Patents

Literature

89results about How to "No maintenance fee" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

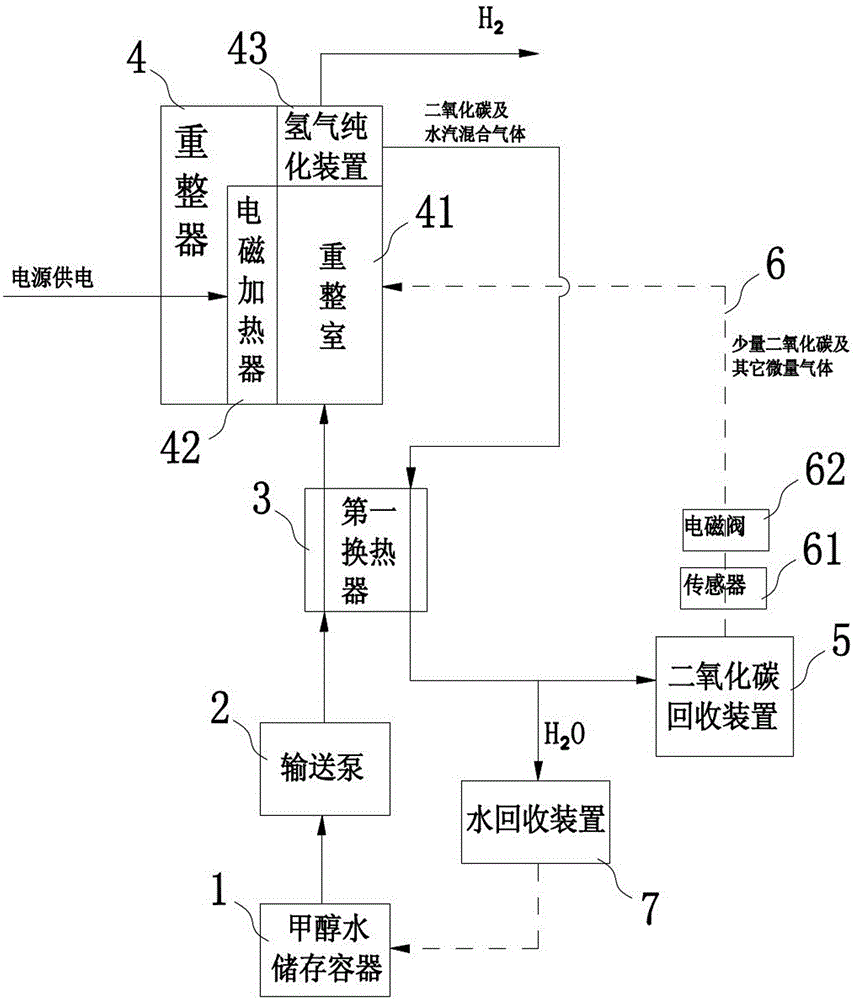

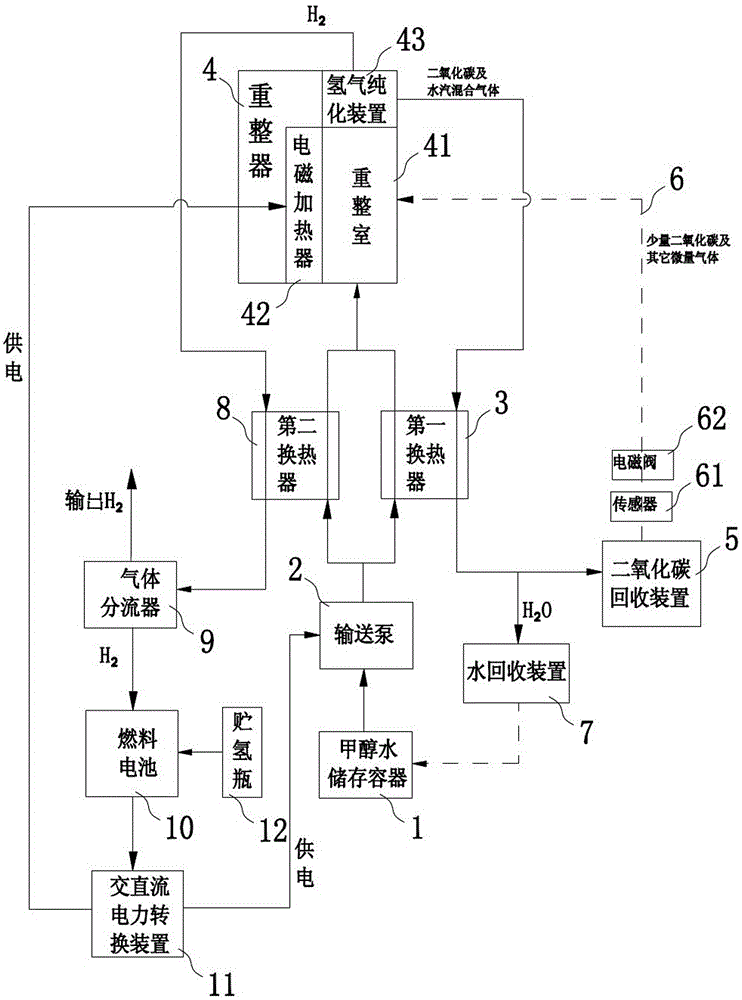

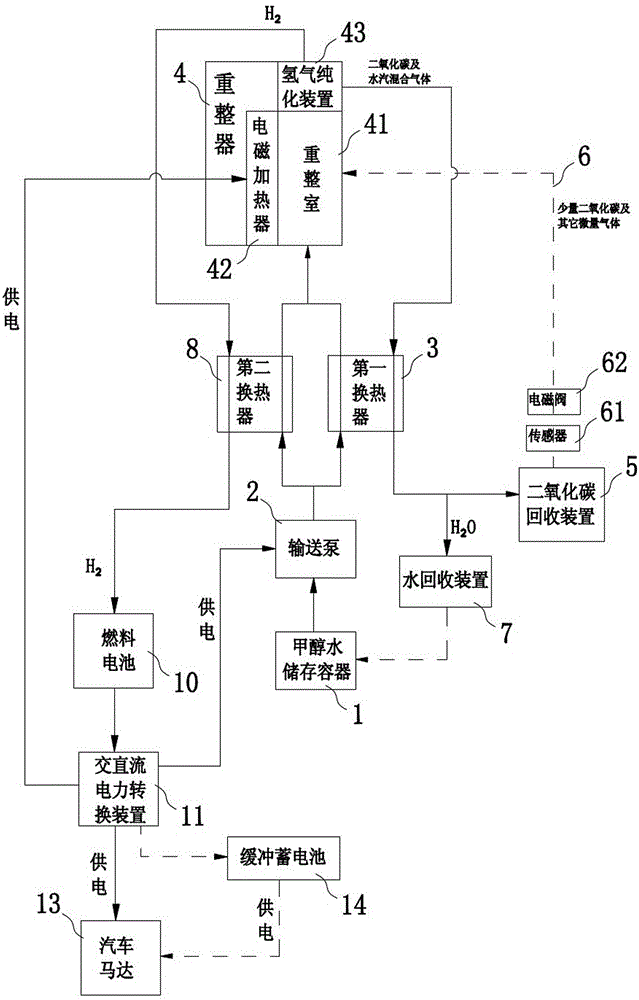

Zero-carbon-emission hydrogen production system by methanol water reforming as well as application and hydrogen production method thereof

The invention discloses a zero-carbon-emission hydrogen production system by methanol water reforming and application and a hydrogen production method thereof. The hydrogen production system comprises a methanol water storage vessel, a delivery pump, a first heat exchanger, a reformer and a carbon dioxide recovery device, wherein the reformer is provided with a reforming chamber, an electromagnetic heater and a hydrogen purification device; the electromagnetic heater provides heat energy for the reforming chamber; the reforming chamber is used for hydrogen production reaction of methanol and water by reforming to obtain carbon dioxide and hydrogen; carbon dioxide and hydrogen are mixed with water vapor to form high-temperature mixed gas, and the high-temperature mixed gas is delivered into the hydrogen purification device; after purification and separation, hydrogen is delivered out, at the same time carbon dioxide and unreacted water vapor mixed gas are also delivered out, and then carbon dioxide and unreacted water vapor mixed gas are delivered into the carbon dioxide recovery device after passing through the first heat exchanger; the carbon dioxide recovery device is a replaceable modular carbon dioxide recovery device and used for recovering carbon dioxide and part of the water vapor. The zero-carbon-emission hydrogen production system provided by the invention can recover carbon dioxide, has no impact on the environment and causes no harm to the hydrogen production system self and is beneficial for popularization and application in the field of new energy resources such as fuel cell cars.

Owner:GUANGDONG HYDROGEN ENERGY SCI & TECH

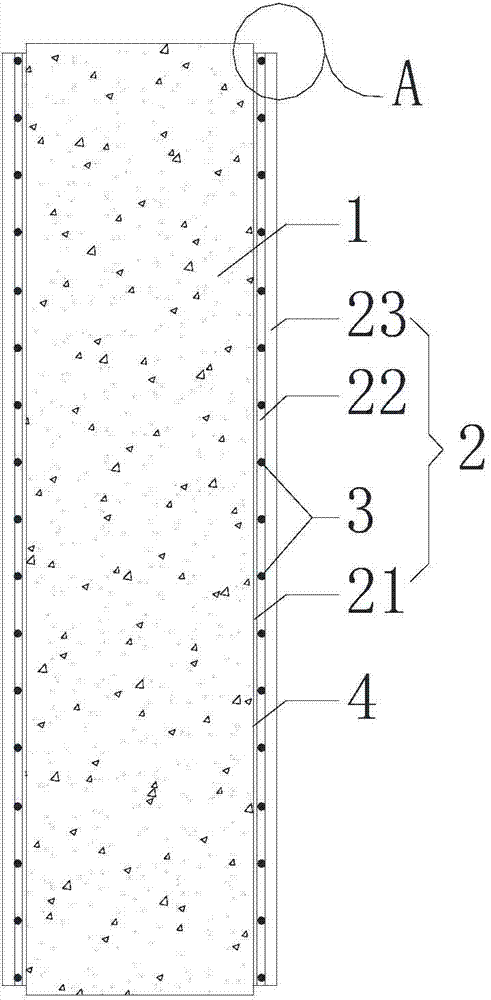

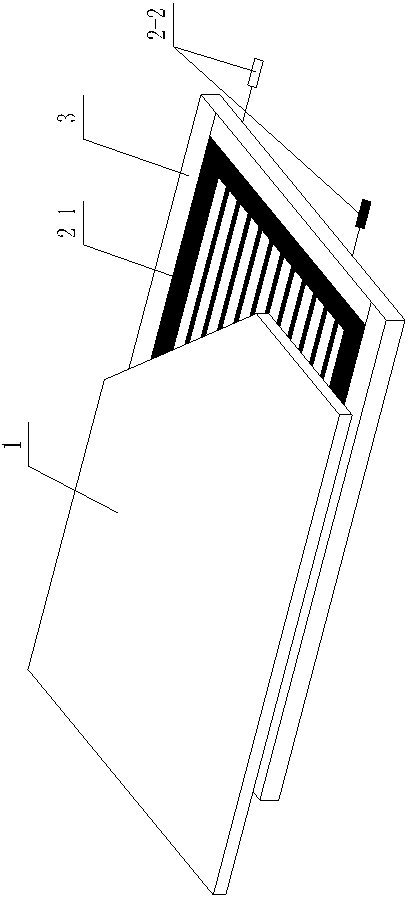

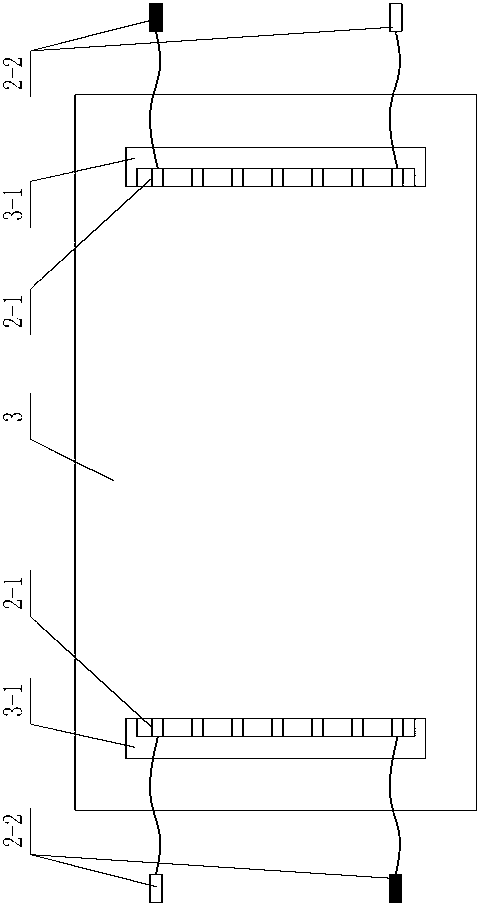

Reactive powder fiber concrete reinforced concrete column and reinforcement method

InactiveCN103590616ALight weightSelf-respect and high strengthBuilding repairsReinforced concrete columnFiber

The invention discloses a method for reinforcing a reactive powder fiber concrete reinforced concrete column. The method includes the steps that firstly, cleaning treatment is carried out on the surface of an original concrete column so that a concrete structure layer of the original concrete column can be exposed, and then impurity removal and dabbing are carried out till a new surface is exposed and an aggregate surface of the concrete structure layer is reached; secondly, positioning, lining and drilling are carried out on the surface of the column, shear pins are embedded into drilled holes through rib embedding glue, and a reinforcing mesh is bound at the lining position; thirdly, interface agents are applied, specifically, reactive powder fiber concrete is applied with the interface agents in a layered mode, joints between the layers are made staggered, and reinforcement of the concrete column is completed after the processes of flattening, burnishing and maintenance. The reinforced concrete column obtained through the method mainly comprises the original concrete column structure layer and a reactive powder fiber concrete reinforced layer, and the reactive powder fiber concrete reinforced layer is formed by mutually overlaying multiple unit reinforced layers with the reactive powder fiber concrete as a base material and the reinforcing mesh as a reinforcing material. The reactive powder fiber concrete reinforced concrete column has the advantages of being small in sectional dimension change, good in durability, long in service life, easy and convenient to construct, high in construction efficiency and the like.

Owner:湖南大兴加固改造工程有限公司

Method for repairing pile foundation and scour pit underwater

InactiveCN108411802AEasy constructionEasy to processFoundation repairBridge structural detailsUnderwaterPortland cement

The invention relates to a method for repairing a pile foundation and a scour pit underwater. The method includes the following steps that (1), a steel plate pile cofferdam is adopted for conducting construction around the local scour pit of a pier needing to be repaired; (2), a concrete cushion layer is laid within the range 2 m away from the pier; (3), the condition that the pier is damaged dueto scouring and corrosion is checked, and the pier is repaired firstly; (4), natural backfill soil is packed in the scour pit; (5), multiple stones are packed in the scour pit; and (6) ordinary Portland cement mortar is laid flatly on a macadam grouting protection layer, an RPC material is packed in the portion at the depth 15% of the remaining depth of the scour pit, an RPC layer is formed untilthe RPC layer is flush with the bottom face of a riverbed, and a soil layer is backfilled in the portion, around the RPC layer, in the scour pit. By the adoption of the method, the effect that the scoured and damaged pier foundation and the scour pit can be repaired, the bearing capacity of the original structure is improved, the service life of the structure can be prolonged by the adoption of the RPC material, and maintenance cost is saved.

Owner:YANGZHOU UNIV

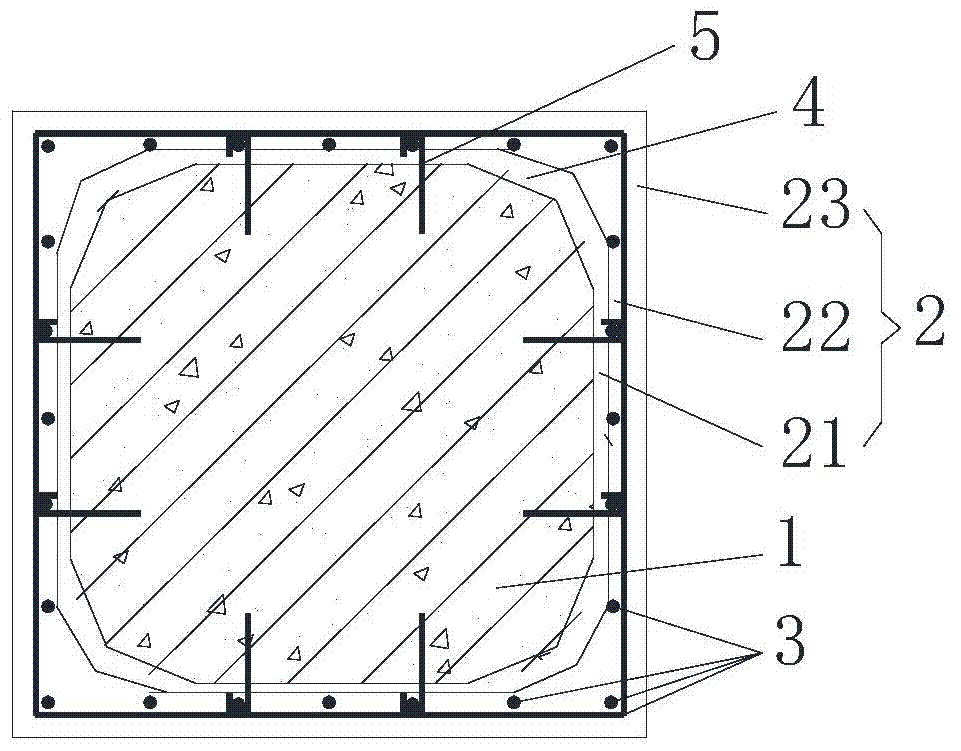

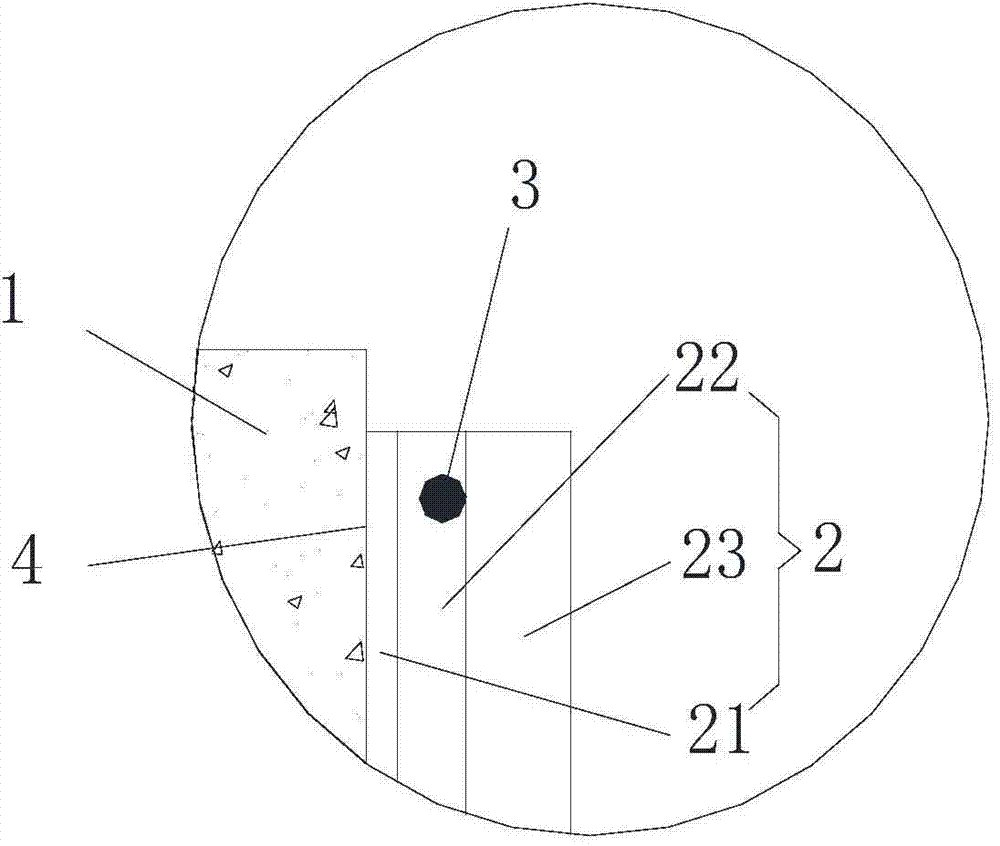

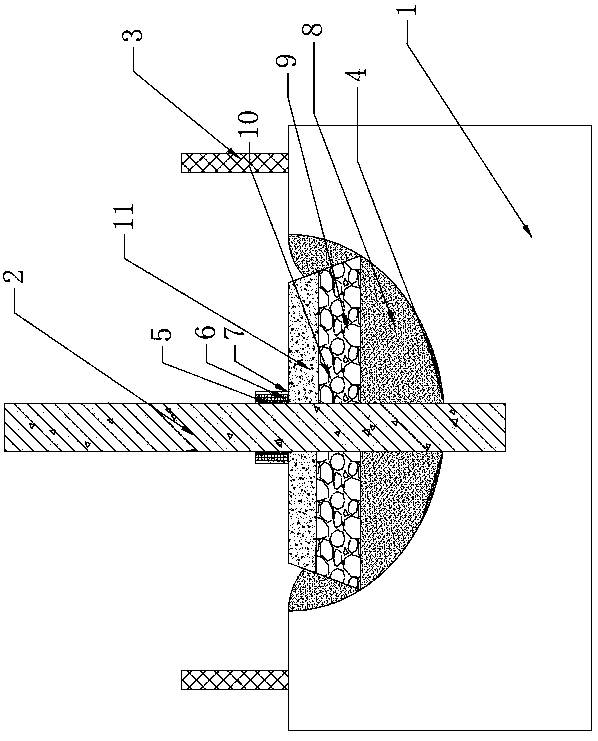

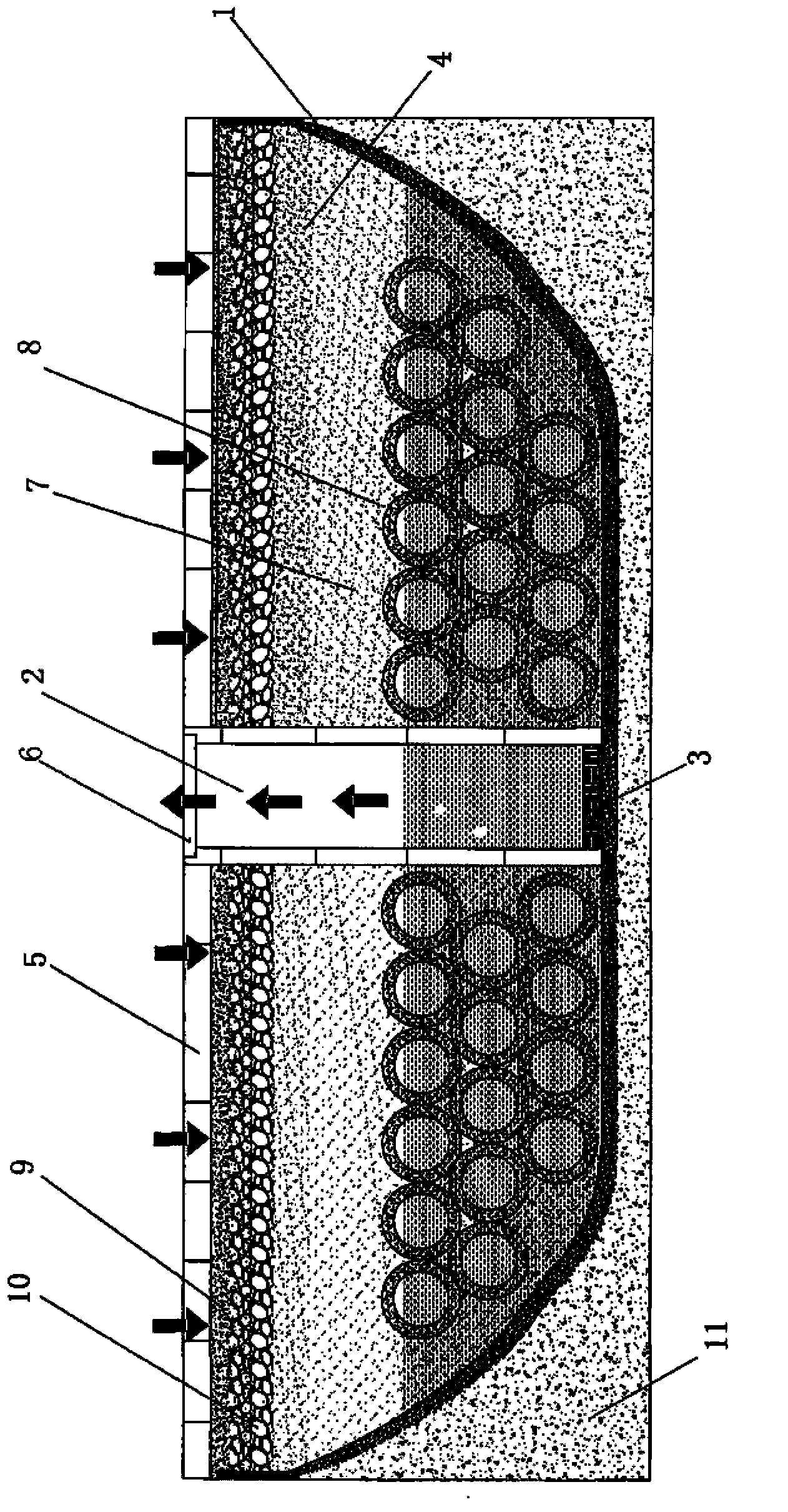

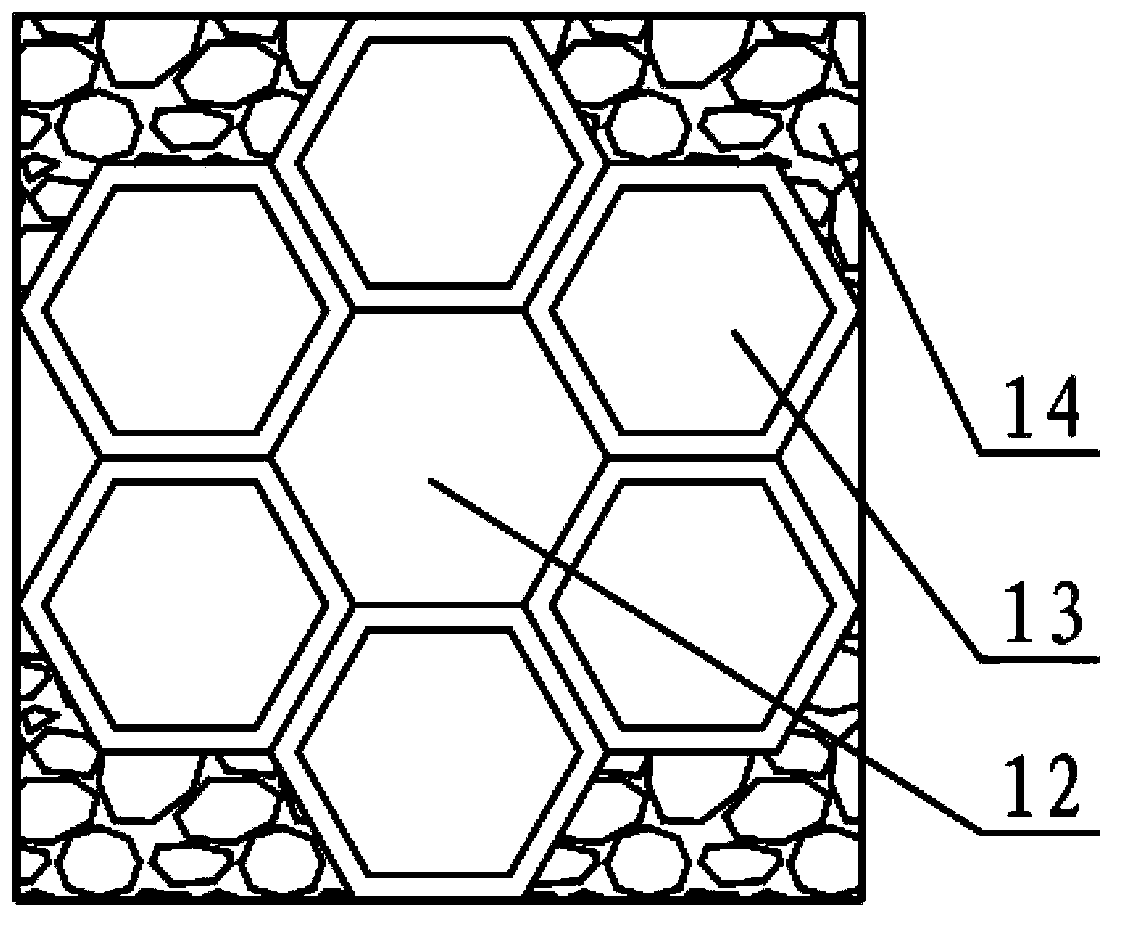

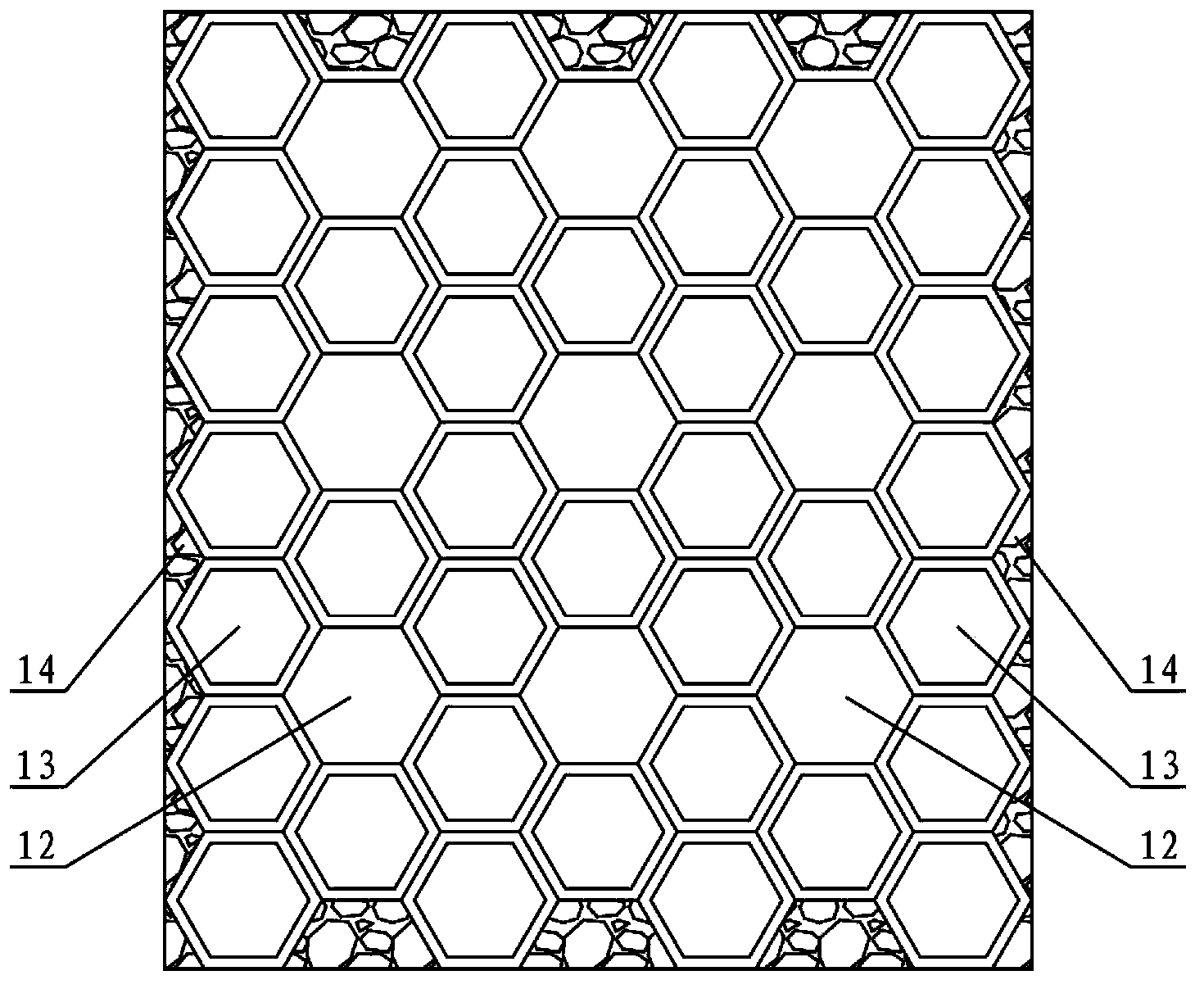

Water purifying and water storing unit, and water purifying and water storing system

ActiveCN103408187AWon't settleWon't spoilGeneral water supply conservationMultistage water/sewage treatmentWater dischargeFiltration

The invention belongs to the field of municipal engineering technologies, and especially relates to a water purifying and water storing unit, and a water purifying and water storing system provided with the water purifying and water storing unit, which are used for collection, filtration, purification treatment and storage of rain water. The container wall of a water container of the water purifying and water storing unit is water resistant; a water discharging well and invisible wells around the water discharging well are arranged in the water container; pervious structures are employed for the well walls of the water discharging well and the invisible wells; spaces between the water discharging well and the container wall of the water container, and spaces between the invisible wells and the container wall of the water container are all filled with a filling material; and a pervious surface bed is arranged on the invisible wells and the filling material. A combination mode of ventilation anti-seepage treatment and concrete floor is employed for the well bottom of the water discharging well and the invisible wells, so that water will not deteriorate, and subsidence of the water discharging well and the invisible wells will not happen; hexagonal honeycomb structures are employed for the water discharging well and the invisible wells, so that the structures are stable, specific surface area is large, carriers are provided for biofiml formation, water processing performance is obtained, and no energy is consumed.

Owner:北京仁创生态科技有限公司

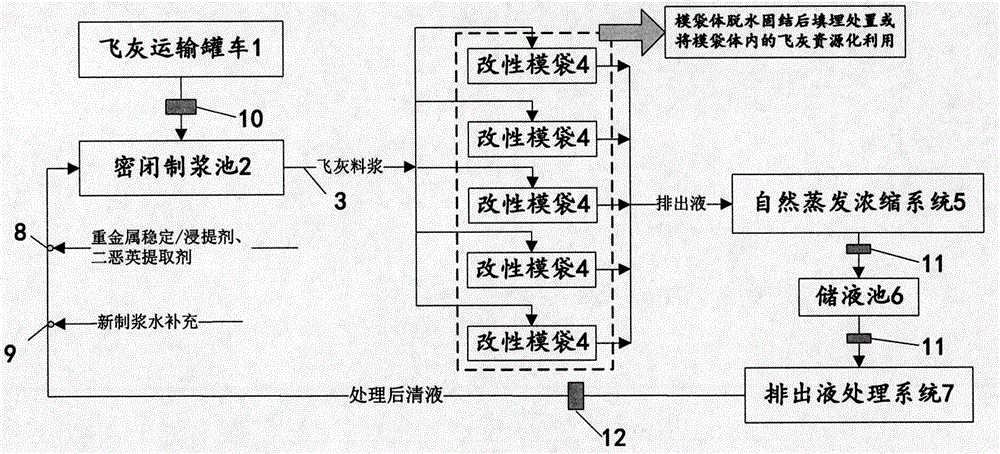

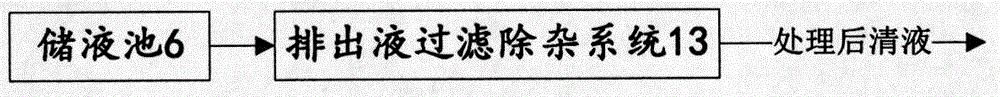

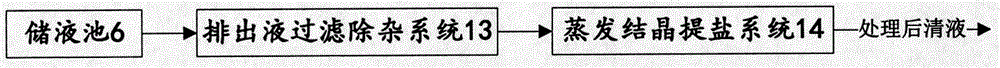

Household garbage incineration fly ash wet-method mold bag treatment method and system

ActiveCN106734045ASimplify processingExpansion of storage capacity utilization factorSolid waste disposalLandfill technologiesHeavy metalsResource utilization

The invention discloses a household garbage incineration fly ash wet-method mold bag treatment method. By means of three links of fly ash slurrying, fly ash slurry conveying and fly ash slurry dewatering / hydrating solidification, fly ash homogenizing, heavy metal and dioxin detoxifying, desalting and spontaneous hydrating solidification forming are achieved sufficiently at the same time; fly ash in mold bags after solidification meets related national standard requirements, solidified mold bag bodies can be subjected to landfill disposal, and fly ash can be taken out of the mold bags to be subjected to resource utilization; and liquid drained out of the mold bags is subjected to natural evaporation and concentration through a landfill space, after heavy metal and dioxin are recycled and impurities are filtered and removed, the liquid is recycled, or after further salt removing is carried out, the liquid is recycled. The invention further discloses a household garbage incineration fly ash wet-method mold bag treatment system. The household garbage incineration fly ash wet-method mold bag treatment method and system can overcome the defects of traditional fly ash dry-method landfill and a water washing pretreatment technology in large-scale industrial application, fly ash homogenizing, detoxifying, desalting, spontaneous hydrating solidification and landfill integrated treatment can be achieved, a basis is laid for follow-up fly ash resource utilization, the treatment cost is low, and the household garbage incineration fly ash wet-method mold bag treatment method and system can be applied to large-scale industrial production.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

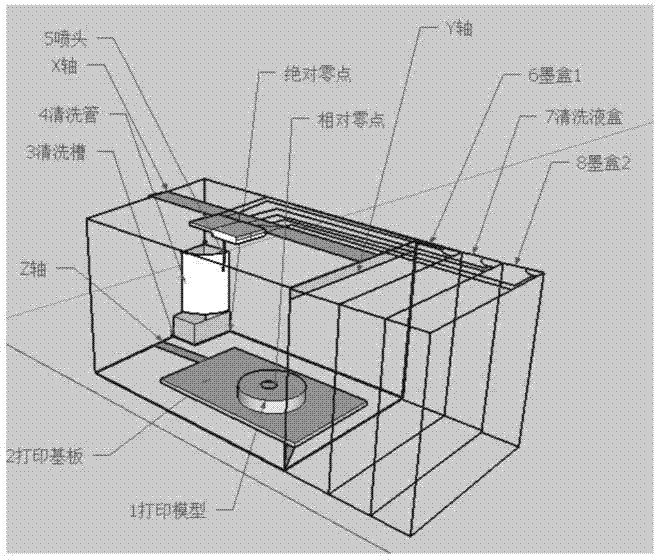

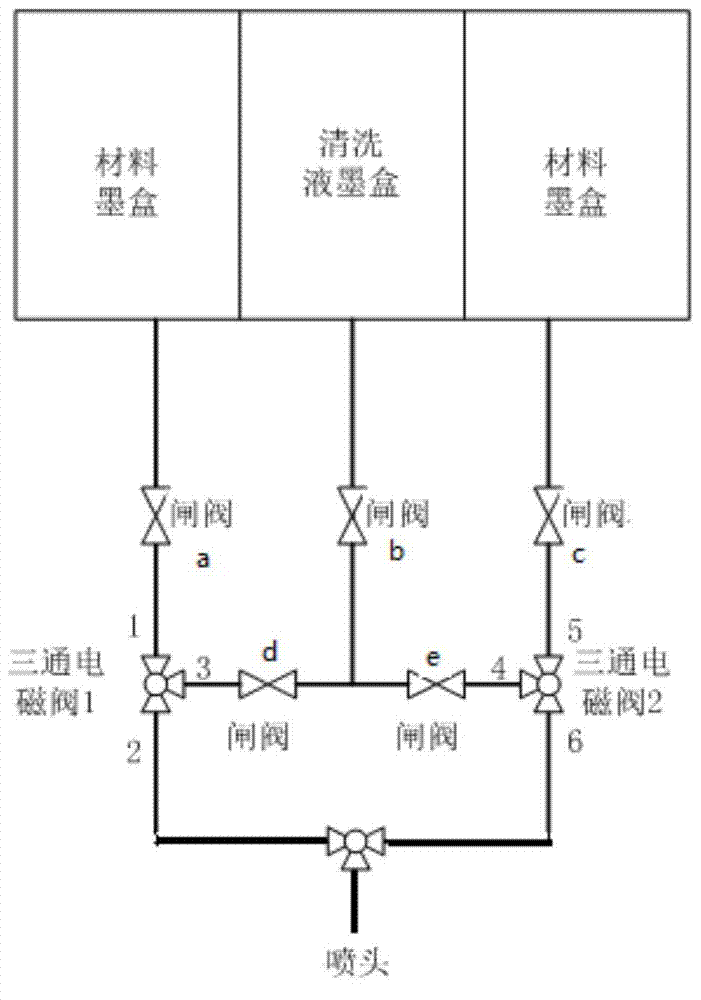

Micro spray 3D printing device capable of automatically washing sprayer as well as working method of micro spray 3D printing device

InactiveCN104760286AReduce power consumptionQuick responseAdditive manufacturing apparatusLiquid wasteChemical composition

The invention discloses a micro spray 3D printing device capable of automatically washing a sprayer as well as a working method of the micro spray 3D printing device. The 3D printing device comprises a printing base plate, the sprayer, an ink box, a waste liquid recycling tank and a sprayer washing device, wherein the sprayer washing device comprises a washing liquid ink box, a washing pipe and a washing tank; washing liquid is contained in the washing liquid ink box; a material box and the washing liquid ink box are arranged side by side; a detachable pipeline is arranged at the lower part of the box; a gate valve is arranged in the middle of the pipeline; a tee electromagnetic valve is arranged at the lower part of the material ink box pipeline; the other two ends of the tee electromagnetic valve are connected with pipelines, one pipeline is connected with the sprayer; a gate valve is arranged in the middle of the other pipeline and the other pipeline is connected with the pipeline at the lower end of the washing liquid ink box; the washing tank and the liquid recycling tank are movably connected on the cavity wall of the printer; the printing base plate is arranged at the center of the bottom of the cavity of the printer; the number of the material ink boxes is greater than 2; the washing liquid is contained in the ink cavity of the washing ink box; the residual printing machine in the sprayer can be dissolved by the special chemical component of the washing liquid. According to the 3D printing device, the washing ink box and the material ink boxes are arranged on the printer side by side; the work status of the control system is switched through the tee valve; the washing procedure can be invoked by a printing program to complete washing operation.

Owner:NANJING NORMAL UNIVERSITY +1

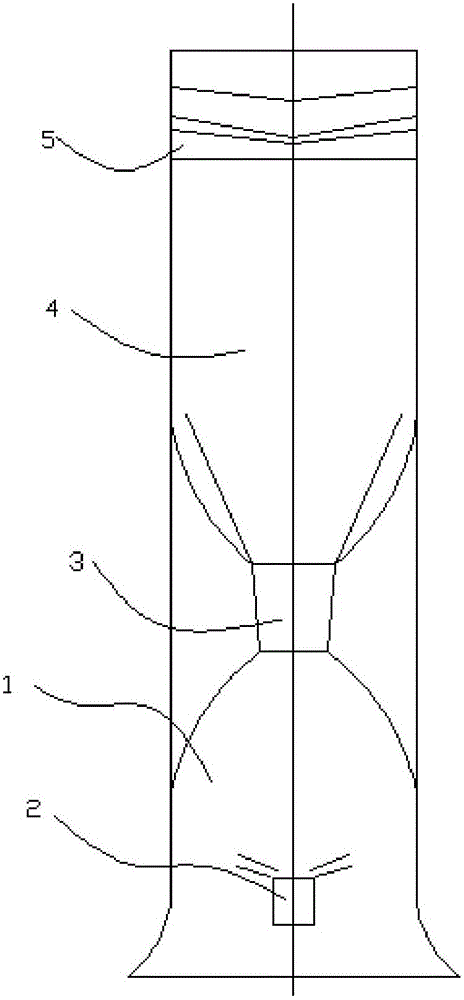

Dust-removing, mist-removing and water-saving technology for desulfurizing of wet desulfurizing tower

ActiveCN104998504AAchieve zero hydrationLow costCombination devicesAuxillary pretreatmentWater savingSpray nozzle

The invention discloses a dust-removing, mist-removing and water-saving technology for desulfurizing of a wet desulfurizing tower and relates to the field of waste gas purifying. The dust-removing, mist-removing and water-saving technology solves the problems that gypsum rain happens in wet type desulfurizing, and the cost is too high in wet type electrostatic dust removing. An impact cooling room, a coagulating room and a fine particle filtering unit are included. An upper opening of the impact cooling room is connected with a lower opening of the coagulating room through a bottleneck, and the fine particle filtering unit is fixed to the top of the coagulating room. An atomizing nozzle is further arranged in the center position, close to the lower opening, in the impact cooling room. An opening of the atomizing nozzle is upward, and the atomizing nozzle is connected with an external water supplying device through a pipeline. The dust-removing, mist-removing and water-saving technology is low in manufacturing cost, simple in installation, long in service life, free of risks of scaling and blocking, and capable of solving the problem of gypsum rain; water in separated smoke can be recovered into a desulfurizing system through a pipeline, separated out water can be used for the desulfurizing system, and zero water supplementing of the desulfurizing system can be achieved basically.

Owner:江苏新中金低碳科技股份有限公司

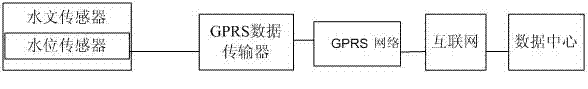

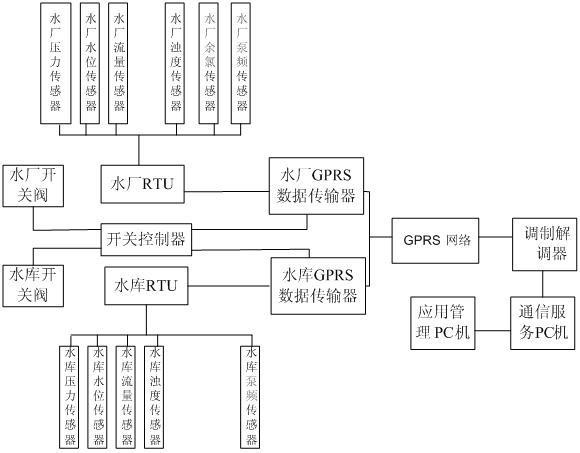

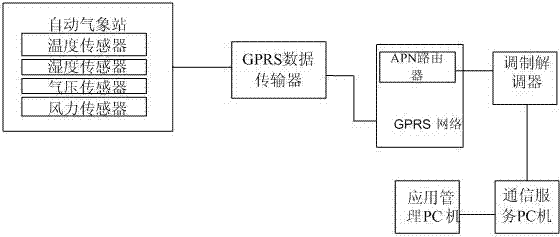

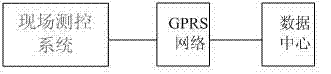

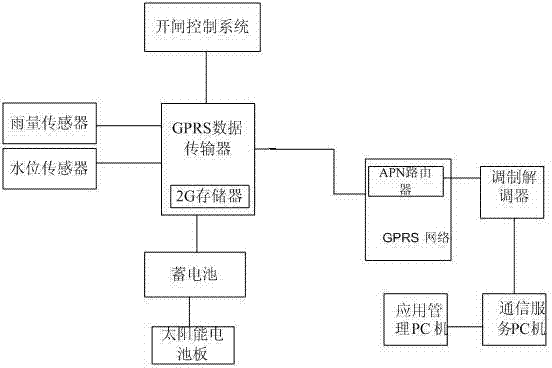

Hydrological data acquisition and transmission system of public network based on GPRS (general radio packet service) network

InactiveCN102364543AGuaranteed normal transmissionAvoid lossTransmission systemsNetwork topologiesModem deviceData center

The invention discloses a hydrological data acquisition and transmission system of a public network based on a GPRS (general radio packet service) network, which mainly comprises a hydrological sensor, a GPRS data transmission device, the GPRS network, the Internet and a data center connected sequentially. The data center comprises a modem, and the modem is connected with the Internet. The invention has the advantages that: 1, the reliability is high; 2, the real-time performance is high; 3, the collection and reading scope is wide; 4, the system construction cost is low; 5, the system operating cost is low; and 6, the system transmission capacity is high.

Owner:CHENGDU ZHONGSHAN SCI & TECH

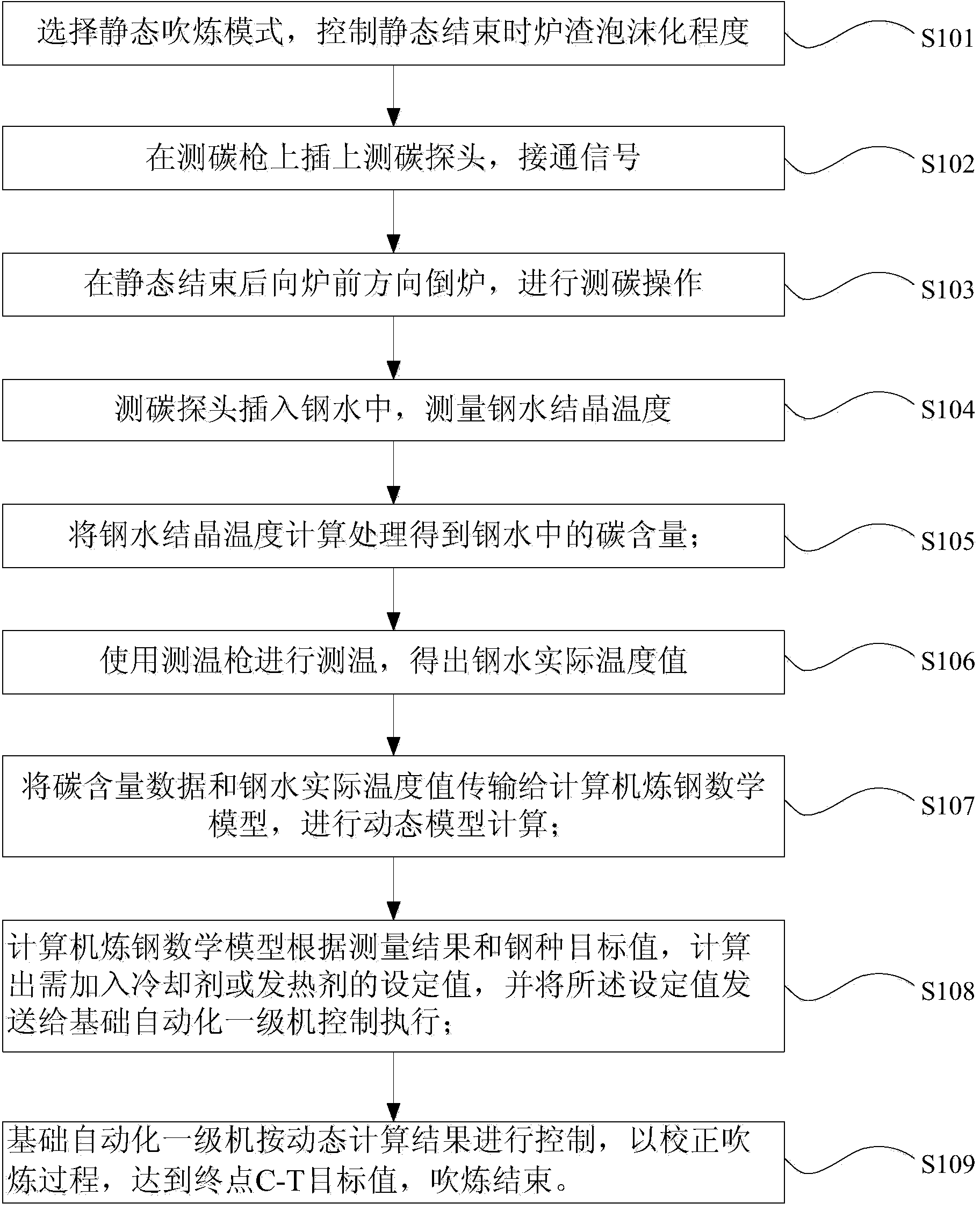

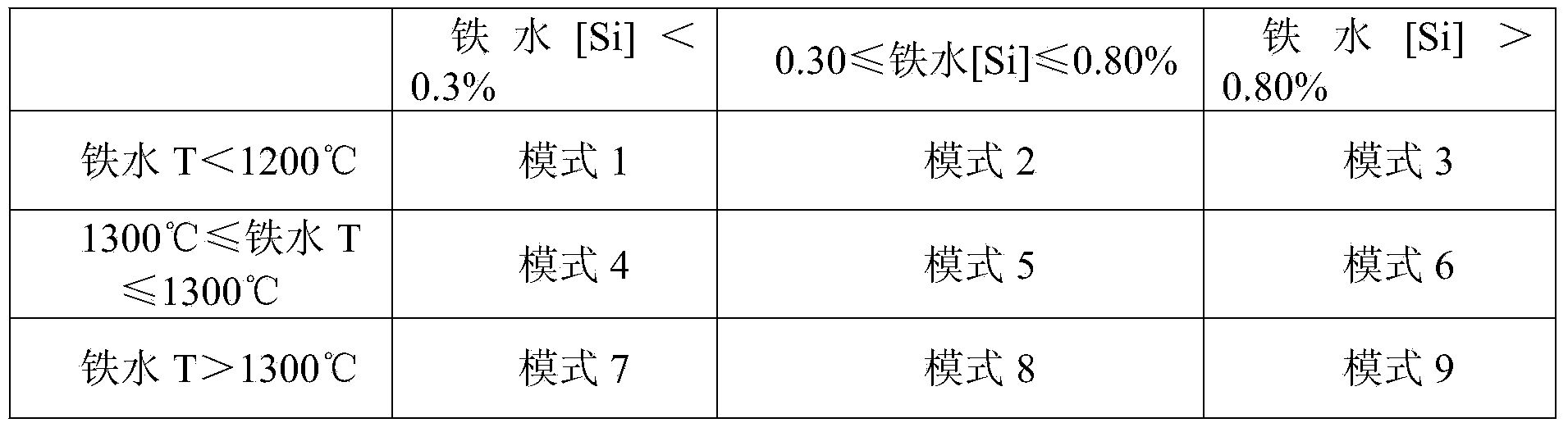

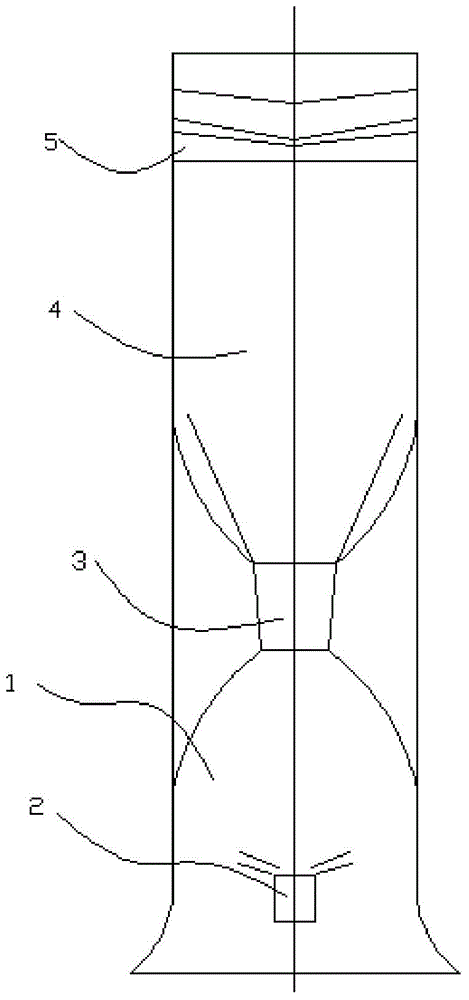

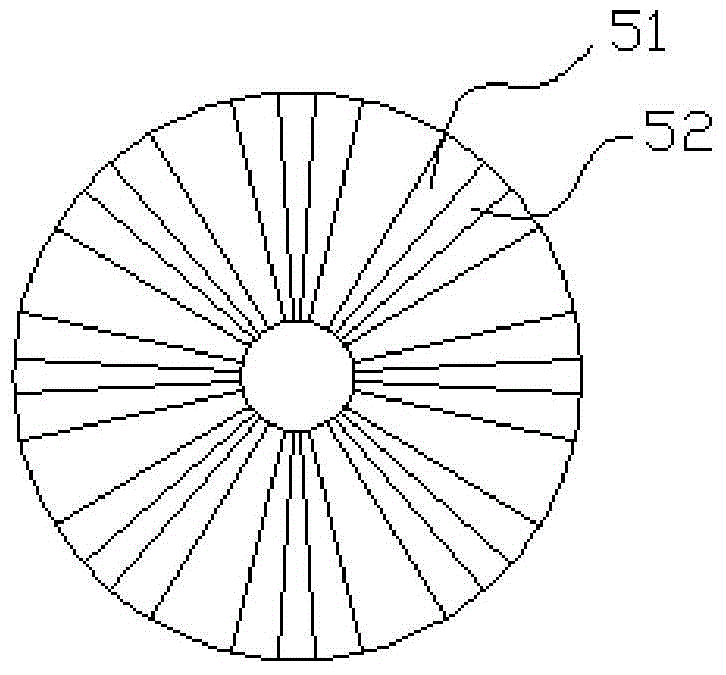

Method for starting dynamic control model of converter based on static detection of simulated sublance

InactiveCN103451353ARealize dynamic control of steelmakingImprove hit rateManufacturing convertersSteelmakingMathematical model

The invention discloses a method for starting a dynamic control model of a converter based on static detection of a simulated sublance. The method comprises the following steps: selecting a static blowing mode and controlling the foaming degree of furnace slag when static state control is finished; detecting the crystallization temperature of molten steel by using the simulated sublance; obtaining carbon content in the molten steel according to the crystallization temperature of the molten steel; detecting an actual temperature value of the molten steel by using a temperature measuring lance; transmitting carbon content data in the molten steel and the actual temperature value of the molten steel to a computer steelmaking mathematical model to carry out dynamic model calculation, calculating a setting value of a cooling agent or a heating agent needing to be added and sending the setting value to a basic automatic first-grade machine to carry out control execution; and controlling by the basic automatic first-grade machine according to a dynamic computation result to correct a blowing process and realize a finishing point C-T target value. According to the method disclosed by the invention, computer dynamic control steelmaking of the converter is realized by detecting relevant data through the simulated sublance, measuring the temperature by the temperature measuring lance and starting the dynamic control model of the converter.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Desulfurating, dust-removing, demisting and water-saving process for wet-type desulfurization tower and apparatus thereof

ActiveCN105056671AAchieve zero hydrationLow costCombination devicesAuxillary pretreatmentWater savingFlue gas

The invention discloses a desulfurating, dust-removing, demisting and water-saving process for a wet-type desulfurization tower and an apparatus thereof, relates to the field of exhaust gas purification, and aims at solving the problems of gypsum rain in a wet desulfurization process and high wet-type electrostatic dust-removing cost. The apparatus comprises an impingement cooling chamber, a coalescence chamber, and a fine particle filtering unit, wherein an upper opening of the impingement cooling chamber is connected with a lower opening of the coalescence chamber through a passage; the fine particle filtering unit is fixed on the top of the coalescence chamber; an atomizing spray nozzle is further arranged at the central position, close to the lower opening, of the coalescence chamber; and the atomizing spray nozzle is upward and is connected with external water supply equipment through a pipeline. The apparatus disclosed by the invention is low in cost, simple to mount, long in service life, and free of risk of blockage caused by scaling; the problem of gypsum rain is solved; water in separated flue gas can be recycled into to the desulfurization system through a pipeline; and the separated water can be used for the desulfurization system, so that the desulfurization system almost realizes no water supplement.

Owner:江苏新中金低碳科技股份有限公司

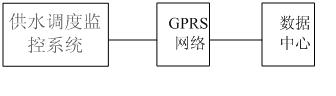

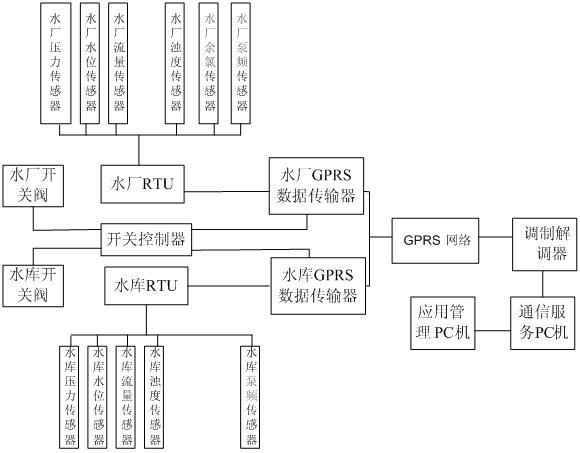

Water supply scheduling system based on GPRS network

InactiveCN102411348AExpand coverageTake advantage ofTotal factory controlProgramme total factory controlData centerMonitoring system

The invention discloses a water supply scheduling system based on a GPRS network. The water supply scheduling system is formed by a water supply scheduling monitoring system, the GPRS network and a data center, wherein the GPRS network and the data center are successively connected with the water supply scheduling monitoring system. The system has the following advantages: 1. reliability is high; 2. instantaneity is strong; 3. a collecting meter reading range is wide; 4. system construction costs are low; 5. system operation costs are low; 6. a system transmission capacity is large.

Owner:CHENGDU ZHONGSHAN SCI & TECH

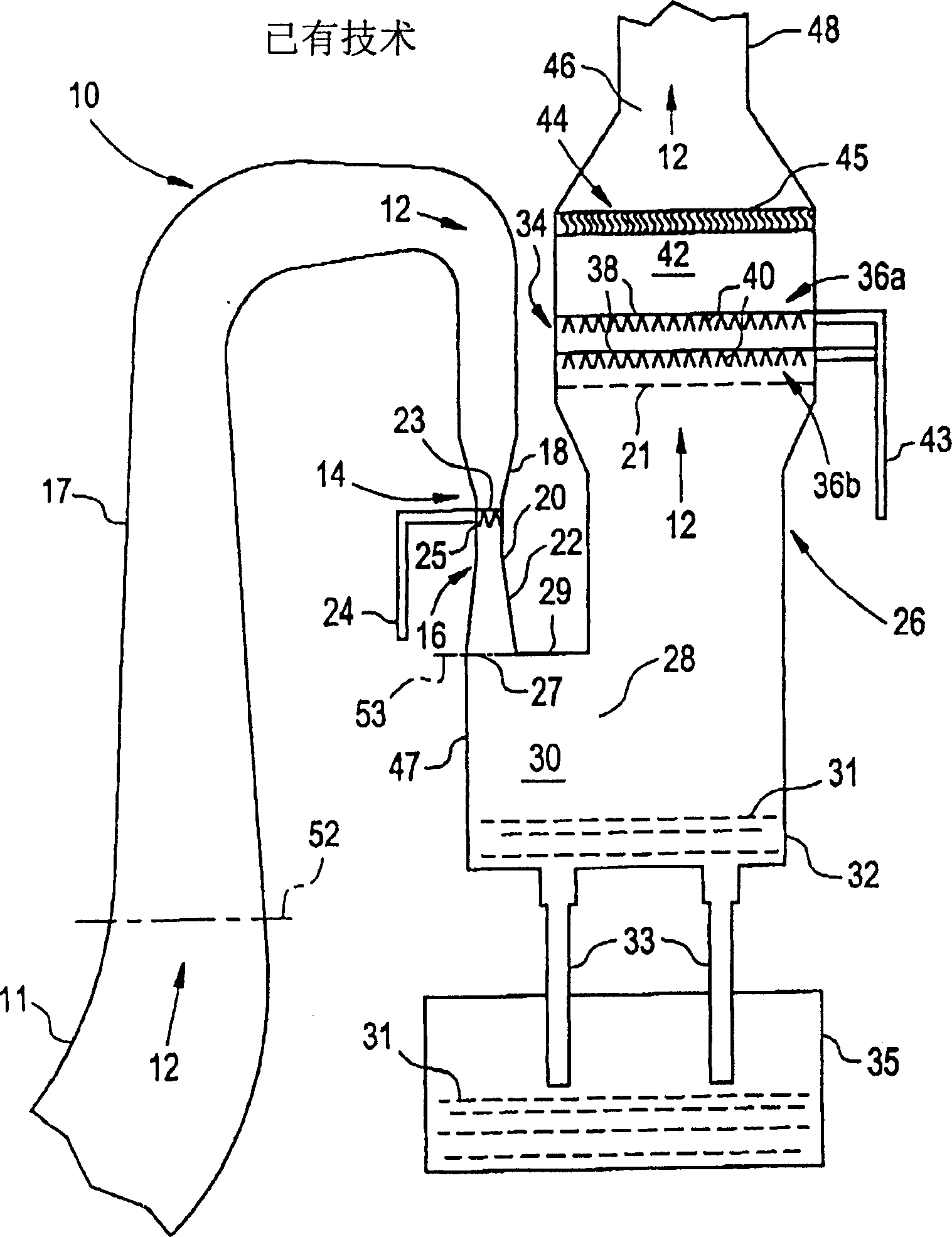

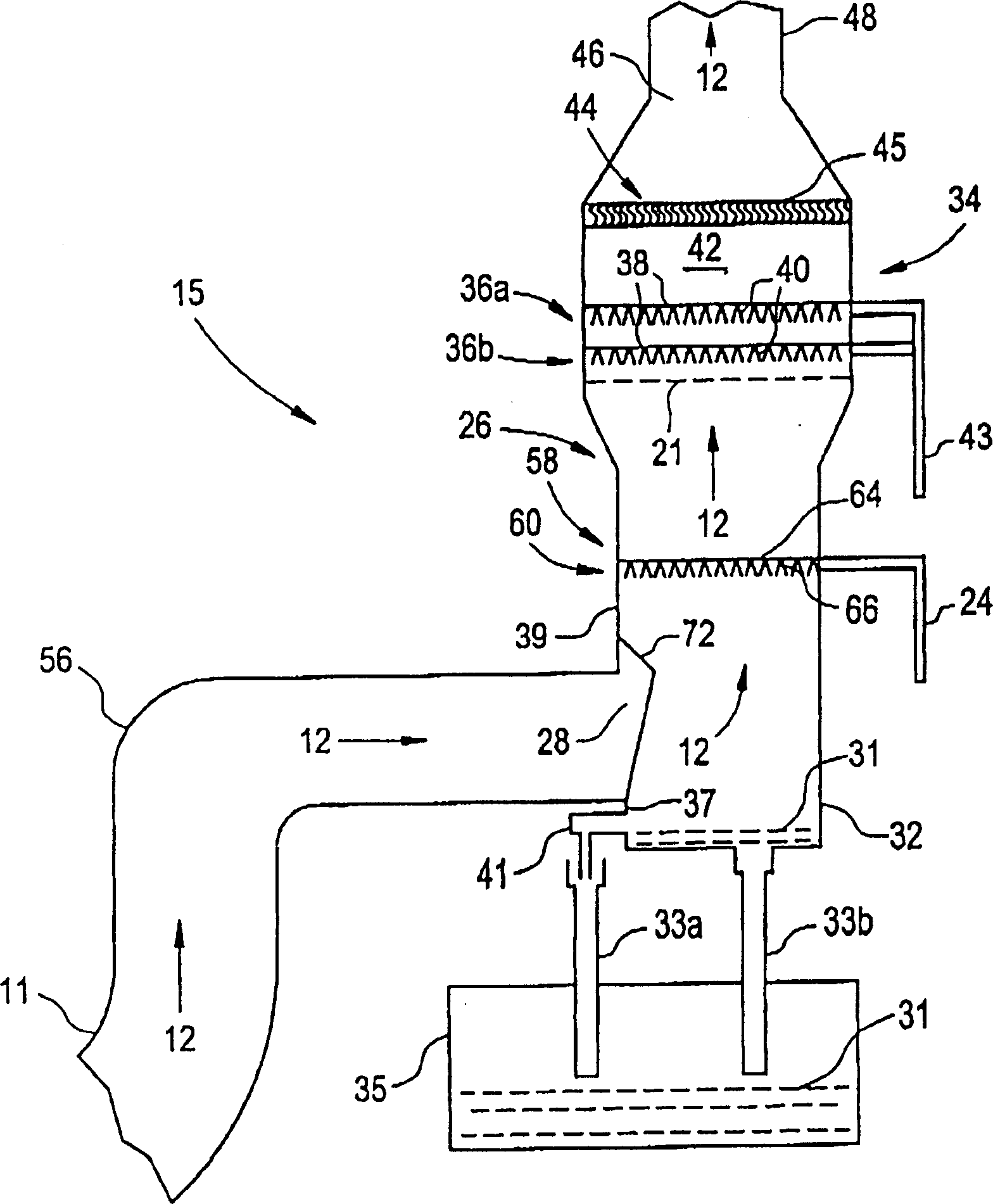

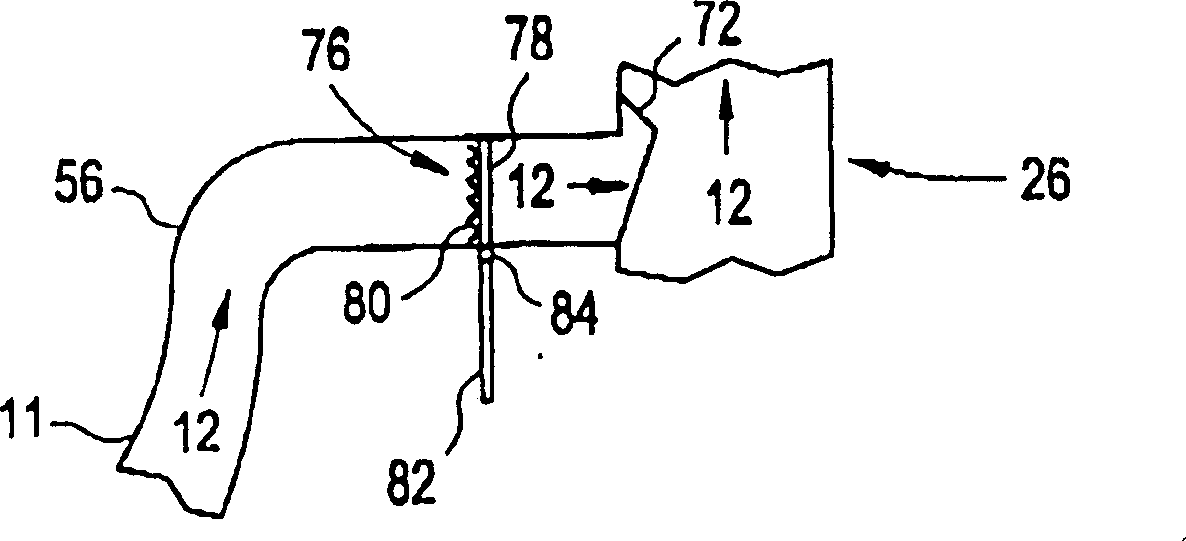

Method of transforming upflow/downflow type wet flue gas desulfur system as single circuit upflow type wet flue gas desulfur system

InactiveCN1493391AReduce the required powerLower requirementDispersed particle separationThermodynamicsFlue gas

A method of reducing the pressure drop in a downflow / upflow wet flue gas desulfurization (WFGD) system and of improving overall sulfur dioxide collection efficiency by converting the downflow / upflow WFGD system to an upflow single-loop WFGD system. The method includes the replacing of the downflow quencher and related duct work with a bypass for connecting the incoming flue gas duct with the upflow absorber, and the adding of a quenching zone in the absorber comprised of spray headers.

Owner:THE BABCOCK & WILCOX CO

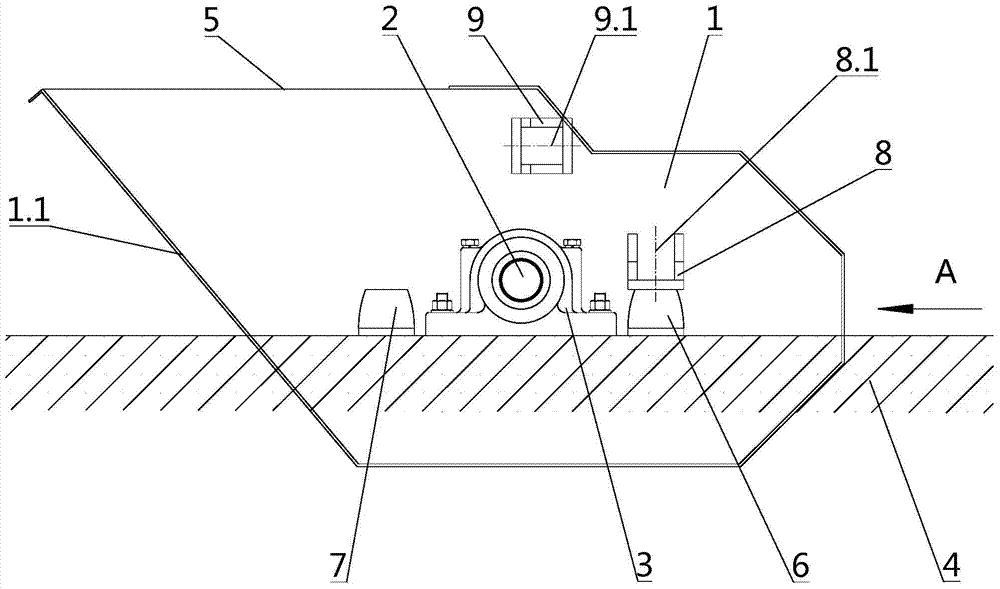

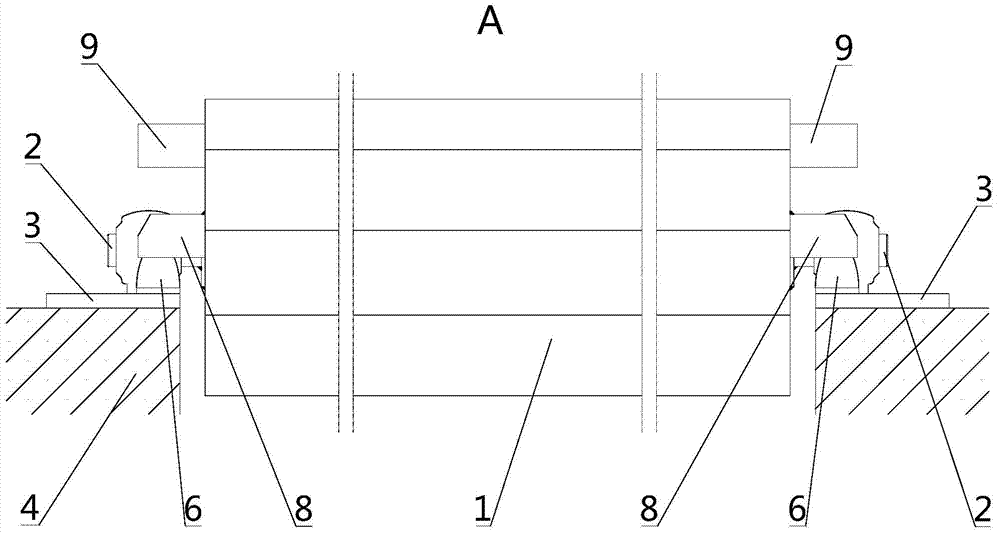

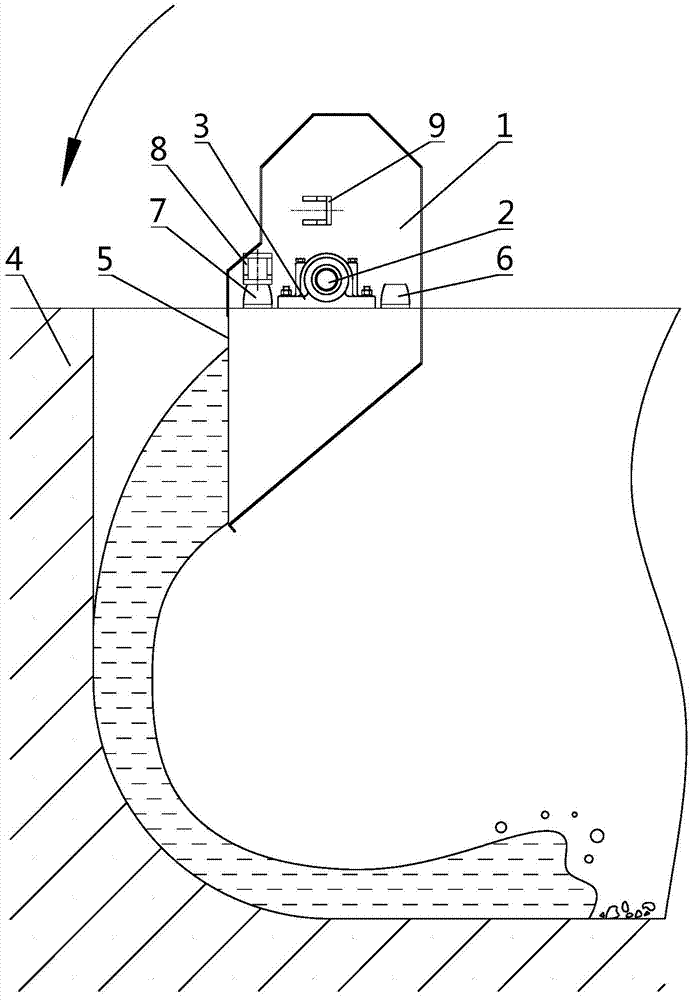

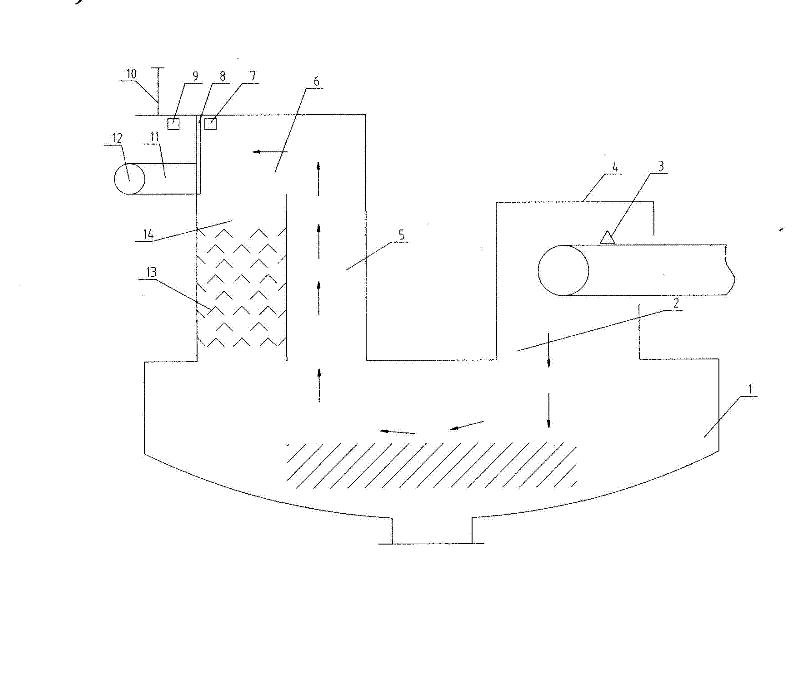

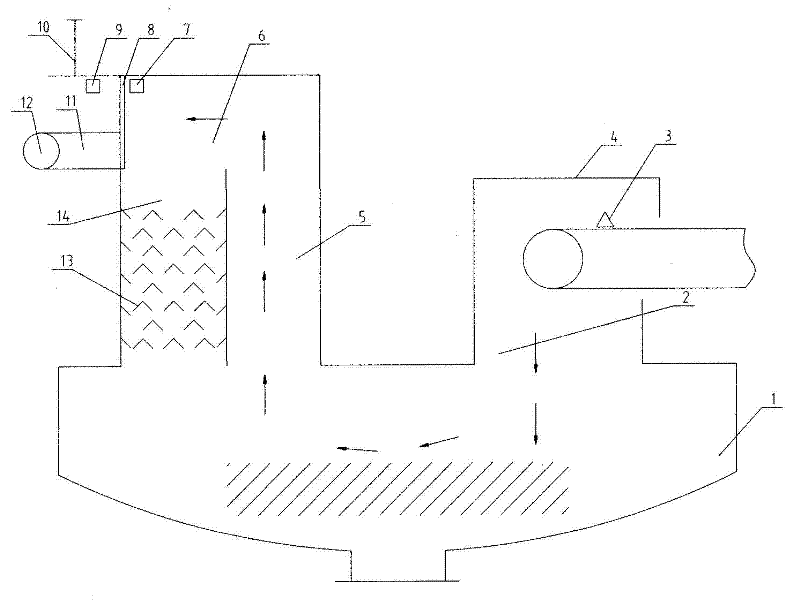

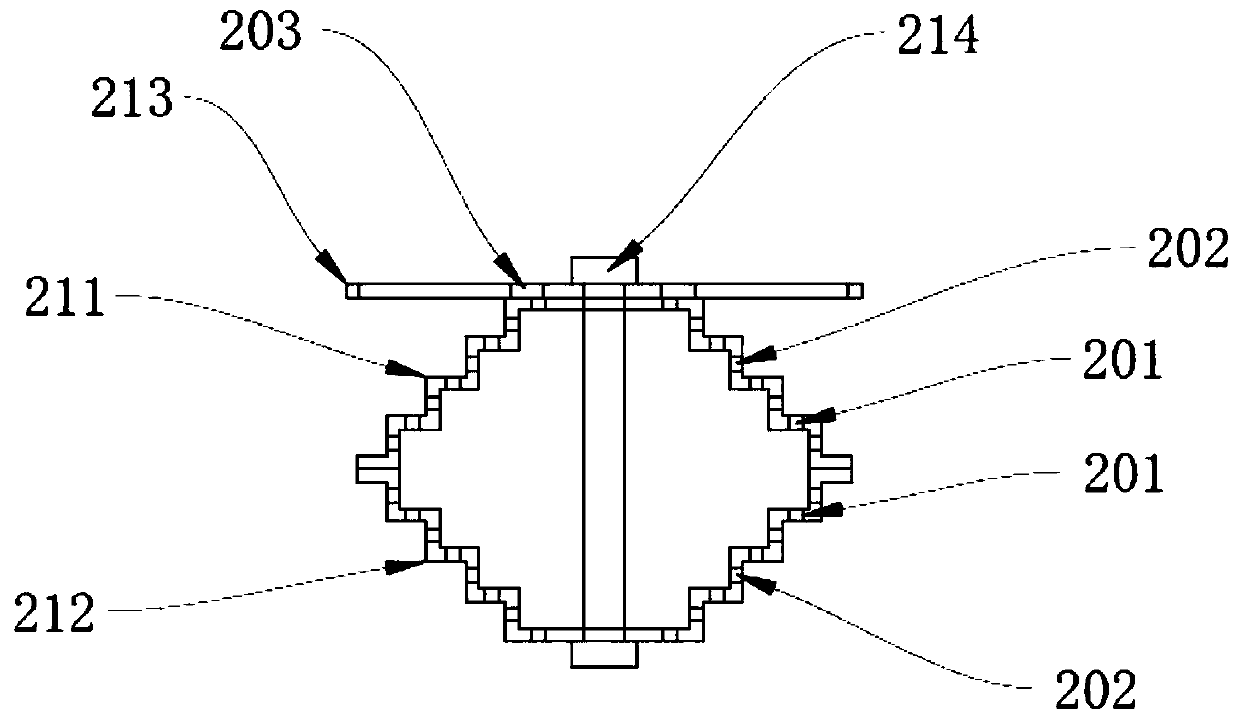

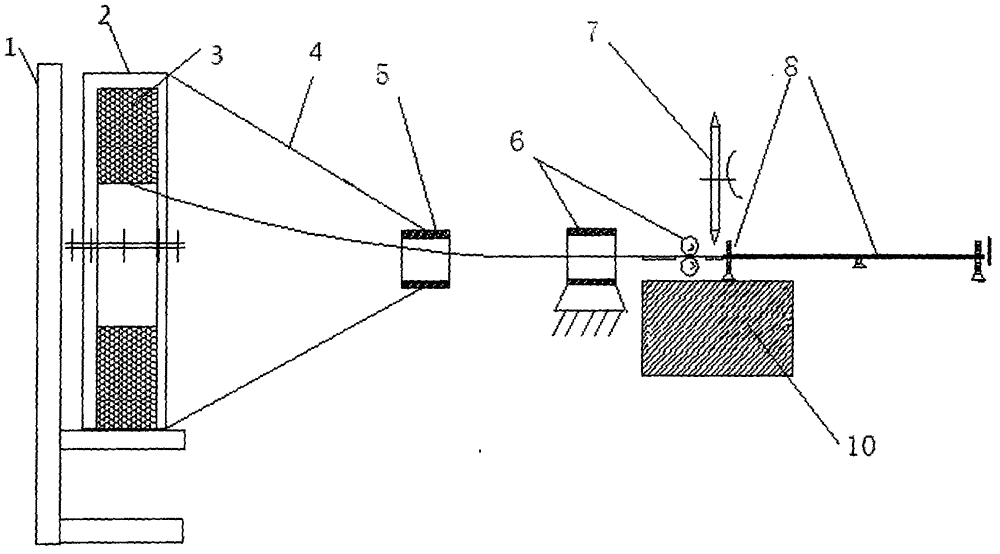

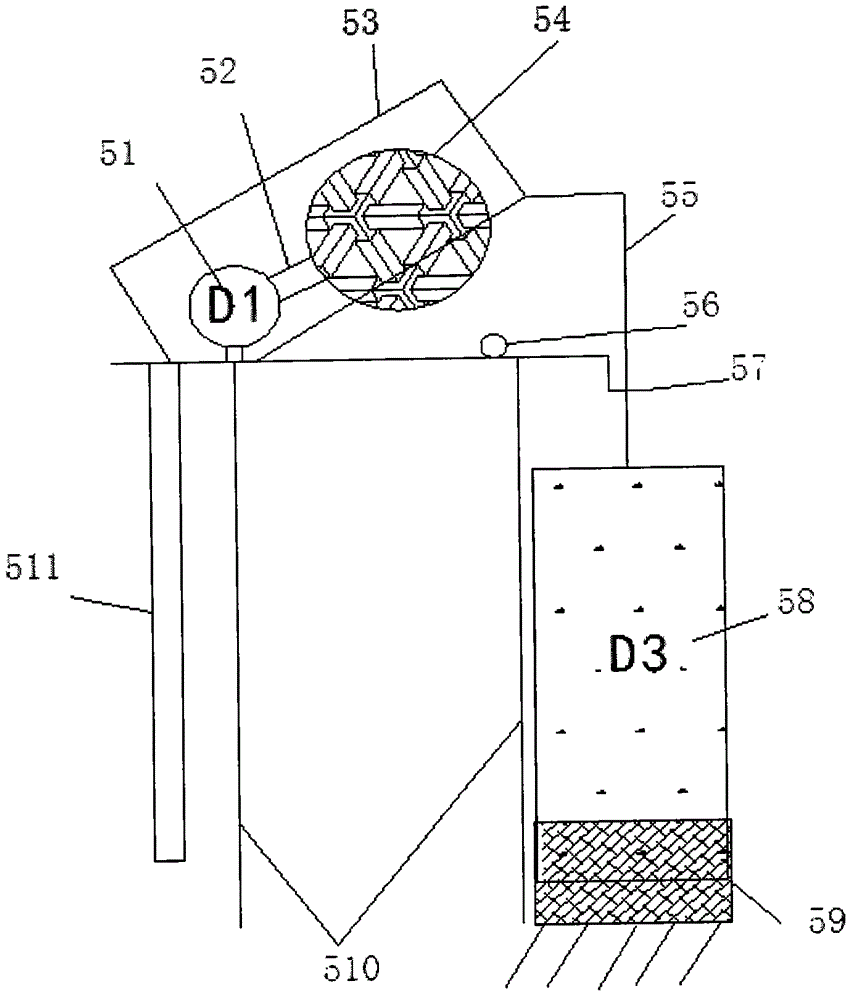

Waterpower flushing skip bucket of rainwater regulation and storage pond

ActiveCN104120781ANo maintenance feeNo maintenance costsSewerage structuresGravity centerEngineering

The invention discloses a waterpower flushing skip bucket of a rainwater regulation and storage pond. The skip bucket comprises a skip bucket body and is characterized in that a rotary shaft is arranged on the side wall of the skip bucket body, and the rotary shaft is installed on the top face of the rainwater regulation and storage pond through an installing base; an opening is formed in the top face of the skip bucket body; the center of gravity of the opening and the center of gravity of the skip bucket body are located on the two sides of the rotary shaft; with the rotary shaft as a boundary, the volume of the side, provided with the opening, of the skip bucket body is larger than the volume of the other side of the skip bucket body; a no-load limiting device and a tip-over limiting device are further arranged on the top face of the rainwater regulation and storage pond and located on the two sides of the rotary shaft; a no-load limiting block matched with the no-load limiting device and a tip-over limiting block matched with the tip-over limiting device are arranged on the side wall of the skip bucket body. According to the waterpower flushing skip bucket of the rainwater regulation and storage pond, due to changes of the center of gravity of the skip bucket which has no loads and is full of loads, the skip bucket automatically tips over and returns, no extra power is needed, only a small-power water pump for injecting water into the skip bucket is needed, and low carbon and environmental protection are achieved; almost no noise exists when the skip bucket tips over to pour out water. The waterpower flushing skip bucket of the rainwater regulation and storage pond is high in running stability, free of running and maintaining cost, economical and durable.

Owner:WUHAN SHENGYU DRAINING SYST

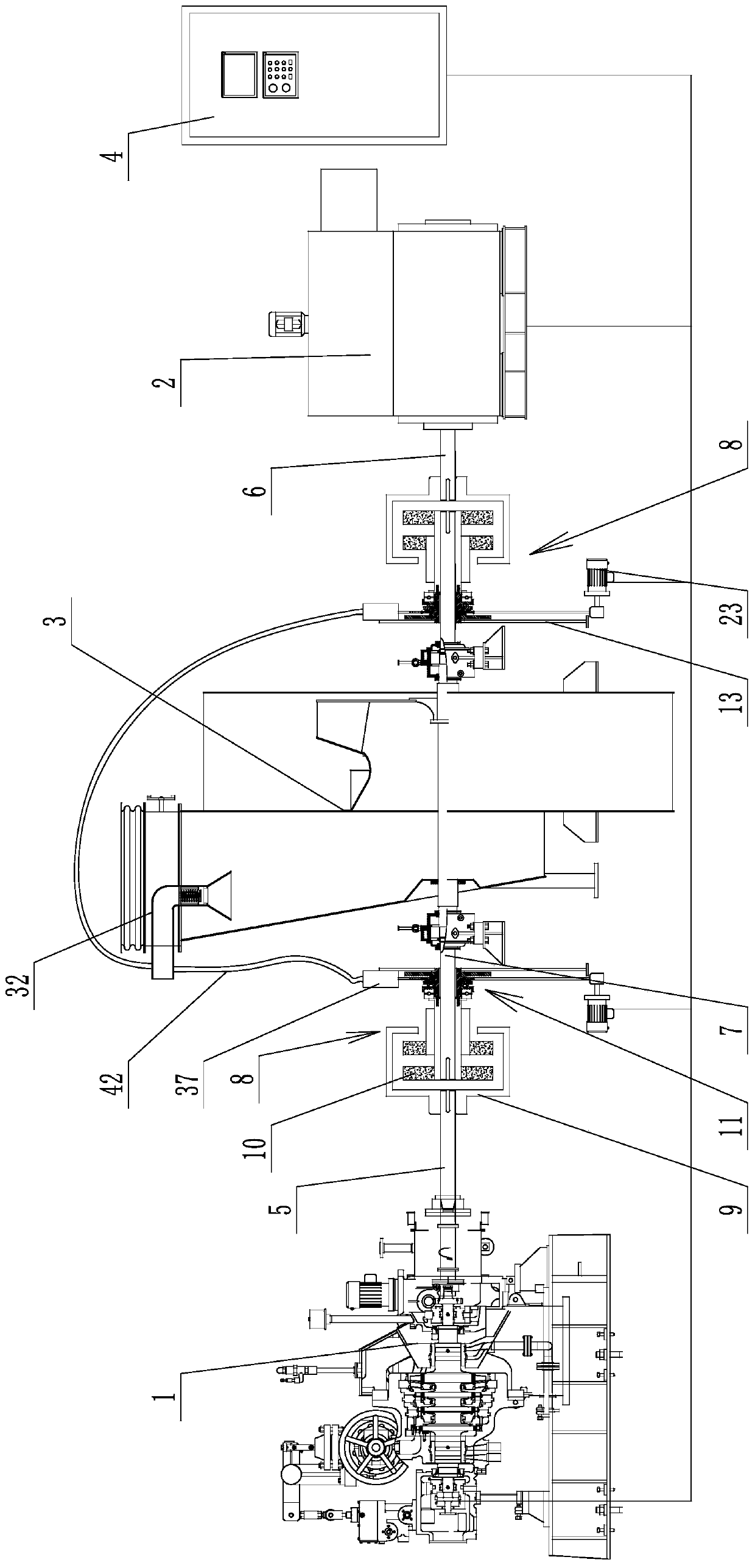

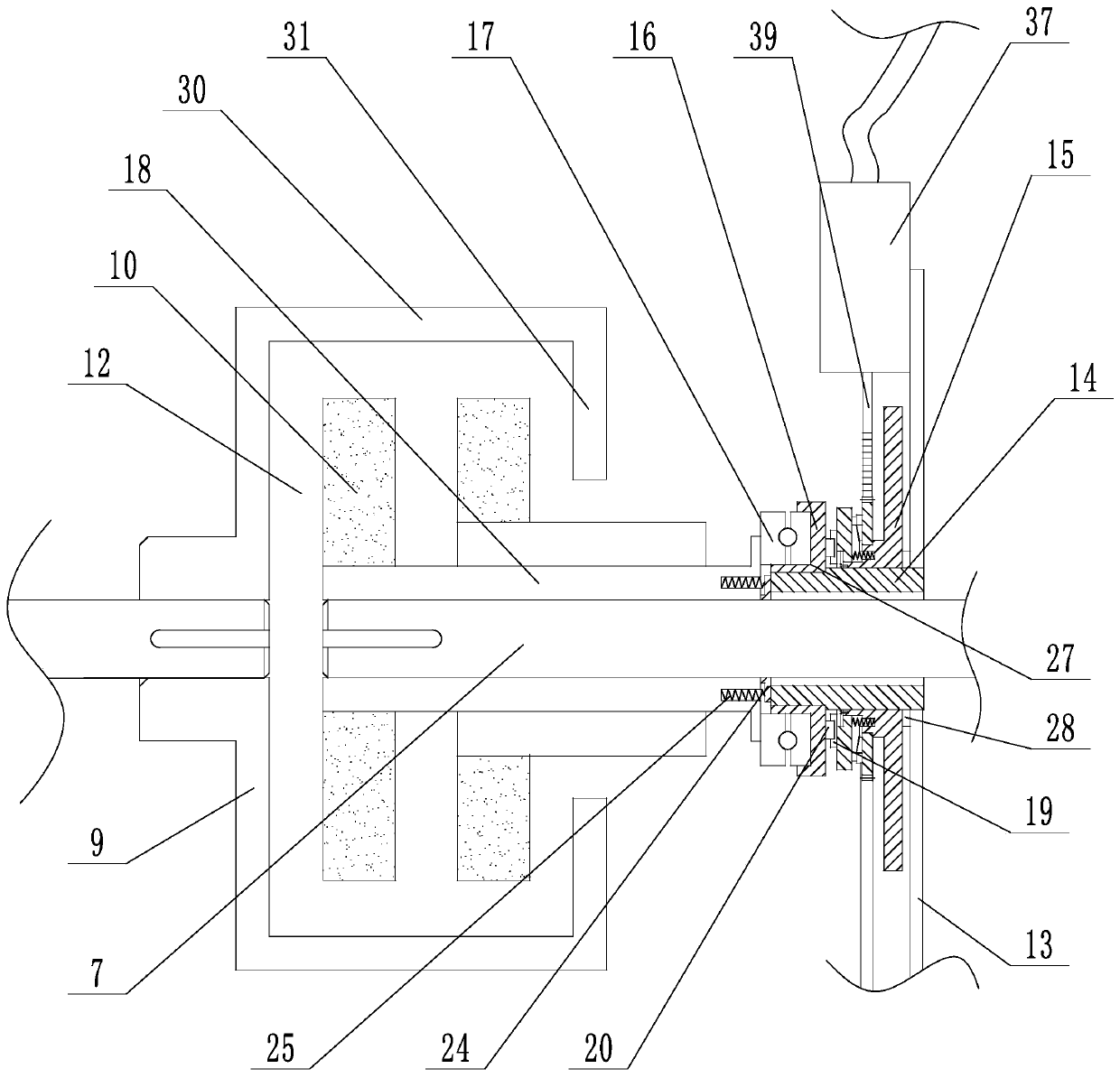

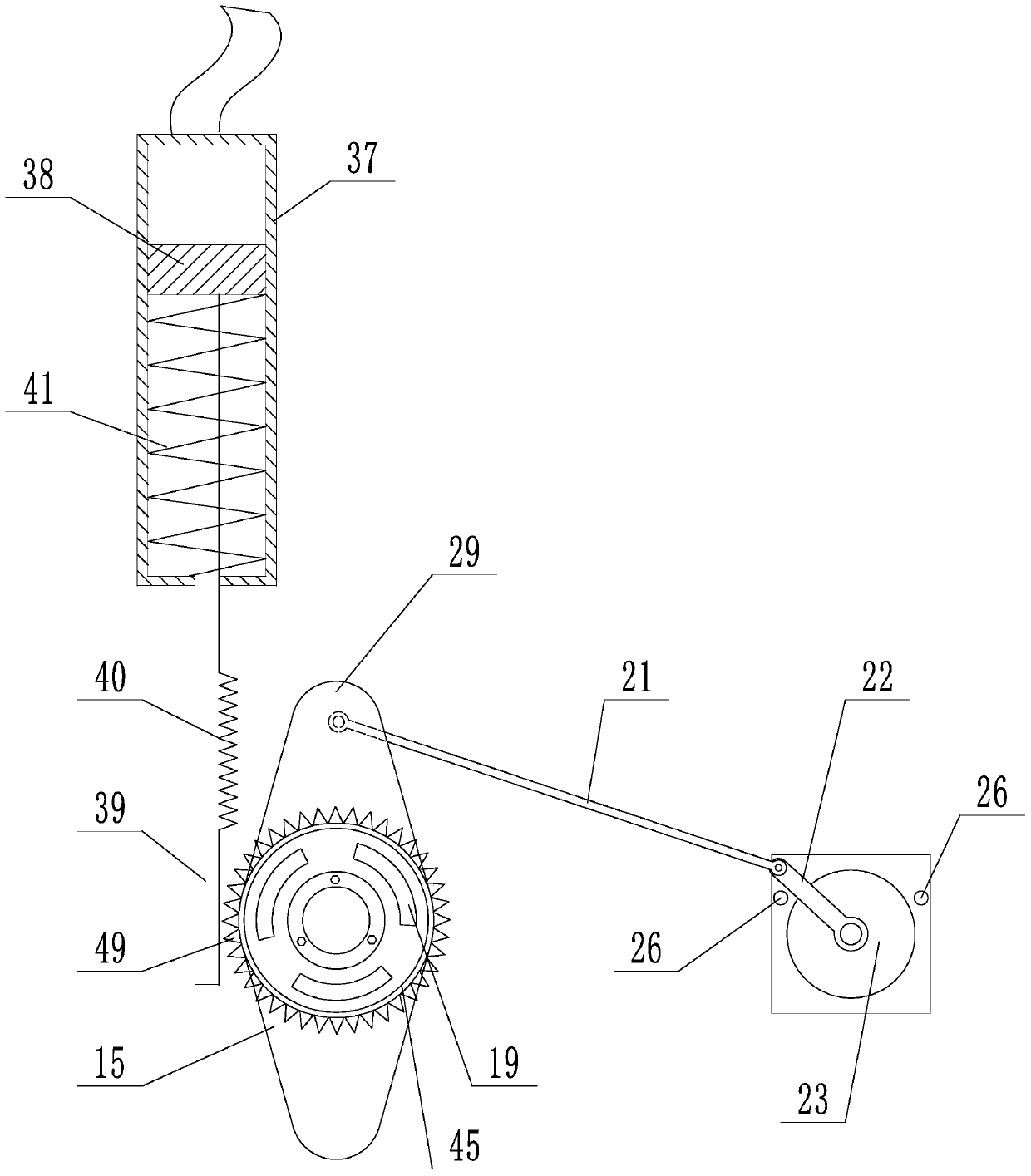

Steam and power dual-power-drive fan structure capable of achieving automatic switching

ActiveCN110145477ASimple structureMeet normal operation requirementsPump componentsMechanical energy handlingElectrical conductorCoupling

The invention discloses a steam and power dual-power-drive fan structure capable of achieving automatic switching. The problems that a fan drive structure is complex, single gas source drive or motordrive is adopted, at most of time, normal running needs cannot be met, and normal production is affected are solved. Two permanent magnet couplings are selected according to the actual industry and mining, when the permanent magnet couplings work, a controller controls an executor motor to work, an output shaft of the executor motor rotates and drives a pushing disc to rotate through a swing rod and a connecting rod, a pushing convex strip slides over a convex block from thin to thick, a sliding sleeve and a shaft sleeve are pushed to move in the direction away from the pushing disc, a permanent magnet disc gets close to a conductor disc, the air gap between the conductor disc and the permanent magnet disc is reduced, a steam turbine output shaft or electric motor output shaft can drive afan rotating shaft to rotate, the controller controls the rotation angle of the output shaft of the executor motor to achieve output torque adjusting between 0 and 100%, and engaging and disengaging between a steam turbine and a fan and between an electric motor and the fan can be achieved.

Owner:杭州科晟能源技术有限公司

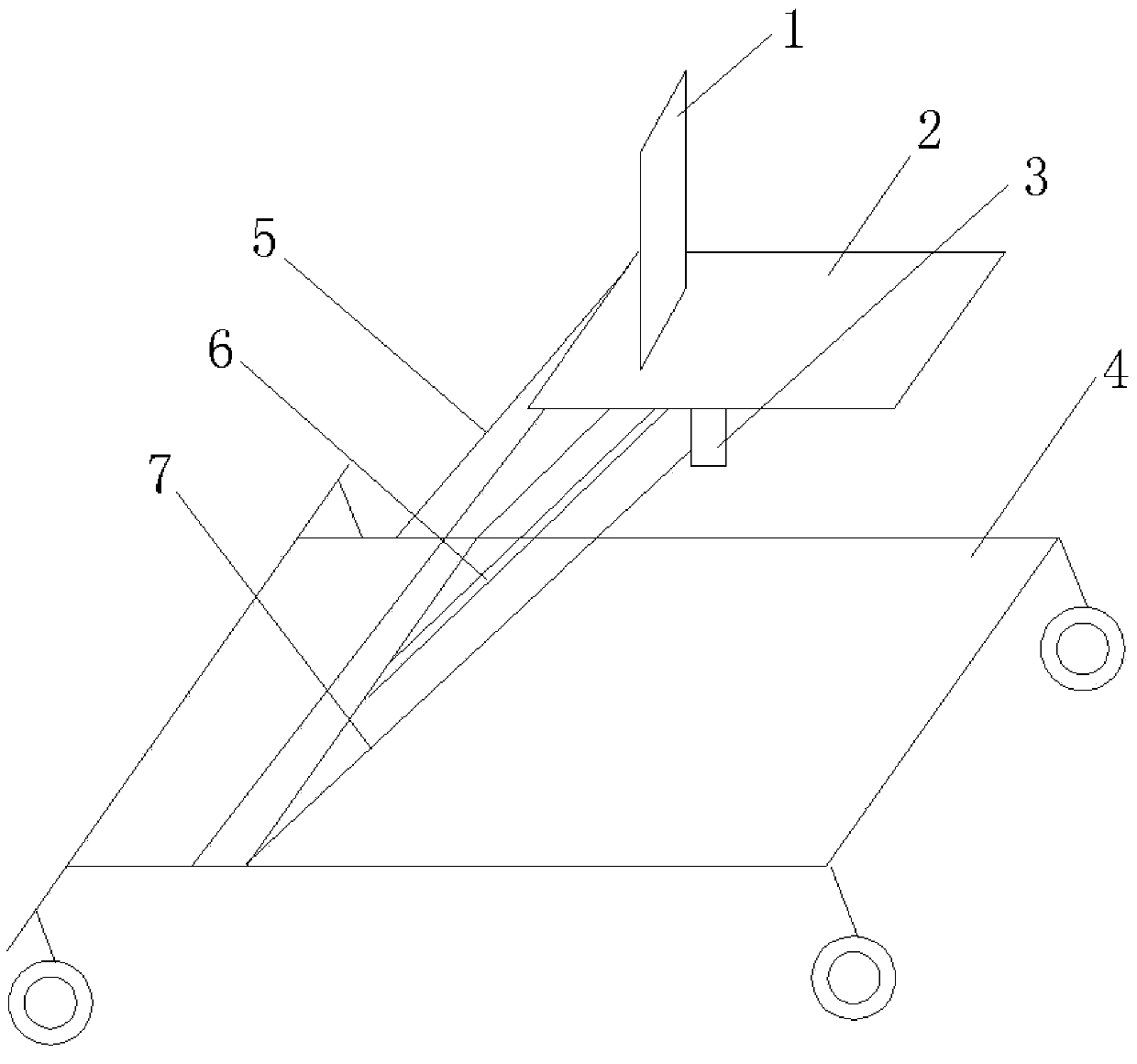

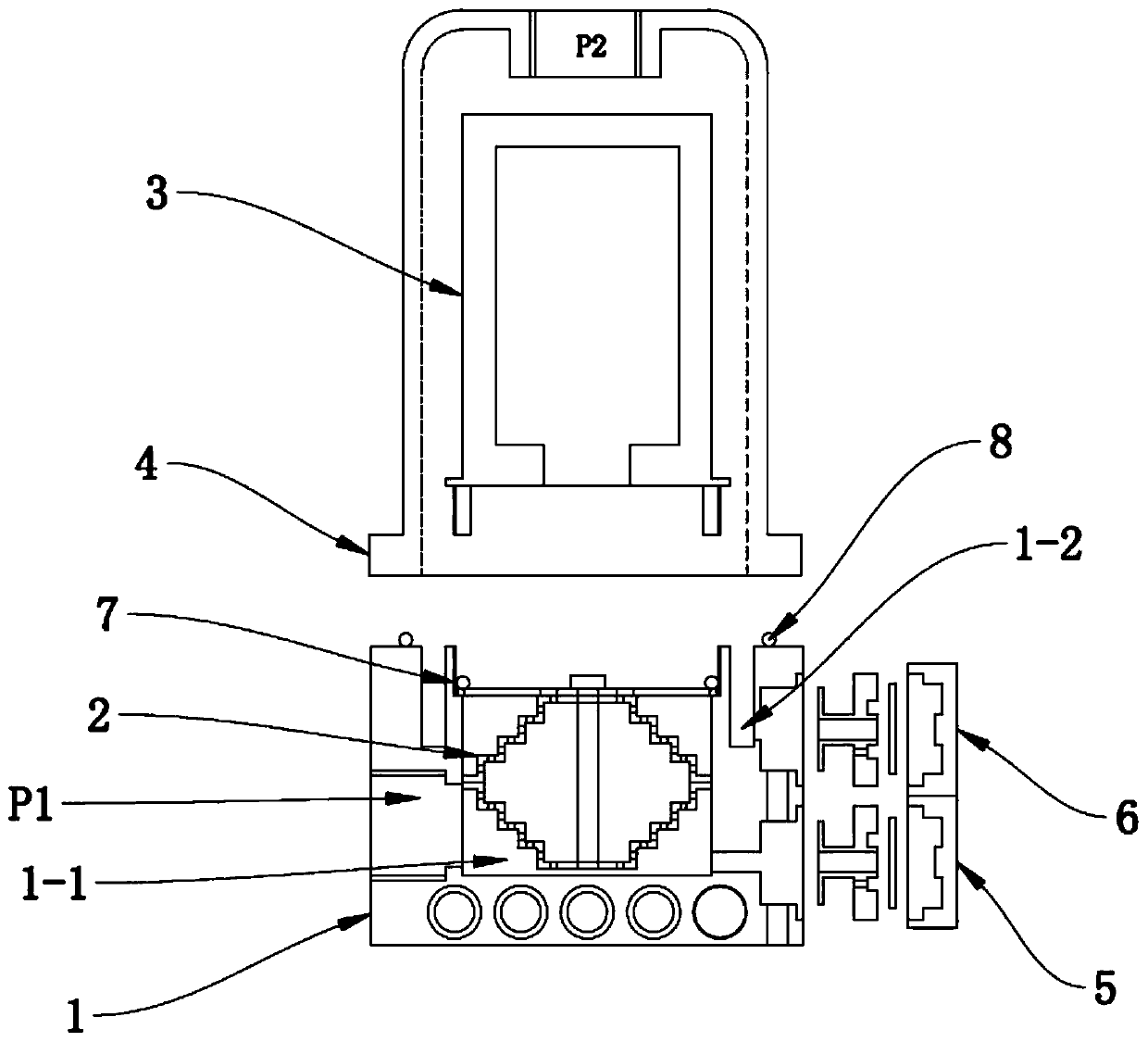

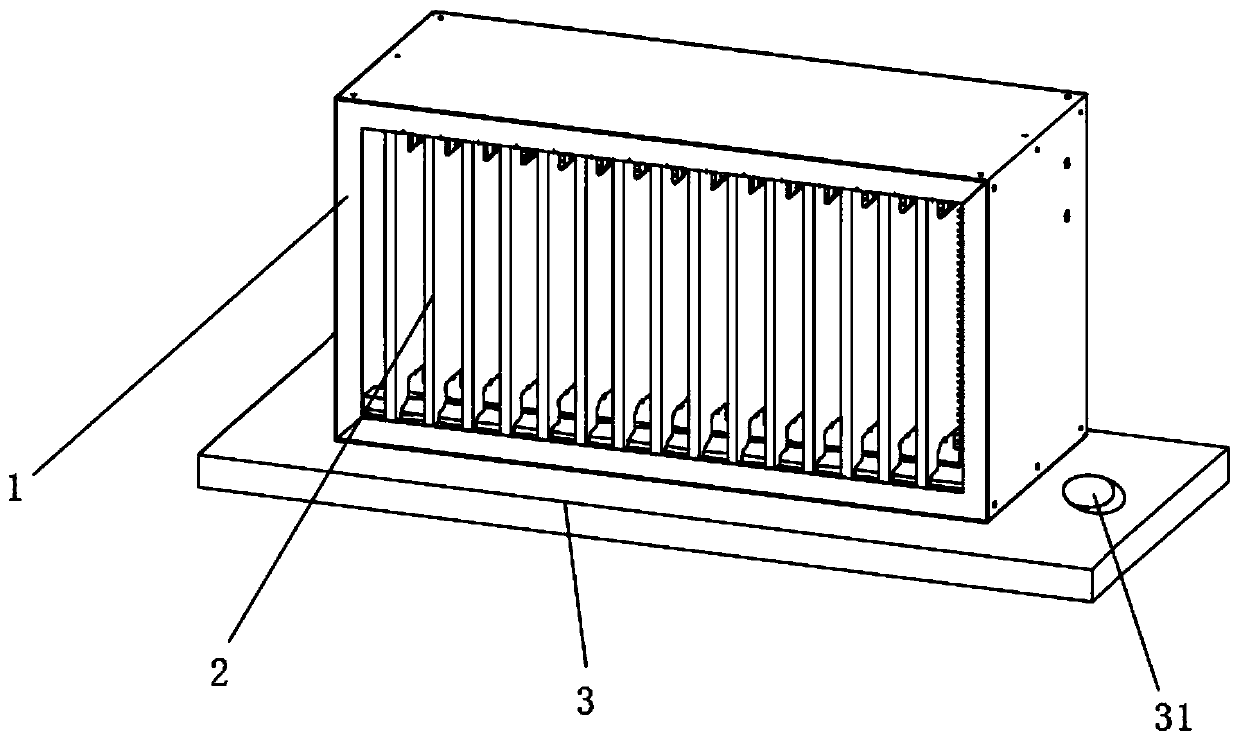

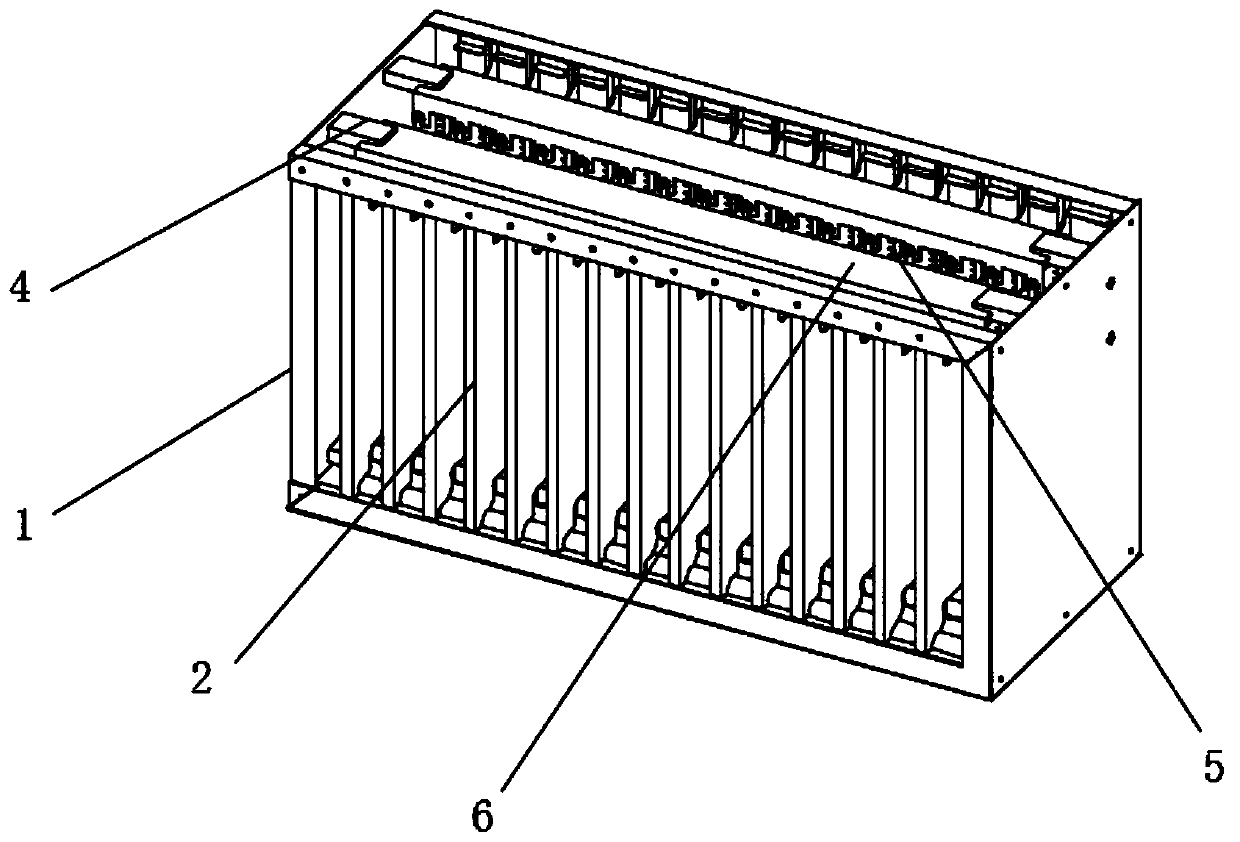

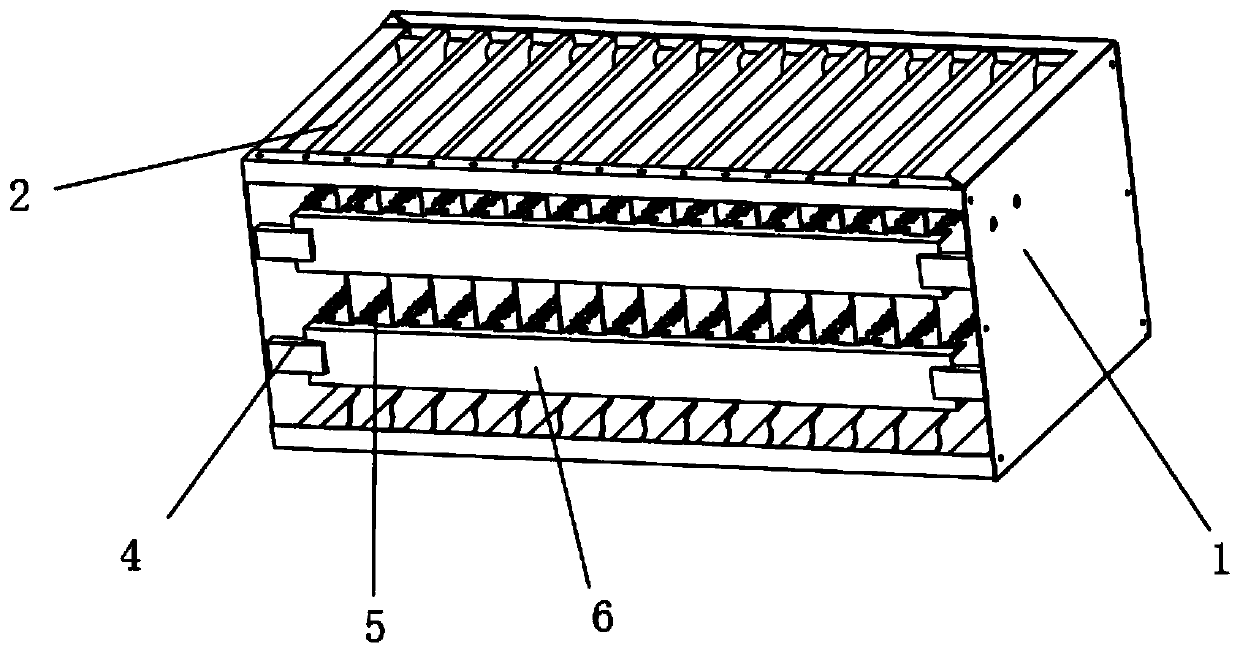

Hydraulic push-in replacing device for current transformer

The invention relates to a hydraulic push-in replacing device for a current transformer. The hydraulic push-in replacing device for the current transformer is characterized by comprising a base (4). The base (4) is fixedly provided with a hydraulic jack (6); both sides of the hydraulic jack (6) are respectively provided with a support pillar (7); the bottom part of each support pillar (7) is hinged to the base (4). The hydraulic push-in replacing device for the current transformer also comprises a support platform. The lower bottom face of the support platform is fixedly provided with a connecting yoke (3); the connecting yoke (3) and the head part of a piston rod of the hydraulic jack (6) are hinged together, and meanwhile, the connecting yoke (3) and top parts of the two support pillars (7) are also hinged together. After the replacing device provided by the invention is adopted, manual operation is replaced. The replacing device is stable in movement, convenient to use, low in cost and basically free of maintenance cost in the later period. Workers can be reduced to 2 persons, so that the replacing time of the current transformer is greatly shortened, the working performance is improved, and the power supply reliability is ensured.

Owner:STATE GRID CORP OF CHINA +1

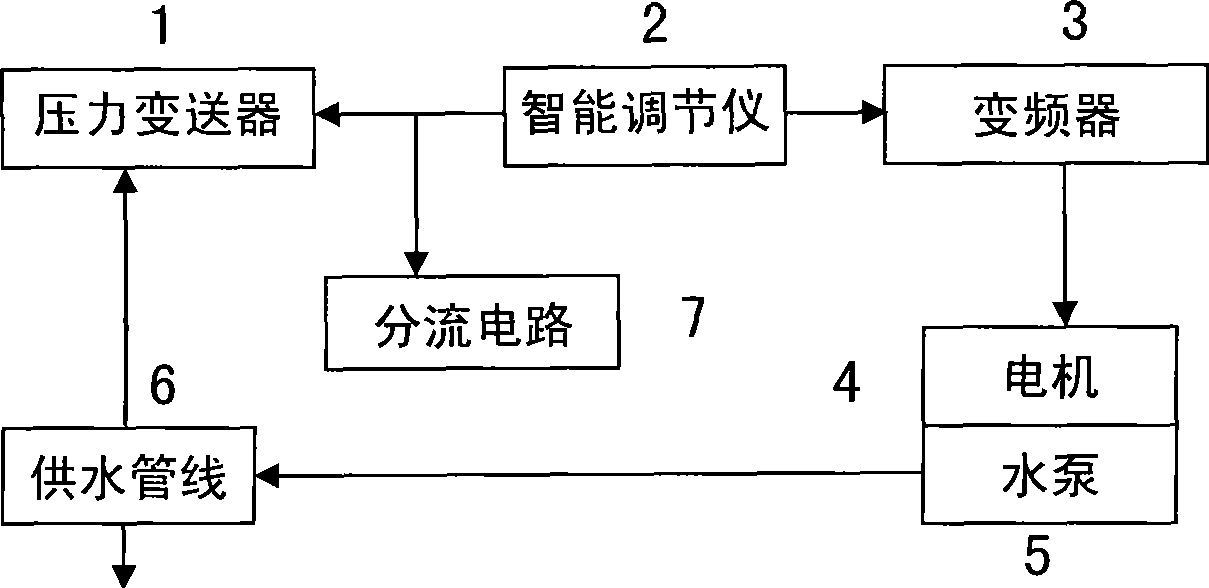

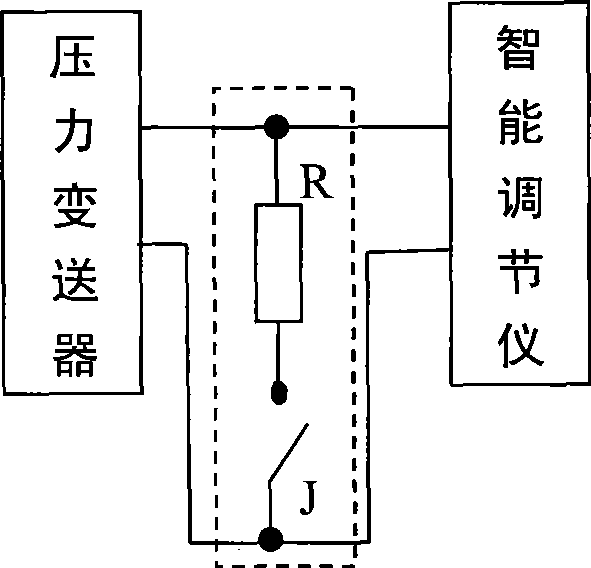

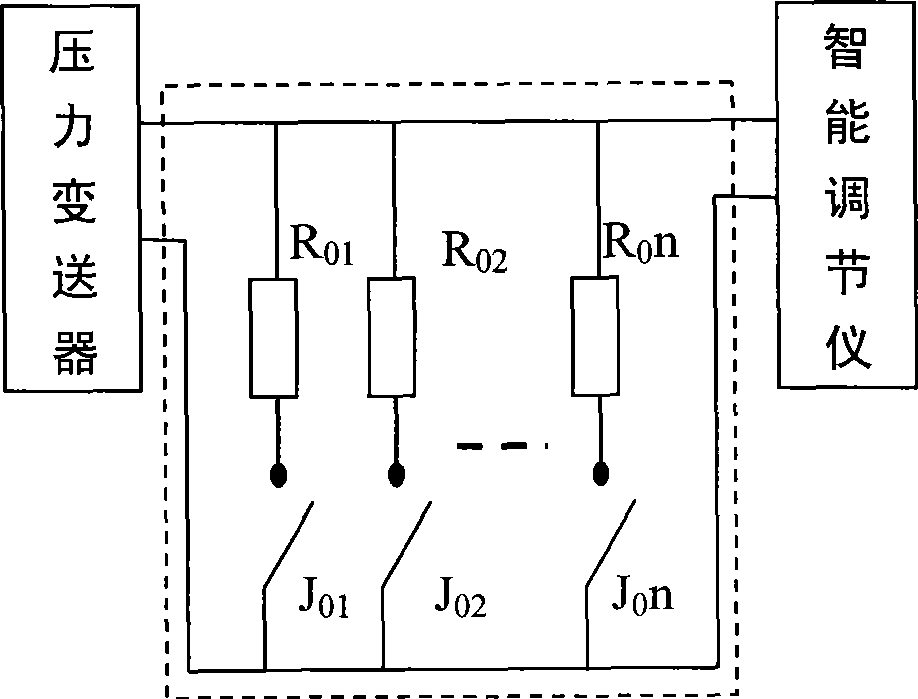

Frequency conversion voltage transformation water supply installation according to period of time

InactiveCN101392546ASimple structureLittle cost increaseFluid pressure control using electric meansService pipe systemsElectrical resistance and conductanceFrequency conversion

The invention provides a time-sharing variable-frequency variable-pressure water supply device, which is a closed loop system. The device comprises a pressure transmitter, an intelligent regulator, a frequency converter, a mating motor, a water pump and a water supply pipeline, wherein at least one current division circuit is in parallel connection with a connecting line of the pressure transmitter and the intelligent regulator; each current division circuit consists of a resistor and a pair of output contacts of a programmable time controller, which are in series connection, or consists of a triode in parallel connection with the connecting line of the pressure transmitter and the intelligent regulator, as well as a base voltage control circuit; a base of the triode is connected with the voltage output end of the base voltage control circuit; and the base voltage control circuit consists of a pair of contacts of the programmable time controller and a voltage division circuit which are in series connection. The current division circuit in parallel is automatically turned on or off through the programmable time controller according to preset time, so as to realize the variable-frequency variable-pressure water supply with different water supply pressures in different periods. The device can lower the water supply pressure in a low water peak period by more than 10 percent, and saves about 5 percent of energy throughout one day.

Owner:中国石化集团河南石油勘探局水电厂

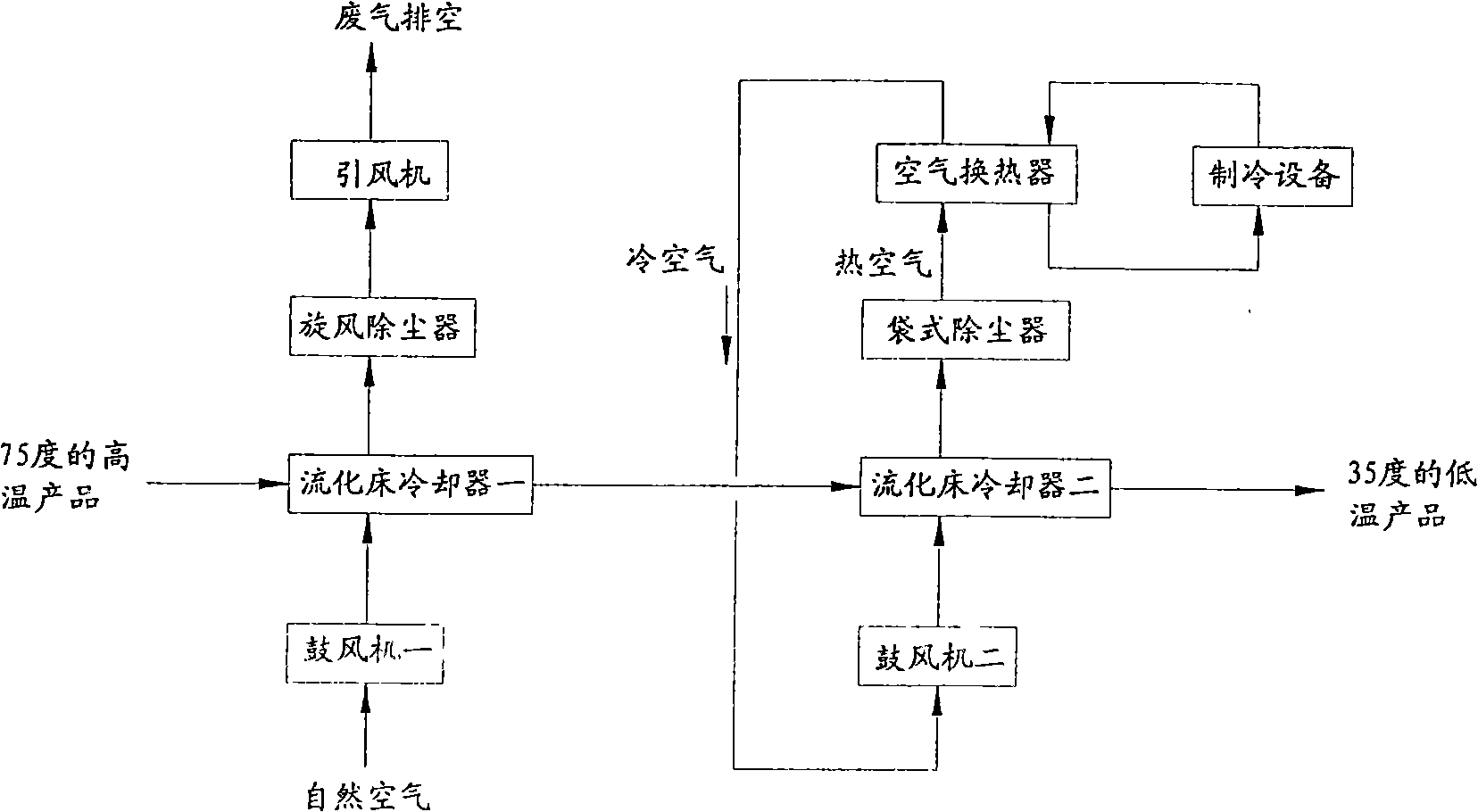

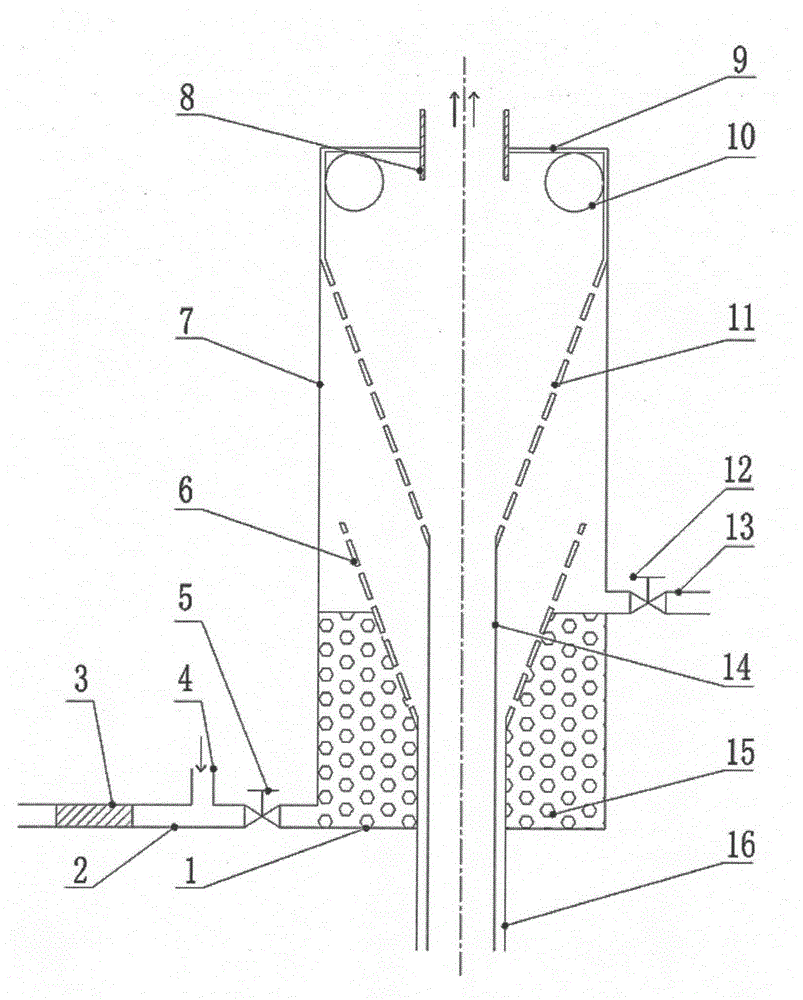

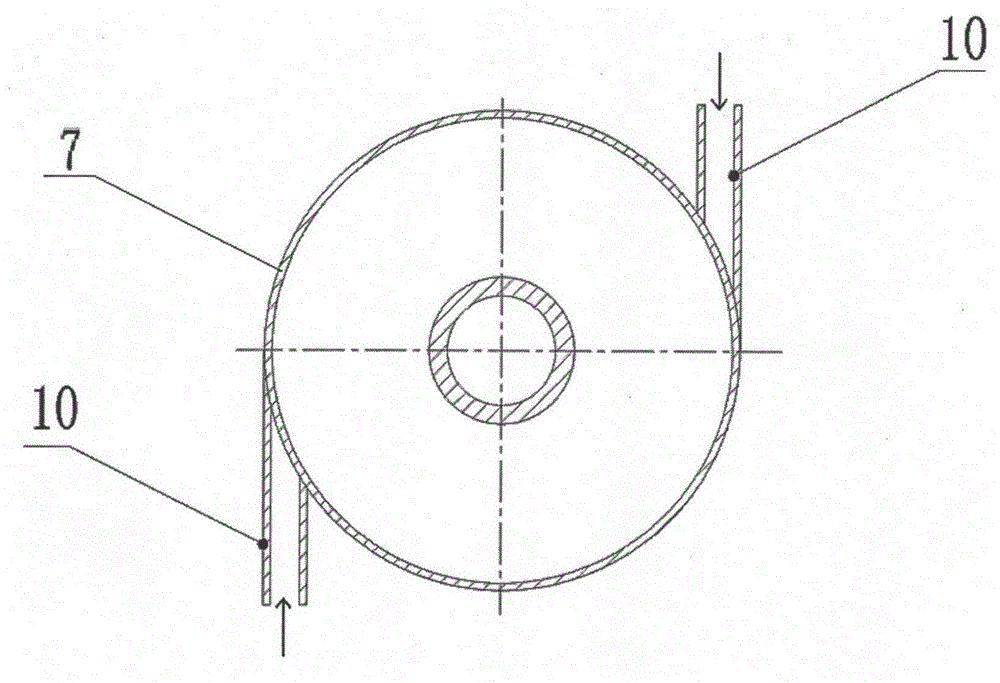

Cooling method for compound fertilizer

ActiveCN101302125ASolve many problems caused by high temperatureImprove heat transfer efficiencyFertilizer mixturesHigh energyFluidized bed

The invention provides a method for cooling a compound fertilizer to solve the problems of the prior compound fertilizer cooling method of large occupied area of the used device, high energy consumption and low cooling efficiency. The high-temperature compound fertilizer product is sent to a first fluidized bed cooler by a conveyor; high-pressure normal temperature air is blown by a first fan so that the high-temperature compound fertilizer product is boiled on the first fluidized bed; and the heat exchange of the high-temperature compound fertilizer product with the normal temperature air is realized on the first fluidized bed sufficiently.

Owner:成都云图控股股份有限公司

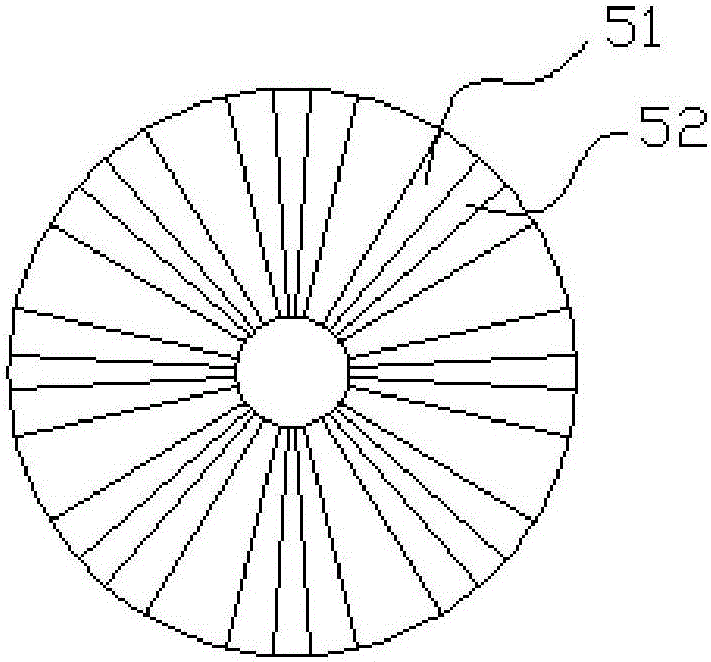

Rainwater collection and reuse integrated device

InactiveCN104480995AMeet the needs of water purificationWith rainwater harvestingGeneral water supply conservationTreatment involving filtrationFiltrationWater quality

The invention discloses a rainwater collection and reuse integrated device. The device is characterized by comprising a columnar shell. An upper cover plate is arranged on the top of the columnar shell, a lower bottom plate is arranged at the bottom of the columnar shell, at least one feeding inlet is formed in the top of the columnar shell, a first filter screen is arranged in the upper portion of the columnar shell, a first filtering area is formed between the first filter screen and the columnar shell, the bottom of the first filter screen is connected with a first filter residue outlet pipe, a first water outlet is formed in the bottom of the first filtering area, the first water outlet is exposed out of the side wall of the columnar shell, a second filter screen is arranged below the first filter screen, a second filtering area is formed among the second filter screen, the first filter screen and the columnar shell, the bottom of the second filter screen is connected with a second filter residue outlet pipe, the first filter residue outlet pipe is arranged in the second filter residue outlet pipe, and a second water outlet is formed in the bottom of the second filtering area. The rainwater collection device comprises a coarse filtration area and a fine filtration area, can meet the requirements of different users for water qualification and has the integrated function of rainwater collection and reuse.

Owner:DONGHUA UNIV

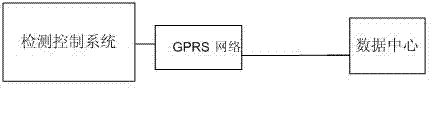

Special network weather monitoring system based on GPRS (General Packet Radio Service) network

InactiveCN102364913AGuaranteed normal transmissionAvoid lossIndication of weather conditions using multiple variablesTransmissionSite monitoringGeneral Packet Radio Service

The invention discloses a special network weather monitoring system based on a GPRS (General Packet Radio Service) network, which mainly comprises an on-site monitoring and controlling system, and the GPRS network and a data center which are sequentially connected with the on-site monitoring and controlling system. The special network weather monitoring system based on the GPRS network has the advantages that: 1. the reliability is high; 2. the real-time performance is strong; 3. the reading range is wide; 4. the operating cost of the system is low; and 5. the transmission capacity of the system is large.

Owner:CHENGDU ZHONGSHAN SCI & TECH

Multi-layer ceramic-wood composite heating floor tile and preparing method and laying method thereof

PendingCN111058593AEasy to installHeating up fastLighting and heating apparatusElectric heating systemComposite materialCeramic tiles

The invention discloses a multi-layer ceramic-wood composite heating floor tile which comprises a ceramic tile layer. A wood layer is arranged on the back face of the ceramic tile layer. A heating layer is arranged between the ceramic tile layer and the wood layer. The heating layer comprises a heating chip and a positive and negative electrode connector led out of the heating chip. A wire outletslot is formed in the back face of the wood layer. The heating floor tile is easy and rapid to install and maintain and is installed in the same way as an ordinary floor rapidly and easily, floor heating is realized after the floor tile is laid, and the floor tile is an independent unit and can be replaced conveniently and rapidly.

Owner:JIANGSU D VEO FURNITURE MFG

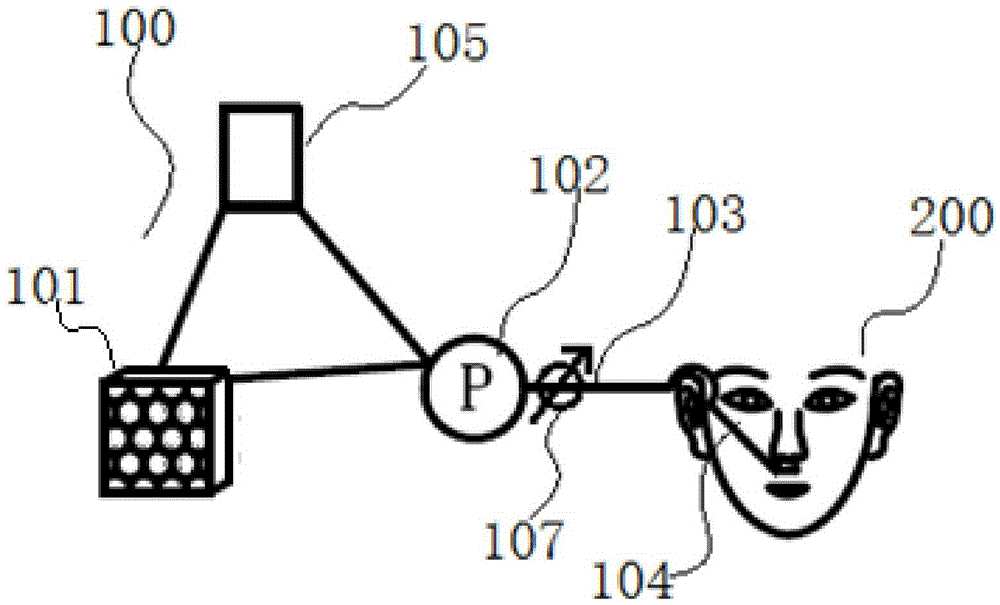

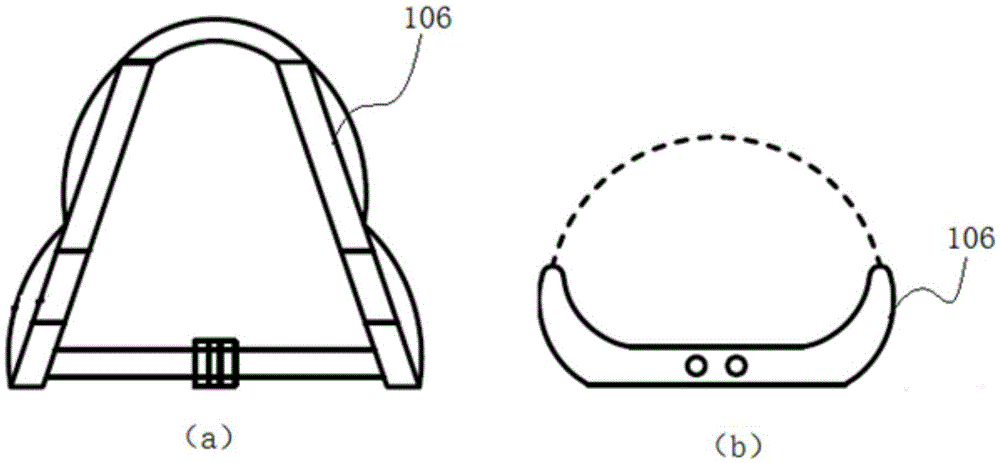

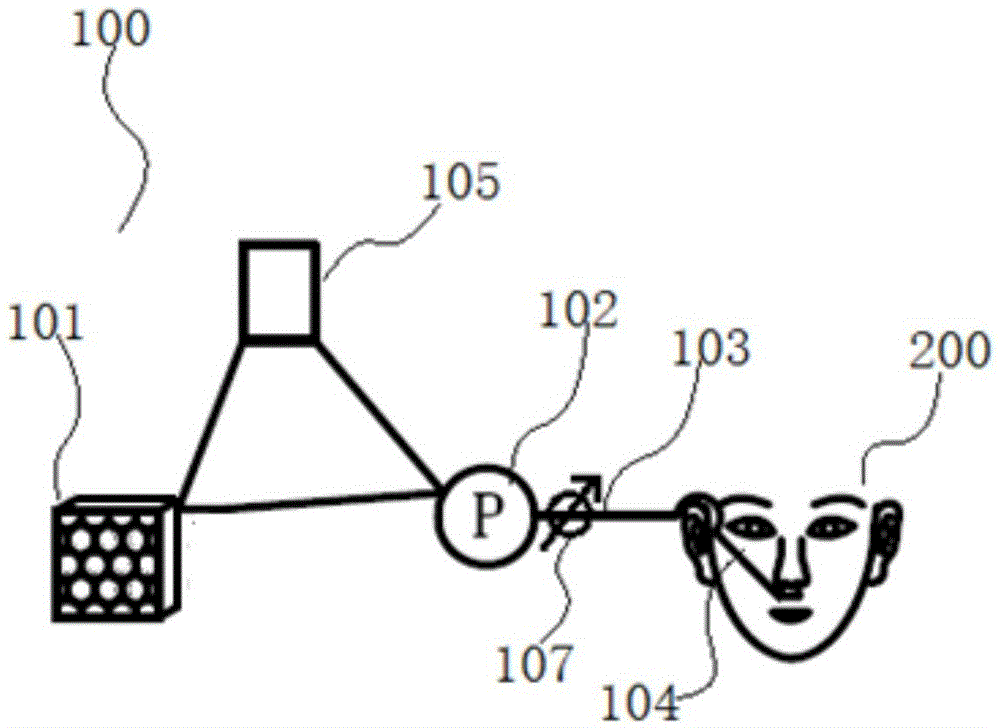

Wearable air purification device and method

InactiveCN105617553AValid inputSimple structureFire rescueRespiratory apparatusElectricityAir purifiers

The invention discloses a wearable air purification device and method. The wearable air purification device and method can purify air mainly based on an air purifier, an air pump, an air guide pipe, an air outlet part, a power source device and a wearable part. The air purifier, the air pump and the power source device are arranged on the wearable part. An air outlet of the air purifier communicates with an air inlet of the air pump through the air guide pipe. An air outlet of the air pump communicates with the air outlet part through the air guide pipe. The air outlet part is of a wearable structure, and when the air outlet part is worn, air outlets of the air outlet part correspond to nostrils of a wearer. The power source device is electrically connected with the air purifier and the air pump. In this way, according to the scheme, the wearable air purification method comprises the steps that firstly, sucked air is purified through the air purifier; secondly, the purified air is pressurized; and finally, the pressurized purified air is directly supplied to the wearer, and air which is not purified is prevented from being inhaled. According to the wearable air purification device and method, the clean air can be carried to the wearer effectively, and the effect that the wearer inhales only the purified clean air is effectively ensured; meanwhile, the wearable air purification device is simple in overall structure, low in cost and stable and reliable in operation performance.

Owner:SHANGHAI LINKEPAI ENERGY SAVING ENVIRONMENTAL PROTECTION TECH

Method by which passenger can be on-off without stopping train

InactiveCN101152871AShorten the timeReduce operating costsRailway auxillary equipmentEngineeringCar door

The present invention provides a method that passengers can get up and take off without stopping the train which comprises a dump composite train. Two parts of the dump composite train can be connected and separated. A baby train is arranged on the side of the mother train and is connected with a cushioning device by a car coupler. A vehicle door is arranged on the side which is corresponding to the mother train. Another door is arranged on the other side of the baby train. A railway is paved beside the main railway of the mother railway for the working of the baby train. Another baby train is arranged on the railway in the platform section. The technique is used in the metro car in china, according to conservative estimating, the capacity can increase by about 140 percent, energy can be saved by about 50 percent, passengers time can be saved by about 58 percent, the area of the platform can be about half saved; the mechanical damage caused by braking and starting can be reduced, and the number of the arranged carriages can also be reduced.

Owner:DAJING HIGH SCHOOL AFFILIATED TO SHANGHAI INT STUDIES UNIV

The plow unloader for feeding the bin body and the unpowered dust removal device for the unloading truck to remove dust

The invention relates to a plough tripper for feeding a silo and a power-free dust-removing device of removing dust of the tripper. The device is characterized in that: a silo feed facility is arranged at a silo feed port of a silo; a cover is arranged at a material falling position on the silo feed facility; the bottom of a rectangular closed dust guiding channel arranged on the top of the silo,is communicated with the silo; refracted flow baffles which are oriented to the silo, have an include angle less than a right angle and staggered are arranged in a dust downlink channel, a filter facility in the dust downlink channel is communicated with the outside; an anti-static roller is arranged at the position close to the filter facility, in a gas-dust separation chamber; a dust oscillation device is arranged at the position close to the filter facility, outside the gas-dust separation chamber; and a motor dust collection duct and a dust collection motor are arranged on the lower part of the filter facility. The plough tripper and the power-free dust-removing device have the characteristics of simple structure, little investment, no need of any energy, no maintenance cost and no noise or secondary emission and pollution.

Owner:刘欣

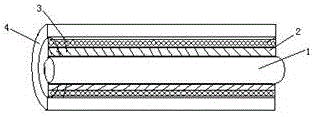

Frequency-conversion electromagnetic heating energy-saving system

InactiveCN106545990AAvoid distributingTake advantage ofWater heatersTemperature controlThermal insulation

The invention discloses a frequency-conversion electromagnetic heating energy-saving system. The frequency-conversion electromagnetic heating energy-saving system comprises a pipeline, a heating coil, an insulation and thermal insulation dielectric layer, a heat sensor, a frequency-conversion module and a cloud control module. The insulation and thermal insulation dielectric layer is wound on the outer wall of the pipeline; the high temperature resistance coil is arranged outside the insulation and thermal insulation dielectric layer; the frequency-conversion module is connected with the two ends of the coil; the frequency-conversion module is connected to the cloud control module; one end of the heat sensor is connected with the outer wall of the pipeline and the other end of the heat sensor is connected to the cloud control module; and liquid is placed in the pipeline. According to the technical scheme, high efficiency and energy saving are achieved, the service life is long, safety and reliability are realized, temperature control is accurate, and the insulation property is good.

Owner:于永年

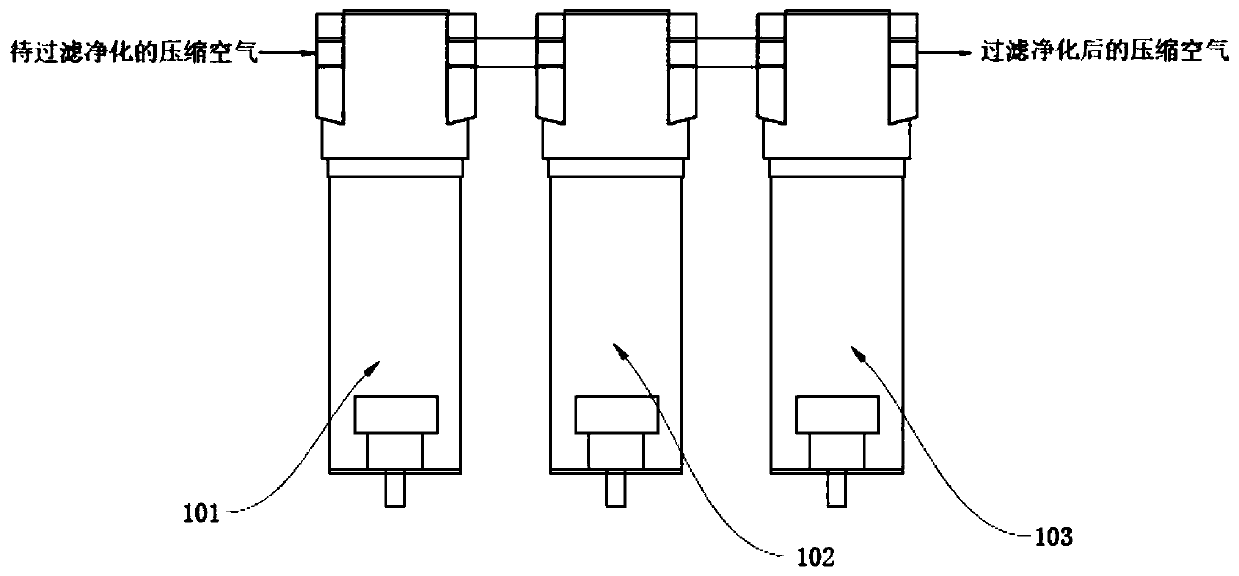

Integrated compressed air filtering and purifying apparatus and filtering and purifying method thereof

PendingCN110585809ASimple structureEasy to useDispersed particle filtrationTransportation and packagingWater dischargePollution

The invention discloses an integrated compressed air filtering and purifying apparatus and a filtering and purifying method thereof. The integrated compressed air filtering and purifying apparatus comprises a filtering cover body and a filtering base, wherein the filtering cover body and the filtering base are fixedly connected to form a filtering body, a filtering chamber is arranged in the filtering body, a filtering core is arranged in the filtering cover body, a flow guide device matched with the filtering core in a sealed manner is arranged in the filtering base, an air inlet for flowingcompressed air into the flow guide device is arranged on the first side wall of the filtering base, a gas discharge port is arranged on the top portion of the filtering cover body, and a first-stage water discharge valve and a second-stage water discharge valve are respectively arranged on the second side wall of the filtering base. The method is applied to the apparatus. According to the invention, the apparatus has advantages of simple structure, convenient use, high purification efficiency, powerful pollution discharge function, long service life, small installation space, convenient maintenance, low power consumption, low cost and the like.

Owner:珠海市广鑫机电设备有限公司

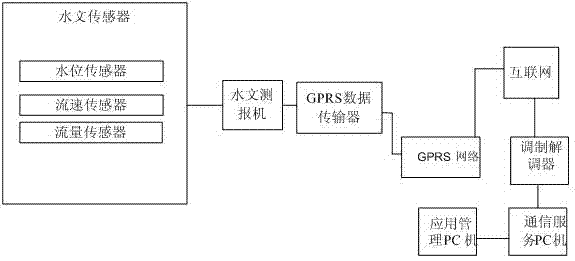

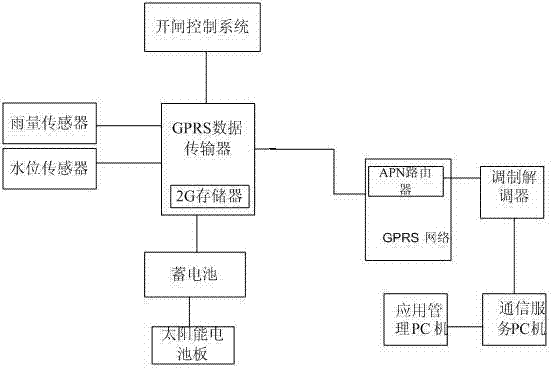

Private network type flash flood disaster warning system based on GPRS (general radio packet service) network

InactiveCN102364536AGuaranteed normal transmissionAvoid lossHuman health protectionAlarmsMonitoring siteModem device

The invention discloses a private network type flash flood disaster warning system based on a GPRS (general radio packet service) network, which mainly comprises a detection control system, the GPRS network and a data center connected sequentially in series. The GPRS network comprises an APN (access point name) router, the data center comprises a modem, and the APN router is connected with the modem. The invention has the advantages that: 1, no distance limitation is needed; 2, the reliability is high; 3, the real-time performance is high; 4, the system construction cost is low; 5, the system operating cost is low; 6, the power consumption for transmission of the GPRS network is low; and 7, remote control for operating devices at each monitoring site can be realized.

Owner:CHENGDU ZHONGSHAN SCI & TECH

Purifier for purifying air

InactiveCN110270435AQuick eliminationEliminate effectiveGas treatmentNon-rotating vibration suppressionBenzeneElectricity

The invention discloses a purifier for purifying air. The purifier comprises a box body, an electrode plate, a base, a high-voltage protective tetrafluoro end block, a discharge electrode, an electrode shell, a cover plate and a centrifugal fan. The top of the base is uniformly provided with four sleeves. Slide blocks are fixedly connected on the two sides of a support plate through bolts. The two slide blocks slide with the inner wall of the sleeves. The top of the support plate is fixedly connected with one end of a support column. The other end of the support column extends out of the sleeves and is connected with the bottom of the box body. The purifier can quickly and effectively eliminate harmful substances such as formaldehyde, benzene and TVOC and the like. Meanwhile, the generated ozone can purify the air in each corner without dead angle. The harmful substances such as formaldehyde, benzene and TVOC can be decomposed and eliminated by means of physical and chemical methods so that the total amount of the harmful substances in the air can be removed rather than simple adsorption resulting in secondary pollution. The purifier has no other consumables and is easy to assembly without maintenance cost and is high in economic benefit.

Owner:HEFEI CRRC ROLLING CO LTD

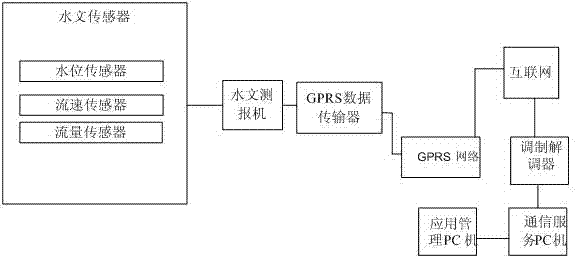

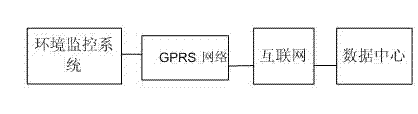

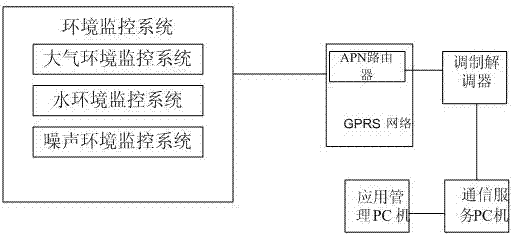

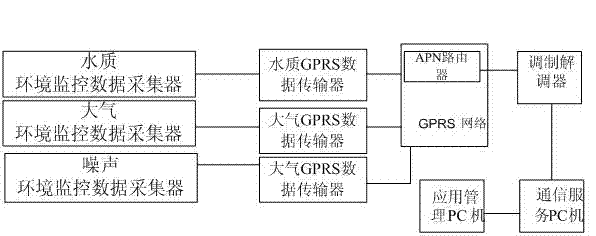

GPRS network based private network environmental protection data acquisition system

InactiveCN102364542AGuaranteed normal transmissionAvoid lossTransmission systemsData centerPrivate network

The invention discloses a GPRS network based private network environmental protection data acquisition system, which is mainly composed of an environment monitor system, a GPRS network and a data center which are sequentially connected. The environment monitor system comprises an air environment monitor system, a water environment monitor system and a noise environment monitor system. The invention has the following advantages of: 1, high reliability; 2, strong real-time property; 3, wide meter reading range; 4, low system construction cost; 5, low system operation cost; 6, large transmission capacity of the system.

Owner:CHENGDU ZHONGSHAN SCI & TECH

Full-automatic steel strand cutter

The invention discloses a full-automatic steel strand cutter. The full-automatic steel strand cutter comprises a supporting frame, a protection device, a steel strand containing frame, an output protecting bush, a feeding device, an automatic lifting cutting device, a size positioning device, an automatic finished-product discharging device and an electric control device. The full-automatic steel strand cutter is simple in structure, convenient to install, reliable in operation, low in investment and high in yield; manual operation is replaced by production automation operation, at least three persons are saved, a forty-steel-strand machining task which originally needs four persons to cooperatively work can be completed in one hour, more than thirty steel strands can be cut per hour, and the labor cost can be saved by 600 yuan every day. By means of the full-automatic steel strand cutter, manual operation is completely changed into automation operation, and the full-automatic steel strand cutter is a great trend of the current social development; in addition, no automatic special equipment for cutting the steel strands in the aspect exists in the society, and the large social popularization potential is achieved; the maintenance cost is quite low, the manufacturing cost is low, operation is convenient, the quality of finished products is high, size positioning is reliable, and the production requirement can be met.

Owner:XUCHANG UNIV

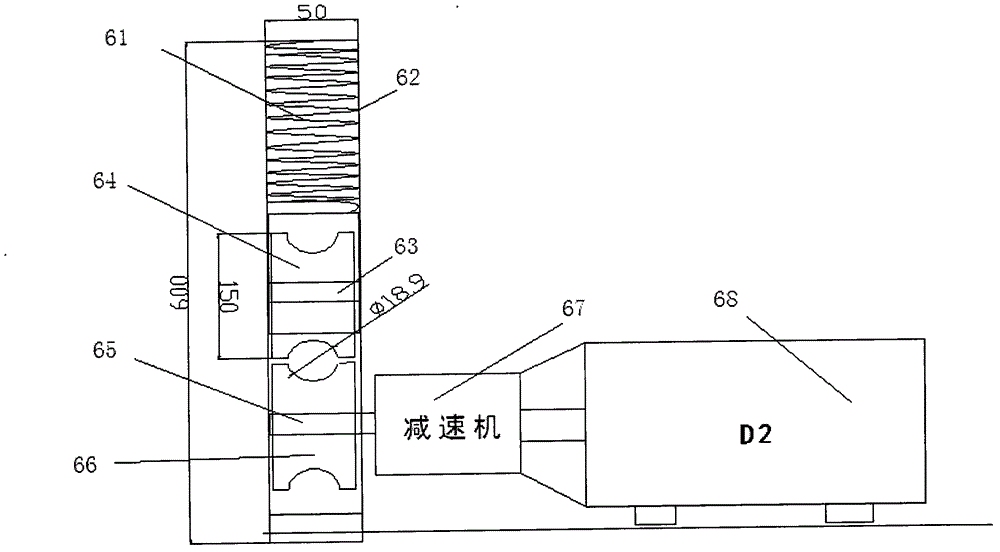

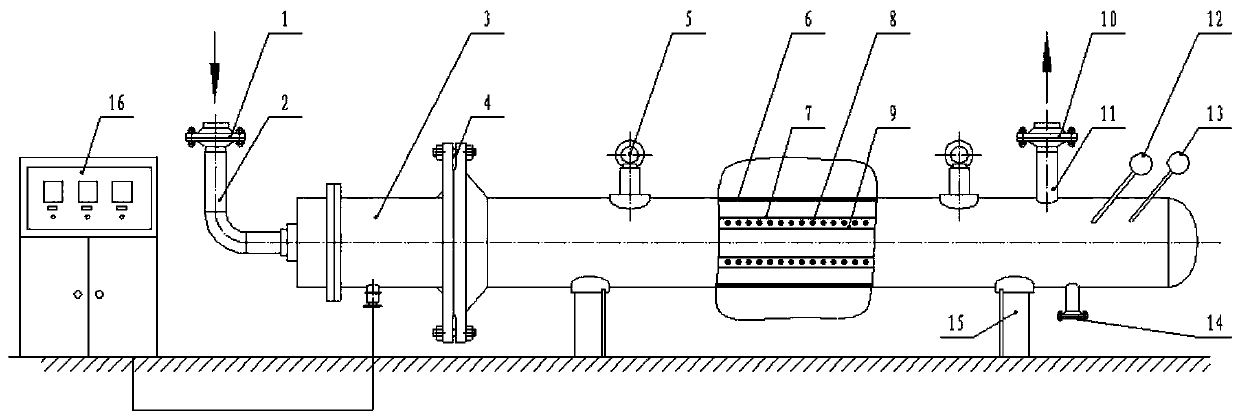

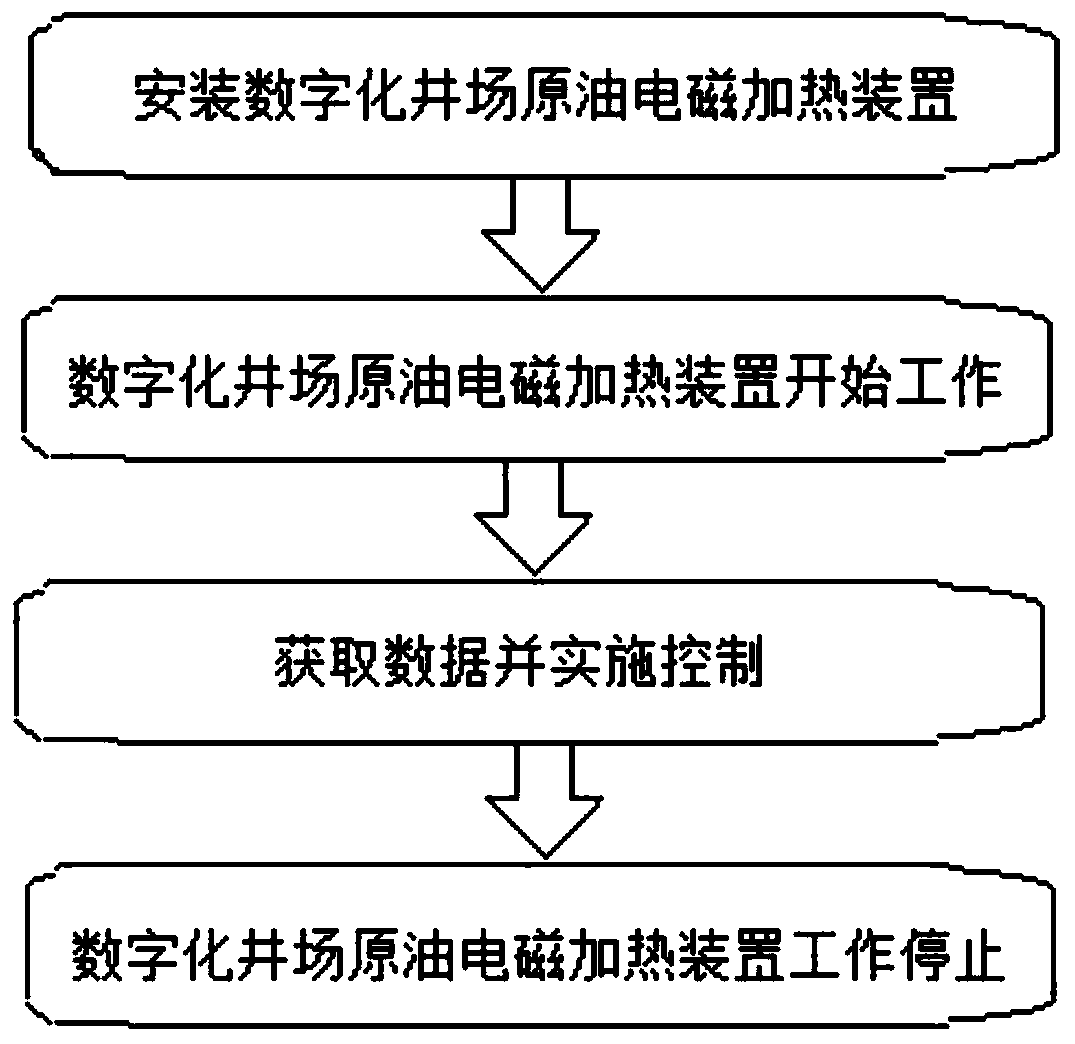

Digitalized well site crude oil electromagnetic heating device and heating method

PendingCN110608370AImprove thermal efficiencyShorten warm-up timePipe heating/coolingPipeline systemsFailure rateEngineering

The invention belongs to the technical field of crude oil heating and specifically relates to a digitalized well site crude oil electromagnetic heating device and heating method. The digitalized wellsite crude oil electromagnetic heating device provided by the invention is organically provided with an electromagnetic heating body used for heating crude oil passing through the electromagnetic heating body, a frequency conversion control cabinet being in wire connection with the electromagnetic heating body and used for changing the input power frequency supply frequency and a remote monitoringsystem being in electric signal connection with the frequency conversion control cabinet and used for receiving and transmitting electric signals and controlling starting and stopping of the frequency conversion control cabinet and can conduct one-way internal heating without a heat source and is high in thermal efficiency, safe, friendly to environment and energy-saving. The digitalized well site crude oil electromagnetic heating device and heating method have the characteristics of being high in electric heating thermal efficiency, low in failure rate and easy and convenient to maintain.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com