Device and method for mineralizing desalinated seawater

A technology for desalinating water and concentrated brine, applied in chemical instruments and methods, seawater treatment, separation methods, etc., can solve problems such as waste, bipolar membrane clogging, and inability to achieve precise control of acid concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

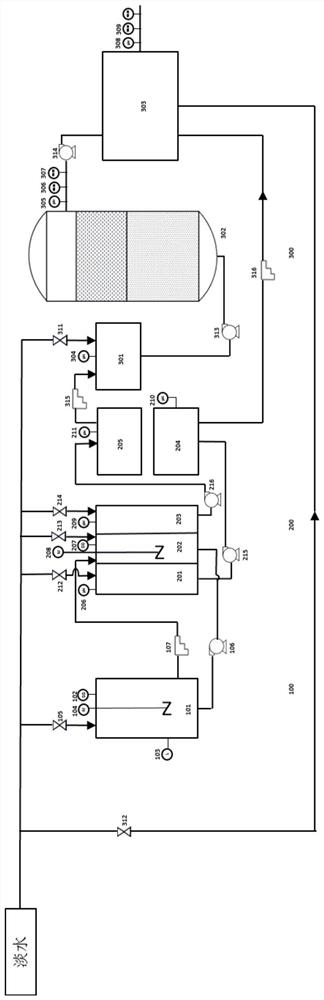

Image

Examples

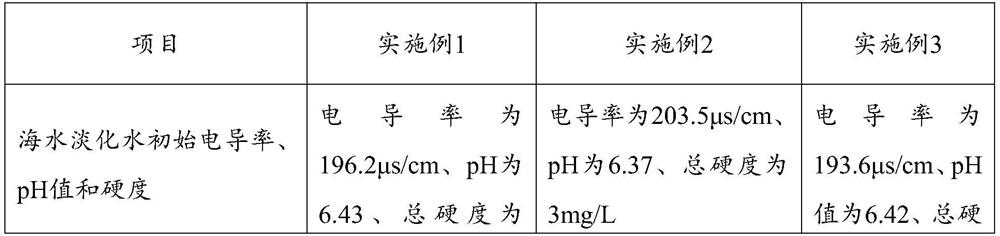

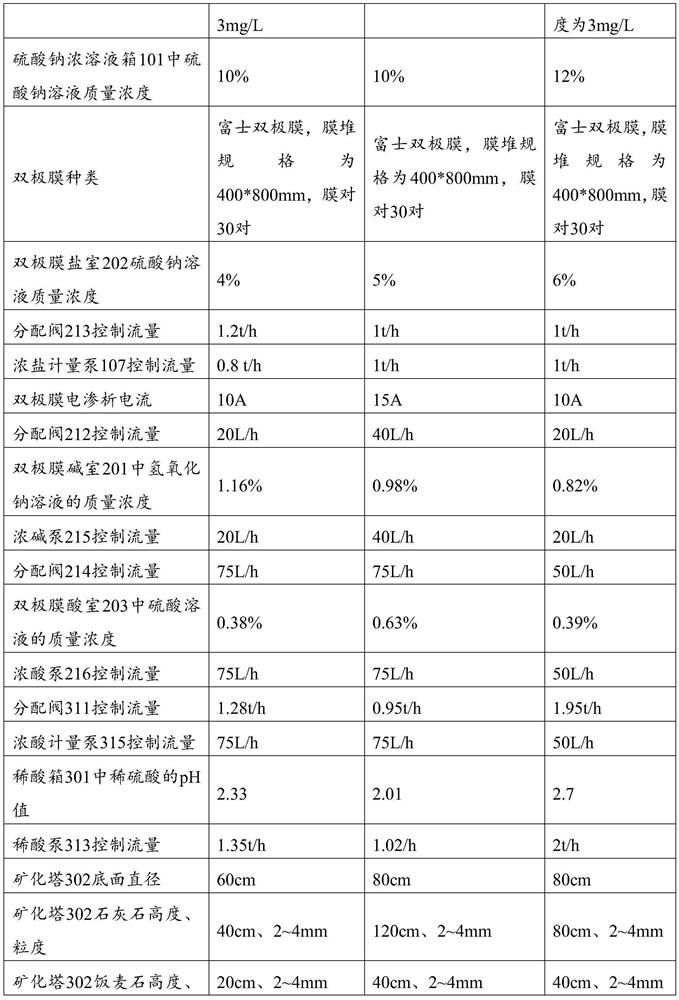

Embodiment 1

[0077]The conductivity of the desalinated water is 196.2μs / cm, the pH is 6.43, and the total hardness is 3mg / L, which is highly corrosive water. Use the device of the present invention to perform seawater desalination water mineralization, and the parameters are shown in Table 1.

Embodiment 2

[0079] The conductivity of the desalinated water is 203.5μs / cm, the pH value is 6.37, and the total hardness is 3mg / L, which is highly corrosive water quality. Use the device of the present invention to perform seawater desalination water mineralization, and the parameters are shown in Table 1.

Embodiment 3

[0081] The conductivity of the desalinated water is 193.6μs / cm, the pH is 6.42, and the total hardness is 3mg / L, which is a highly corrosive water quality. Use the device of the present invention to perform seawater desalination water mineralization, and the parameters are shown in Table 1.

[0082] The operating conditions when table 1 embodiment 1~3 carries out the mineralization of desalinated water

[0083]

[0084]

[0085]

[0086] It can be seen from Table 1 that the desalinated seawater mineralized water produced by the device and method of the present invention can meet drinking standards and safe transportation and distribution requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com