Horizontal well leakage-proof rotational flow sand-washing device and sand-washing technology thereof

A technology for horizontal wells and sand flushing, which is applied in flushing wellbore, wellbore/well components, earth-moving drilling, etc. problems, to achieve the effect of improving flushing and sand carrying efficiency, improving utilization efficiency and reducing formation pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

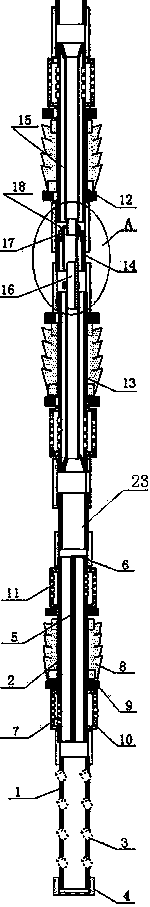

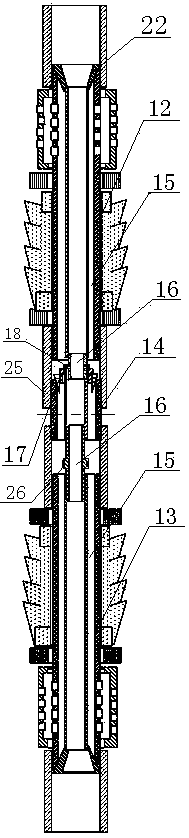

[0037] see figure 1 , a horizontal well leakage prevention swirl sandwasher device, comprising a horizontal well swirl sandwasher connected through an ordinary oil pipe 29 and a horizontal well leakage prevention double-layer oil pipe isolation circulation mechanism, and the two ends of the ordinary oil pipe 29 respectively pass through the oil pipe coupling 21. It is connected with the horizontal well cyclone sand flusher and the horizontal well leakage prevention double-layer oil pipe isolation circulation mechanism;

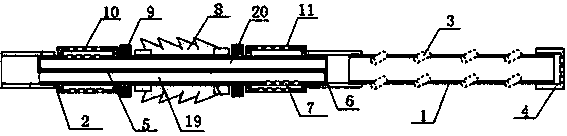

[0038] see figure 2 and Figure 7 , horizontal well swirl sand flusher, including vector flushing pipe 1 and isolation flushing pipe 2 connected by tubing collar 21; The oil pipe collar 21 at one end is connected with the vector flushing pipe 1; several vector nozzles 3 are arranged on the body of the vector flushing pipe 1, and a female plug 4 with nozzles is arranged at the end of the pipe body;

[0039] see Figure 6 , Figure 8 , Figure 9 and Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com