Heat insulation board anchoring part and external wall heat insulation system construction technology adopting same

A technology for plate anchors and construction technology, which is used in thermal insulation, building components, construction, etc., can solve problems such as affecting the flatness of the wall, falling off the thermal insulation board and the adhesive, affecting the expansion and deformation of the thermal insulation board, etc. and anchoring quality, shorten the construction period, and ensure the effect of anchoring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

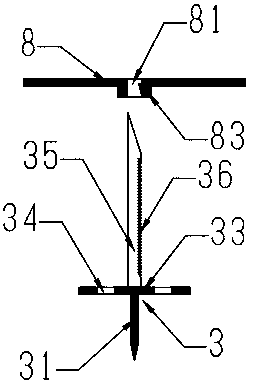

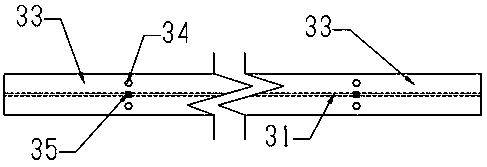

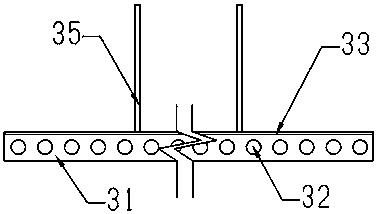

[0029] Such as Figure 1-Figure 5 As shown, the insulation board anchor provided in this embodiment includes an anchor strip 3 and a plurality of chucks 8 detachably connected to the anchor strip; the anchor strip 3 includes strip-shaped wing plates 33 and respectively On the one-way cassette 35 and the web 31 on the upper end surface and the lower end surface of the wing plate 33, the one-way cassette 35 is provided with multiple, and arranged at intervals, and the central points of all the one-way cassettes 35 are all on the same straight line. A chuck 8 is sheathed on each one-way cassette 35; the web 31 is arranged along the length direction of the wing 33, and the length of the web 31 is equal to the length of the wing 33, and is positioned at the middle of the wing 33, and The lower end of the web 31 is wedge-shaped or triangular, and a plurality of through holes 32 are evenly distributed on the web 31 , and the through holes 32 are equidistantly arranged and distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com