Micro spray 3D printing device capable of automatically washing sprayer as well as working method of micro spray 3D printing device

An automatic cleaning and 3D printing technology, applied in additive processing and other directions, can solve problems such as poor cleaning effect, and achieve the effect of reducing maintenance costs, low power consumption, and simplifying the cleaning and maintenance process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

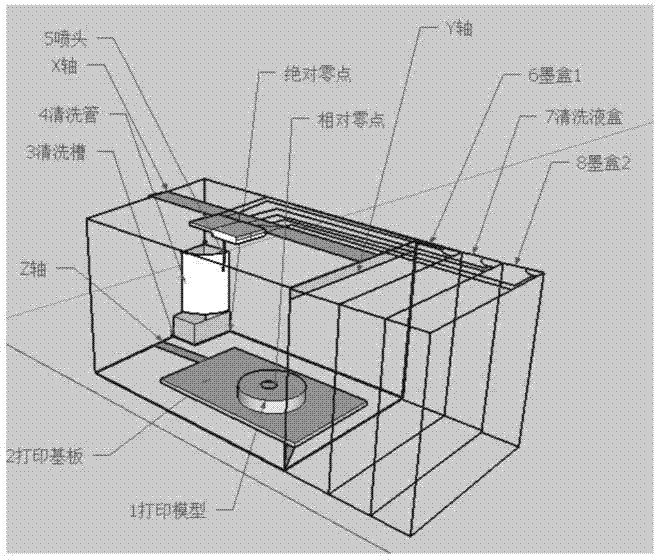

[0028] 3D printer with cleaning function, its structure and working principle are as follows: figure 1 .

[0029] 1. Equipment composition

[0030] 3D printer three-axis motion platform, ink cartridge, cleaning ink cartridge, cleaning pipe, waste liquid recovery device, related supporting control components, electro-pneumatic control part of the equipment circuit. The overall structure of the printer is as follows figure 2 shown.

[0031] 2. Working principle

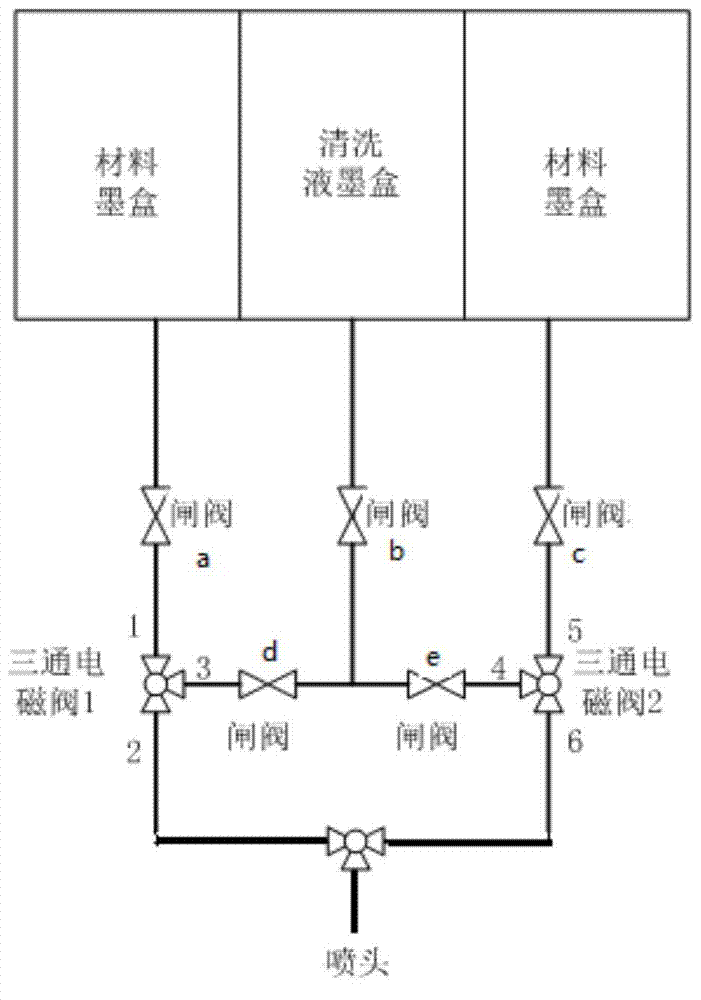

[0032] (1) In order to achieve multi-material printing with one nozzle, the cleaning process is called before changing the material, and the pre-spraying process is called after cleaning, so that the printer is at the initial point of benign work. The pre-spraying process is to switch to the printing working state at the initial point, flush the pipeline and nozzle with printing materials, ensure the degree of wetting of the nozzle, and ensure the printing accuracy and effect of the printing starting point.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com