Rolling bearing test table and test method

A rolling bearing and test bench technology, which is applied in the direction of mechanical bearing testing, mechanical component testing, machine/structural component testing, etc., can solve the problem that bearings cannot carry out variable load tests, liquid hydrogen and oxygen media are dangerous, and load force measurement Inaccurate and other problems, to save test time and economic costs, solve the problem of applicability, and avoid safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

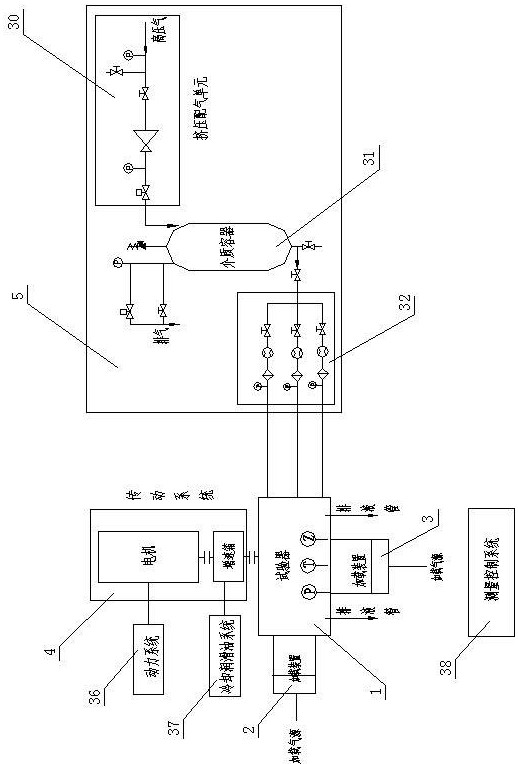

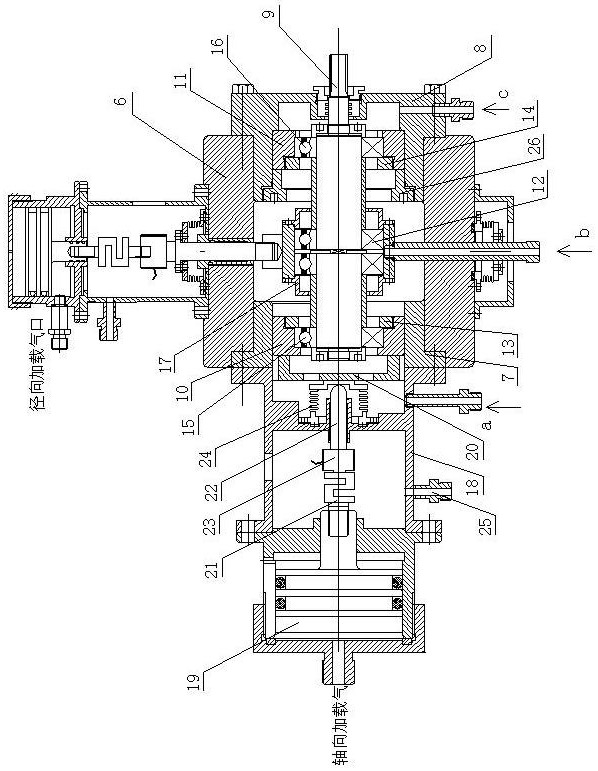

[0036] A rolling bearing test bench of the present invention is composed of a tester 1, a radial bearing loading device 2, an axial bearing loading device 3, a transmission system 4, a power dynamic system 36, a cooling lubricating oil system 37, a medium supply system 5, a measuring The control system 38 is composed. The tester 1 is a device for installing the tested bearing, on which pressure, temperature and vibration sensors are installed to measure the pressure and temperature in the tester and the vibration of the tester. There is a tester housing 6 in the tester. A rotating shaft system composed of the tested bearing, the process bearing 12 and the main shaft 9 is installed in the body, and a medium drain pipe is arranged on the top, such as figure 1 As shown; the radial bearing loading device 2 and the axial bearing loading device 3 provide radial load and axial load to the tested bearing to simulate the stressed state when the bearing is running; the output shaft of t...

Embodiment 2

[0053] A kind of rolling bearing test bench of the present invention, its low-temperature medium test procedure is as follows:

[0054] a. Preparation before the test: install the tested bearing and the process bearing on the main shaft of the tester, and adjust the coaxiality between the main shaft and the output shaft of the transmission system, and connect the two shafts with a coupling; seal the tester shell, Connect the inlet and outlet medium pipelines; connect the lubrication system pipeline to the motor of the transmission system or the oil point of the gearbox;

[0055] b. System blow-off stage: blow off the containers, piping systems, and valve systems in the medium supply system with dry compressed air or nitrogen;

[0056] c. Filling stage: fill the container with medium;

[0057] d. Pre-cooling stage of the tester: start the extrusion air distribution unit to pressurize the medium, adjust the flow of the medium through the valve on the medium supply pipeline, and...

Embodiment 3

[0062] A kind of rolling bearing test bench of the present invention, its normal temperature or high temperature oil medium test steps are as follows:

[0063] a. Preparation before the test: install the tested bearing and the process bearing on the main shaft of the tester, adjust the coaxiality between the main shaft and the output shaft of the transmission system, and connect the two shafts with a coupling; seal the tester shell, Connect the inlet and outlet medium pipelines; connect the lubrication system pipeline to the motor of the transmission system or the oil point of the gearbox;

[0064] b. Oil supply stage to the tester: start the lubricating oil pump, supply oil to each bearing of the tester through the oil medium supply adjustment device, and adjust the flow and pressure, and the return oil of the tester returns to the oil storage tank through the oil return pipe; if high temperature oil test is required , then preheat the oil in the oil storage tank to the requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com