Ultrasound vibration type rolling type ultrafiltration membrane group device and ultrafiltration device thereof

A technology of vibrating membrane group and ultrafiltration membrane, which is applied in the direction of ultrafiltration, membrane technology, semi-permeable membrane separation, etc. It can solve the problems that the flow channel is easy to be blocked by fouling and the requirements for membrane strength are high, so as to achieve enhanced scouring and scrubbing, and slow down Effect of Membrane Fouling and Fouling Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

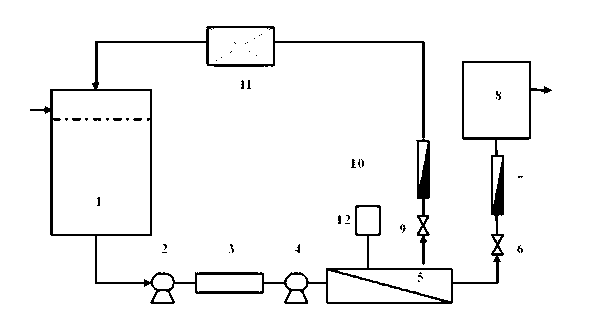

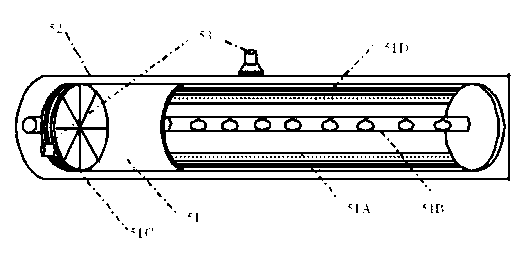

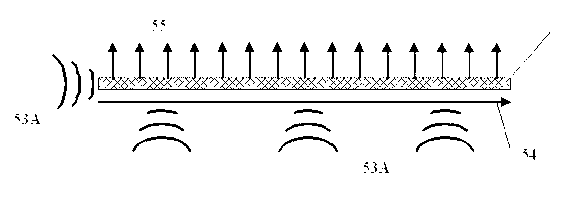

Method used

Image

Examples

example 1

[0030] The purification and separation of traditional Chinese medicine in a certain factory adopts the vibrating coil ultrafiltration device of the present invention, with a processing capacity of 10 tons per day. The equipment cleaning cycle is extended from the original 8 hours to 12 hours, and the membrane flux is changed from the original 40L / m 2 .h increased to 47L / m 2 .h.

example 2

[0032] Emulsified waste liquid treatment project with a treatment capacity of 50m3 / h, raw water COD cr 20000-40000 mg / L, oil 1000-3000 mg / L, pH 9.0-11.5. After treatment, the effluent COD cr Less than 5000mg / L, oil less than 30mg / L. The membrane flux of ultrafiltration operation reaches 25L / m 2 .h, which is 150% higher than that of ordinary membrane units, and the operating pressure is 0.3-4.0Mpa, which is lower than that of ordinary membrane units, and the operation is stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com