Multistage middle shaft rapid flushing gate

A fast flushing and rotating shaft technology, which is applied in water conservancy projects, artificial waterways, sea area projects, etc., can solve problems such as uncontrollable drainage of irrigation canals, and achieve the effects of uniform force, fast opening, and reduced size and strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

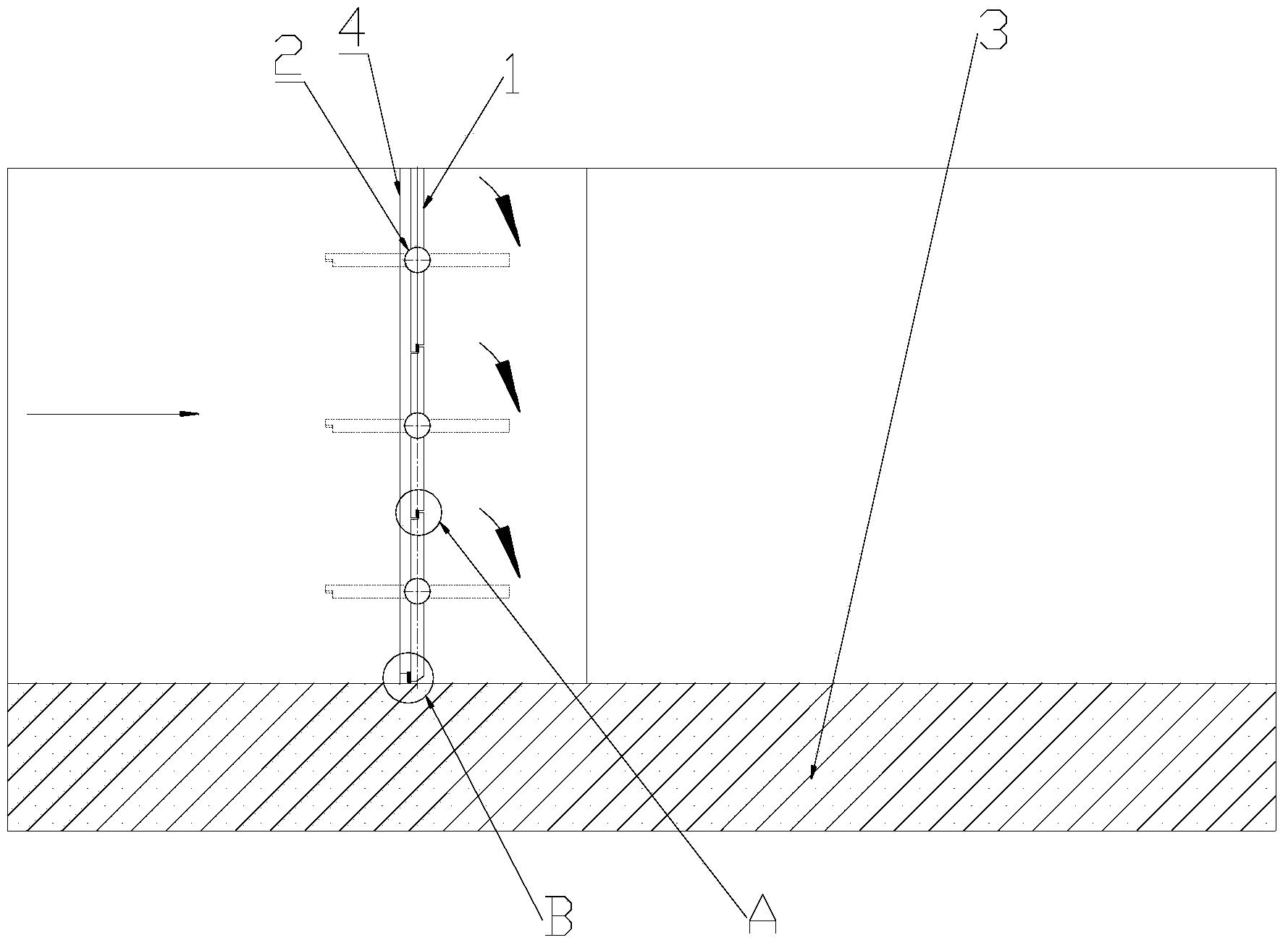

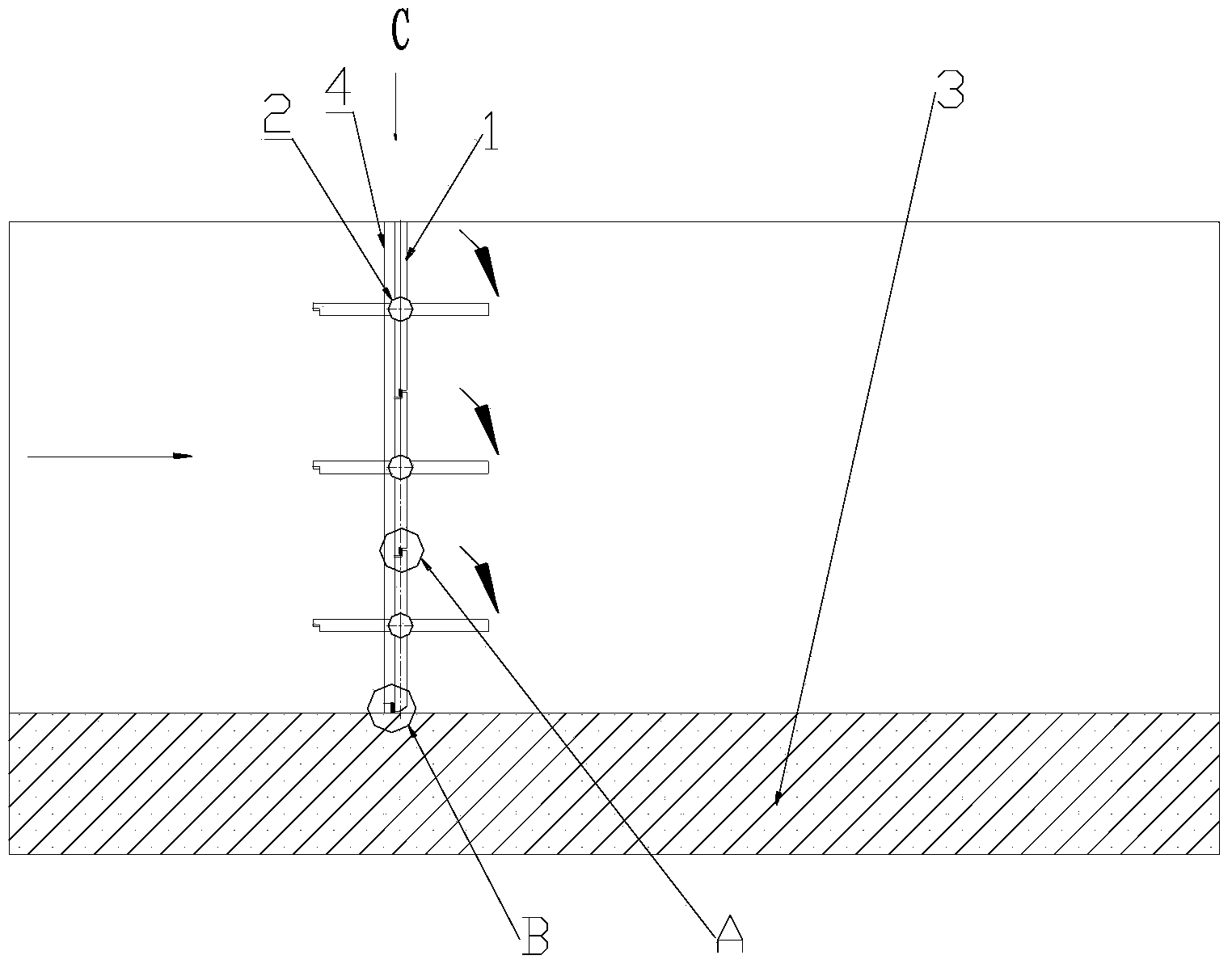

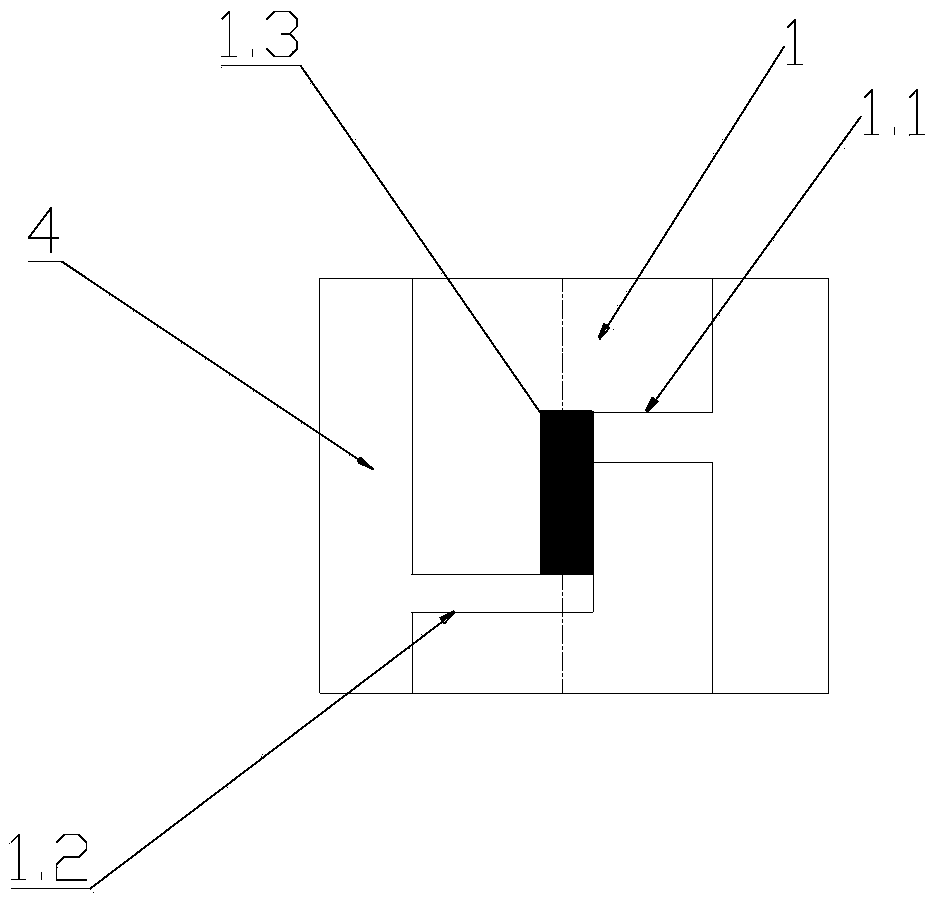

[0026] Such as figure 1 , figure 2 A multi-stage central axis quick flushing door is shown, which includes a plurality of weir plates 1 installed in the conduit 3, and the plurality of weir plates 1 are installed on the vertical surface, and the middle part of each weir plate 1 is connected with a corresponding The rotating shaft 2, in this embodiment, the rotating shaft 2 passes through the longitudinal central axis of the weir plate 1, and the end of the rotating shaft 2 is connected to the output end of the driving device 5, and a second A sealing structure; a second sealing structure is provided at the bottom of the lowermost weir plate.

[0027] In this embodiment, the driving device 5 drives the rotating shaft 2 to rotate, and then drives the weir plate 1 corresponding to the driving shaft 2 to rotate. When each weir plate 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com