Once cold extrusion shaping method of automobile power steering gear jacketed screw and its multiple key and oil distributing groove

A power steering gear and screw technology, applied in steering gear, steering mechanism, fluid steering mechanism, etc., can solve the problems of repositioning in the circumferential direction, affecting production efficiency, and many processing procedures, so as to ensure relative position accuracy and dimensional accuracy, The effect of improving production efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

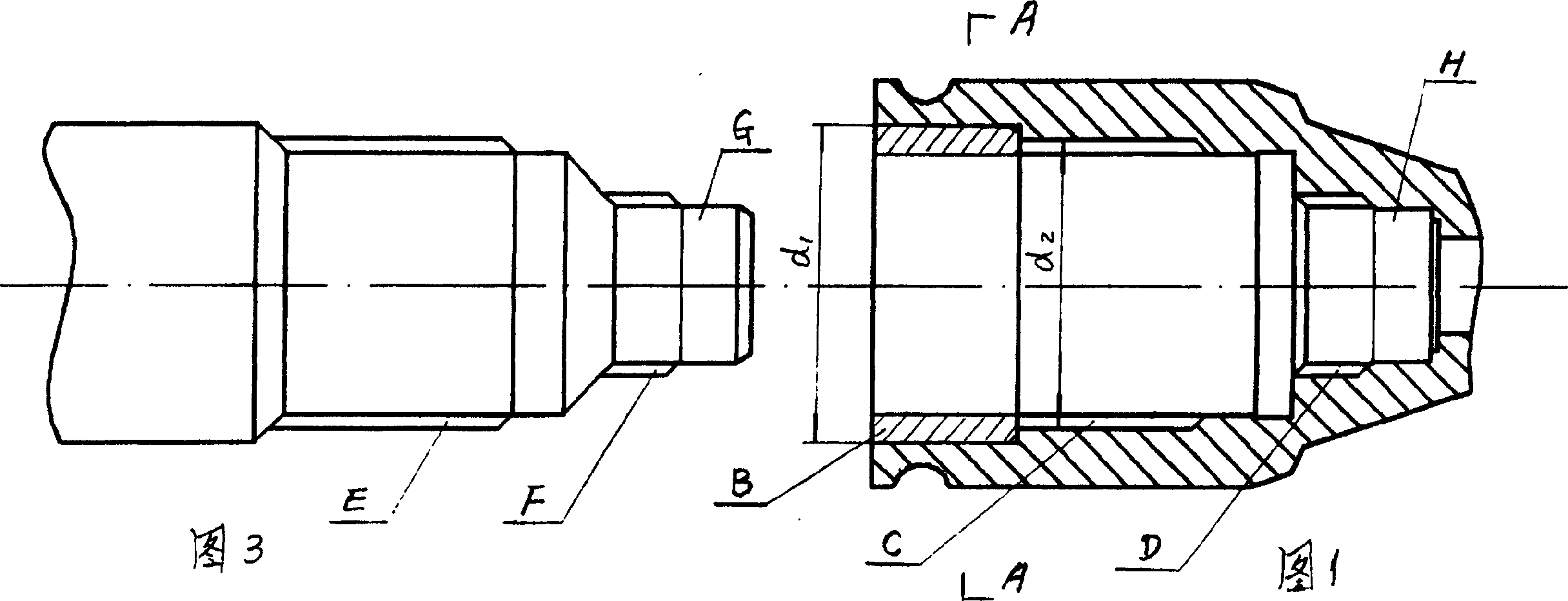

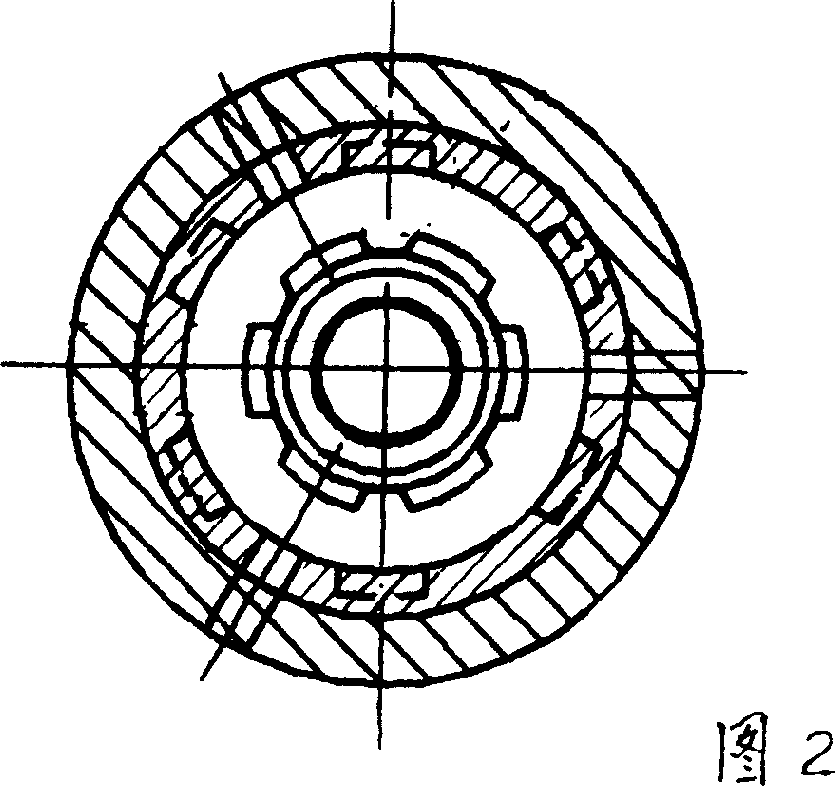

[0011] As shown in Figure 1 and Figure 2, a steel sleeve B is embedded in the upper end of the screw, the upper end surface of the steel sleeve B is ground together with the upper end surface of the screw rod, the lower end surface is flush with the upper end of the oil tank C, the inner diameter is equal to the diameter of the top circle of the oil tank C, and the outer diameter d 1 Greater than the root circle diameter d of the oil tank C 2 2-4mm, press fit is used between the steel sleeve B and the screw hole.

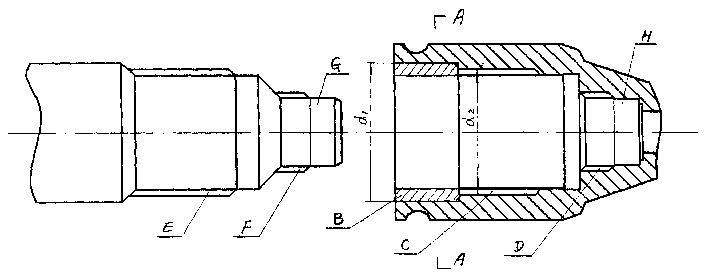

[0012] As shown in Figure 1 and Figure 3, the punch has extrusion teeth E and F for extrusion oil groove C and extrusion spline D on the position opposite to the spline and oil groove. The parts are processed on the press, and when the punch enters the screw, the oil groove C and the spline D are squeezed out at the same time. The cylindrical part G at the lower end of the punch enters the screw bearing hole H to play a guiding role during the extrusion process. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com