Production process for oil tank

A production process and oil tank technology, applied in metal material coating process, fixed filter element filter, filtration separation, etc., can solve the problems of lowering the product quality of the oil tank, not cleaning the surface of the oil tank very thoroughly, affecting the quality of spray painting, etc., to achieve improvement The quality and effect of pickling, the realization of cleaning and automatic collection, and the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: a kind of production technology for oil tank, comprises the following steps:

[0054] S1, cutting the plate, cutting the plate according to the actual size requirement of the fuel tank, and making the cut plate larger than the actual size requirement of the fuel tank.

[0055] S2, stamping, stamping the cut plate to form the prototype of half a fuel tank.

[0056] S3, edge trimming, cutting the corners around the stamped plate.

[0057] S4, punching, punching the punched plate to form the fuel tank port.

[0058] S5, welding, fasten a pair of preliminarily formed fuel tanks together, and weld the joints of the two, and weld the corner ears and oil pipes at the same time.

[0059] S6, air-tightness test, immersing the formed fuel tank in clear water, observing whether there are bubbles in the clear water, so as to judge the air-tightness of the fuel tank.

[0060] S7, cleaning, cleaning the surface of the oil tank.

[0061] S8, plastic spraying, spray p...

Embodiment 2

[0069] Embodiment 2: Steps S71, S72, S73 and S74 are all performed in cleaning equipment.

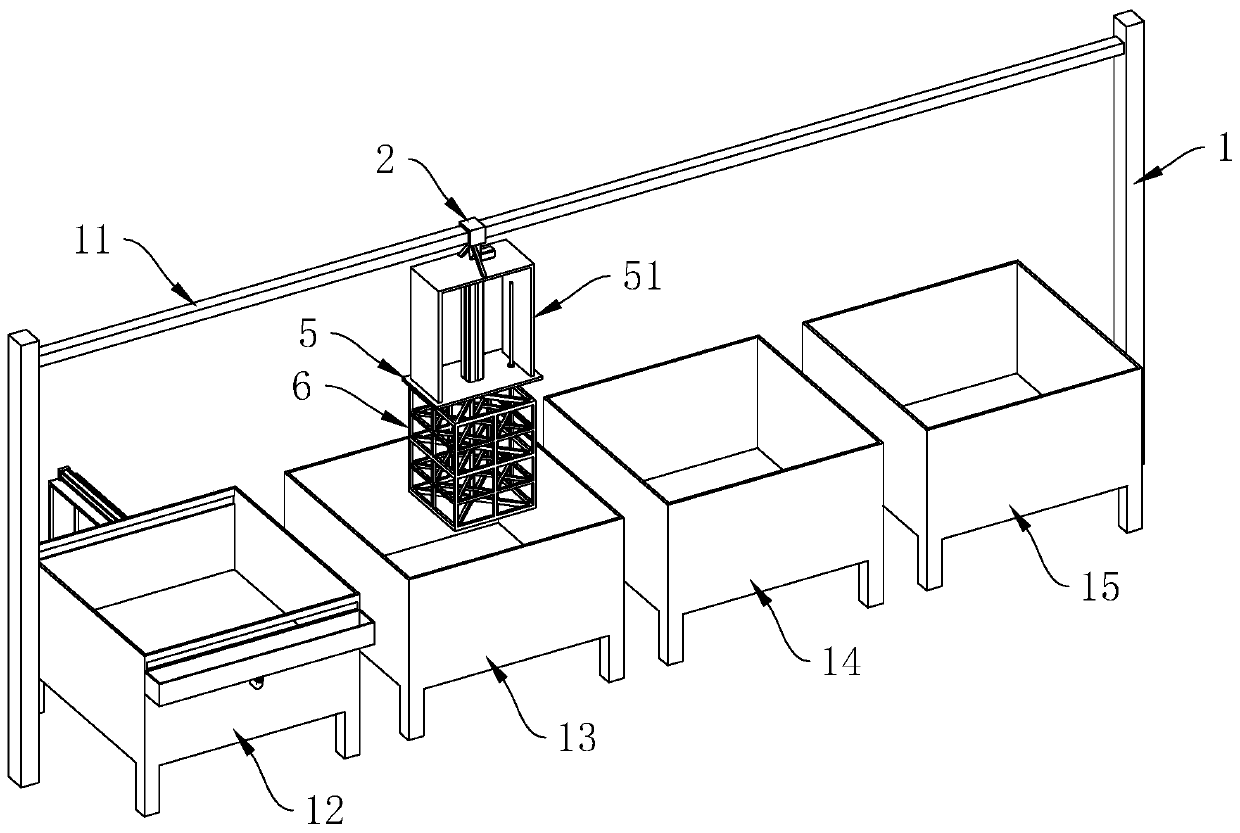

[0070] Such as figure 1 As shown, the cleaning equipment includes a pair of vertical columns 1, a beam 11 is horizontally arranged between the upper ends of the pair of columns 1, and a pickling pool 12, a neutralization pool 13, and a phosphating pool are sequentially arranged below the beam 11 14 and washing pool 15.

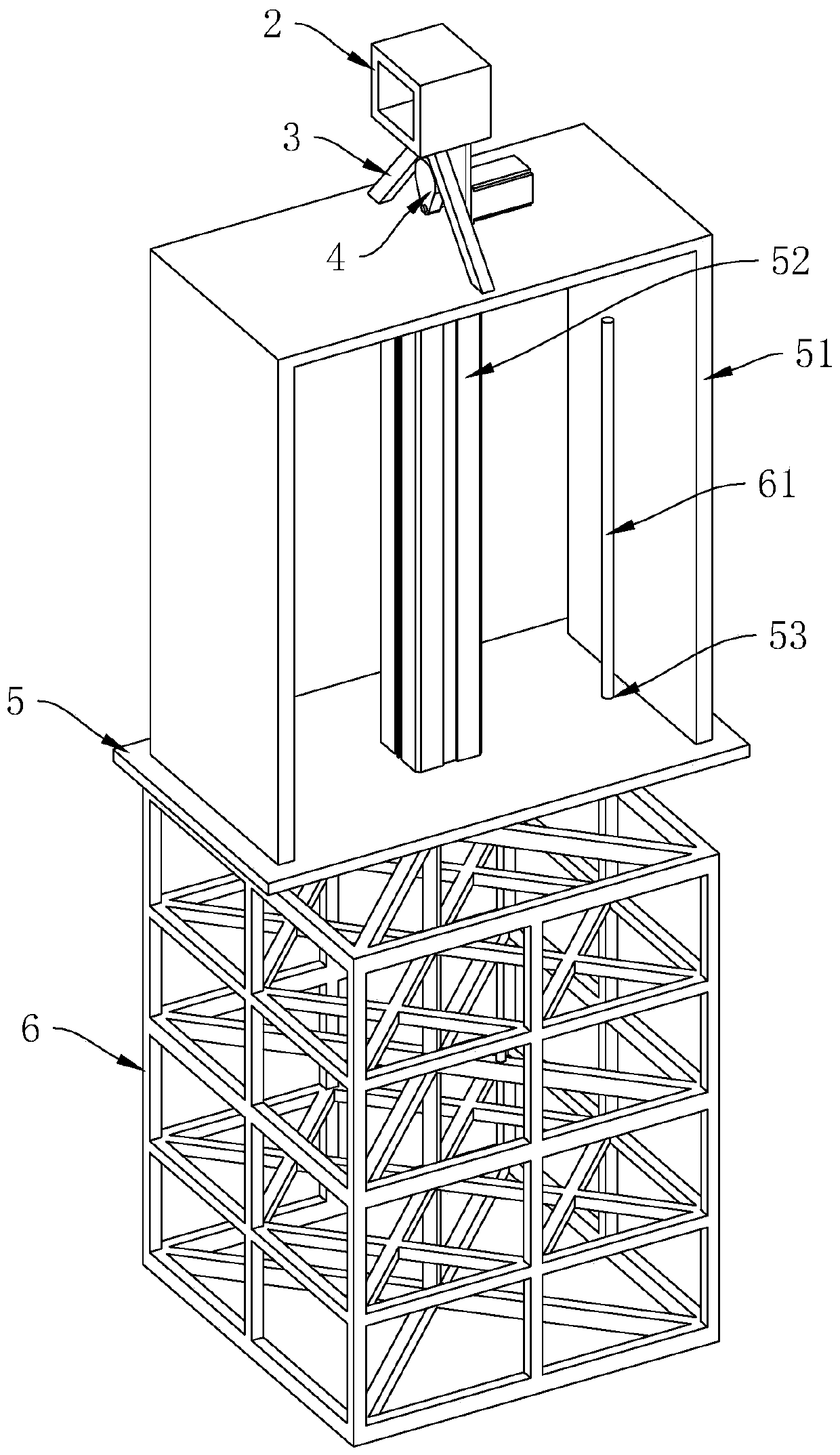

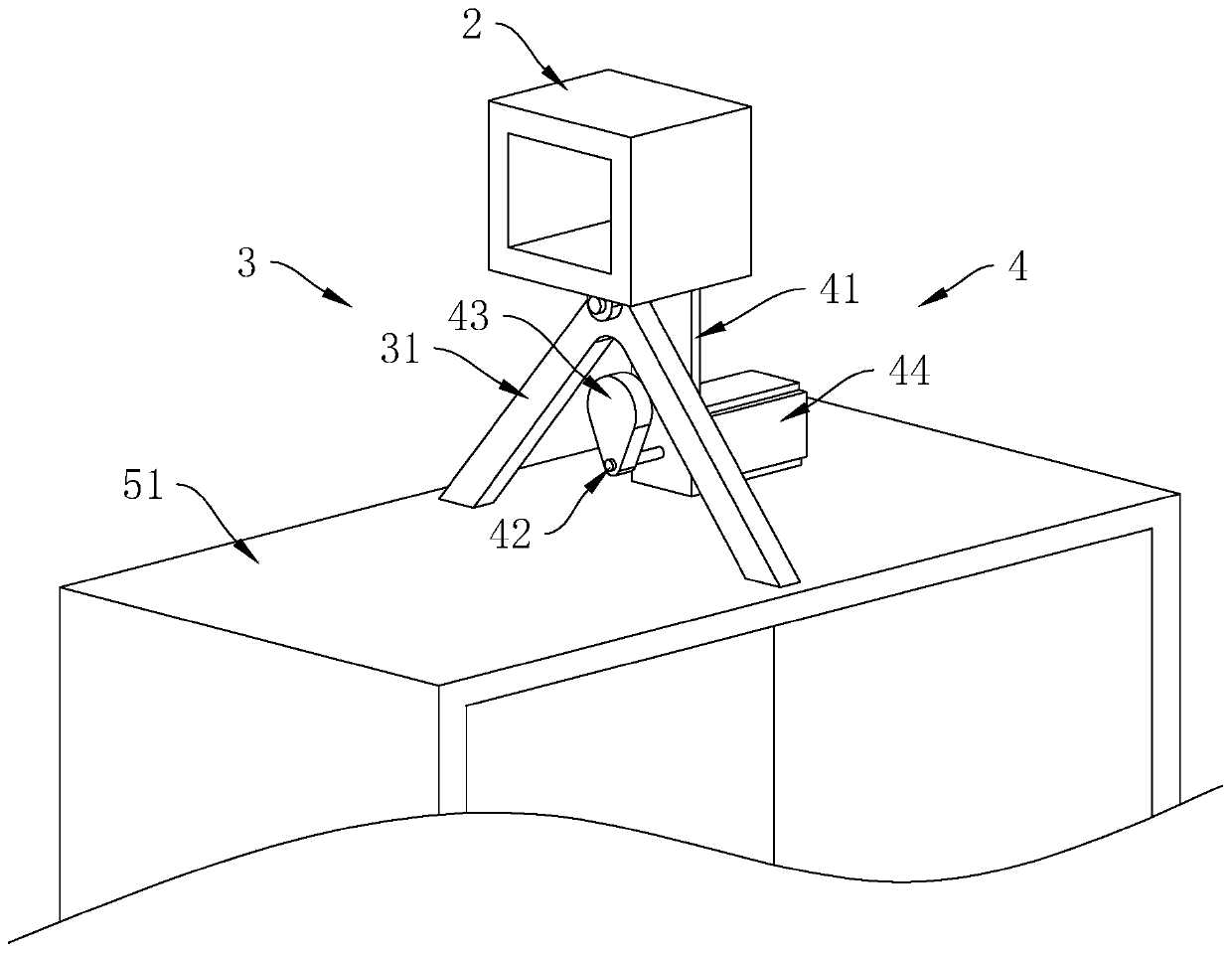

[0071] Such as figure 1 , figure 2 As shown, a sliding seat 2 is horizontally slidably connected to the beam 11, and the lower end surface of the sliding seat 2 is hingedly provided with a supporting seat 3, and the lower end surface of the sliding seat 2 is provided with a driving mechanism 4 for driving the supporting seat 3 to reciprocate and swing.

[0072] Such as figure 1 , figure 2 As shown, a mounting base 5 is provided below the support base 3 , and a gantry frame 51 is provided on the upper end surface of the mounting base 5 , and the upper end of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com