Recycling method of waste acid from stainless steel acid washing process

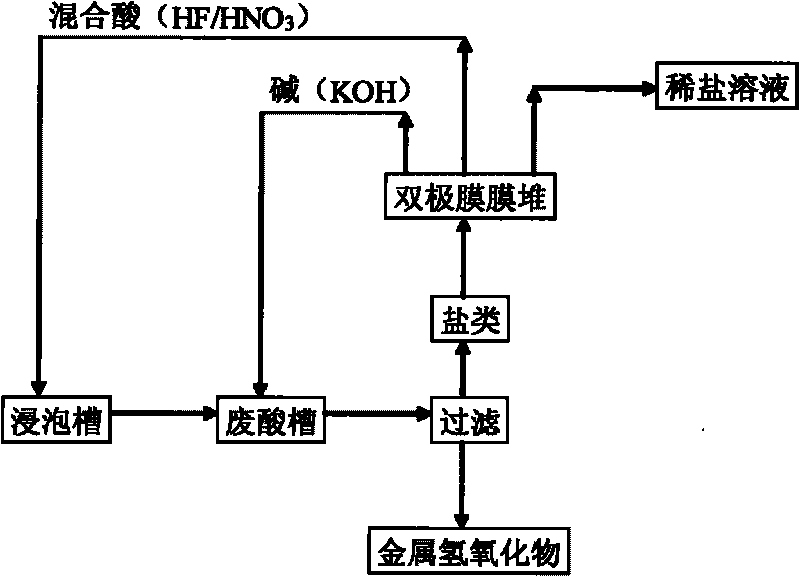

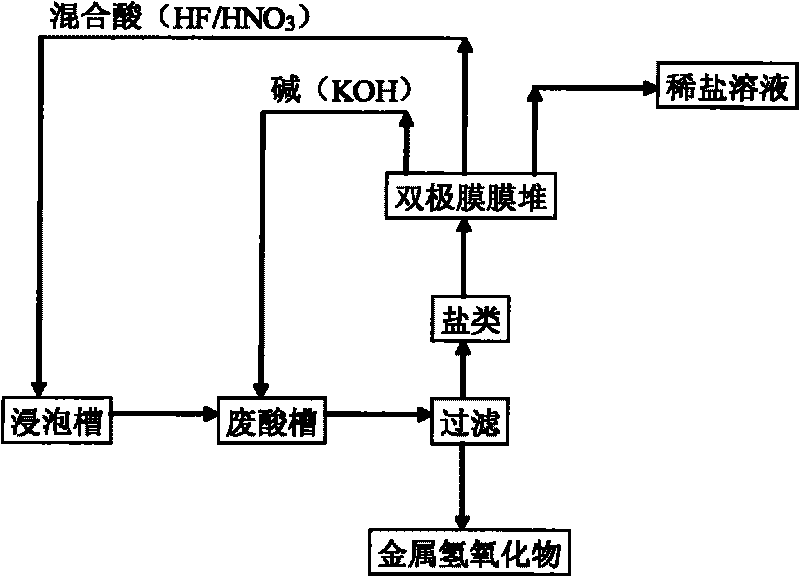

An acid cycle and membrane stack technology, applied in the field of metallurgical environmental protection, can solve problems such as unfavorable energy saving, increase production cost, and environmental harm, and achieve the effects of avoiding the deterioration of pickling quality, improving productivity, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

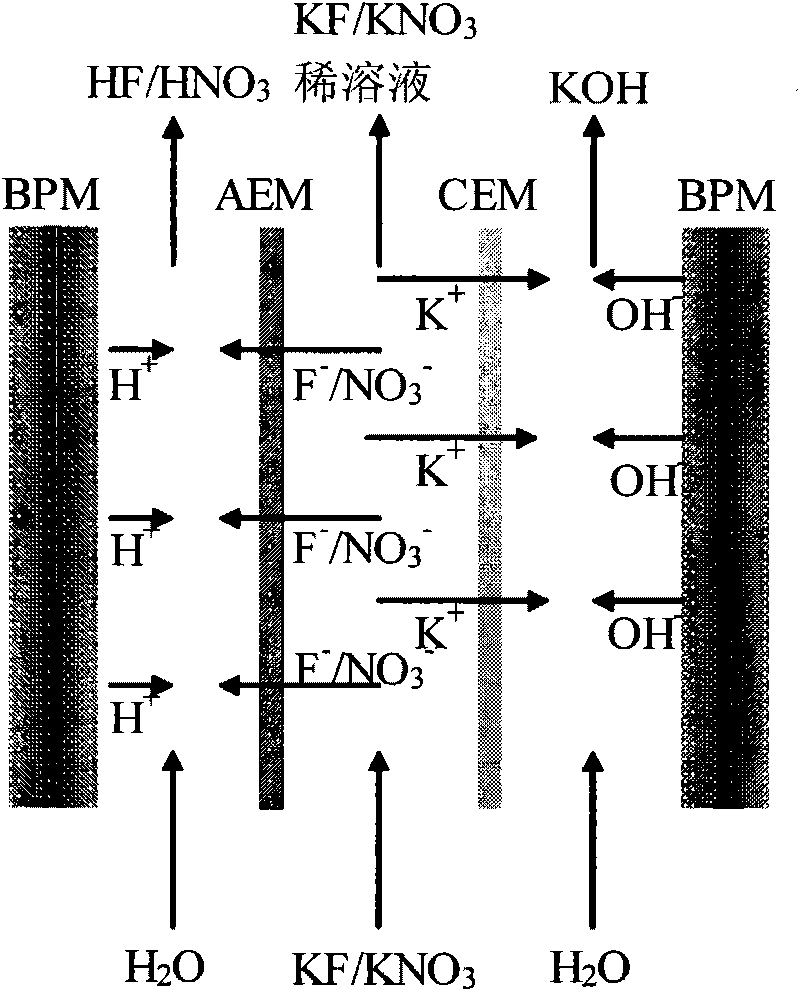

[0032] The waste acid is neutralized by adding alkali, and the concentration of each index is as follows:

[0033] Before treatment: NO in waste acid 3 - Concentration 2.23mol / L, F - The concentration is 5.70mol / L; it contains a certain amount of metal ions (when KOH is added, a certain amount of water is added, so the concentration decreases).

[0034] Capacity: 1000L / h, NO 3 - : 1.86mol / L, F - : 4.75mol / L, K + : 6.61mol / L, the total of multivalent cations (Fe, Cr, Ni, Ca, Mg, etc.) is 1mg / L. The waste liquid does not contain membrane fouling substances such as oil, particulate polymers, and surfactants, and acidifiers that easily cause membrane degradation, and the waste liquid does not contain SS components. The liquid temperature is below 35°C.

[0035] After the bipolar membrane stack reaction, the indicators of acid solution, alkali solution and dilute salt solution are as follows:

[0036] Acid solution: 2000L / h, HF: 2.12mol / L, HNO 3 : 0.93mol / L; lye: 2000L / h,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com