Method for pickling inner and outer surfaces of pipe

A technology for inner and outer surfaces and pipes, which is applied in the field of automatic control of pickling the inner and outer surfaces of multiple pipes at the same time. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

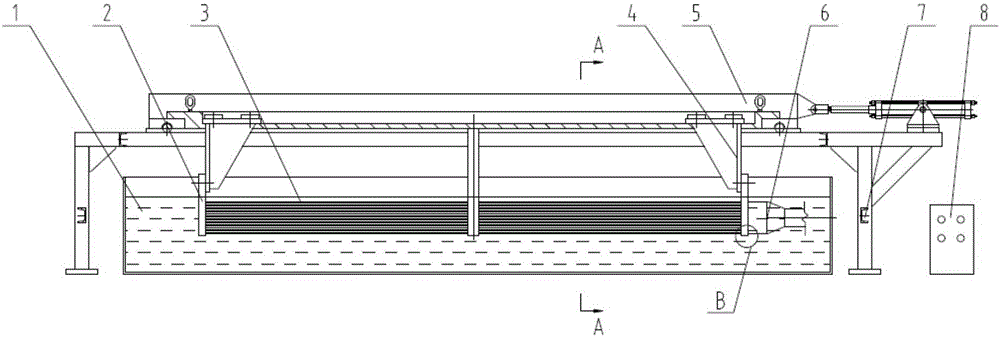

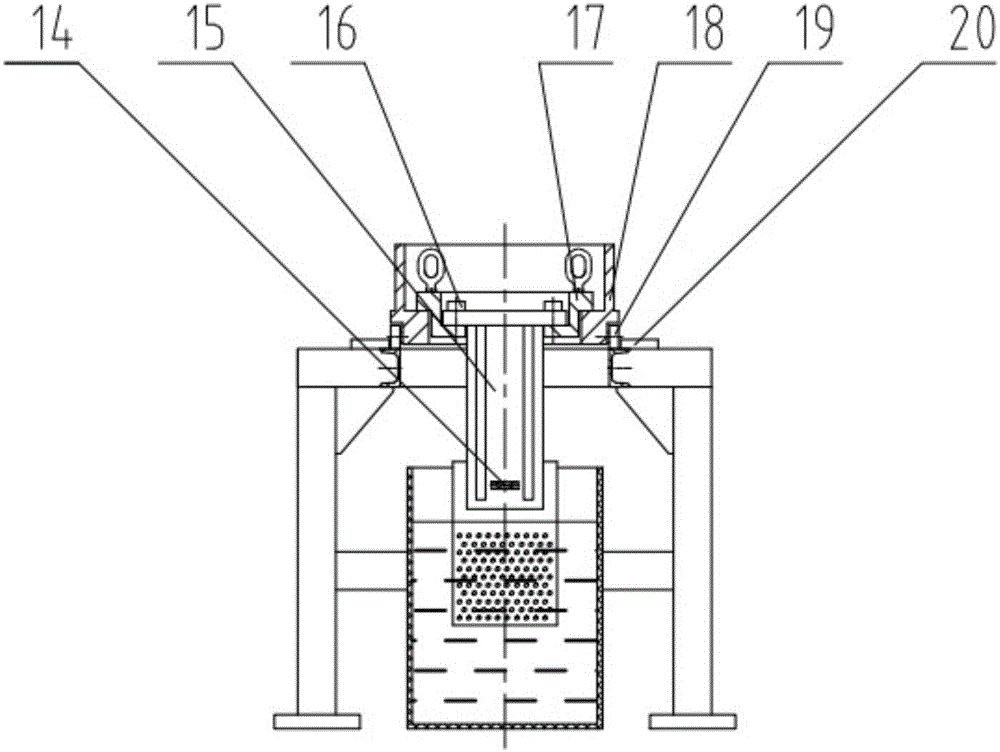

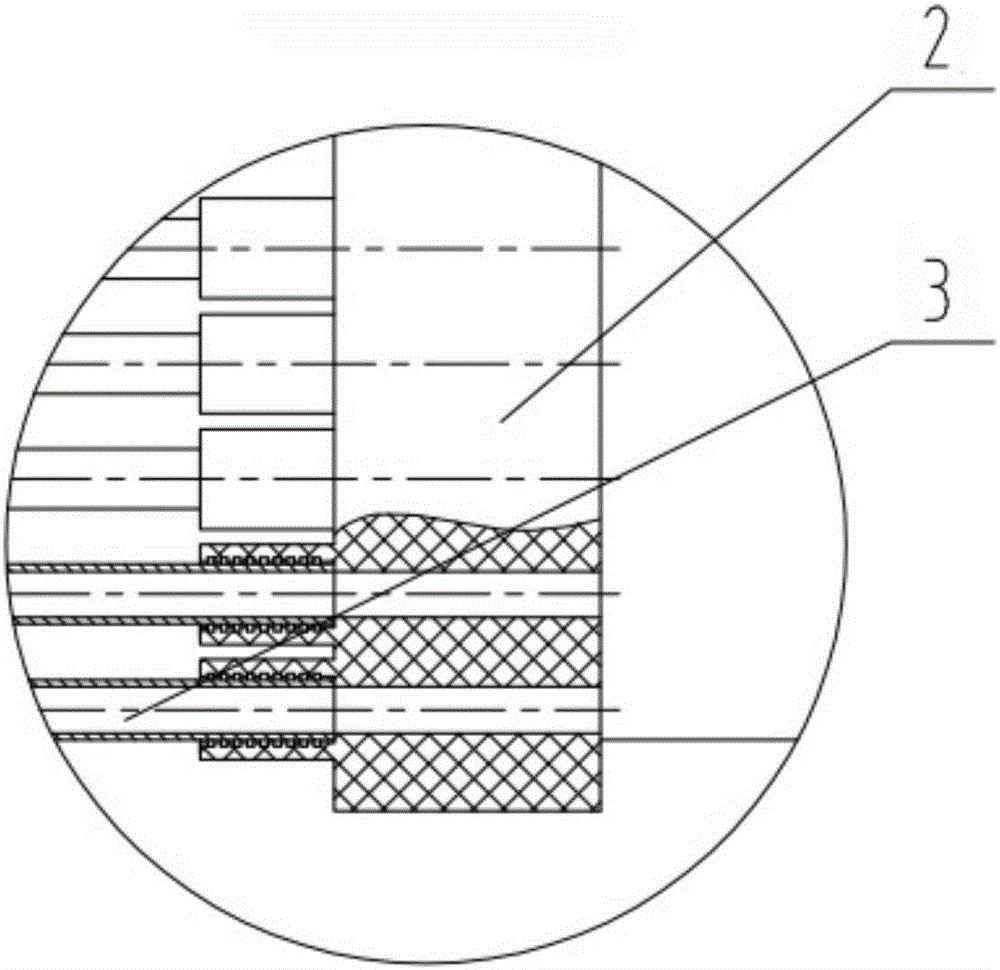

[0031] Such as Figure 1 to Figure 3 As shown, the pickling device for the inner and outer surfaces of pipes used in the pickling method of the present invention includes an acid tank 1 equipped with a pickling solution, a pipe tooling device 2, a tooling clamping mechanism 4, a traverse device 5, and an acid delivery pipeline 6 and rack 7. One side of the pipe tooling device 2 is provided with a number of cylindrical protrusions evenly distributed side by side, and a cylindrical slot is arranged in the middle of the cylindrical protrusion, and the diameter of the slot is slightly larger than the diameter of the outer wall of the pipe. The pipe material 3 and the slot are clearance fit, and the two ends of the pipe material 3 can be quickly inserted into the slot respectively. The frame 7 is arranged above the acid tank 1, and the travers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com