Method of transforming upflow/downflow type wet flue gas desulfur system as single circuit upflow type wet flue gas desulfur system

A desulfurization system, flue gas technology, applied in separation methods, chemical instruments and methods, separation of dispersed particles, etc., can solve problems such as difficulties in updating or improving air pollution control systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

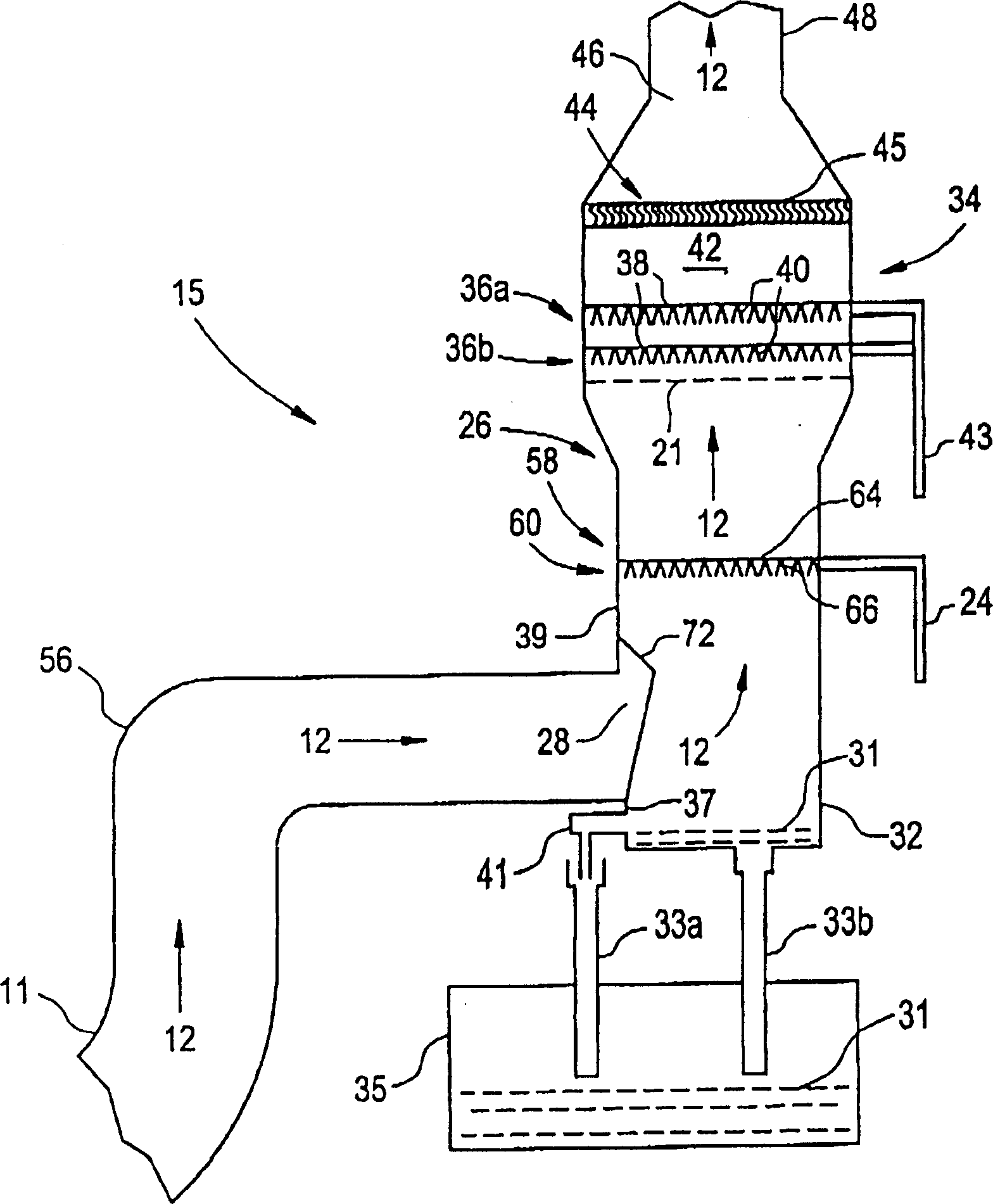

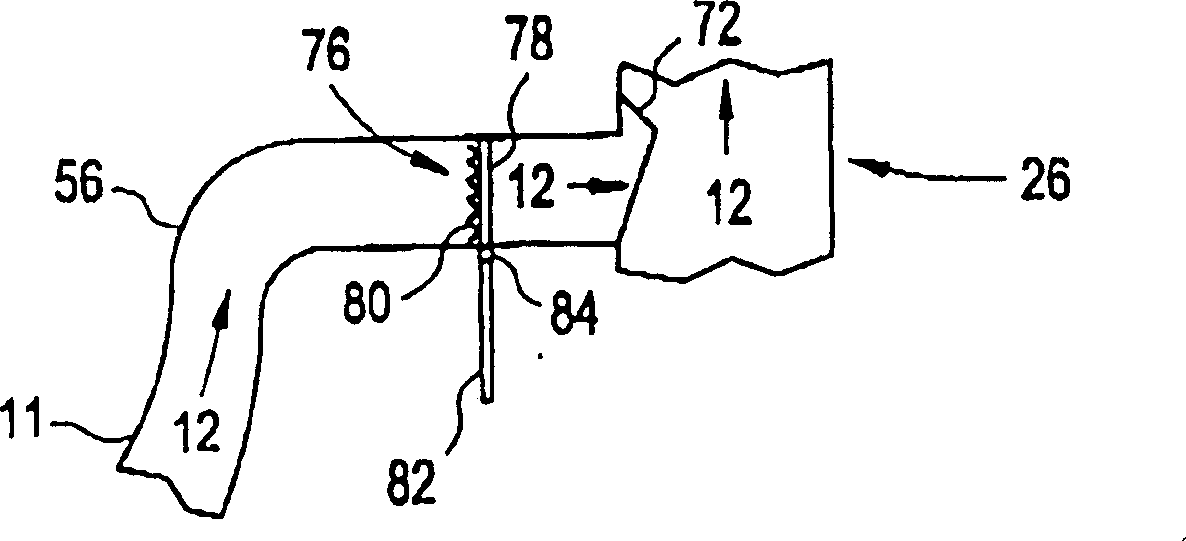

[0022] The present invention is preferably applied to the treatment of boiler flue gas and this embodiment will be described in order to illustrate the invention and its advantages. While the invention is not limited to this illustrative embodiment, it is contemplated that the invention has applicability to various combustion system extracts, packed or other types of scrubbers, and various co-current and / or counter-current flows of reagents.

[0023] The following description will be made with reference to the drawings in which like reference numerals denote like parts.

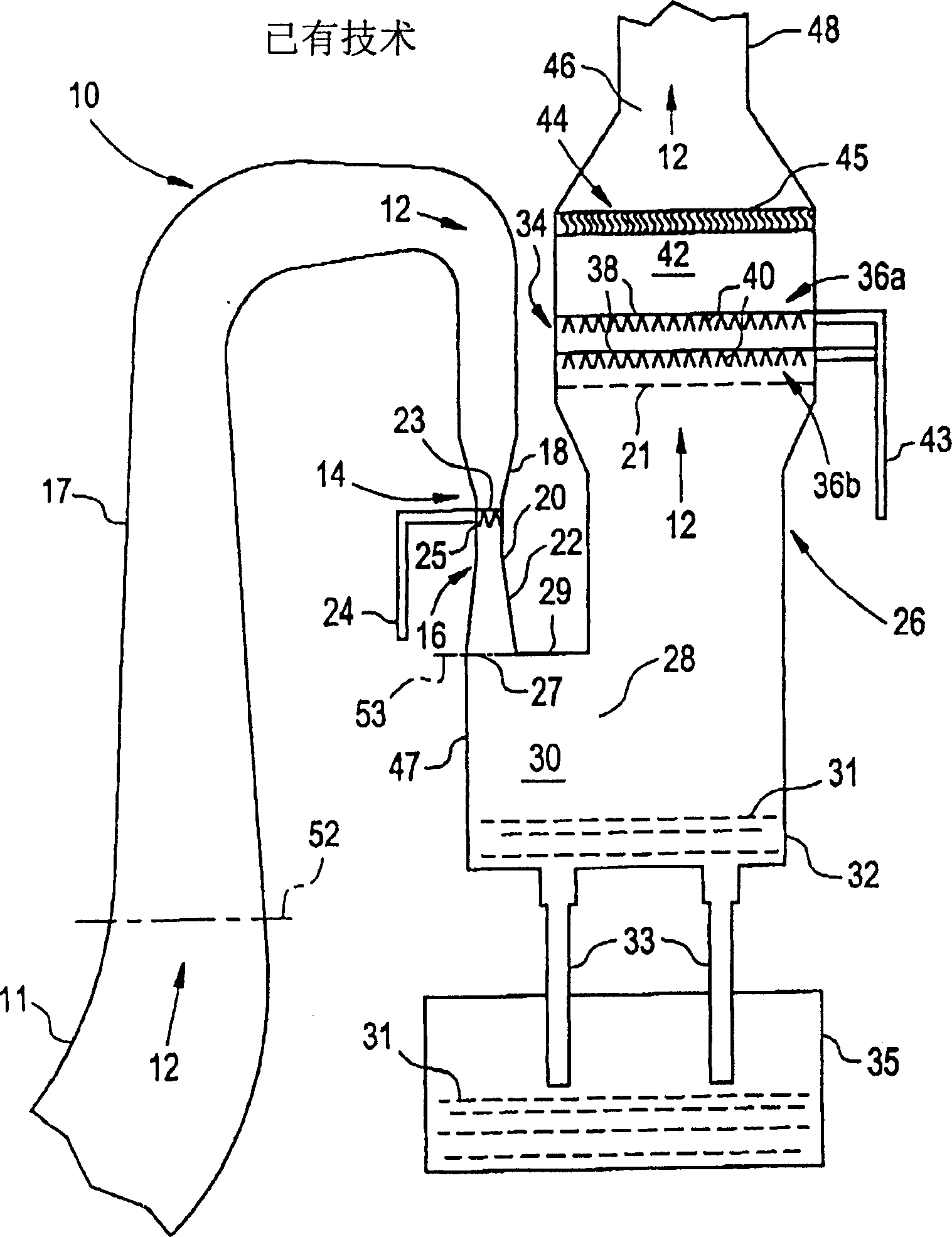

[0024] Referring to the accompanying drawings, especially figure 1 , an upflow / downflow WFGD system 10 is known in the art, and the system includes a flue gas pipeline 11 for receiving flue gas 12 from such as a coal-fired power plant or an industrial boiler (not shown in the figure), the flue gas The flue gas has preferably been passed through an electrostatic precipitator or a fabric filter (neither shown)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com