Pickling method of complex phase steel

A technology of complex-phase steel and pickling, applied in the field of steel rolling, can solve problems such as spots and flaky black spots on the head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

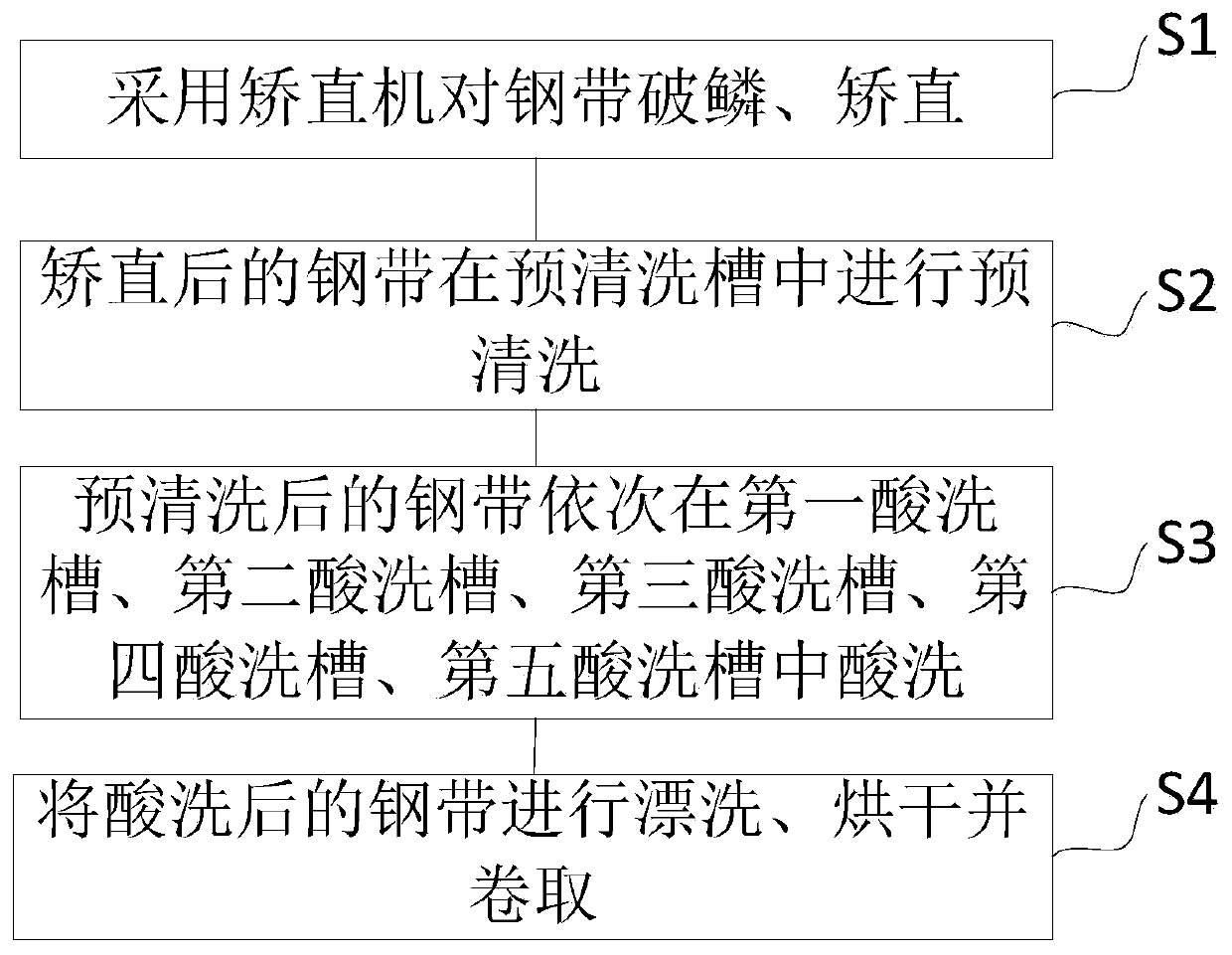

Method used

Image

Examples

Embodiment 1

[0042] In the first embodiment, the threading speed is controlled to 40m / min, the running speed is controlled to 90m / min, and the tail flick speed is controlled to 40m / min. Table 1 is the parameter control range of the hydrochloric acid concentration and temperature in the first embodiment.

[0043] Table 1

[0044] project The first pickling tank The second pickling tank The third pickling tank The fourth pickling tank The fifth pickling tank Concentration setting value, g / L426585105140 Actual concentration range, g / L 41~43 64~66 84~86 103~107 138~142 Temperature setting value, ℃8482787875 Actual temperature range, ℃ 82~85 80~85 76~80 75~80 73~78

Embodiment 2

[0046] In the second embodiment, the threading speed is controlled to 60m / min, the running speed is controlled to 70m / min, and the tail flick speed is controlled to 50m / min. Table 2 is the concentration and temperature of the hydrochloric acid in the pickling tank of the second embodiment. Control range.

[0047] Table 2

[0048] project The first pickling tank The second pickling tank The third pickling tank The fourth pickling tank The fifth pickling tank Concentration setting value, g / L457893110150 Actual concentration range, g / L 43~48 75~80 90~95 108~113 147~152 Temperature setting value, ℃7878777572 Actual temperature range, ℃ 75~80 75~80 73~80 72~78 70~74

[0049] Through the pickling method of Example 1 and Example 2, the straightening machine can fully crush and peel the oxide scale on the surface of the steel strip, and at the same time straighten the wave shape and other plate defects of the steel strip, which is a smooth and stable pickling. Provides a good guar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com