Technological method for cooling steel wires

A process method and steel wire technology, applied in cleaning methods and appliances, chemical instruments and methods, manufacturing tools, etc., can solve the problems of large consumption of bath liquid and high surface temperature of steel wire, so as to reduce the cost of wastewater treatment, avoid environmental pollution, and ensure Effect of Pickling Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

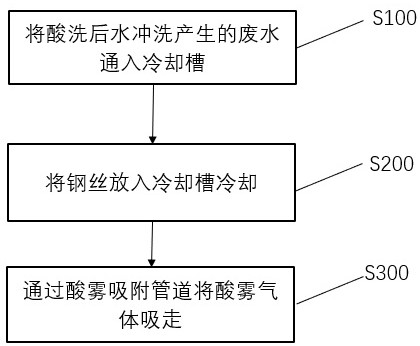

[0012] A process method for steel wire cooling in this embodiment includes the following steps: S100: pass the waste water generated by water washing after pickling into the cooling tank; S200: put the steel wire in the cooling tank to cool; S300: absorb the acid mist Pipes suck up the acid mist gas. In the above technical scheme, the cost of wastewater treatment can be reduced by using the pre-treated acid water to flush the overflow water and reuse it instead of tap water; at the same time, the pre-coated pickling steel wire is achieved in the production process, which better ensures the pickling quality of the steel wire . Pickling water is corrosive to a certain extent, and acid mist gas will be generated when passing through the high-temperature steel wire. The acid mist c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com