Multifunctional pipe pickling device and picking method

An acid and multi-functional technology for pipes, applied in the fields of metallurgy and machinery, which can solve the problems of low pickling output and difficult control of surface quality, achieve good pickling quality, improve pickling uniformity, and reduce the opportunity for personnel to approach the acid solution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

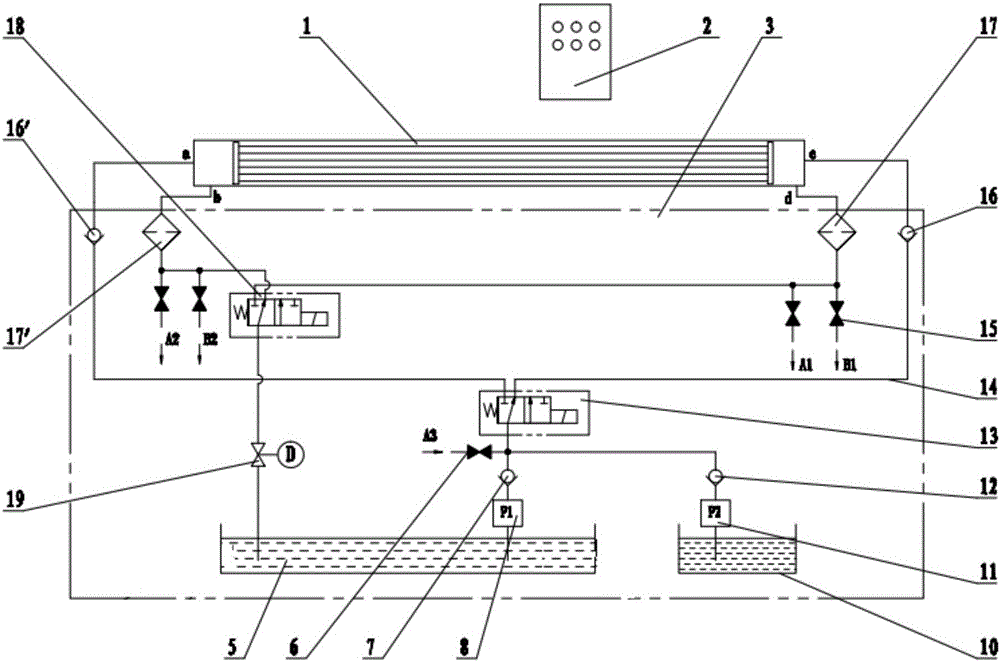

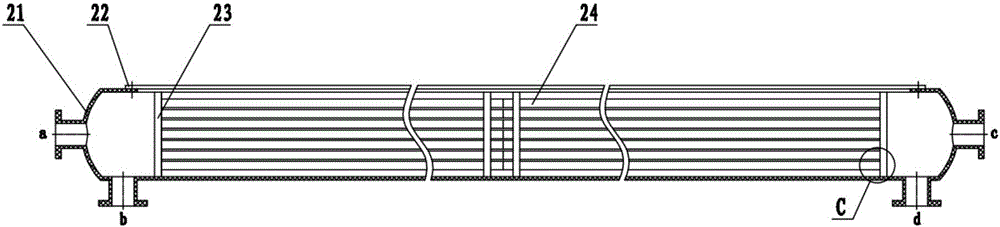

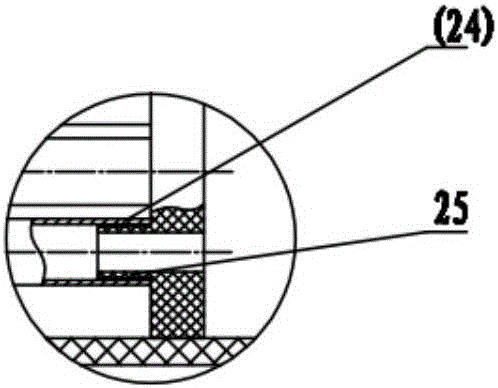

[0019] like Figure 1 to Figure 6 As shown, a multifunctional pipe pickling device of the present invention includes a pickling tank assembly 1, an acid storage tank and an electrical control system 2, and both ends of the pickling tank assembly 1 are provided with a liquid inlet and an outlet The liquid port, the liquid inlets at both ends of the pickling tank assembly 1 are connected to the first reversing valve 13 through the check valve 16, and the first reversing valve 13 is connected to the acid storage tank through the acid pump 8, and the pickling tank assembly 1 The liquid outlets at both ends are connected to the second reversing valve 18, and the liquid outlets at both ends of the pickling tank assembly 1 are respectively connected to the second reversing valve 18 through the filter 17, and the filter 17 is connected to the second reversing valve 18. A drain port is provided between the reversing valves 18 , the second reversing valve 18 is connected to the acid sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com