Solid rocket engine with high thrust ratio and manufacturing method thereof

A solid rocket, high-thrust technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve problems such as small thrust ratio, and achieve the effect of improving total thrust, simplifying manufacturing process, and large thrust ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

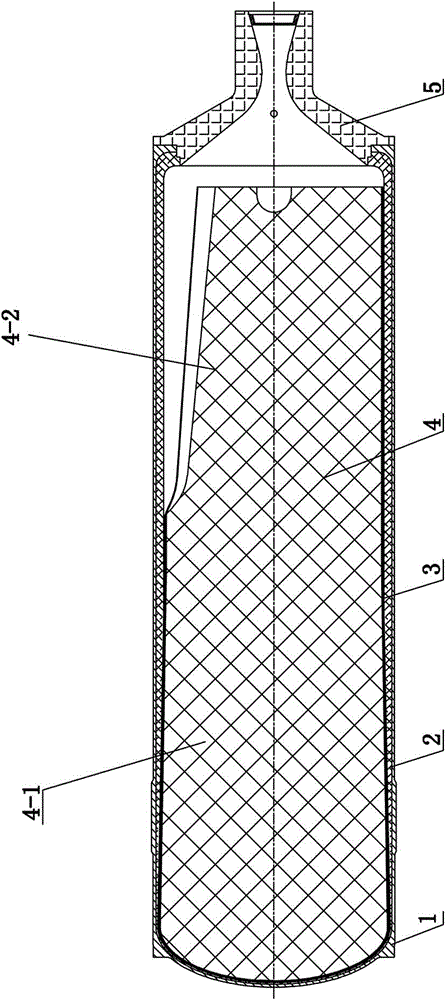

[0033] Such as figure 1 , figure 2 with image 3 As shown, a solid rocket motor with a high thrust ratio includes a combustion chamber casing 1, a heat insulating layer 2 is pasted on the inner surface of the combustion chamber casing 1, and a heat insulating sleeve 3 is bonded to the outer surface of the grain 4 and forms a joint with the grain. Overall, the charge column 4 with the heat insulating sleeve 3 is installed in the combustion chamber shell 1 with the heat insulating layer 2 in a free-loading manner, and the outlet end of the combustion chamber shell 1 is installed with a nozzle 5;

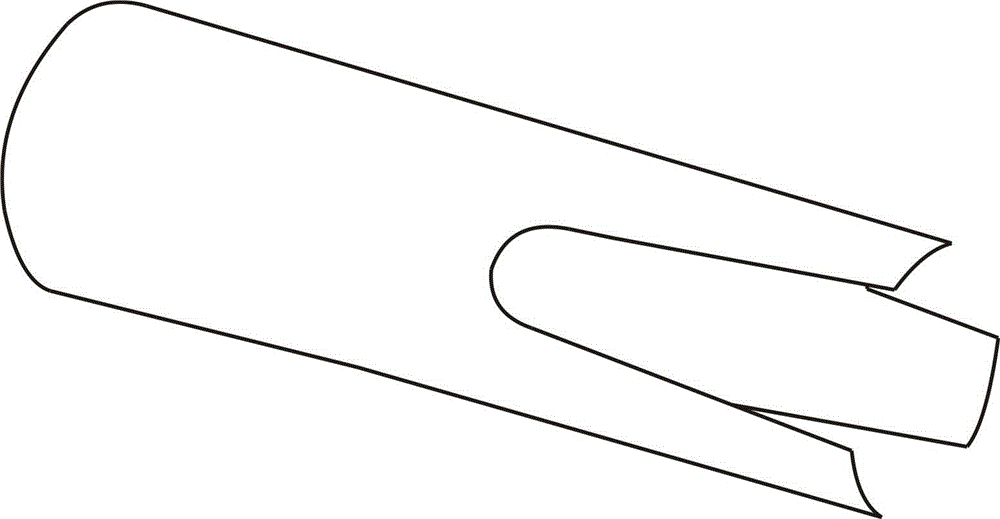

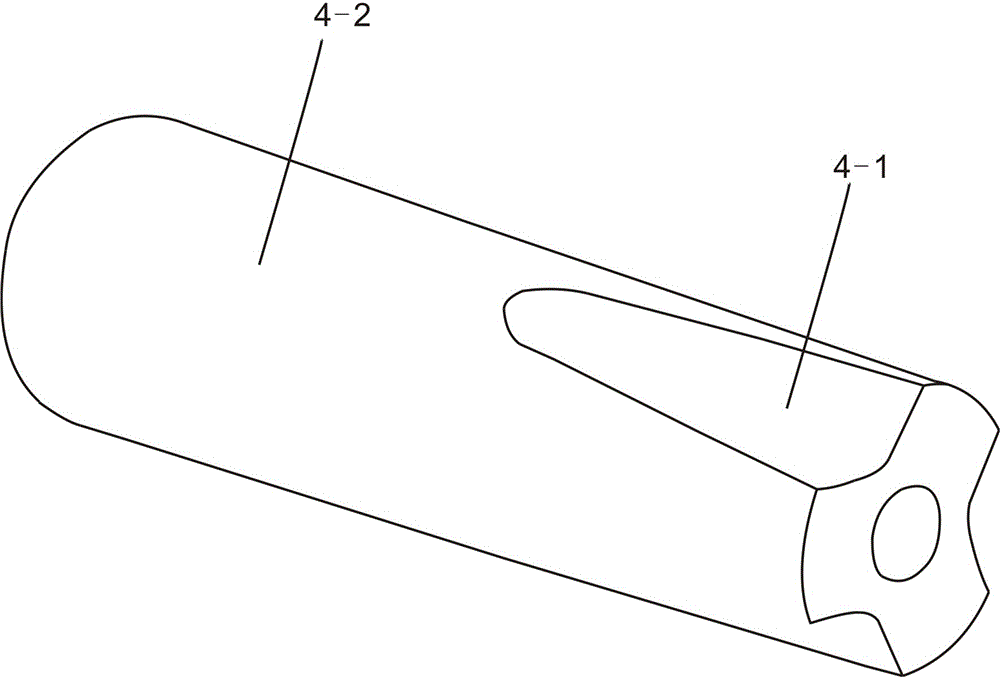

[0034] The grain 4 includes a booster-level three-arm grain 4-1 and a cruise-level end-fired grain 4-2, and the booster-level three-arm grain 4-1 and the cruise-level end-fire grain 4-2 are connected in series to form a Whole drug column;

[0035] The booster-level three-arm grain 4-1 and the cruise-level end-burning grain 4-2 are BOH four-component propellant grains with the same ...

Embodiment 2

[0042] A preparation method of the above-mentioned solid rocket motor with high thrust ratio, the method comprises the following steps:

[0043] 1) Adhesive heat insulation layer in combustion chamber shell 1 to manufacture heat insulation sleeve 3;

[0044] 2) Treat the inner surface of the heat insulation sleeve 3 and paint the butyl hydroxy lining;

[0045] 3) Install the heat insulating sleeve 3 prepared in step 2) in the combustion chamber shell 1 with the heat insulating layer 2;

[0046] 4) Molding of the grain 4: Install the mold for forming the three-armed grain 4-1 on the heat insulating sleeve 3, pour the same formula of butylated hydroxyl four-component propellant into the heat insulating sleeve 3 and the mold, and vulcanize and form under normal pressure , remove the mold;

[0047] 5) install nozzle 5;

[0048] Promptly make the solid rocket motor of described high thrust ratio.

[0049] In step 4), the vulcanization temperature is 50-60 degrees Celsius.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com