The plow unloader for feeding the bin body and the unpowered dust removal device for the unloading truck to remove dust

A plow-type unloader and dust removal device technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of not being able to use water spray, small feeding port, and large investment, and achieve no maintenance cost, simple structure, The effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

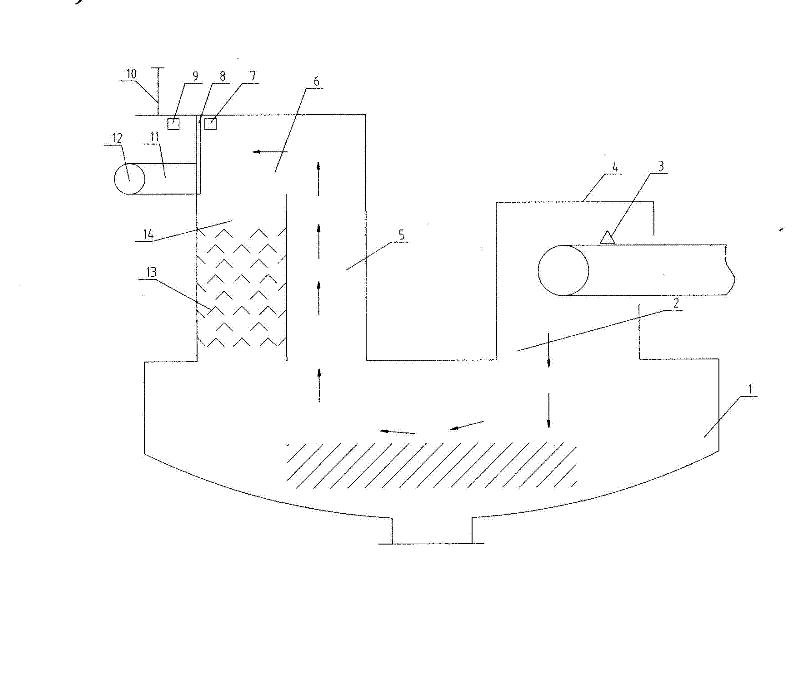

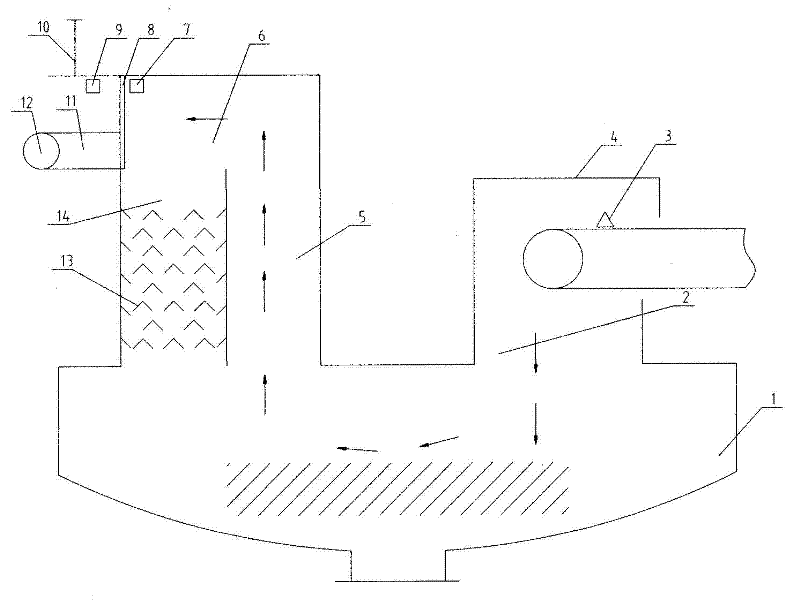

[0012] The design concept of the plow unloader for feeding the bin body and the non-powered dust removal device for the unloading truck dust removal of the present invention is to use the relevant principles of physics energy conservation and fluid mechanics in the prior art to separate the gas and dust, and the dust energy The exhausted environment completes effective dust removal, solves the problems of unsatisfactory dust removal effect and frequent maintenance in traditional dust removal methods, and can achieve consistent dust removal effects to meet the requirements of GB16248_1996 "Hygienic Standards for Respirable Dust in the Air of Workplaces". The following is combined with the attached drawings Be specific.

[0013] See figure 1 , the plow unloader for feeding the bin body and the unpowered dust removal device for the unloading truck dust removal are composed of: bin body 1, bin body inlet 2, bin body feeding facility 3, buckle cover 4, and dust guide Channel 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com