Steel pipe galvanizing pretreatment equipment

A technology for pretreatment and steel pipes, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of low work efficiency, large quantity of feeding, and inability to clean up, so as to reduce the process, improve efficiency, reduce The effect of time spent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

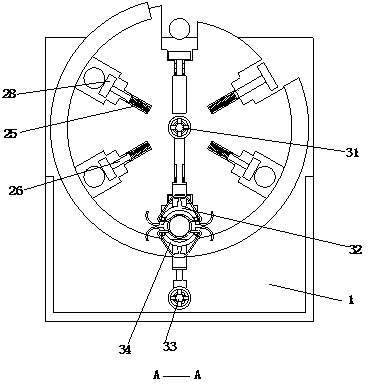

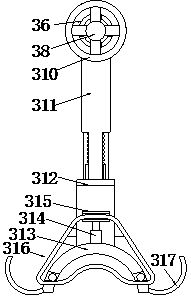

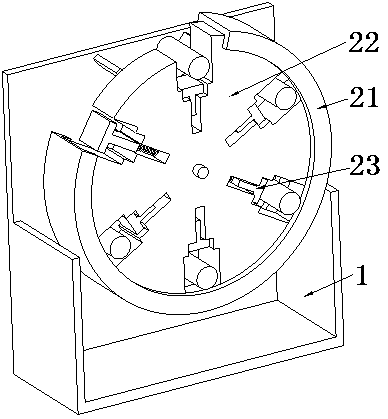

[0033] Such as Figure 1 to Figure 6 As shown, this embodiment provides a steel pipe galvanizing pretreatment equipment, including a cleaning frame 1, a transmission unit 2 is arranged between the inner walls of the cleaning frame 1, a cleaning unit 3 is arranged between the transmission units 2, and the cleaning frame 1 A driving unit is installed on the inner wall of the lower side, and the front end of the cleaning frame 1 is provided with a guide frame inclined downward from back to front.

[0034] The steel pipes that need to be pickled can be placed one by one in the cleaning frame 1 with the pickling liquid through the transmission unit 2, so that the pickling liquid can fully contact the surface of the steel pipes to ensure the quality of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com