Full-automatic magnetic tile sticking machine

A magnetic tile machine, fully automatic technology, applied in the manufacture of stator/rotor body and other directions, can solve the problems of non-compliance with the quality management system and humanized development ideas, high labor cost input, and low efficiency of magnetic tile sticking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

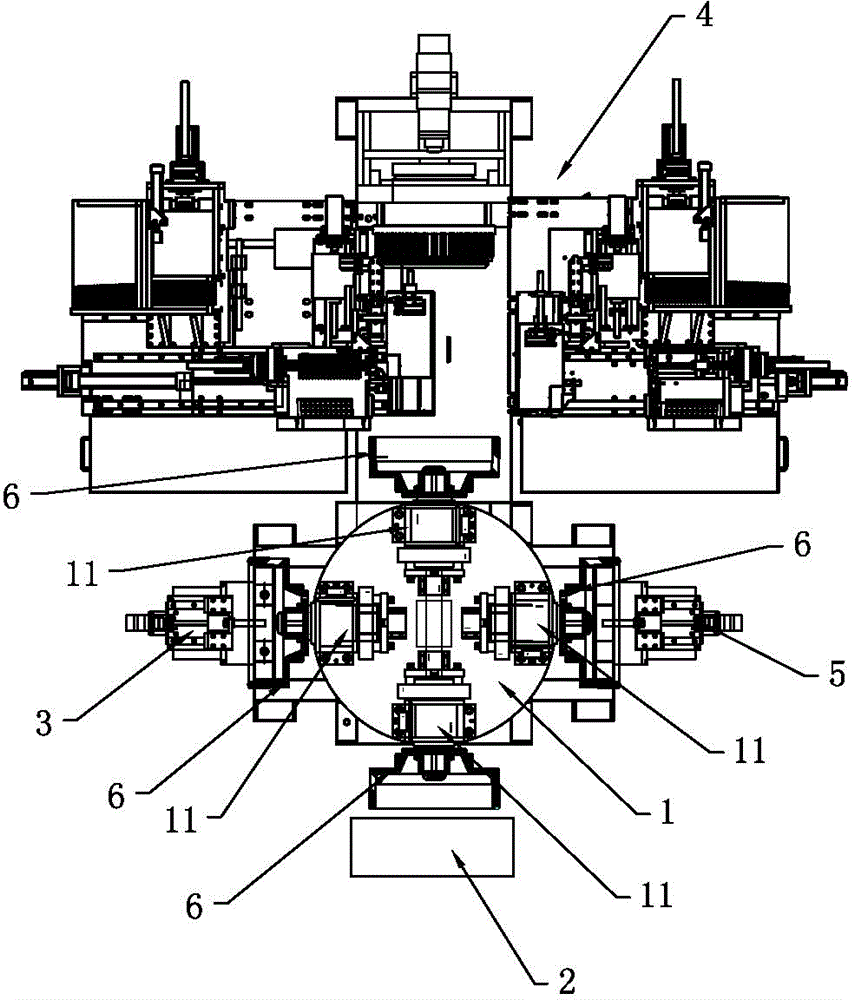

[0071] like Figure 1 to Figure 6 As shown, a fully automatic tile sticking machine includes a control system and a rotatable turntable mechanism 1 with at least four stations arranged in a ring. Each station of the turntable mechanism 1 is provided with a clamping rotor 6. The shaft expansion mechanism 11 also includes a loading and unloading mechanism 2, a glue application mechanism 3, a magnetic tile mounting mechanism 4 and a filling glue glue application mechanism 5 arranged in sequence.

[0072] The loading and unloading mechanism 2 includes the loading and unloading manipulator for feeding and taking out the rotor 6 into and out of the shaft expansion mechanism 11 and the loading and unloading positioning drive device for driving the loading and unloading manipulator; the glue applying mechanism 3 includes applying glue to the rotor. The first gluing machine on the inner wall of 6 and the first glue head positioning drive device for driving the first gluing machine; the...

Embodiment 2

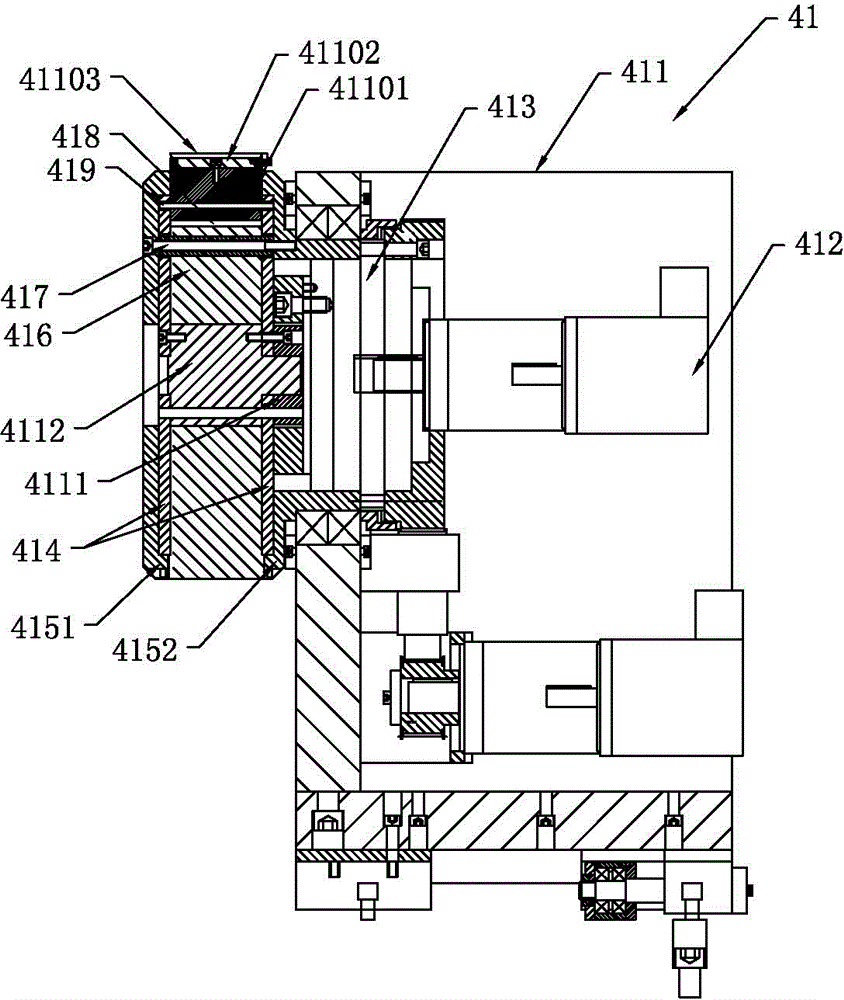

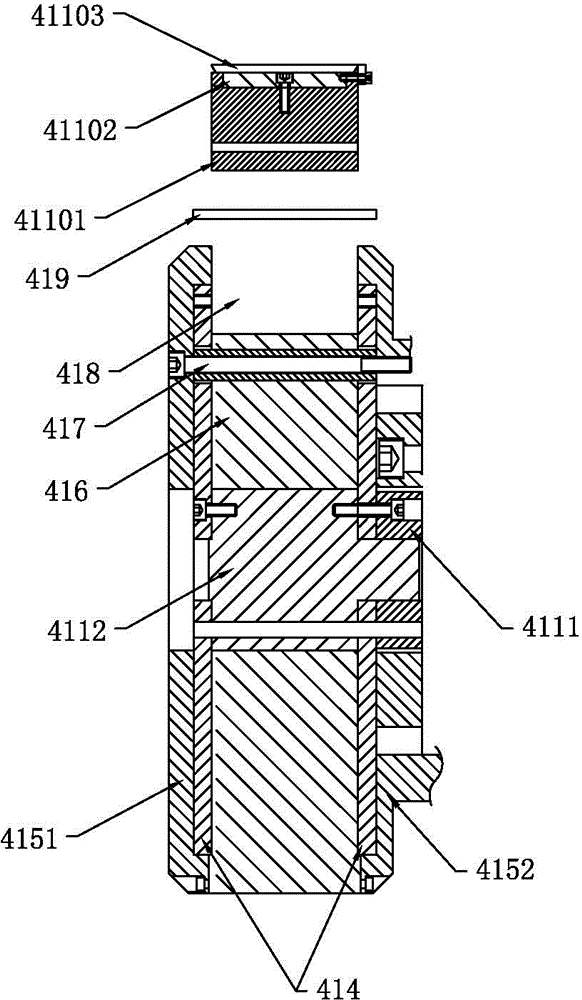

[0080] One of the implementation modes of a fully automatic tile sticking machine of the present invention, such as Figure 1 to Figure 7 As shown, the main technical solutions of this embodiment are basically the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is: as Figure 7As shown, the magnetic tile library device 41 also includes a protective cover 4113 and a protective cover driving device 4114 that drives the movement of the protective cover 4113. The protective cover 4113 is arranged in a bottomless cylindrical shape, and the protective cover 4113 covers the charging unit 4110 inside. .

[0081] The protective sheath driving device 4114 is drivingly connected with the protective sheath 4113 . Wherein, the protective cover driving device 4114 includes a servo motor 4116, a driving wheel 4115, a synchronous belt and fou...

Embodiment 3

[0084] One of the implementation modes of a fully automatic tile sticking machine of the present invention, such as Figure 1 to Figure 11 As shown, the main technical solution of this embodiment is basically the same as that of embodiment 1 or embodiment 2, and the features not explained in this embodiment are explained in embodiment 1 or embodiment 2, and will not be repeated here . The difference between this embodiment and embodiment 1 or embodiment 2 is: as Figure 8 to Figure 11 As shown, the magnetic tile pushing device 42 includes a pushing controller, a first pushing mechanism, a Hall sensor 425, a turning mechanism, a second pushing mechanism discharge device 4211 and a third pushing mechanism, and the first pushing mechanism includes a first push rod 421 , the first guide rod 423 and the first push rod 421 drive device for driving the first push rod 421 to move along the first guide rod 423, the first push rod 421 drive device is connected with the push controller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com