Heat-radiating base plate and heat sink using the same

a technology of heat-radiating base plate and heat-sink, which is applied in the direction of lighting and heating apparatus, tubular elements, semiconductor devices, etc., can solve the problems of base b>11/b> being usually overweight, and the error in size, so as to achieve a less copper material and enhanced heat-dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

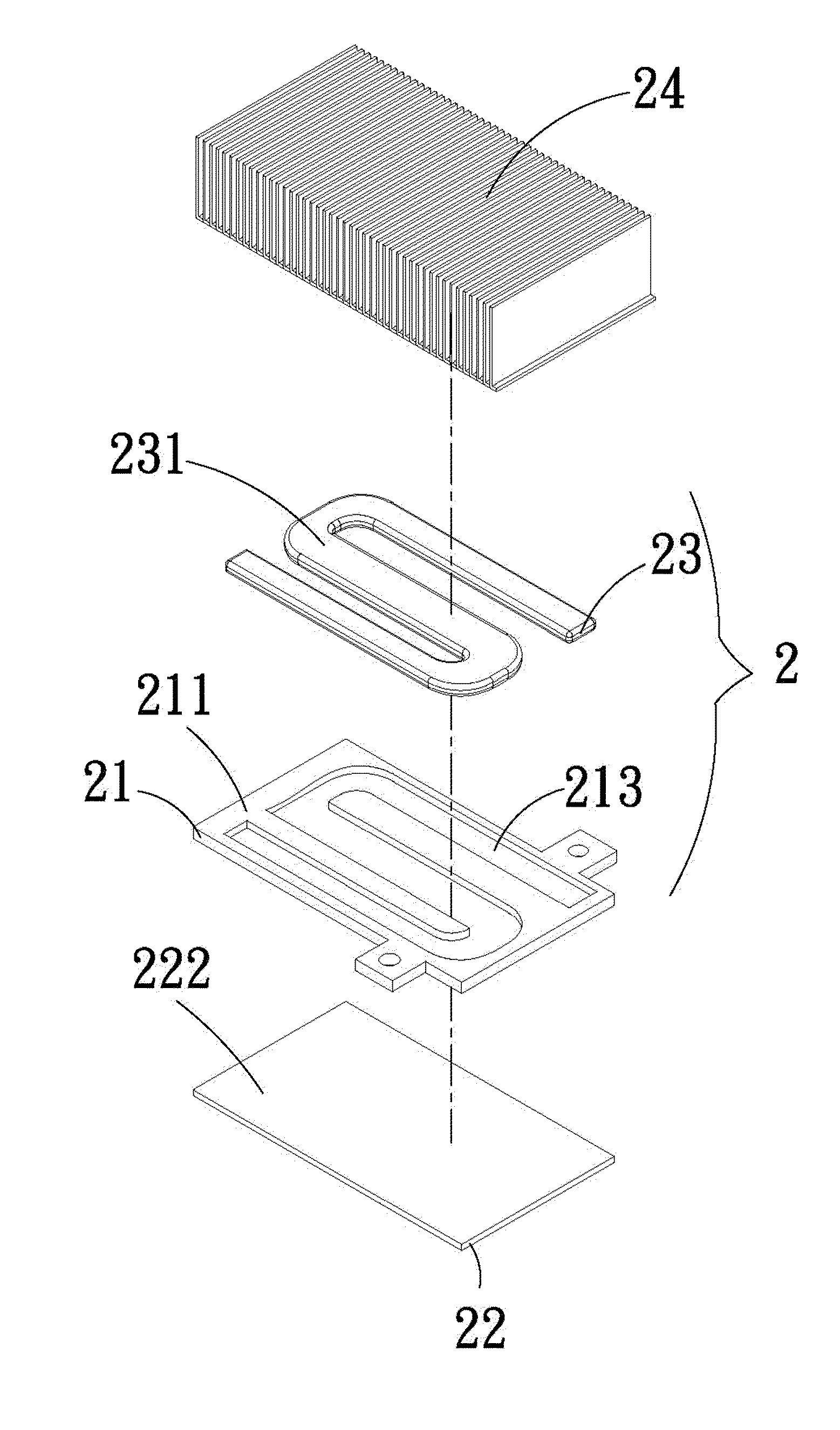

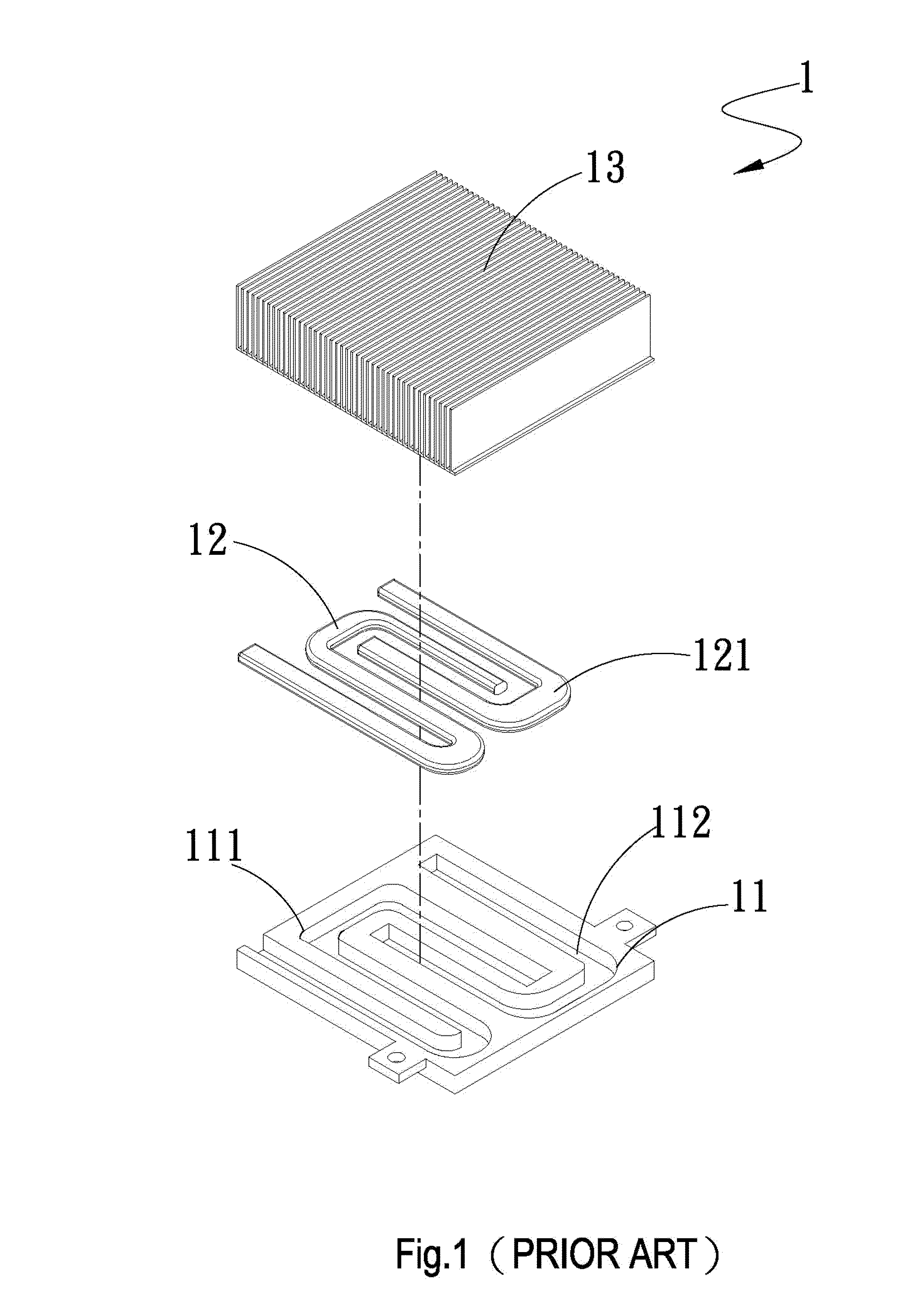

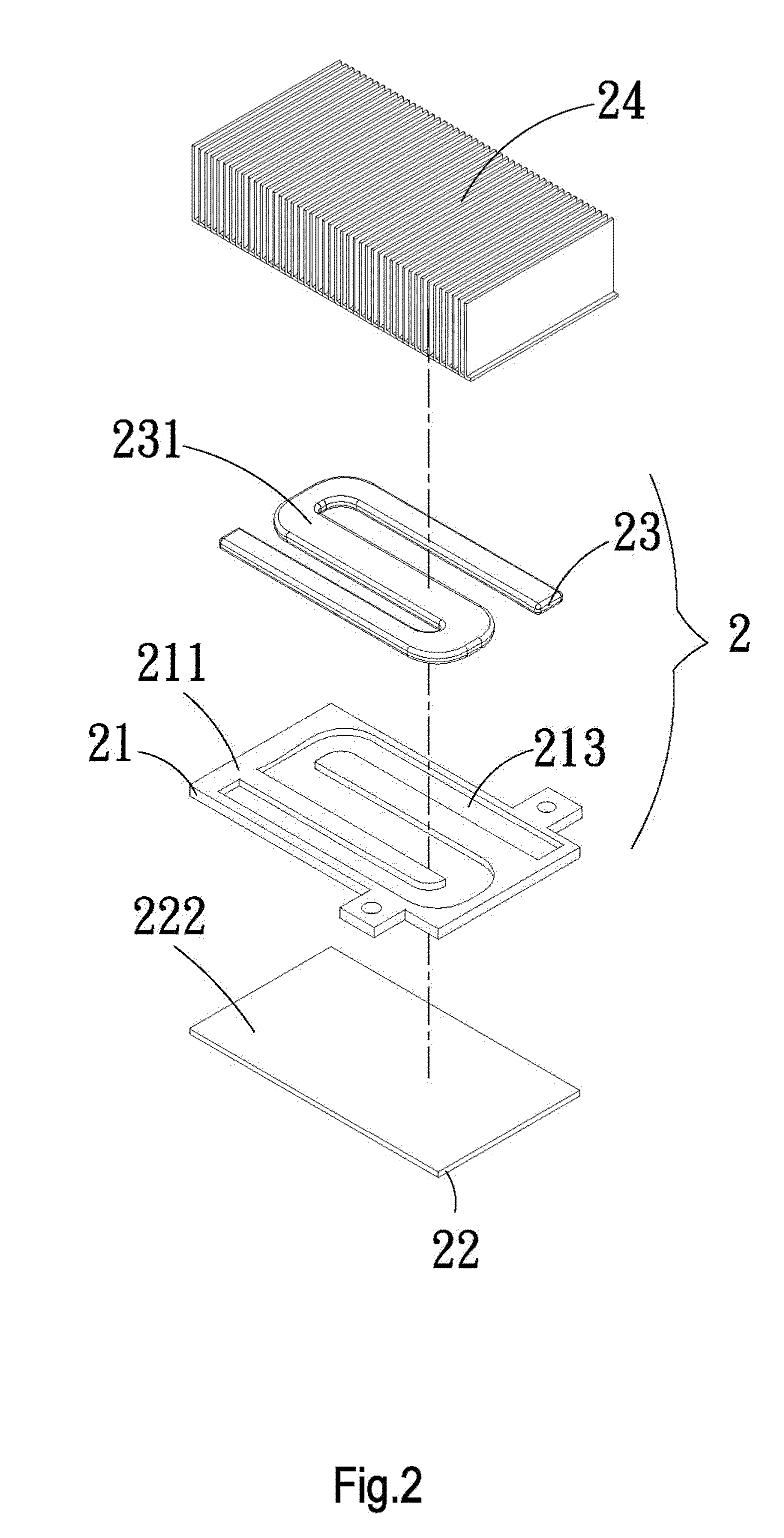

[0019]Please refer to FIGS. 2, 3 and 4. A heat-radiating base plate 2 according to a preferred embodiment of the present invention includes an upper base plate 21, a lower base plate 22, and a heat pipe unit 23. The upper base plate 21 has a first face 211, a second face 212 opposite to the first face 211, and a slotted pattern 213. The slotted pattern 213 is extended through the upper base plate 21 in a thickness direction to communicate the first face 211 with the second face 212. The upper base plate 21 can be made of an aluminum material. The heat pipe unit 23 is set in the slotted pattern 213. The heat pipe unit 23 includes at least one heat pipe, which is set in the slotted pattern 213. The heat pipe unit 23 has a thickness equal to a depth of the slotted pattern 213, and has a flat first heat-conducting face 231 and a flat second heat-conducting face 232 corresponding to and flush with the first face 211 and the second face 212 of the upper base plate 21, respectively. The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com