Heat treatment technology of cold-rolled strip steel

A cold-rolled strip and process technology, applied in the field of heat treatment, can solve the problems of uneven cooling speed and hardness, reduced pickling efficiency, large residual stress, etc., to promote roughness, reduce difficult to be cleaned, and improve pickling effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

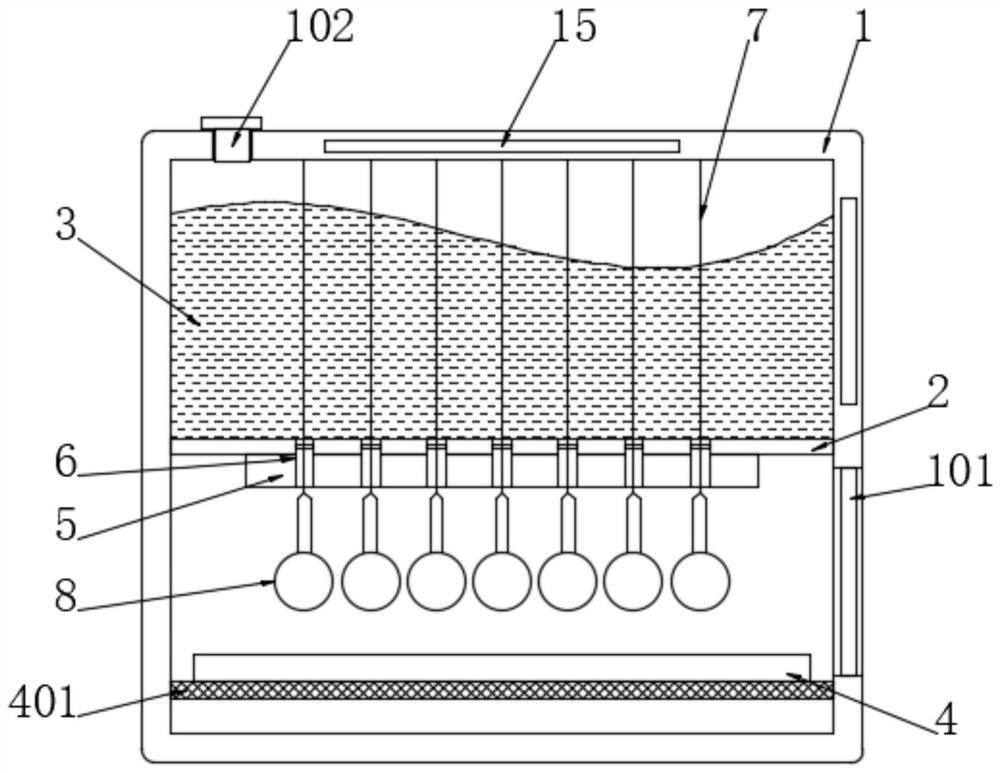

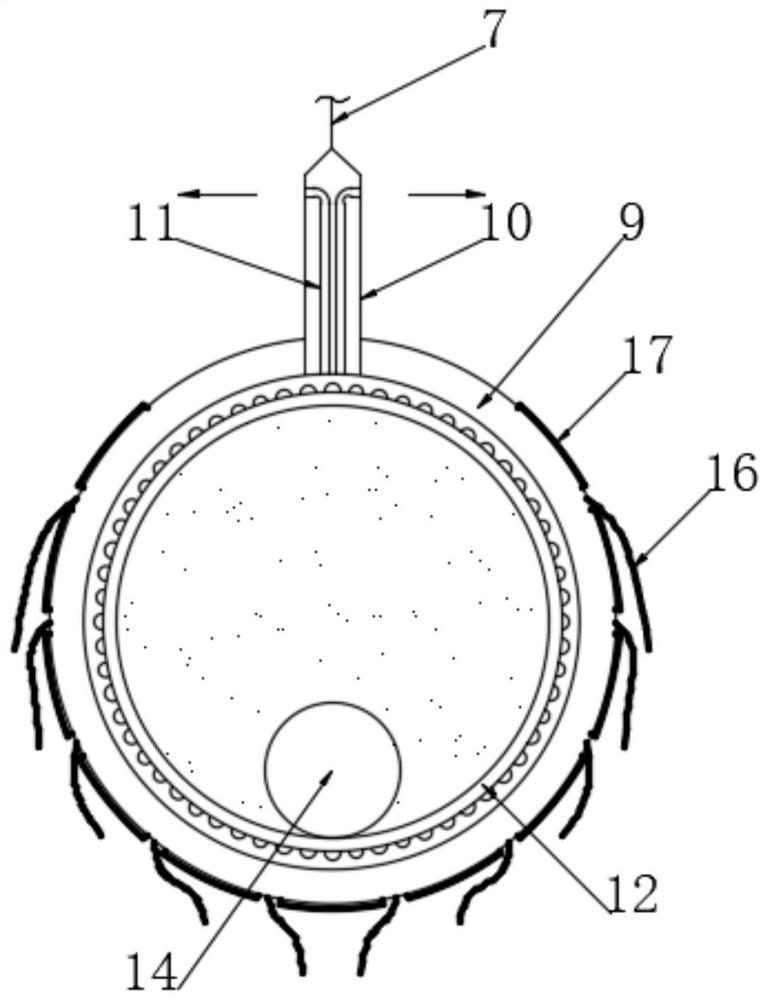

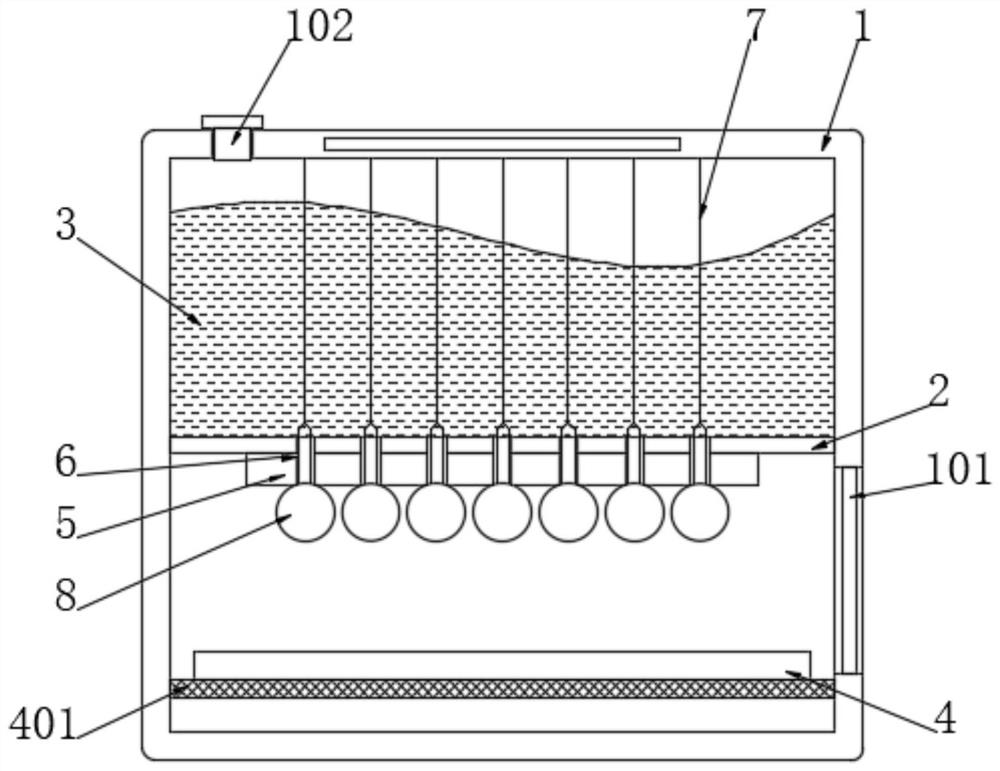

Image

Examples

Embodiment 1

[0050] A heat treatment process for cold-rolled strip steel, comprising the following steps:

[0051] S1. Lead the molten steel into the casting slab in the continuous casting machine, control the casting speed to 35-50m / min, and then transport the casting slab to the heating furnace for heating;

[0052] S2. Use a tension leveler to pull out the cast slab, cool it at a rate of 50-100°C / s under nitrogen atmosphere conditions, use a coiler to roll it at a temperature of 550-600°C, and roll the cast slab Remove the scale, and re-coil the billet after the scale is removed, coated with an alumina release agent;

[0053] S3, heat-treating the cast slab coil coated with release agent in S2, followed by heat preservation for 10-20h and annealing, and removing the release agent on its surface;

[0054] S4. After the billet roll is re-rolled and the release agent is removed, it is put into a closed cycle pickling box, and hydrochloric acid is used to depick it, so as to improve the ut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com