Silicon briquette washing method and application

A silicon block and cleaning device technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve problems such as inability to guarantee etching uniformity, large fluctuations in surface metal impurities, and increased product backwashing volume. Achieve the effect of optimizing the silicon block cleaning process, alleviating uneven pickling, improving pickling efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] A method for cleaning a silicon block, comprising the steps of:

[0114] 1. Pickling

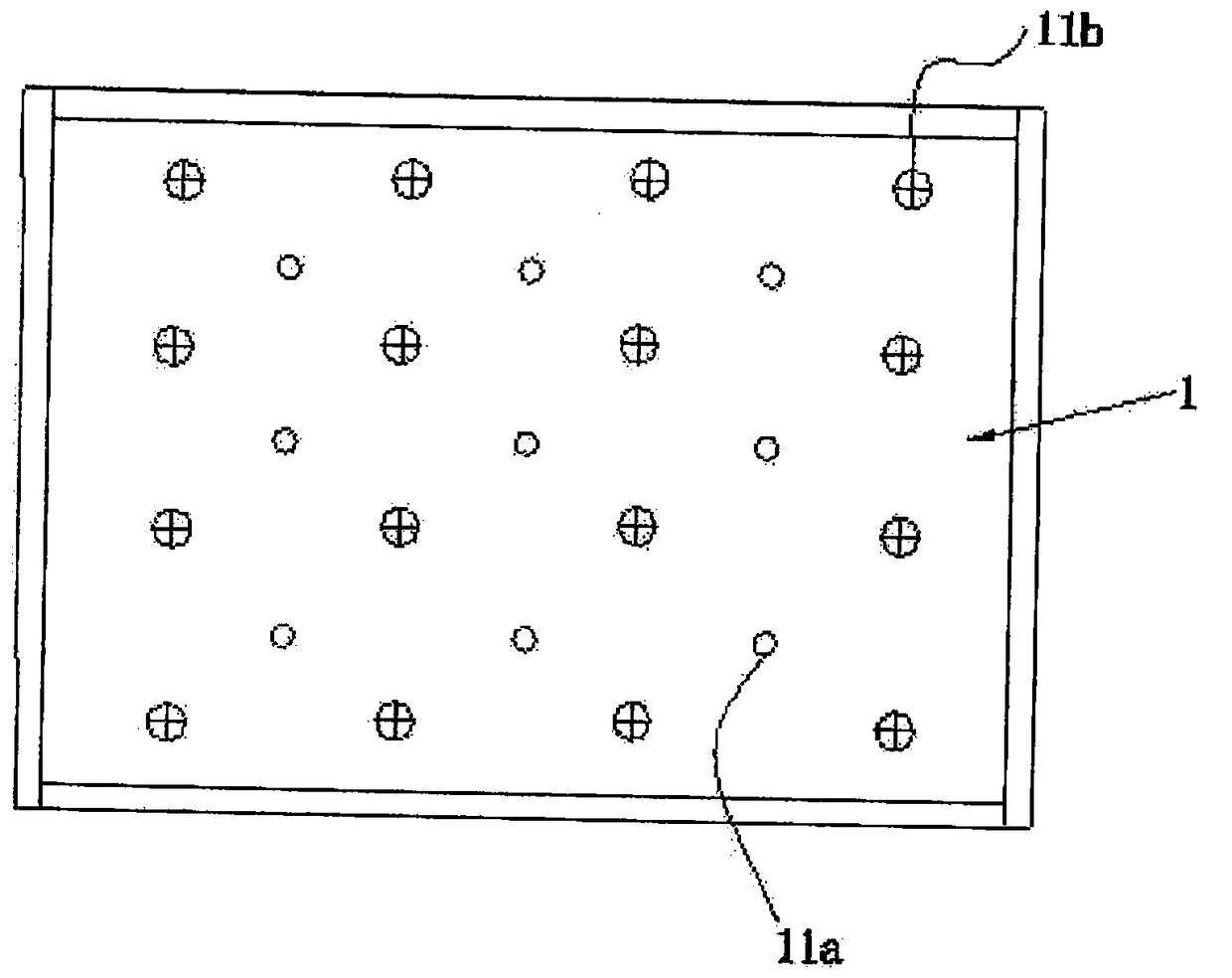

[0115] The silicon blocks were pickled three times. Figure 5 A plan view of the acid pool for silicon block cleaning, placing the silicon blocks in sequence Figure 5 Nitric acid in TK-40002A: hydrofluoric acid = 10:1 acid solution pool, nitric acid in TK-40002B: hydrofluoric acid = 15:1 acid solution pool, nitric acid in TK-40002C: hydrogen Hydrofluoric acid = 30:1 acid pool.

[0116] The pickling liquid used for the first pickling is nitric acid:hydrofluoric acid=10:1v / v, the temperature is 33°C, and the time is 5min.

[0117] The pickling liquid used for the second pickling is nitric acid:hydrofluoric acid=15:1v / v, the temperature is 36°C, and the time is 5min.

[0118] The pickling liquid used for the third pickling is nitric acid:hydrofluoric acid=30:1v / v, the temperature is 31°C, and the time is 5min.

[0119] Wherein, nitric acid is an aqueous solution of nitric acid with...

Embodiment 2-9

[0130] In the silicon block cleaning method in embodiment 2-embodiment 9, the proportion of nitric acid and hydrofluoric acid and the mass fraction of nitric acid and hydrofluoric acid in pickling are shown in Table 1, and the rest of the steps are the same as in embodiment 1.

[0131] Table 1 The proportioning ratio of nitric acid and hydrofluoric acid, the mass fraction of nitric acid and hydrofluoric acid

[0132]

[0133]

Embodiment 10

[0135] A method for cleaning a silicon block, comprising the steps of:

[0136] 1. Pickling

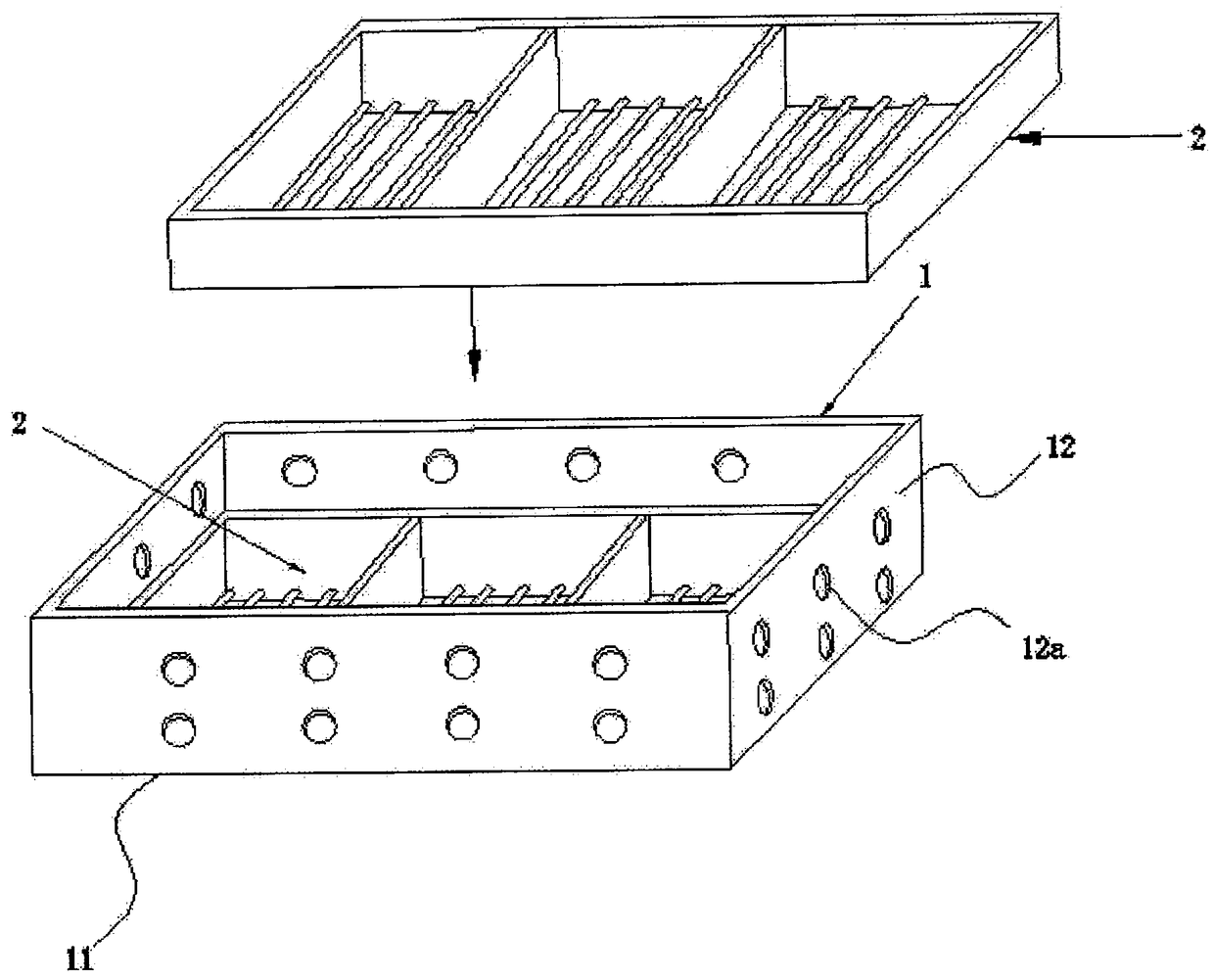

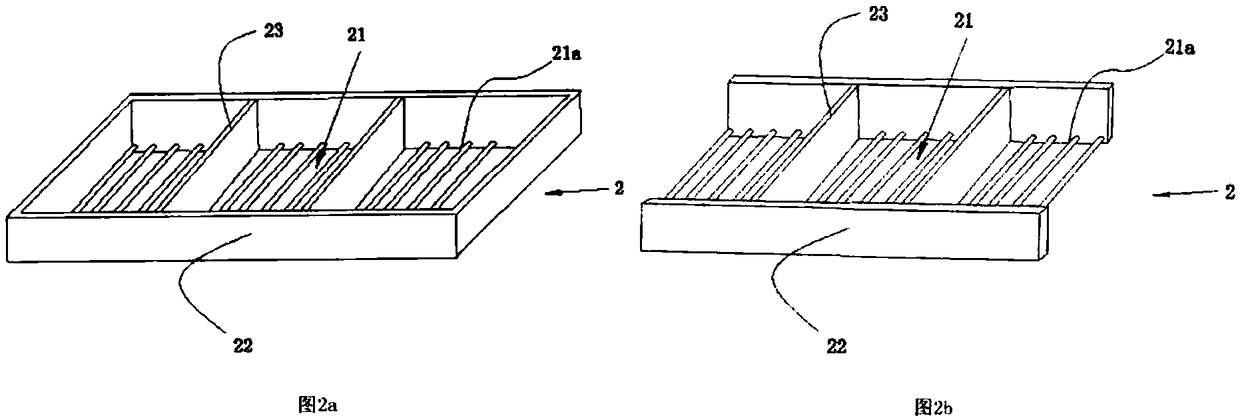

[0137] The silicon block is laid in the cleaning device described in CN205264678U, and then pickled three times.

[0138] The pickling liquid used for the first pickling is nitric acid:hydrofluoric acid=10:1v / v, the temperature is 32°C, and the time is 6min.

[0139] The pickling liquid used for the second pickling is nitric acid:hydrofluoric acid=15:1v / v, the temperature is 35°C, and the time is 4min.

[0140] The pickling liquid used for the third pickling is nitric acid:hydrofluoric acid=30:1v / v, the temperature is 33°C, and the time is 6min.

[0141]Wherein, nitric acid is an aqueous solution of nitric acid with a mass fraction of 70%; hydrofluoric acid is an aqueous solution of hydrofluoric acid with a mass fraction of 49%.

[0142] 2. Rinse

[0143] Use ultrapure water for overflow rinsing.

[0144] 3. Soak

[0145] (1) Cold soaking

[0146] Soak at 22°C for 5h.

[0147]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com