Revolving drum type micro-filter and sewage treatment method

A filter and drum technology, which is applied in the field of drum-type micro-filter, drum-type micro-filter and sewage treatment, can solve the problems of inconvenient disassembly and cleaning, low work efficiency, complicated structure of the drum-type filter, etc. Simple and compact, high work efficiency, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

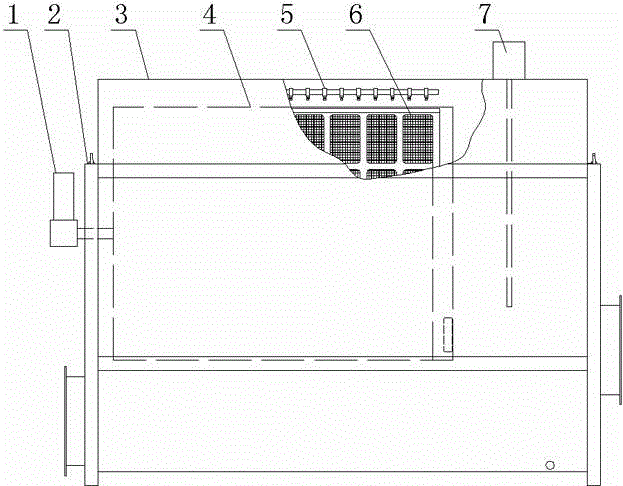

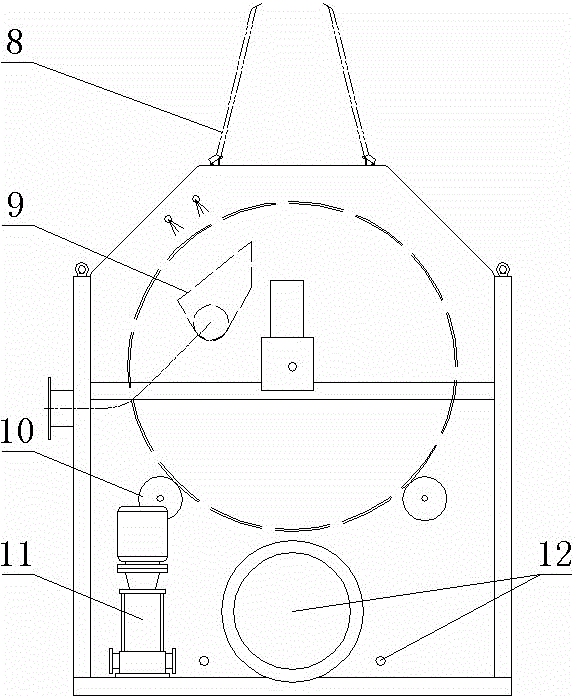

[0030] see figure 1 and figure 2 , the present invention relates to a drum type microfilter, which is mainly composed of a driving device 1, a box body 2, a casing 3, a drum 4, a flushing device 5, a microfilter 6, a liquid level detection 7, and a movable observation door 8 , Sewage tank 9, drum support device 10, flushing water pump 11 and pipeline system 12 constitute.

[0031] Driving device 1: It provides power for the rotation of the drum, adopts direct-connection driving, without intermediate transmission pair, and has a simple and stable structure.

[0032] Box 2: The box is a semi-closed structure and is the carrier of the drum. The interior is equipped with a water inlet area and a steady flow area to stabilize the shape of the water flow entering the drum and improve the filtering effect.

[0033] Cover 3: Make the whole machine in a closed structure, effectively avoid water splashing and improve the operating environment.

[0034] Drum 4: It is the micro-filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com