A method of pickling and purging hydraulic pipelines

A hydraulic pipeline and pickling technology, which is applied to cleaning methods and appliances, chemical instruments and methods, and cleaning hollow objects, etc., can solve the problems of inconvenience, pipeline pollution, increasing installation flanges and unions, etc. The method is feasible and the cost is low The effect of low and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

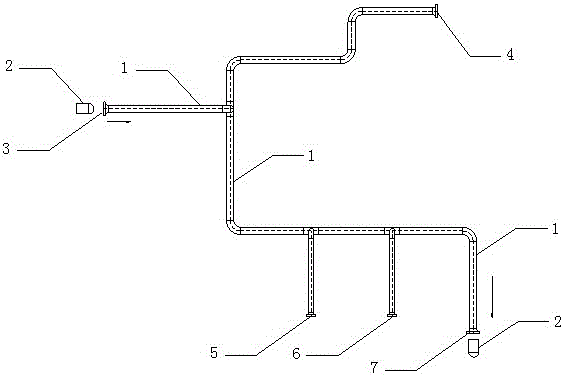

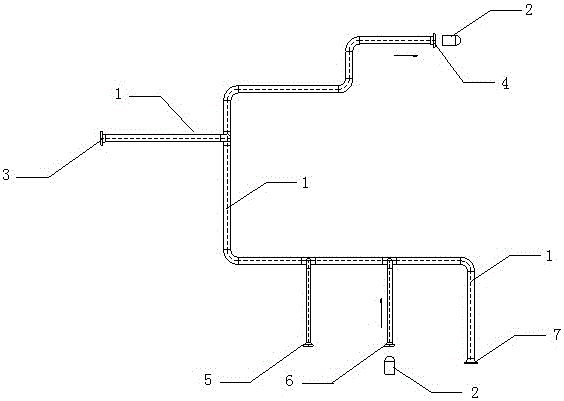

Image

Examples

Embodiment 1

[0040] The pickling and purging method for hydraulic pipelines of the present invention is characterized in that it comprises the following steps:

[0041] a. Tank-type pickling of hydraulic pipelines, including the following steps:

[0042] (1) Carry out tank pickling and passivation of hydraulic pipelines;

[0043] (2) After pickling and passivation, dry the water in the pipe with compressed air;

[0044] (3) After the pipe is blown, apply 20# weather anti-rust oil;

[0045] (4) Seal the nozzles at both ends of the oil-coated pipeline with sealing tape;

[0046] (5) When the nominal diameter of the pipeline is less than DN50, the pipeline is filled with some nitrogen gas when sealing the second nozzle, and the degree of nitrogen filling is qualified if the flame of the lighter can be extinguished when the nozzle is opened.

[0047] b. Pipeline installation, including the following steps:

[0048] (1) Pay attention to the dust in the installation environment during pipeli...

Embodiment 2

[0064] The nominal diameter of the pipeline is less than DN50 and the pipeline is purged

[0065] 1) First use abrasive grain type A to clean the head, dip some acetone on the cleaning head when purging;

[0066] 2) After purging, check that there are no large particles on the surface of the cleaning head at the outlet end, and then use the joint type C cleaning head to purge;

[0067] 3) Inspection: The surface color of the imported and exported cleaning head has not changed much; no tiny particles can be seen with the naked eye; the inner wall of the purged pipeline can see metallic luster, which is qualified;

[0068] 4) The number of cleaning heads used for pipeline purging is generally 5 for one pipeline.

[0069] The rest of this embodiment is the same as embodiment 1.

Embodiment 3

[0071] Nominal diameter of pipe > DN50 pipe purging

[0072] 1) The blasting membrane for blasting and purging is made of high-pressure cardboard with a thickness of 2mm, and the initiation pressure is controlled at 0.3Mpa according to the size of the pipe diameter;

[0073] 2) Set a firm target plate and protective measures at the purge port, and the target plate is made of 20mm thick wood.

[0074] The rest of this embodiment is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com