Method for starting dynamic control model of converter based on static detection of simulated sublance

A dynamic control and static detection technology, which is applied in the manufacture of converters, etc., can solve problems such as the harsh environment of the converter site, detection failure, and inability to detect C, T, etc., to reduce one-time equipment investment, improve detection success rate, and consume costs Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The method of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

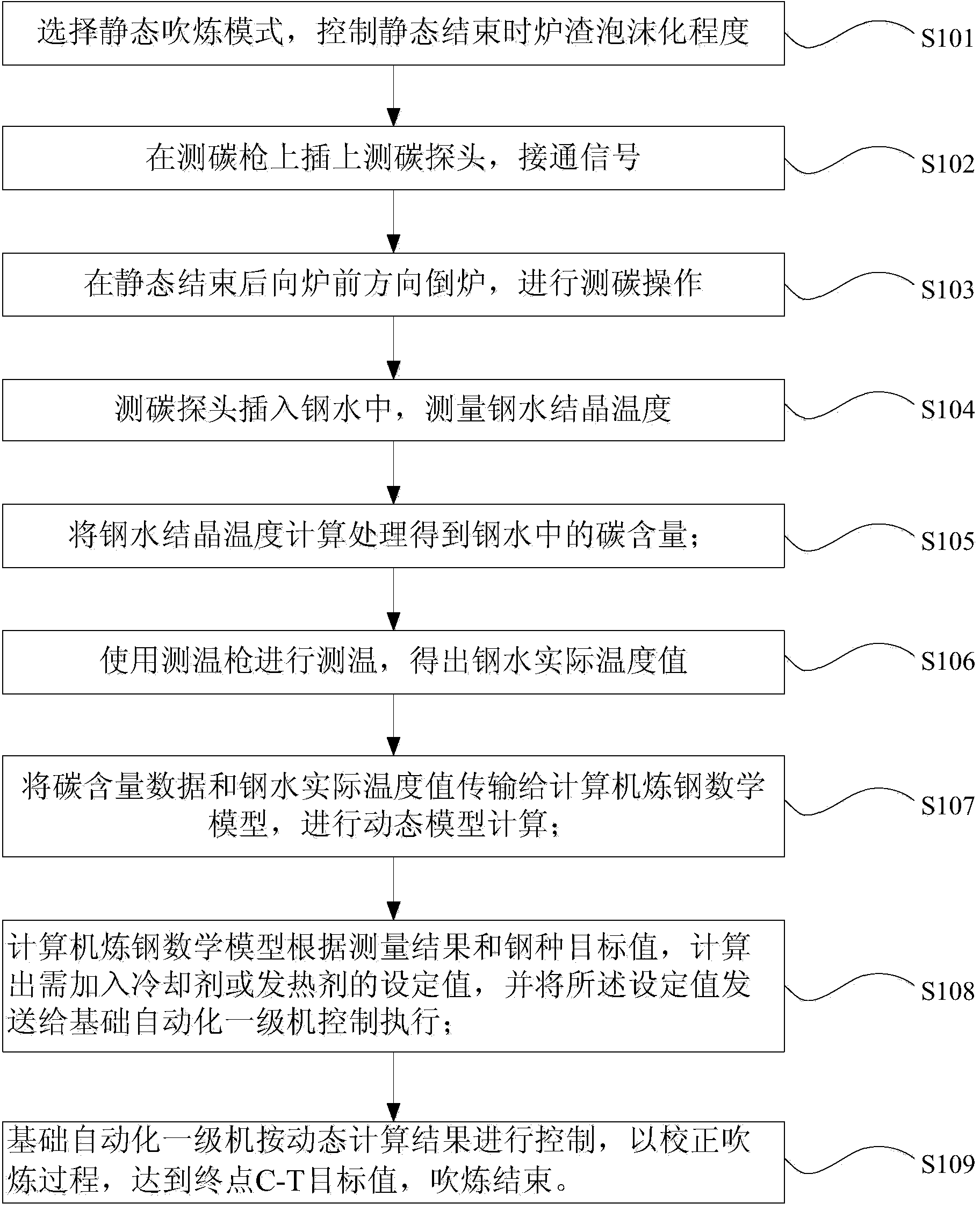

[0029] Such as figure 1 As shown, the present invention is based on the method for starting the dynamic control model of the converter for simulating subgun static detection, comprising the following steps:

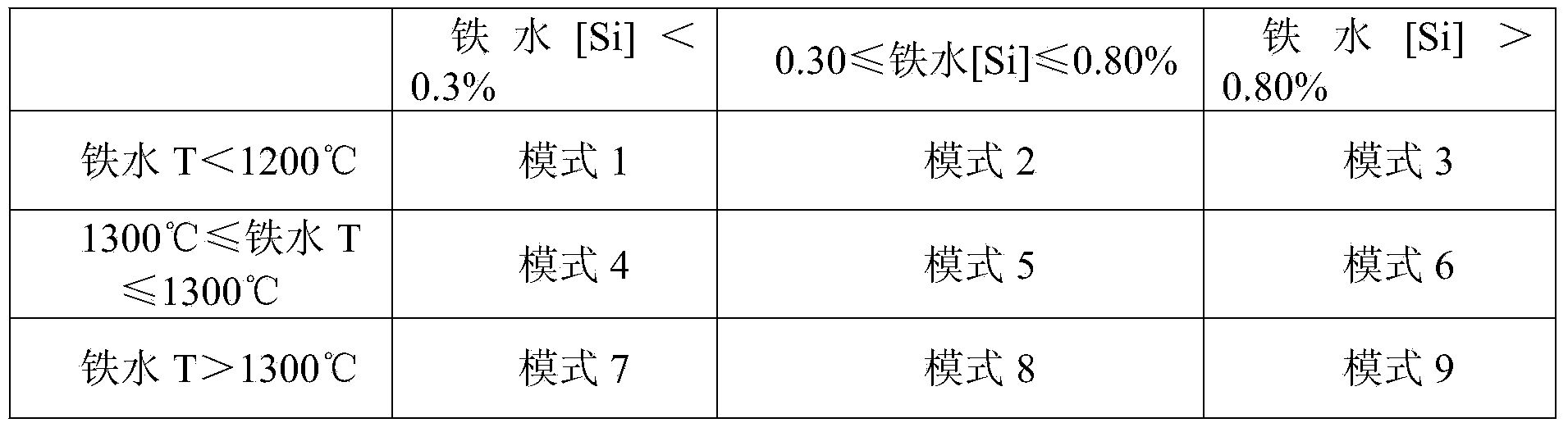

[0030] Step S101, select the static blowing mode, and control the degree of foaming of the slag at the end of the static state; the degree of foaming of the slag is: the slag should not be too foamy to ensure that the slag will not pour out; and the slag should not be too sticky to measure carbon The gun can enter the molten steel shall prevail.

[0031] Step S102, inserting the carbon measuring probe on the carbon measuring gun, after the signal is connected, the green indicator light on the indicator is on.

[0032] Step S103. After the static state is over, turn the furnace to the front of the furnace. After shaking the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com