Hydraulic push-in replacing device for current transformer

A current transformer, push-in technology, used in lifting devices, switch devices, electrical components, etc., can solve problems such as damage to staff or equipment, low work efficiency, poor safety, etc., to achieve no maintenance costs and improve work efficiency. , the effect of moving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

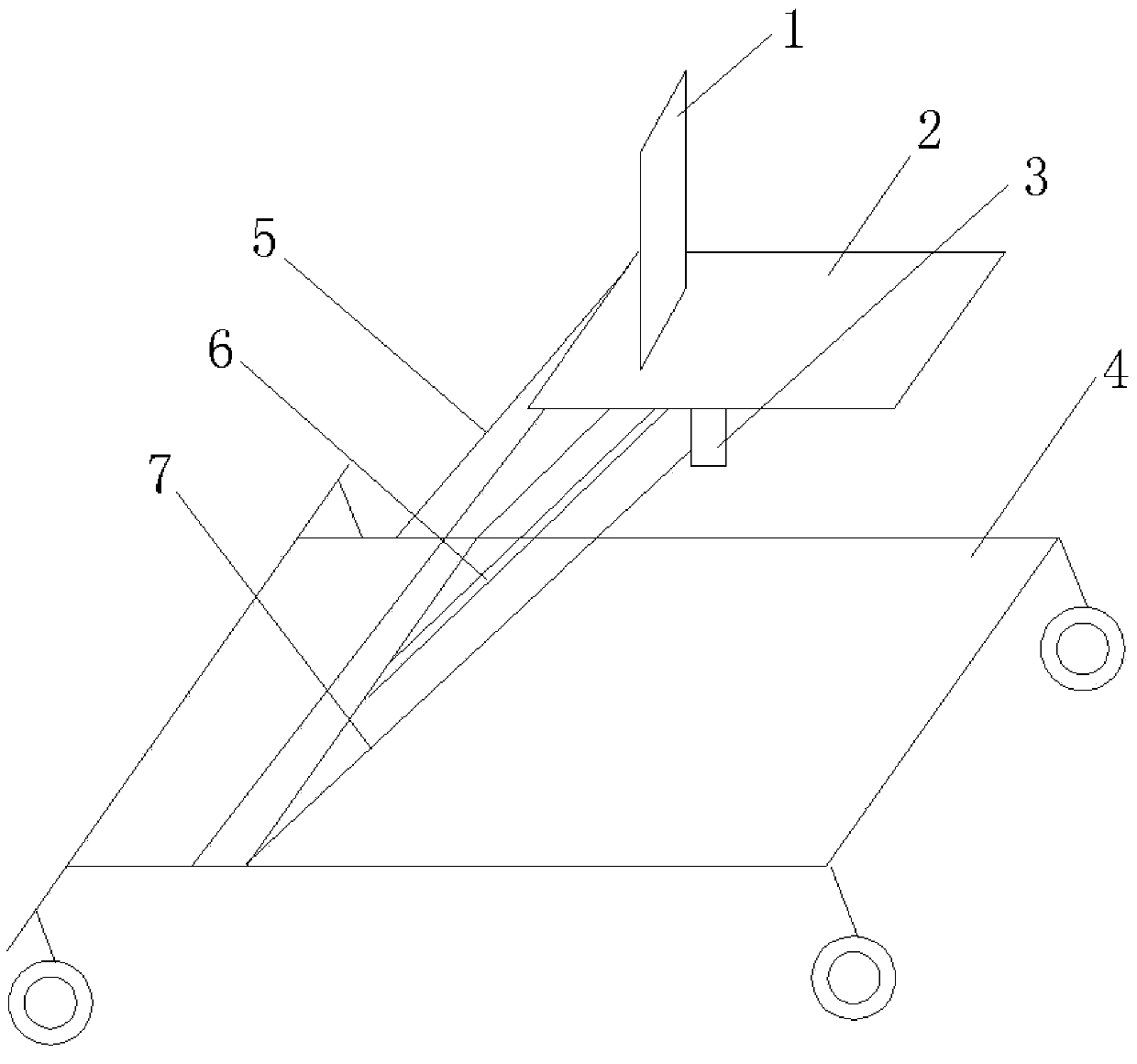

[0014] Such as figure 1 As shown, the present invention is a hydraulic push-in type current transformer replacement device, including a base 4, on which a hydraulic jack 6 is fixedly installed, and a support column 7 is respectively installed on both sides of the hydraulic jack 6, wherein The bottom of every support column 7 is all hinged on the base 4, and also includes a support platform, on the lower surface of the support platform, a connecting frame 3 is fixed, and the connecting frame 3 is hinged together with the piston rod head of the aforementioned hydraulic jack 6 , and the connecting frame 3 is also hinged together with the tops of the two supporting columns 7 .

[0015] Wherein the angle between the hydraulic jack 6 and the base 4 is 45-80 degrees, for example, the angle is 70 degrees, the base 4 is a rectangle, and two universal wheels and two universal wheels are respectively installed on the four corners of the base 4 Orientation wheel. The base 4 is specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com