Advanced dust-removing and demisting device

A defogging device and dust removal technology, which is applied to combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of large operation power consumption, high construction cost, rising operating cost, etc., and achieves good operation effect and flushing. The effect of low frequency and small flushing water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

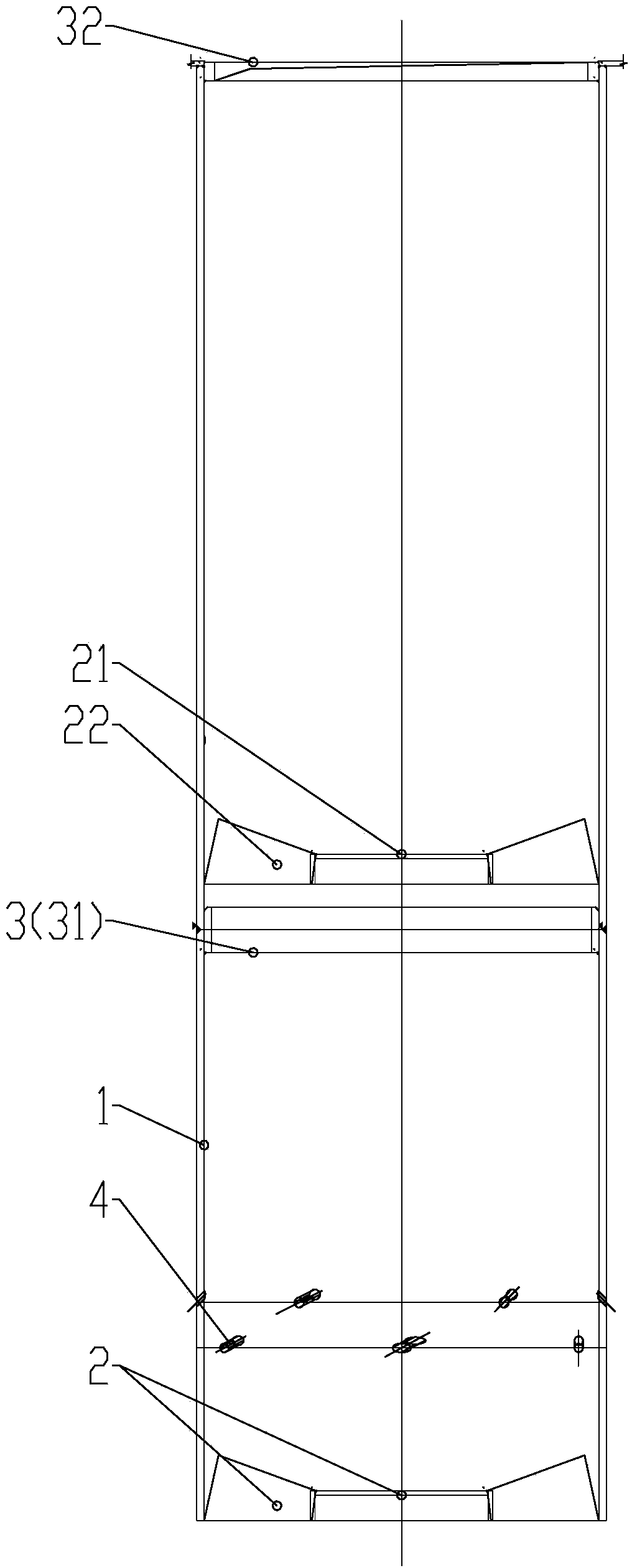

[0032] Such as figure 1 , figure 2 As shown, a deep dedusting and demisting device includes a guide tube 1 and a turbulent element 2 .

[0033] In order to create a flow state of high-speed rotating motion for the flue gas passing through the device, a water retaining ring 3 is also provided in the guide tube 1, and a liquid holding layer with a certain amount of stable liquid is formed through the water retaining ring 3; the said The water retaining ring 3 is a part of the liquid holding capacity of the control device of the dust removal and demisting device, which is an annular part with a certain thickness and height, and is attached in the guide tube.

[0034] In order to control the thickness of the liquid film on the wall surface of the guide cylinder for the dedusting and demisting device, a discharge hole 4 is provided on the guide cylinder. The discharge hole is an opening that is in the same rotation direction as the vane, tangent to the inner wall of the draft tu...

Embodiment 2

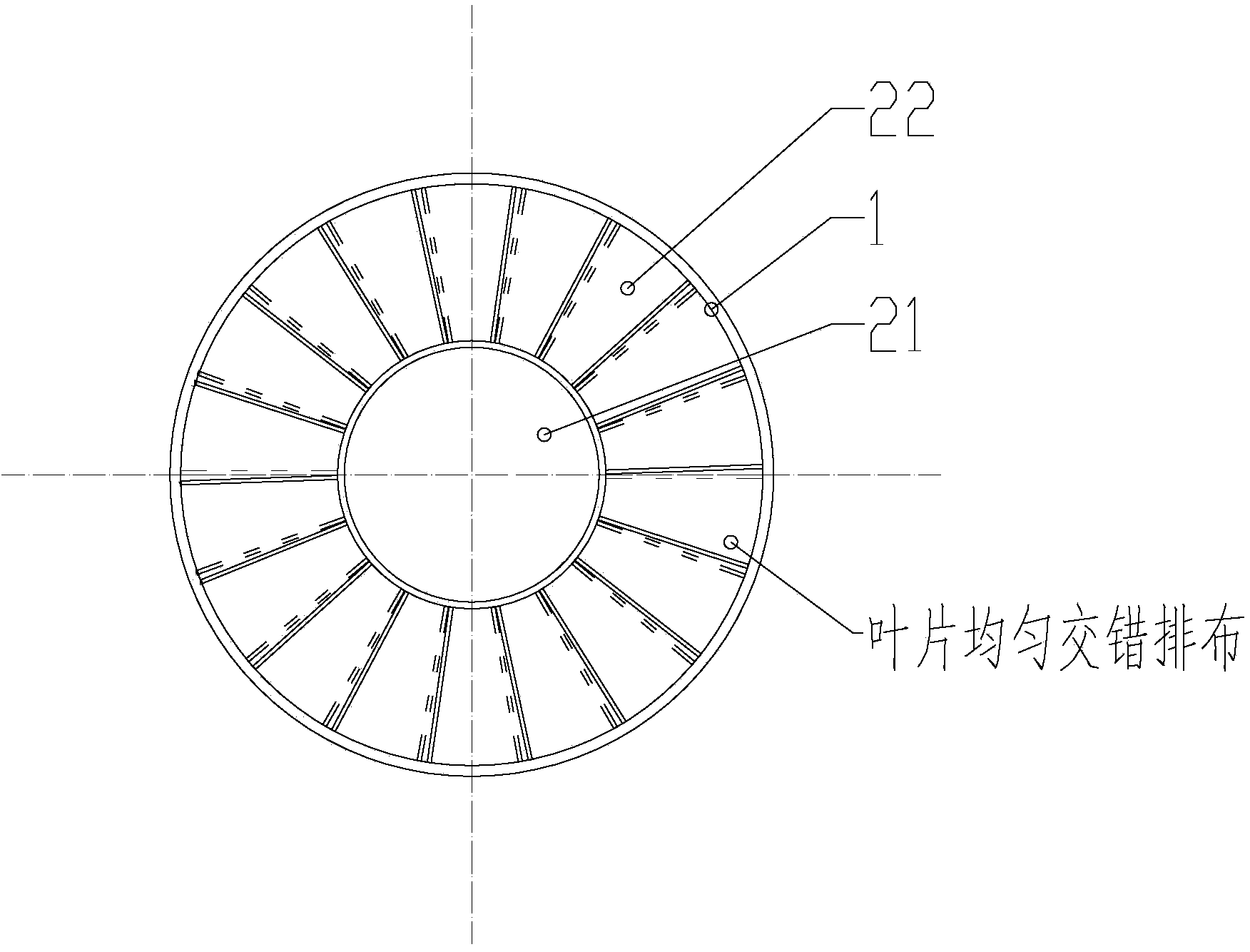

[0039] A turbulent element 2 is placed at the flue gas inlet in the guide cylinder 1; the turbulent element 2 is composed of a central cylinder 21 and blades 22. The 18 turbulent sub-blades 22 are evenly distributed in the annular area between the central cylinder 21 and the guide tube 1 at an inclination angle of 42°, and each turbulent sub-blade covers a fan-shaped area whose vertical projected coverage area is a central angle of 22°. There is a fan-shaped area overlap of 2° in other surrounding leaves.

[0040] In the turbulent flow element 2, the diameter of the central cylinder 21, the number of the blades 22, the inclination angle of the blades 22, and the size of the overlapping area of the vertical projection of the blades 22 need to be determined according to the droplet content and dust content in the inlet flue gas. And export processing effect requirements to be adjusted. Generally speaking, the greater the droplet content at the inlet, the smaller the number an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com