Roof outlet pipeline waterproof structure and construction method thereof

A technology for waterproof structures and pipes, applied to roofs, roof coverings, pipes, etc., can solve the problems of easy leakage of pipes and waterproof casings, achieve good waterproof effect, increase waterproof performance, and increase anti-crack performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

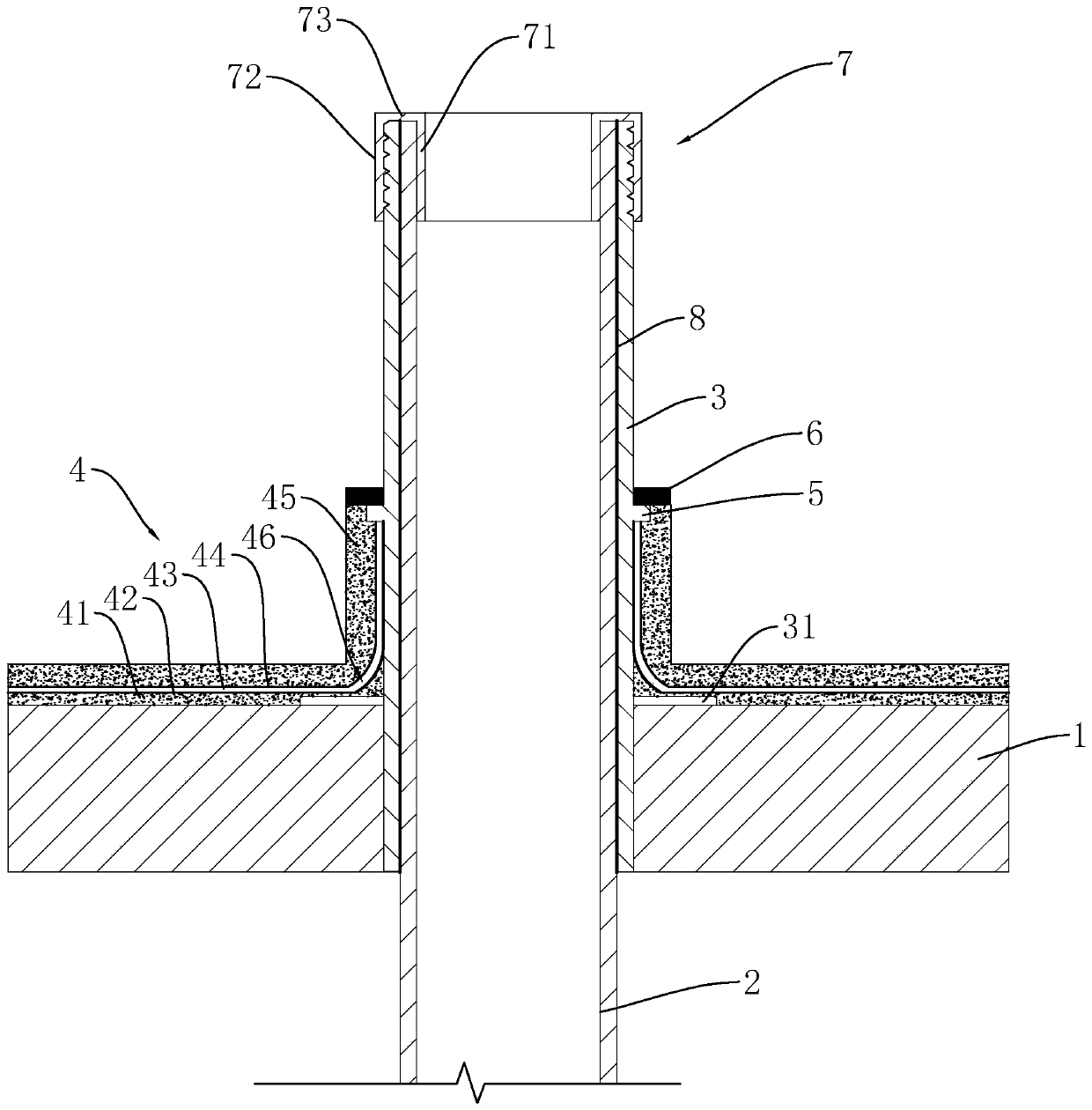

[0043] refer to figure 1, is a kind of waterproof structure of the roof pipeline disclosed by the present invention, including the pipeline 2 protruding from the roof. It is flush with the bottom surface of the roof, and the upper end is flush with the top surface of the pipe 2. A flange 31 is fixedly set on the outer wall of the waterproof casing 3, and the flange 31 is integrally formed with the waterproof casing 3. During installation, the flange 31 is attached to the roof. The waterproof casing 3 is provided with a waterproof layer 4, one end of the waterproof layer 4 extends to the roof, and the other end is folded upwards and wrapped on the waterproof casing 3. Among them, the roof is composed of cast-in-place roof board 1, and the waterproof coiled material 42 is SBS coiled material. The SBS coiled material has the advantages of no flow at high temperature, no brittle crack at low temperature, strong toughness, good elasticity, corrosion resistance, aging resistance, a...

Embodiment 2

[0051] refer to figure 1 , a construction method for a roof pipeline waterproof structure, comprising the following steps:

[0052] S1. Install the roof waterproof casing 3 on the roof cast-in-place slab 1 to ensure that the waterproof casing 3 is perpendicular to the roof and the bottom is flush with the bottom of the roof cast-in-place slab 1 .

[0053] S2. Apply waterproof ointment 8 on the outside of the pipeline 2, and install the pipeline 2 into the waterproof casing 3, so that the top surface of the pipeline 2 is flush with the top surface of the waterproof casing 3, so that the waterproof ointment 8 will connect the waterproof casing 3 and the waterproof casing 3. Gap filling between pipe 2.

[0054] S3. Buckle the connector 7 on the top of the pipe 2 and the waterproof sleeve 3, the inner wall of the waterproof sleeve 3 and the pipe 2 is located between the inner sleeve 71 and the outer sleeve 72, and use a wrench to screw the outer sleeve 72, make the connector 7 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com