Microwave assembly welding device

A technology of microwave components and welding devices, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of uneven pressure point pressure, poor welding air tightness, poor penetration rate, etc., and achieve good welding quality consistency , high welding flatness and high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, various embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

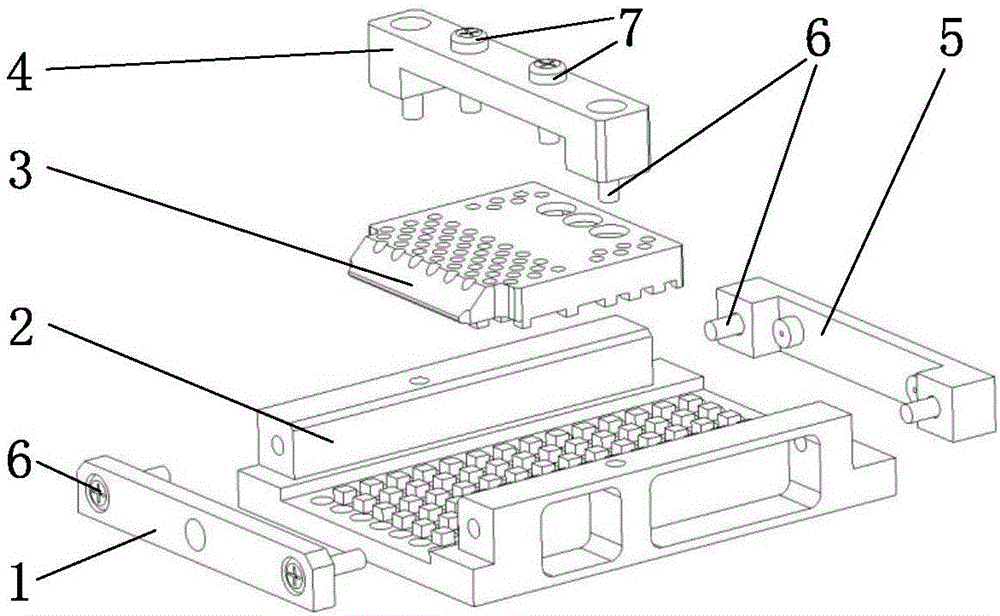

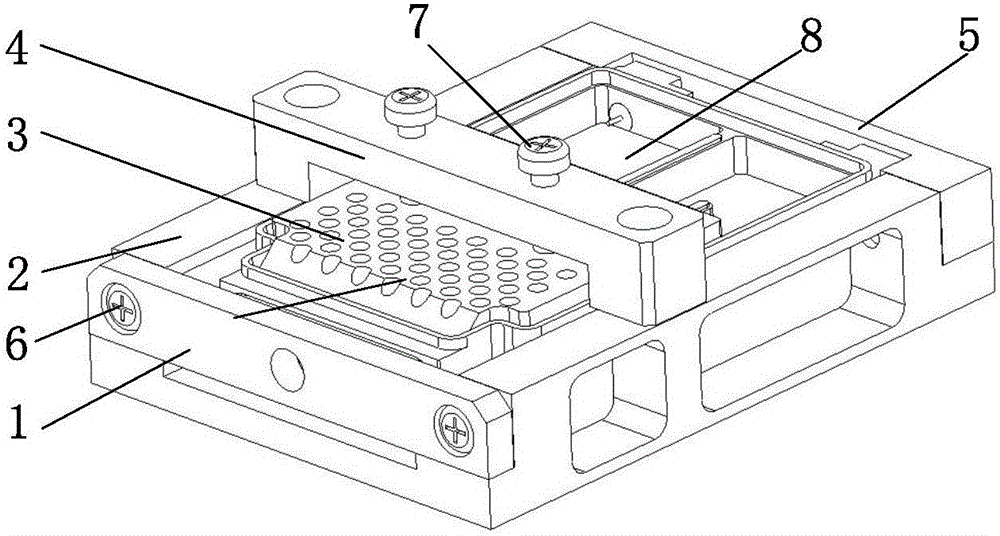

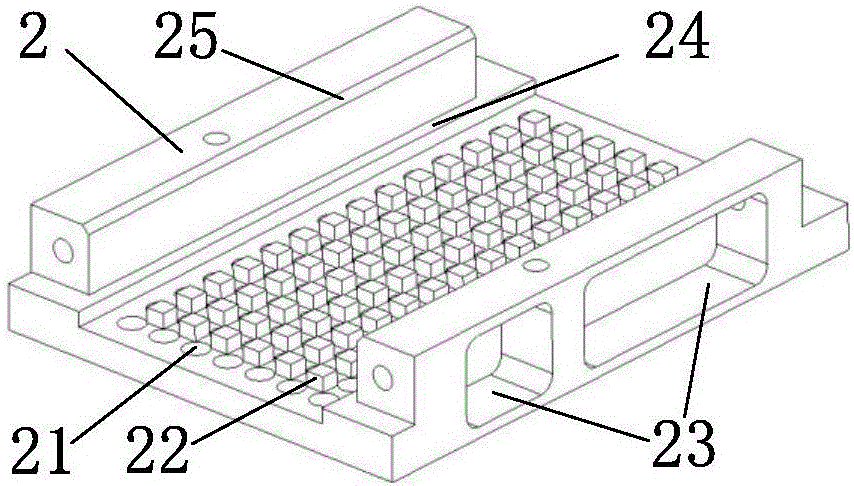

[0039] Please refer to figure 1 with figure 2 , a microwave assembly welding device, used for welding a microwave assembly 8 including a box body 81, a microwave substrate 83, a glass bead 84 and a connector 85, which includes a base 2, a left pressing block 1, a right pressing block 5, Upper pressing block 3 and beam 4;

[0040] The left pressing block 1 is fixedly connected with the base 2 for pressing the connector 85;

[0041] The right pressing block 5 is fixedly connected with the base 2 for pressing the glass beads 84;

[0042] The upper pressing block 3 is placed inside the box body 81 for pressing the microwave substrate 83;

[0043] The beam 4 is fixedly connected with the base 2 and is used for pressing the upper pressing block 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com