A water-saving process for desulfurization, dust removal, fog removal and water saving of wet desulfurization tower

A technology for desulfurization, dust removal, and wet desulfurization, which is applied to the separation of dispersed particles, chemical instruments and methods, and combined devices to achieve the effects of simple installation, long service life, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical problems, technical solutions and implementation effects solved by the present invention will be further described in detail below in conjunction with the accompanying drawings. This description is only used to explain the present invention, not to limit the present invention.

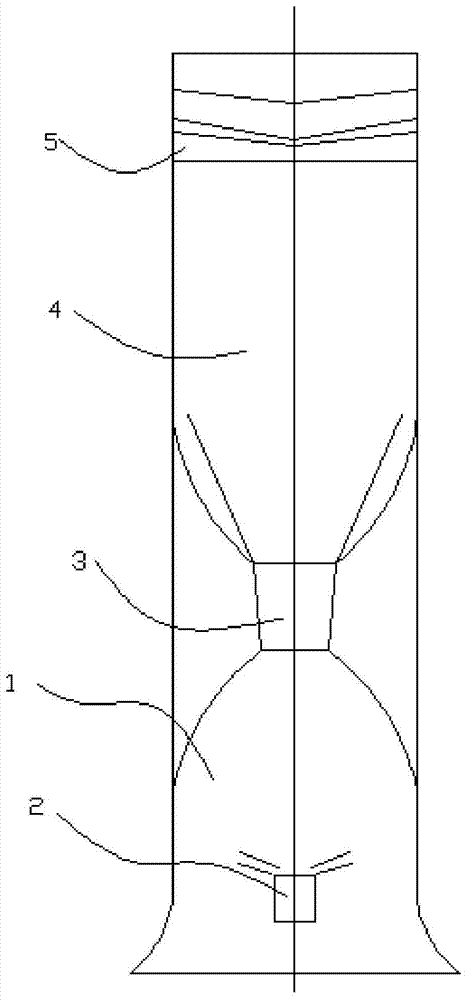

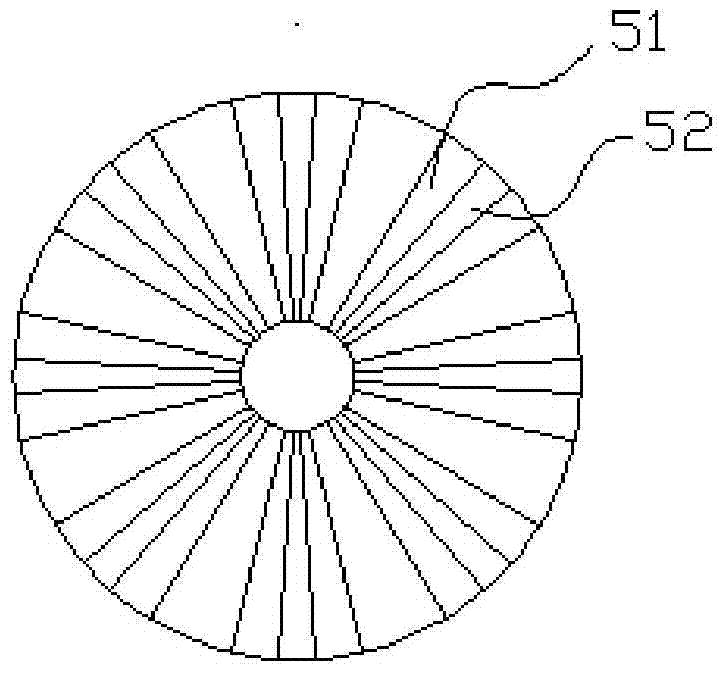

[0026] Such as figure 1 , 2 As shown, the flue gas desulfurized by the wet desulfurization tower enters the dedusting, demisting and water-saving device. The atomization angle is 130°~170°, which is beneficial to the collision and removal between liquid droplets and fine particles. The atomizing nozzle is connected to the water supply equipment through the pipeline. The fine dust and liquid droplets in the flue gas collide strongly with the mist sprayed from the atomizing nozzle, and the water vapor begins to condense and grow on the surface of the dust particles. The impact cooling chamber is spherical or elliptical, with a spherical diameter of 150mm to 1200mm, and an elliptic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com