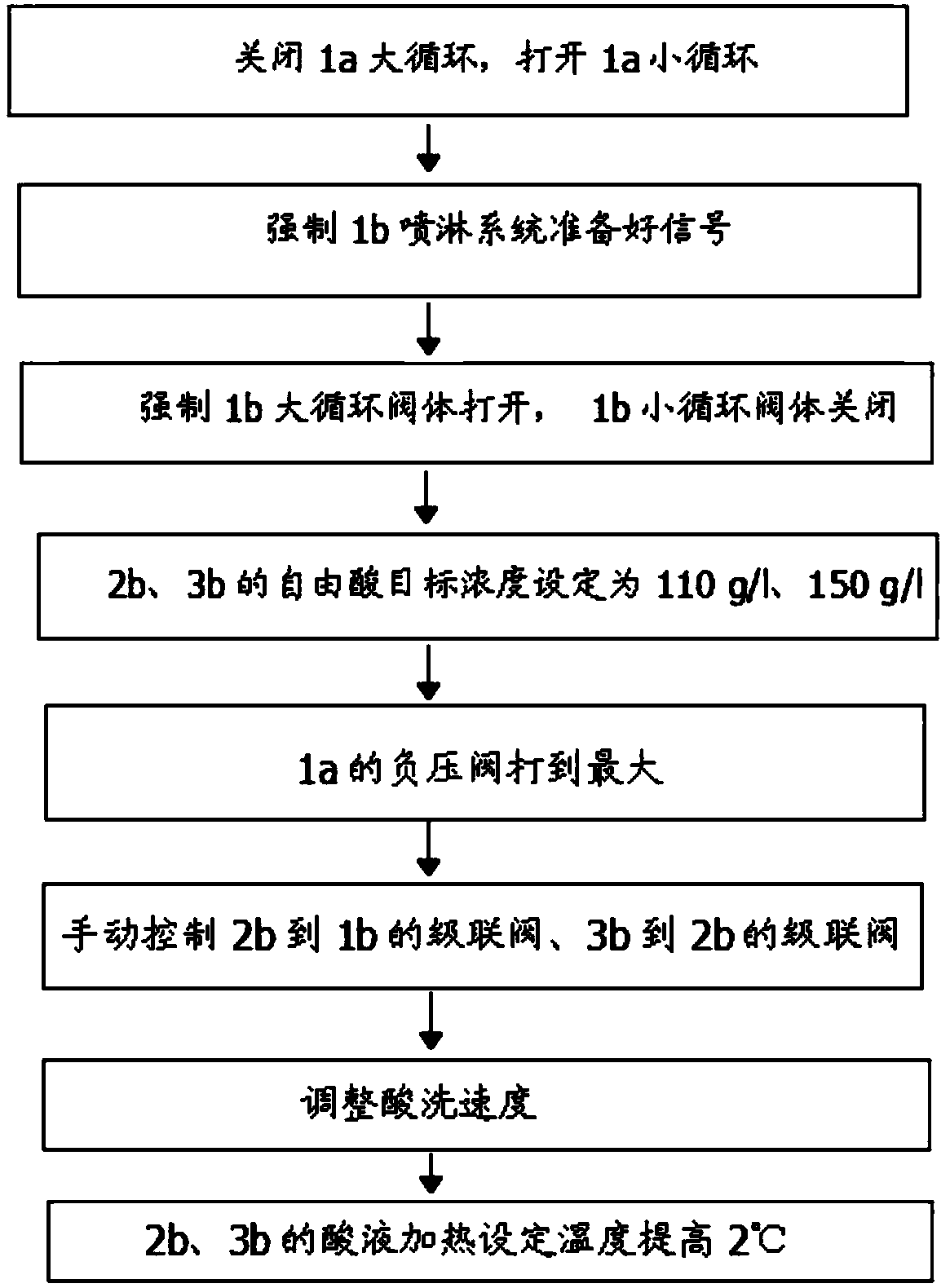

[0082] Embodiment 1: as image 3 In the flow chart shown, when the pickling process section is set to three acid tanks, the treatment method for the acid leakage of the first acid tank 1a in the embodiment of the present application includes the following steps:

[0083] 1. Close the large circulation system of the first acid tank 1a, and open the small circulation system of the first acid tank 1a. Force the ready signal of the sprinkler system of the first acid tank 1b, and at the same time force the large circulation valve body (SSV1111 and SSV1113) of the first acid tank 1b to open, and the small circulation valve body (SSV1112 and SSV1114) of the first acid tank 1b to close.

[0084] 2. Set the free acid target concentrations of the second acid tank 2b and the third acid tank 3b to 110g / l and 150g / l;

[0085] 3. Turn the negative pressure valve of the first acid tank 1a to the maximum position to ensure that the first acid tank 1a is always in a negative pressure state. ...

Embodiment 2

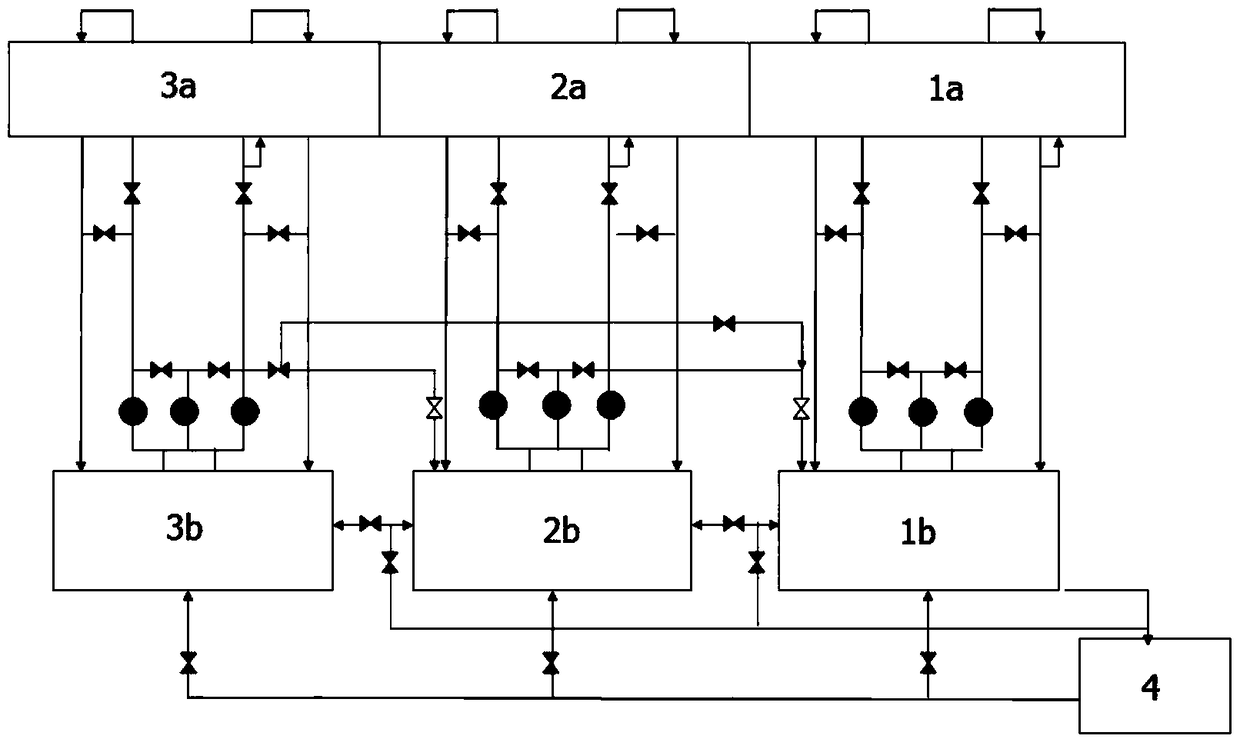

[0089] Embodiment 2: as Figure 4 As shown in the flow chart, when the pickling process section is set to three acid tanks, the treatment method when the third acid tank 3b leaks acid at the 55% liquid level in the embodiment of the present application includes the following steps:

[0090] 1. After the leak is temporarily blocked, open the third acid tank 3b to cascade to the second acid tank 2b, and at the same time open the third acid tank 3b to cascade to the first acid tank 1b (newly modified standby cascade), stop Beat acid and water to the third acid tank 3b.

[0091] 2. Modify the H, H, L, LL of the LIC1131 alarm value of the third acid tank 3b liquid level.

[0092] 3. Start the waste acid pump, and turn the waste acid valve of the third acid tank 3b to the acid regeneration system 4 to the maximum value.

[0093]4. Since the automatic liquid level setting of LIC1131 in the third acid tank 3b is calculated by the amount of spraying, the automatic liquid level settin...

Embodiment 3

[0095] Embodiment 3: as Figure 5 As shown in the flow chart, when the pickling process section is set to three acid tanks, the treatment method when the second acid tank 2b leaks acid at the bottom in the embodiment of the present application includes the following steps:

[0096] 1. The mandatory signal is as follows:

[0097] The second acid tank 2b heating system ready signal;

[0098] The ready signal of the sprinkler system of the second acid tank 2b;

[0099] The operation signal of the heating system of the second acid tank 2b;

[0100] The operation signals of the 3 spray pumps of the second acid tank 2b;

[0101] A total of 6 signals for the automatic heating system and sprinkler system of the second acid tank 2b;

[0102] The second tank 2b size loops a total of 4 signals;

[0103] There are 3 signals for forcing the temperature of the second acid tank 2b and the temperature of the pipeline.

[0104] 2. Stop the circulation pump of the second acid tank 2b, clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com