Combination of body and striking plate for golf club head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

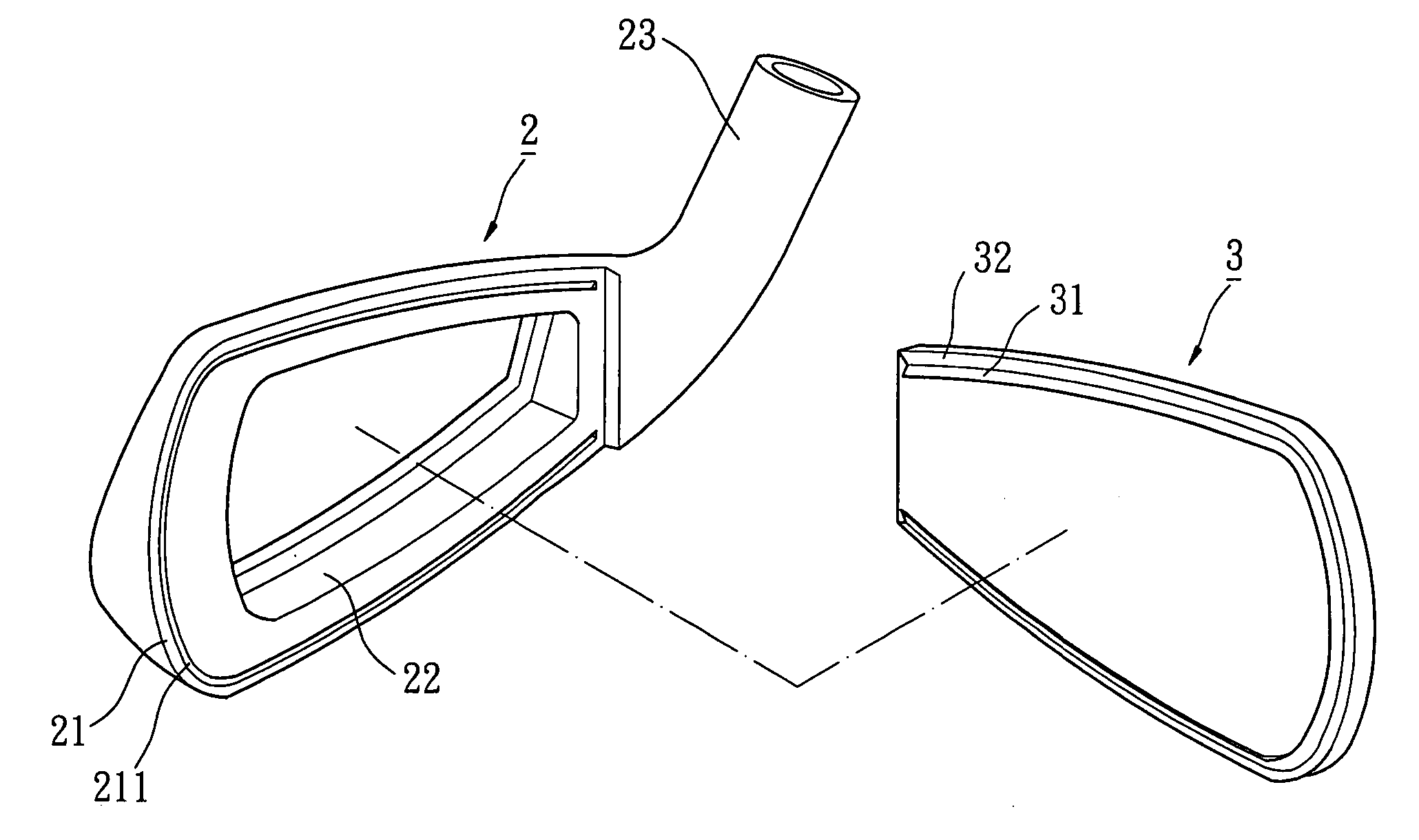

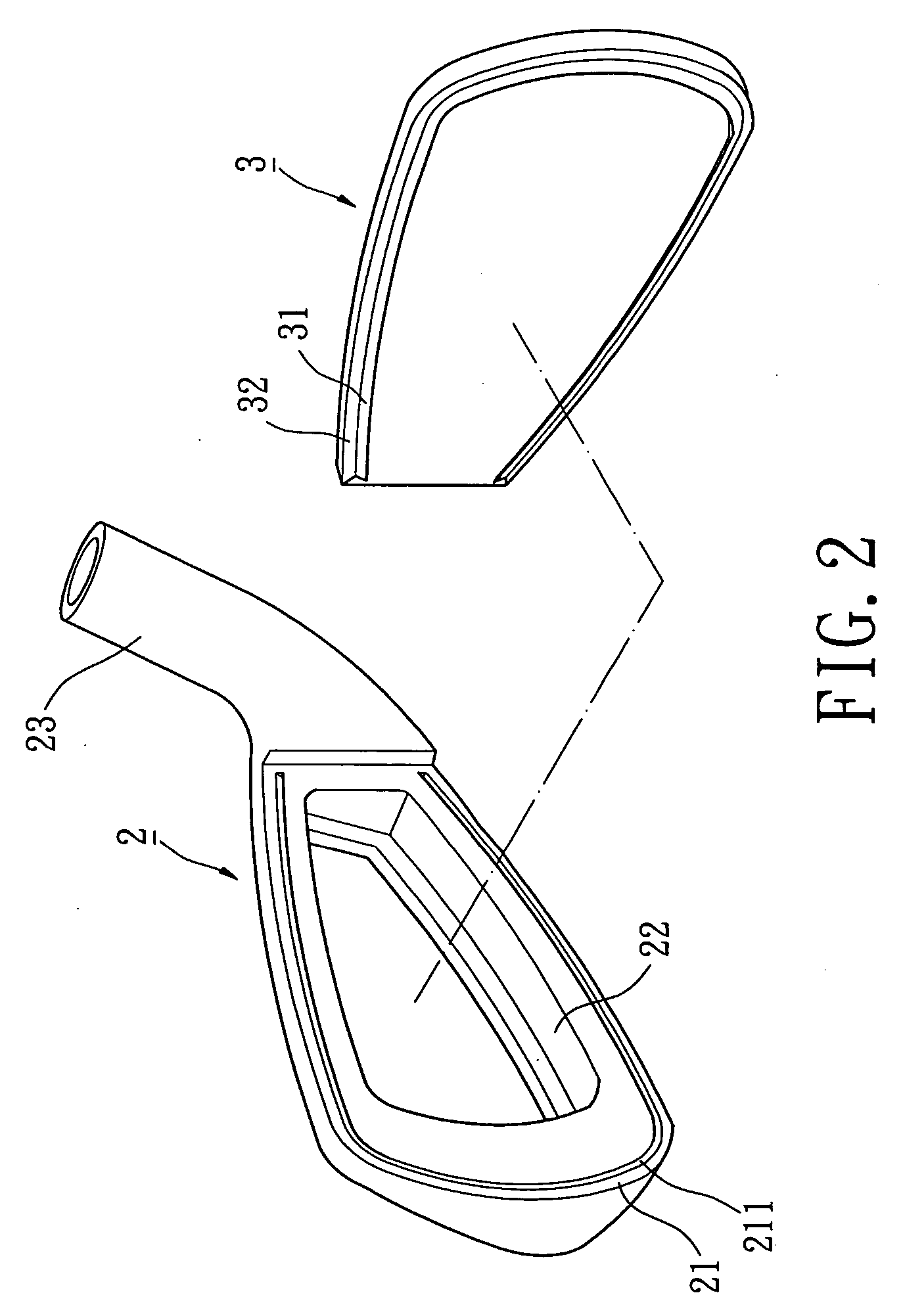

[0031] Referring to FIGS. 2 and 3, a golf club head in accordance with the present invention comprises a body 2 and a striking plate 3. The body 2 is made of a metal material with a relatively higher rigidity, such as stainless steel, low-carbon steel, or alloy steel. The body 2 includes a front side in which a recessed portion 22 is defined, with an engaging face 21 surrounding a front opening of the recessed portion 22. A substantially slantingly V-shaped groove 211 is defined in the engaging face 21. The V-shaped groove 211 is adjacent to and extends along the outer perimeter of the body 2. The V-shaped groove 211 inclines toward the recessed portion 22 or the outer perimeter of the body 2. The recessed portion 22 provides a buffering space for the striking plate 3 that deforms rearward when striking a golf ball. A hosel 23 is provided on a side of the body 2 (preferably a side of the recessed portion 22) for engaging with a shaft (not shown).

[0032] Still referring to FIGS. 2 and...

fifth embodiment

[0041]FIGS. 10 and 11 illustrate the invention. In this embodiment, the golf club head includes a body 4 and a striking plate 5. The body 4 includes a recessed portion 42, a positioning groove 41 surrounding the recessed portion 42, a positioning flange 43, a plastic protrusion 44, and an auxiliary plastic protrusion 45. A positioning flange 51, an engaging face 52, and a groove 53 are formed on a rear side of the striking plate 5.

[0042] In assembly, the positioning flange 51 of the striking plate 5 is engaged with the positioning groove 41, with the positioning flange 43 securely holding the positioning flange 51. A pointed section 441 of the plastic protrusion 44 of the body 4 abuts against a wall delimiting the groove 53. Next, the pointed section 441 of the plastic protrusion 44 deforms plastically and forms an engaging portion 44′ that is securely engaged in the groove 53. The auxiliary plastic protrusion 45 plastically deforms and forms a gap-filling portion, which is similar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com