Frequency-conversion electromagnetic heating energy-saving system

An energy-saving system, electromagnetic technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of difficult and accurate temperature control, resistance wire burnout, short service life, etc., to achieve real-time accurate temperature control, The effect of small thermal retardation and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to clearly understand the technical solution of the present invention, its detailed structure will be presented in the following description. Obviously, the implementation of the embodiments of the invention is not limited to specific details familiar to those skilled in the art. The preferred embodiments of the present invention are described in detail below, and there may be other implementations besides those described in detail.

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

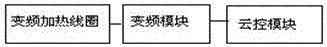

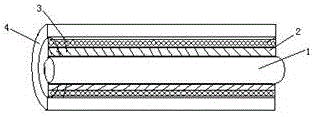

[0016] combine figure 1 and figure 2 , the figure discloses a frequency conversion electromagnetic heating energy saving system. The frequency conversion electromagnetic heating energy saving system includes a pipeline 1, a heating coil 3, an insulating and heat insulating medium layer 2, a thermal sensor, a frequency conversion module, and a cloud control module. The outer wall of the pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com