cooktop burner

A burner and cooker technology, applied in the direction of burner, gas fuel burner, combustion type, etc., can solve the problem of unstable combustion state at the fire hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be more clearly and completely described below by way of a preferred embodiment with reference to the accompanying drawings, but the present invention is not limited to the scope of the described embodiment.

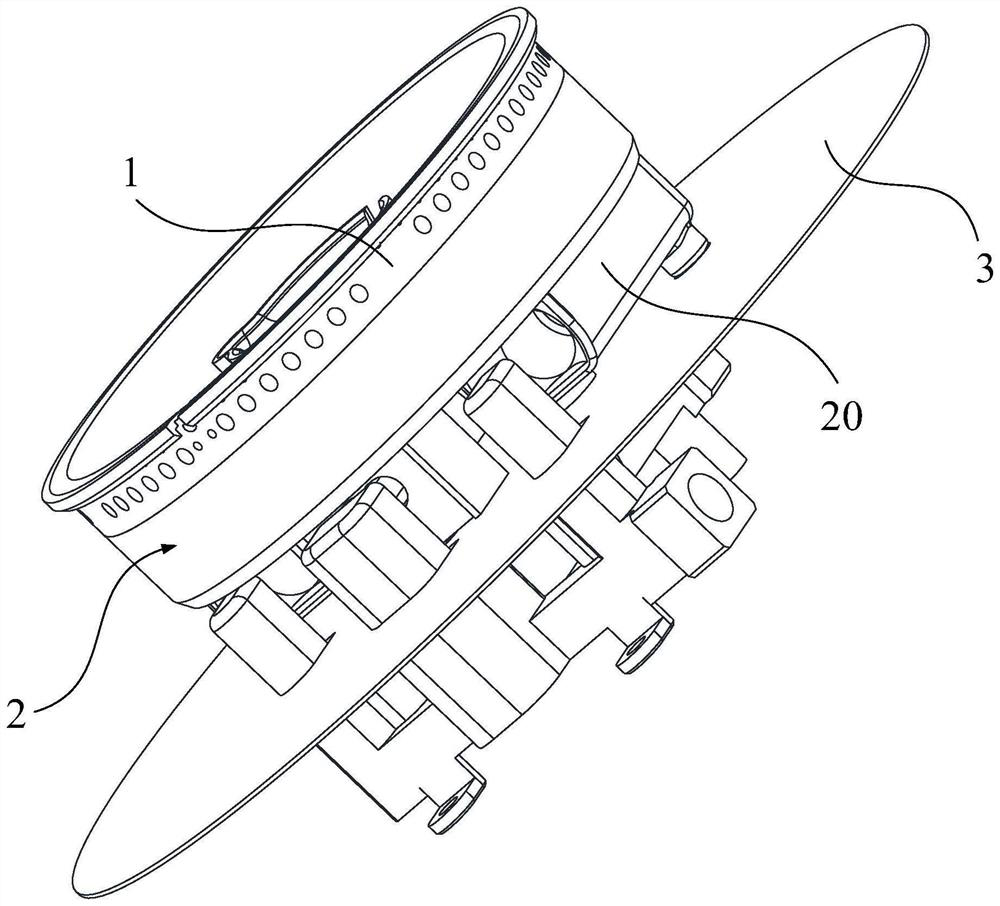

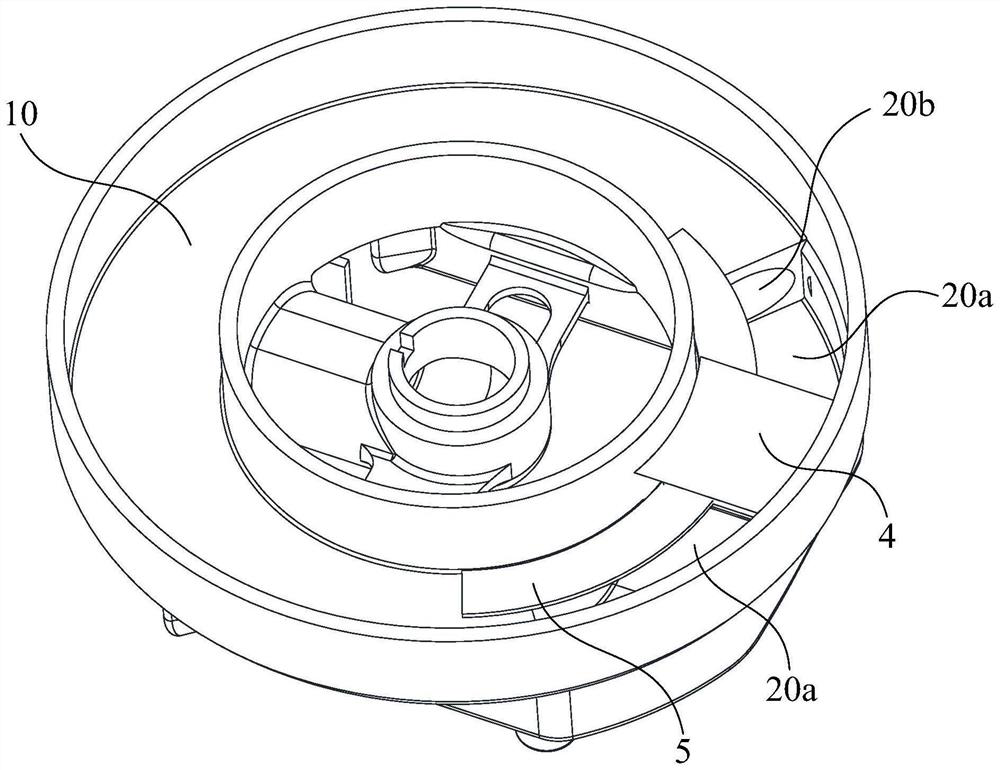

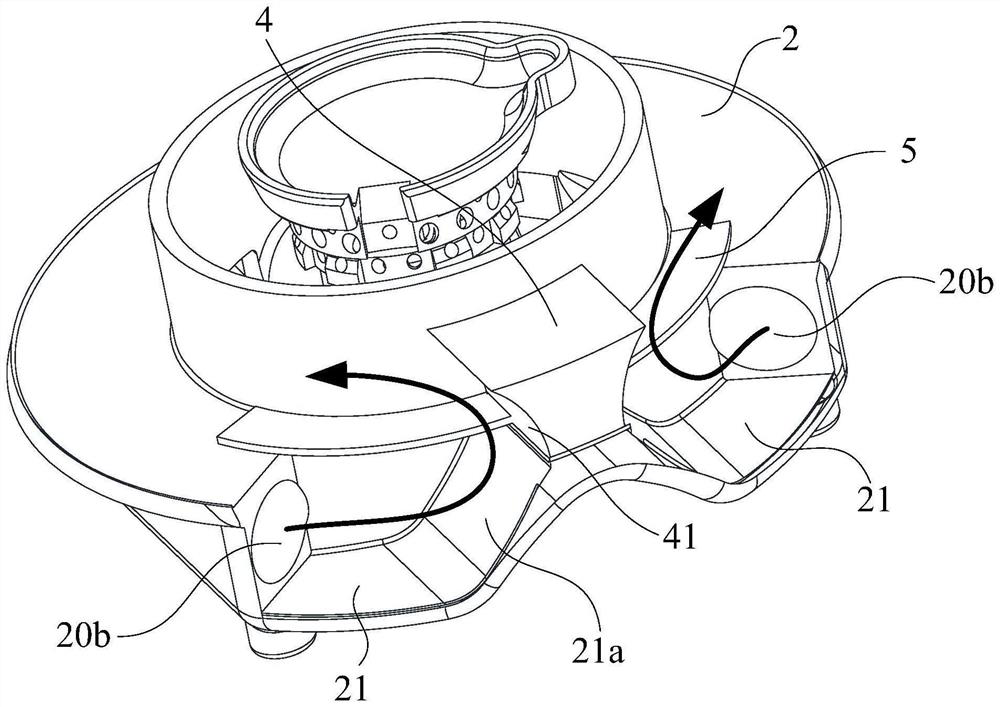

[0047] Such as Figure 1-5As shown, this embodiment provides a cooker burner, which includes an outer ring fire cover 1, a base 2 and two outer ring injection tubes 20, and the outer ring fire cover 1, base 2 and outer ring injection tubes 20 are all provided Above the cooker top 3. The gas outlet ports 20a of the two outer ring injection pipes 20 are both connected to the outer ring gas mixing chamber 10 inside the outer ring fire cover 1, and the two gas outlet ports 20a are oppositely arranged. The outer ring fire cover 1 is set on the upper surface of the base 2 , and the two outer ring ejector tubes 20 are arranged in the base 2 and formed integrally with the base 2 . Of course, in other embodiments, the outer ring injection pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com