Bearing steel pickling, phosphating and saponifying method

A technology for pickling phosphorus soap and bearing steel for steel, applied in the metallurgical field, can solve problems such as failure to meet the requirements of decarburization, and achieve the effects of increasing production capacity, stable and uniform temperature, and reducing consumption of rinsing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

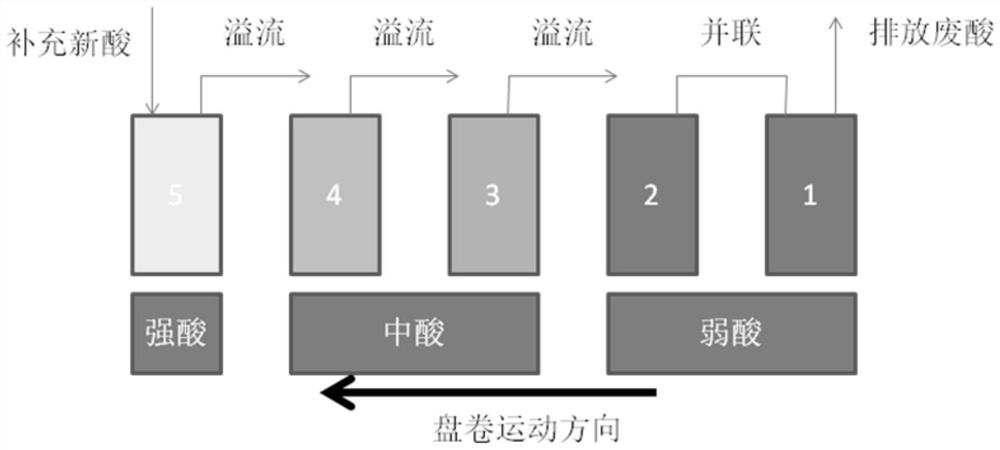

Method used

Image

Examples

Embodiment 1

[0041] 1. Put first The bearing steel wire rods are pickled and limed before entering the heat treatment furnace, and the excess packing tape of the GCr15 bearing steel wire rods is cut off, leaving only one packing tape, which is soaked in a weak acid tank with a vibration function for 10 minutes, while vibrating evenly, hydrochloric acid Concentration is 10%, hydrochloric acid temperature is 35°C, Fe 2+ ≤120 g / L. After pickling, rinse with high-pressure water for 1 minute, and then put it into a lime tank with a mass concentration of 25% to react for 1 minute.

[0042] 2. After the pickling lime process, the bearing steel wire is spheroidized and annealed in the heat treatment furnace and RX gas is added for full gas protection. The spheroidized annealing process is: annealing temperature 795 ° C, annealing time 30 hours.

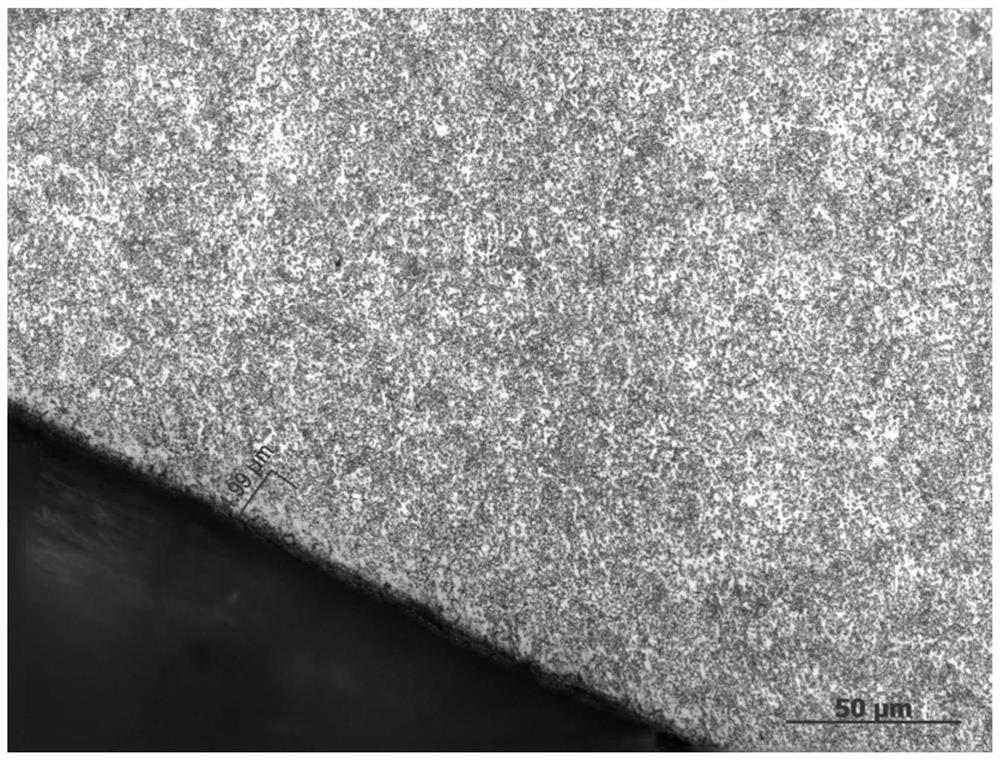

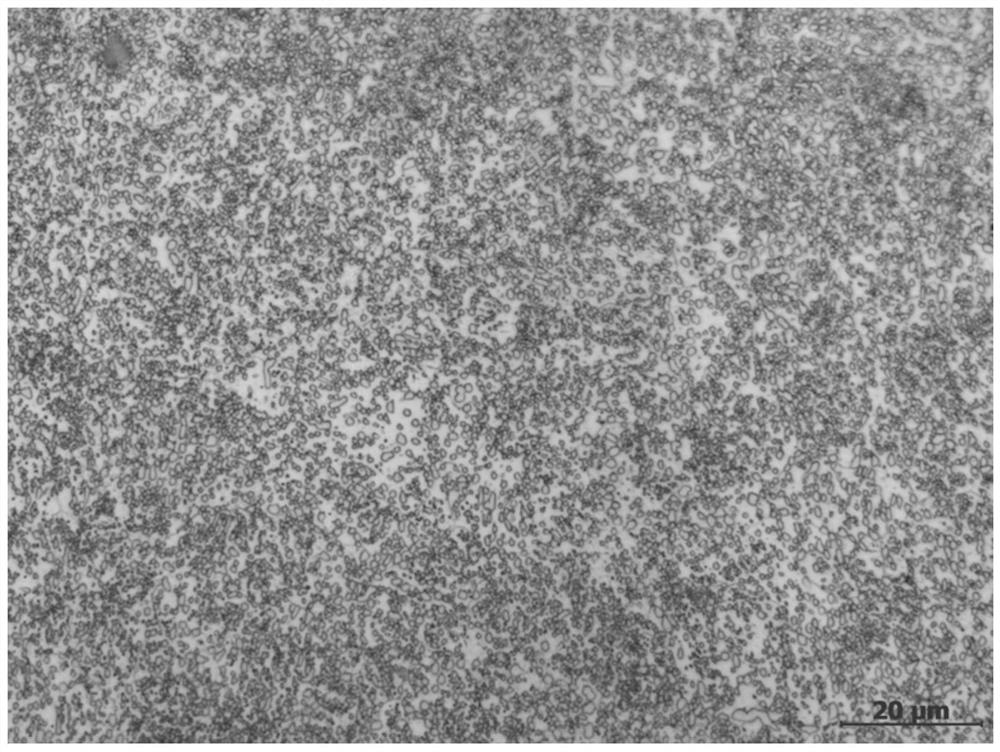

[0043] The composition of RX is: CO: 19%; H 2 : 40%; CO 2 Control range: 0.3%, nitrogen 40.7%, sampling and testing after heat treatment, the detectio...

Embodiment 2

[0054] 1. Put first The bearing steel wire rods are pickled and limed before entering the heat treatment furnace, and the excess packing tape of the GCr15 bearing steel wire rods is cut off, leaving only one packing tape, which is soaked in a weak acid tank with a vibration function for 10 minutes, while vibrating evenly, hydrochloric acid Concentration is 10%, hydrochloric acid temperature is 35°C, Fe 2+ ≤120 g / L. After pickling, rinse with high-pressure water for 1 minute, and then put it into a lime tank with a concentration of 30% for 1 minute to react.

[0055] 2. After the pickling lime process, the bearing steel wire is spheroidized and annealed in the heat treatment furnace and RX gas is added for full gas protection. The spheroidized annealing process is: annealing temperature 795 ° C, annealing time 30 hours.

[0056] The composition of RX is: CO: 19.1%; H 2 : 39.8%; CO 2 Control range: 0.28%, nitrogen 40.82%, sampling and testing after heat treatment, the detec...

Embodiment 3

[0067] 1. Put first The bearing steel wire rods are pickled and limed before entering the heat treatment furnace, and the excess packing tape of the GCr15 bearing steel wire rods is cut off, leaving only one packing tape, which is soaked in a weak acid tank with a vibration function for 10 minutes, while vibrating evenly, hydrochloric acid Concentration is 10%, hydrochloric acid temperature is 35°C, Fe 2+ ≤120 g / L. After pickling, rinse with high-pressure water for 1 minute, and then put it into a lime tank with a concentration of 20 for 1 minute to react.

[0068] 2. After the pickling lime process, the bearing steel wire is spheroidized and annealed in the heat treatment furnace and RX gas is added for full gas protection. The spheroidized annealing process is: annealing temperature 795 ° C, annealing time 30 hours.

[0069] The composition of RX is: CO: 20.3%; H 2 : 40.2%; CO 2 Control range: 0.29%, nitrogen 39.21%, sampling and testing after heat treatment, the detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com