Water drainage cross inspection well preventing water face-to-face flushing

A technology for checking wells and water flow, which is applied to drainage structures, waterway systems, water supply devices, etc., and can solve problems such as large head loss, turbulent flow, and low drainage efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

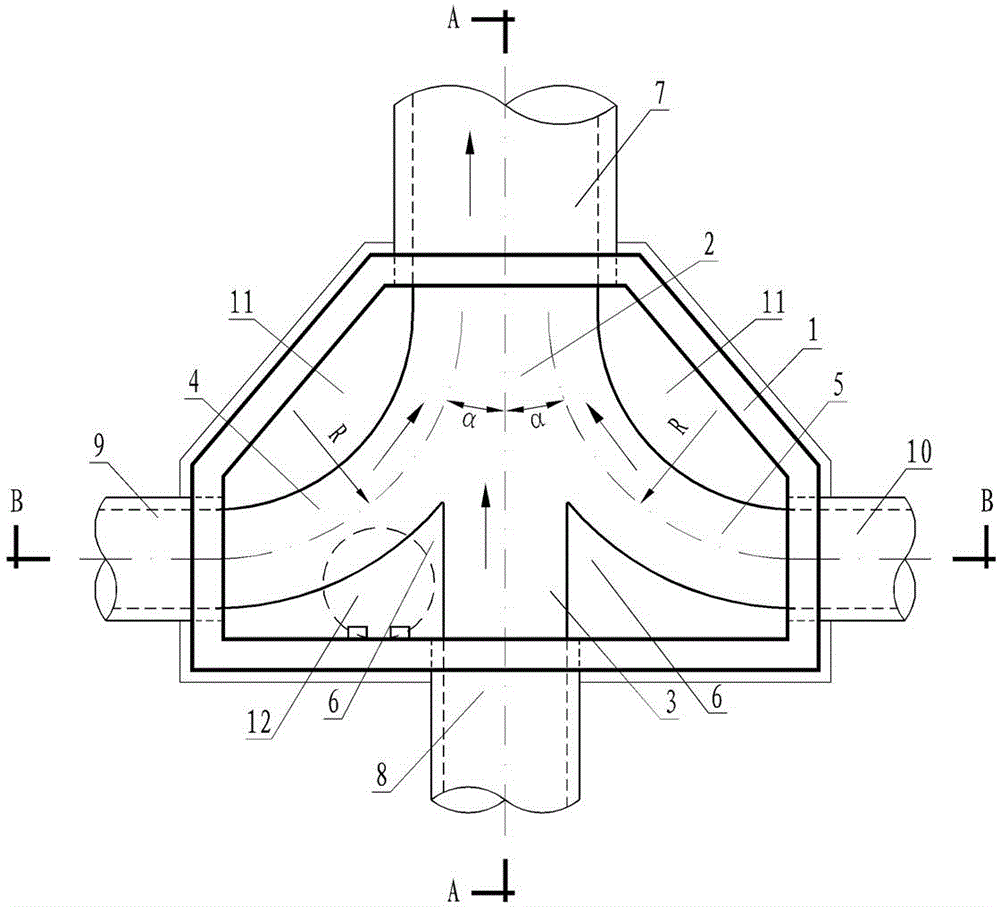

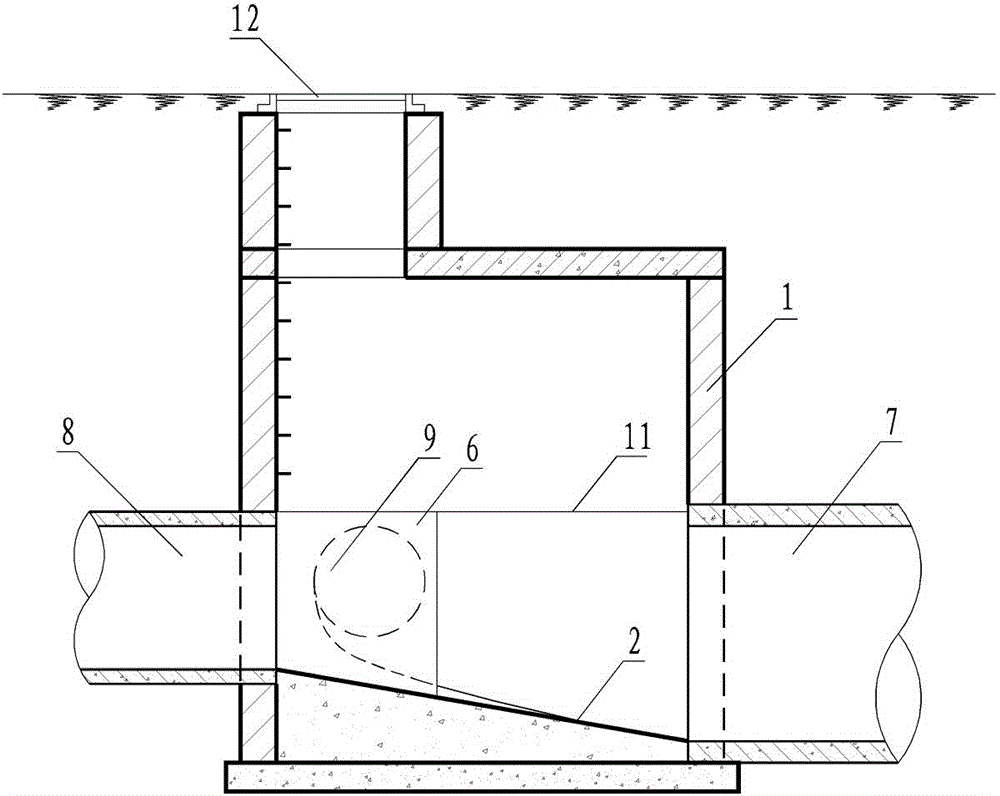

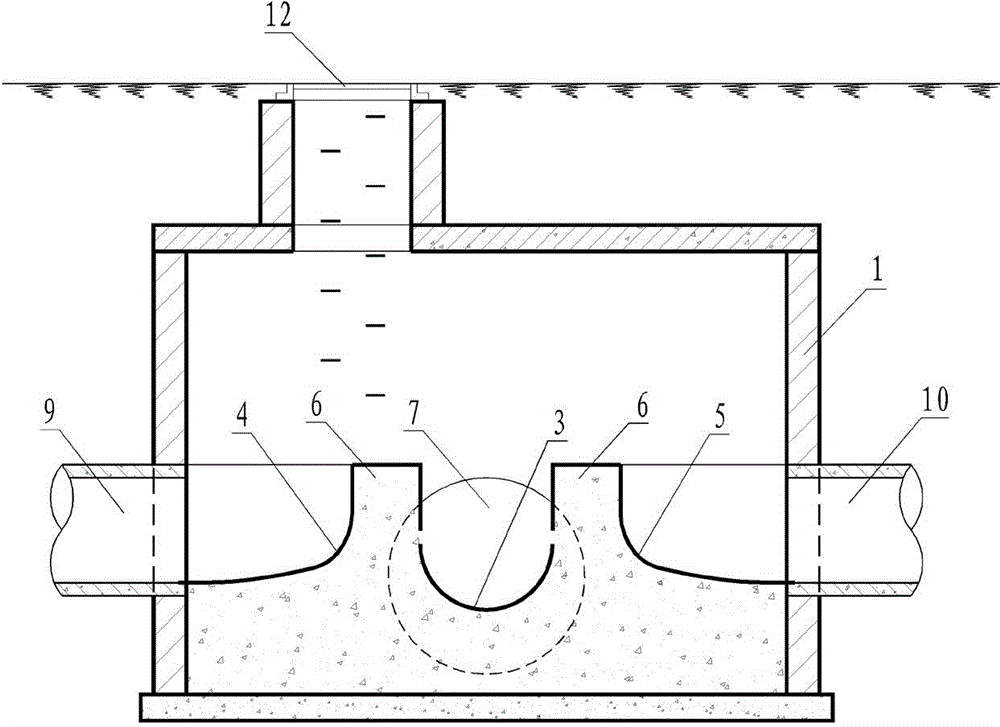

[0016] Embodiment 1: For the plan view of the masonry type four-way inspection well, see figure 1 According to the pipe diameters of the downstream pipe 7, the upstream pipe 8, the left branch pipe 9, and the right branch pipe 10, as well as the angle α between the branch pipes and the radius R, the dimensions of each part are determined. Connected, that is, the inner top of the water inlet and outlet pipes are the same height. Increasing the included angle α can reduce the size of the inspection well, but the water flow conditions will become worse. figure 1 The included angle α in is 20°. The well body 1 is built with bricks, and the distance between the knuckles of the well body 1 at the downstream pipe 7, the left branch pipe 9, and the right branch pipe 10 and the inner diameter of the pipe should be ≥ 150mm. Isolation platform 6 and workbench 11 are poured with formwork concrete, and the catchment trough 2, upstream trough 3, left trough 4, and right trough 5 should be...

Embodiment 2

[0017] Embodiment 2: In addition to the masonry type, the drainage four-way inspection well to prevent water flow hedging can also make the launder into plastic pipe fittings. The catchment launder 2 can be replaced by launder pipe fittings 21, which are arranged in the well body 1, and the upstream flow Groove 3, left trough 4, and right trough 5 can be replaced by upstream straight pipe 31, left curved pipe 41, and right curved pipe 51 respectively, which are arranged outside the well body 1 and correspond to the launder pipe fittings 21 respectively. The interface is connected, and the size of the well body 1 can be greatly reduced. The branch pipes on both sides and the upstream main pipe are separated by pipe fittings and flow into the inspection well at a small angle. The water flow condition is good, the well body size is relatively small, and the construction is convenient. For the plan view of the pipe-fitting four-way inspection well, see Figure 4 , the side branch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com