Metal/ceramic gradient material and preparation method thereof

A technology of gradient materials and ceramics, which is applied in the field of metal/ceramic gradient materials and its preparation, can solve the problems of low density of metal/ceramic gradient materials, large difference in calorific value between metal and ceramics, and inability to react, so as to achieve effective The effect of control, high density and full response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

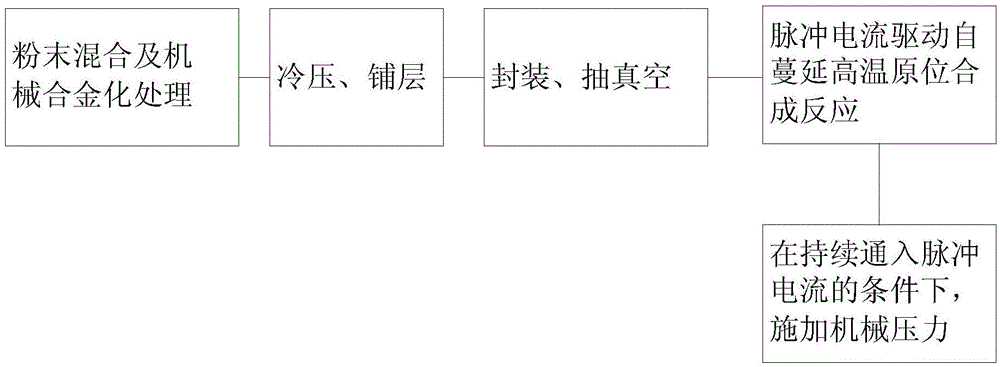

Method used

Image

Examples

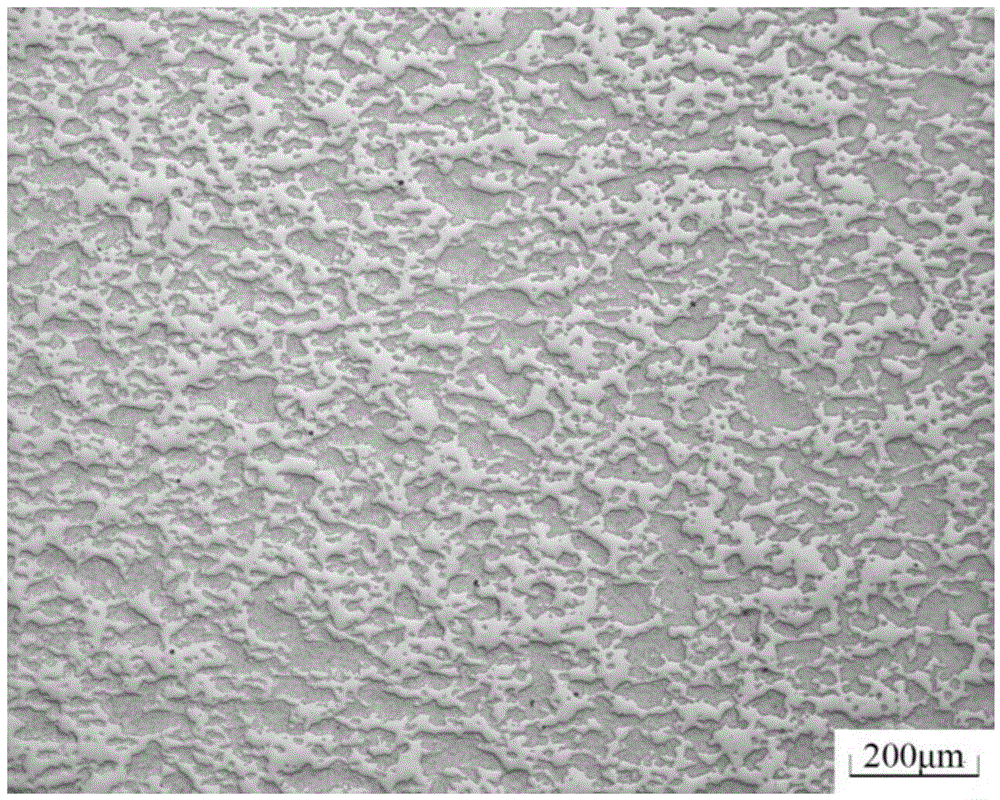

Embodiment 1

[0040] This embodiment provides a method for preparing a WC / Co gradient material, wherein the method includes the following specific steps:

[0041] In this embodiment, W powder, C powder, and Co powder are selected as raw powder materials. The raw particle size of C powder is 70 μm, that of W powder is 10 μm, and that of Co powder is 5 μm. The metal sheath is made of 4mm thick 1Cr18Ni9Ti stainless steel plate.

[0042] 1. Ball milling powder:

[0043] The three powders of W powder, C powder and Co powder were ball milled with a planetary ball mill. The ball milling time was 6 hours, the rotation speed was 300r / min, and the ball-to-material volume ratio was 10:1. During the ball milling process, ethanol solvent was added for wet milling, so that To avoid the oxidation and reaction of W powder and C powder, the solid-liquid volume ratio is 1:1;

[0044] 2. Cold pressing and layering:

[0045] The number of gradient layers of the WC / Co gradient material in this embodiment is ...

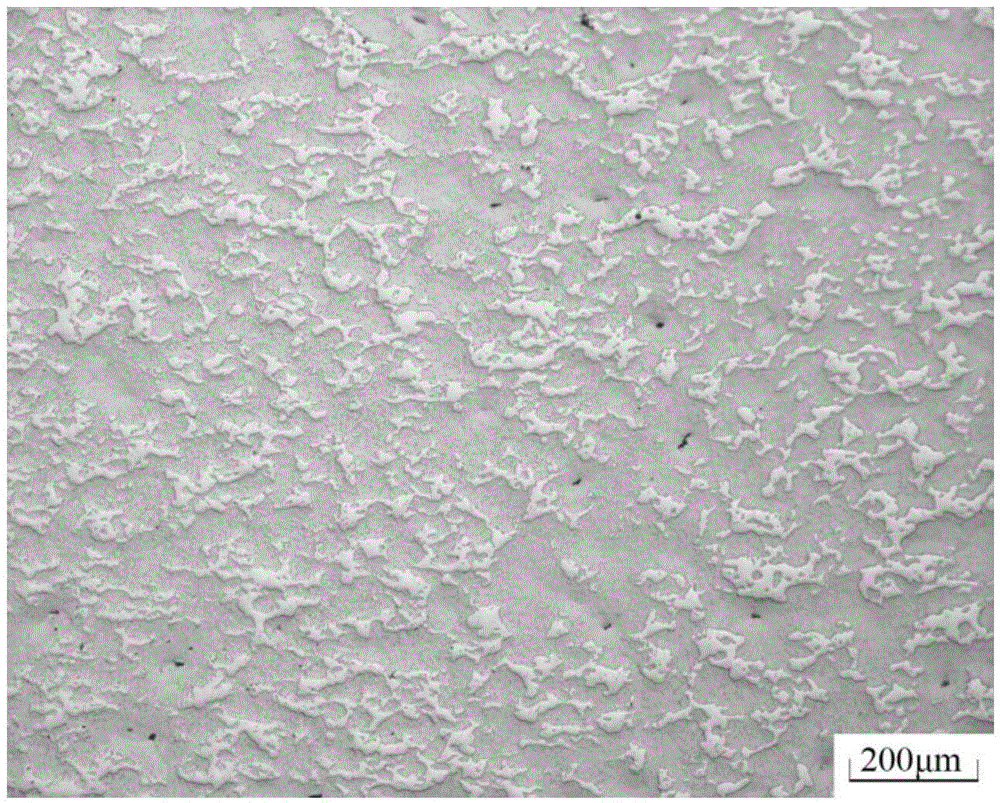

Embodiment 2

[0051] This embodiment provides a method for preparing a Ti / TiC gradient material with a curved surface shape, wherein the method includes the following specific steps:

[0052] In this embodiment, Ti powder and C powder are selected as the original powder materials. The original particle size of the Ti powder and the C powder are both 100 μm, and the material of the metal sheath is TA1 titanium plate with a thickness of 2 mm.

[0053] 1. Ball milling powder:

[0054] Two kinds of powders, Ti powder and C powder, are ball-milled by a planetary ball mill. The ball-milling time is 15h, the rotating speed is 100r / min, and the volume ratio of ball to material is 6:1. During the ball-milling process, ethanol solvent is added for wet milling to avoid Ti powder, Oxidation and reaction of C powder, the solid-liquid volume ratio is 1:1;

[0055] 2. Cold pressing and layering:

[0056] The design gradient layer number of the Ti / TiC gradient material in this embodiment is 6 layers, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com