Patents

Literature

38results about How to "Reduce oxidation burn rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Refining agent for smelting aluminum alloy

The invention relates to a refining agent for smelting an aluminum alloy. The refining agent is characterized by comprising the following components by mass percent: 35% to 45% of NaCl, 25% to 35% of KNO3, 3% to 8% of CaF2, 6% to 10% of Na2SiF6, 7% to 12% of Na3AlF6, 5% to 10% of graphite and 0.5% to 1.5% of rare earth. The refining agent has the characteristics of good refining effect, strong degassing capacity and the like, and cannot generate noxious gas during a production process.

Owner:COSCO W M J ALUMINUM DEV CO LTD

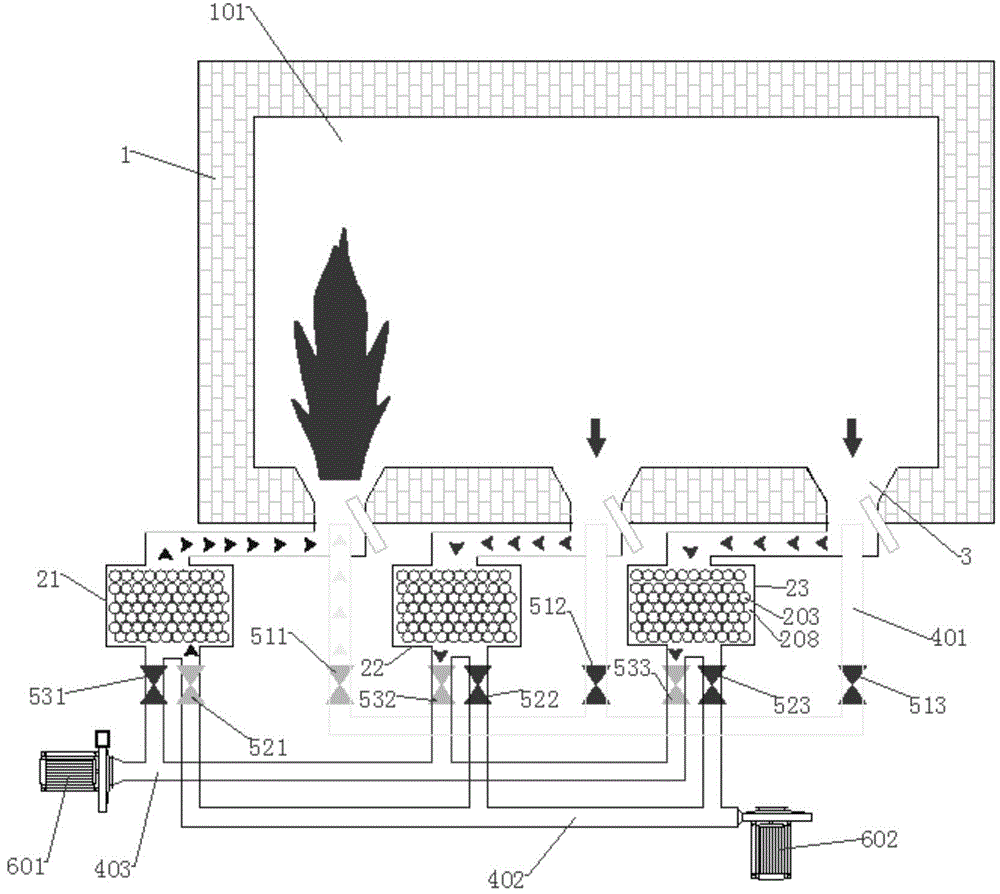

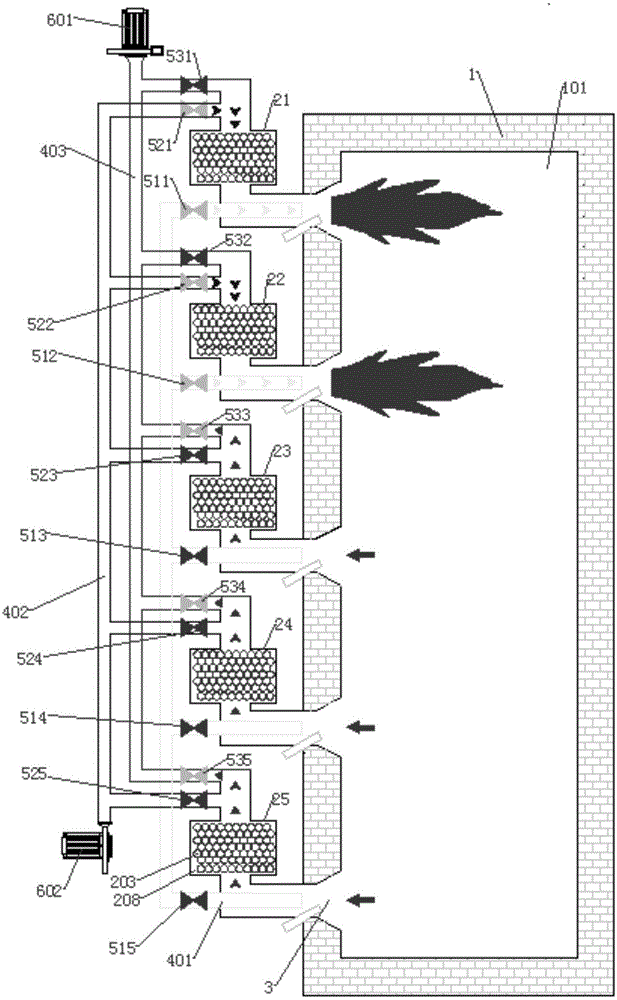

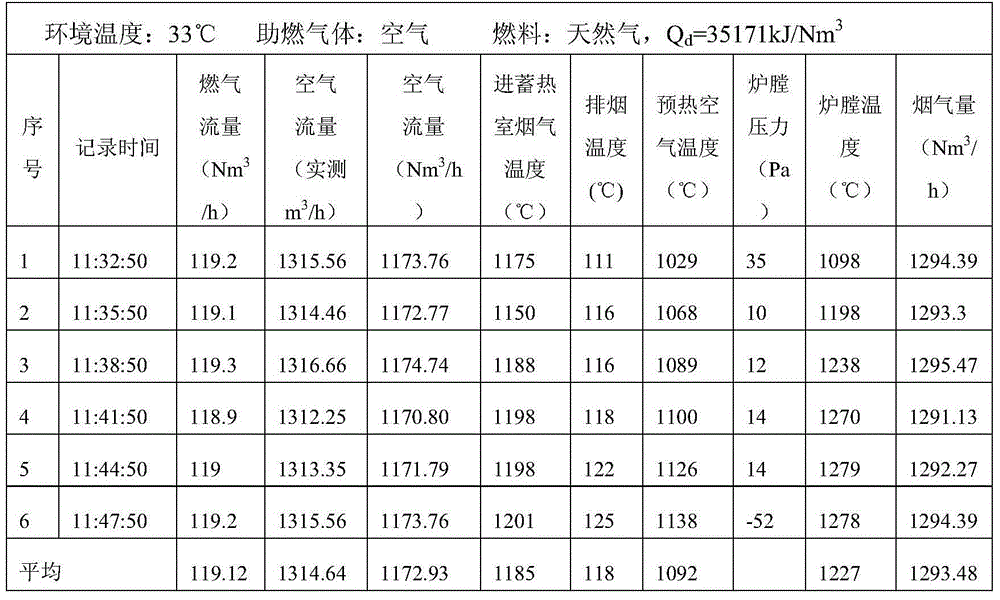

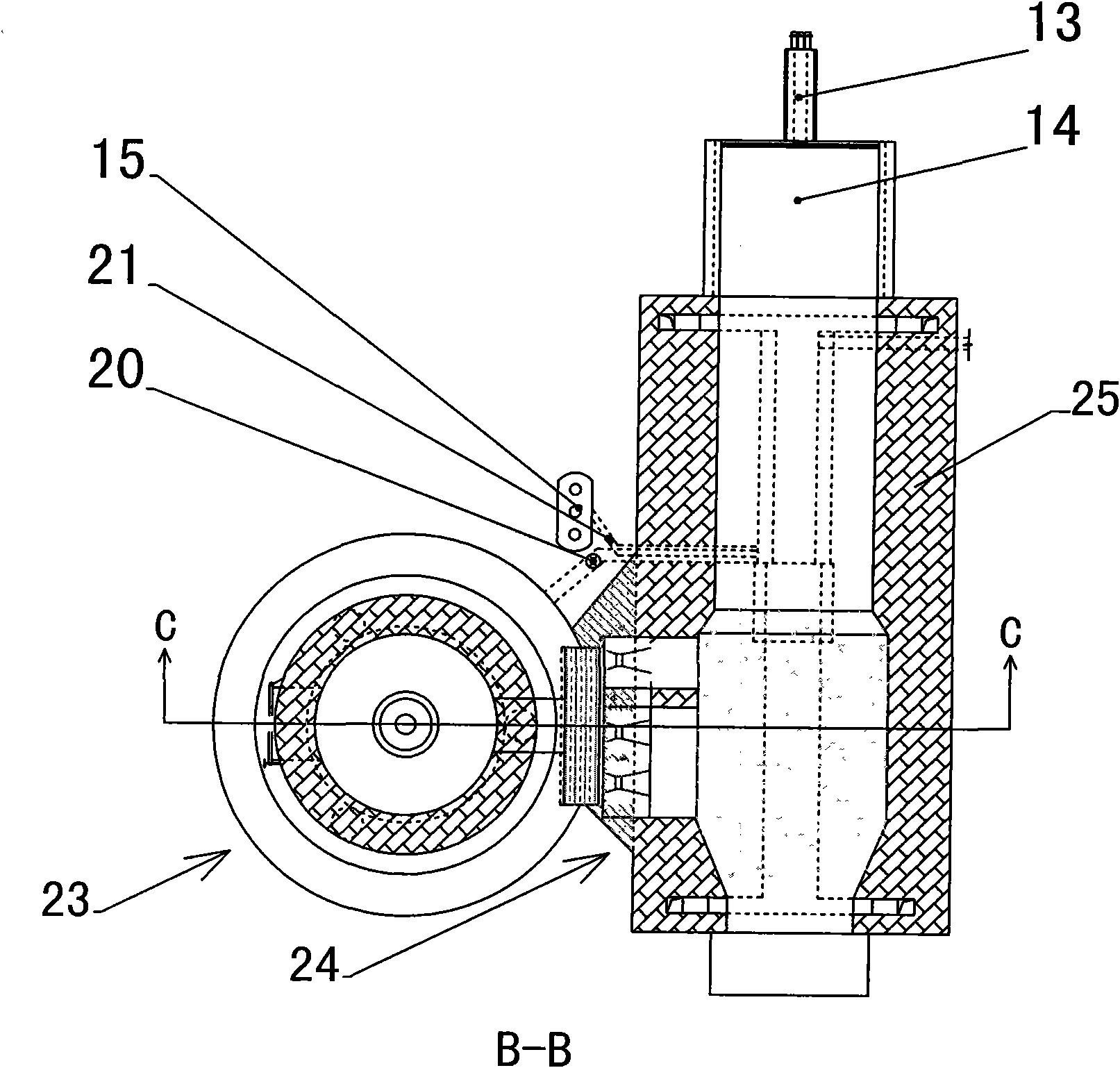

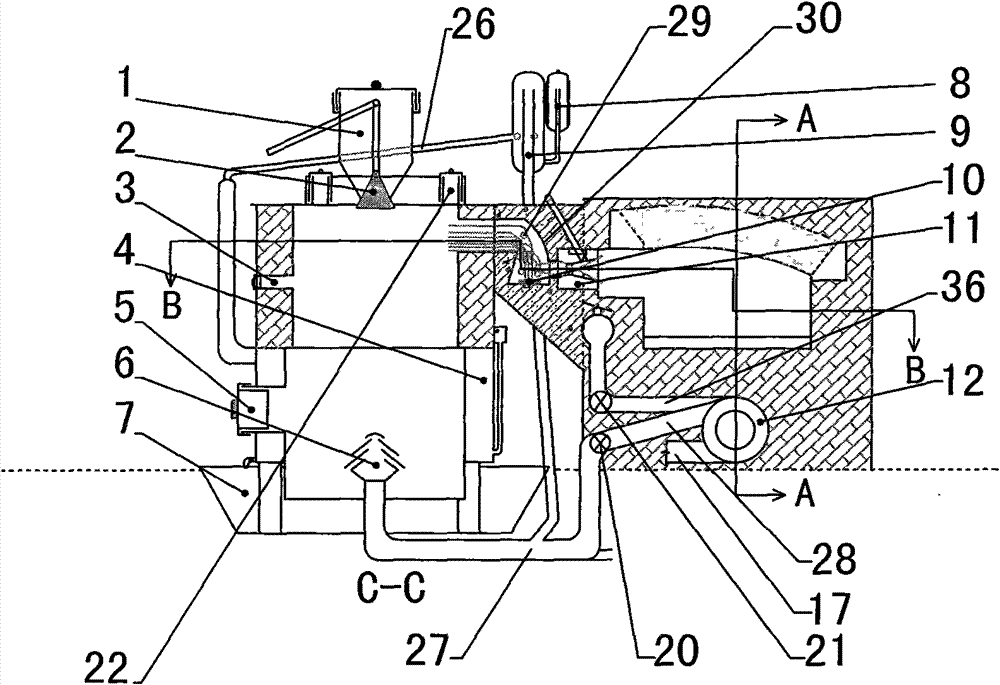

Regenerative combustion device

InactiveCN104457302ASmooth exhaustStable furnace pressureEnergy industryIndirect carbon-dioxide mitigationCombustorLow nitrogen

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

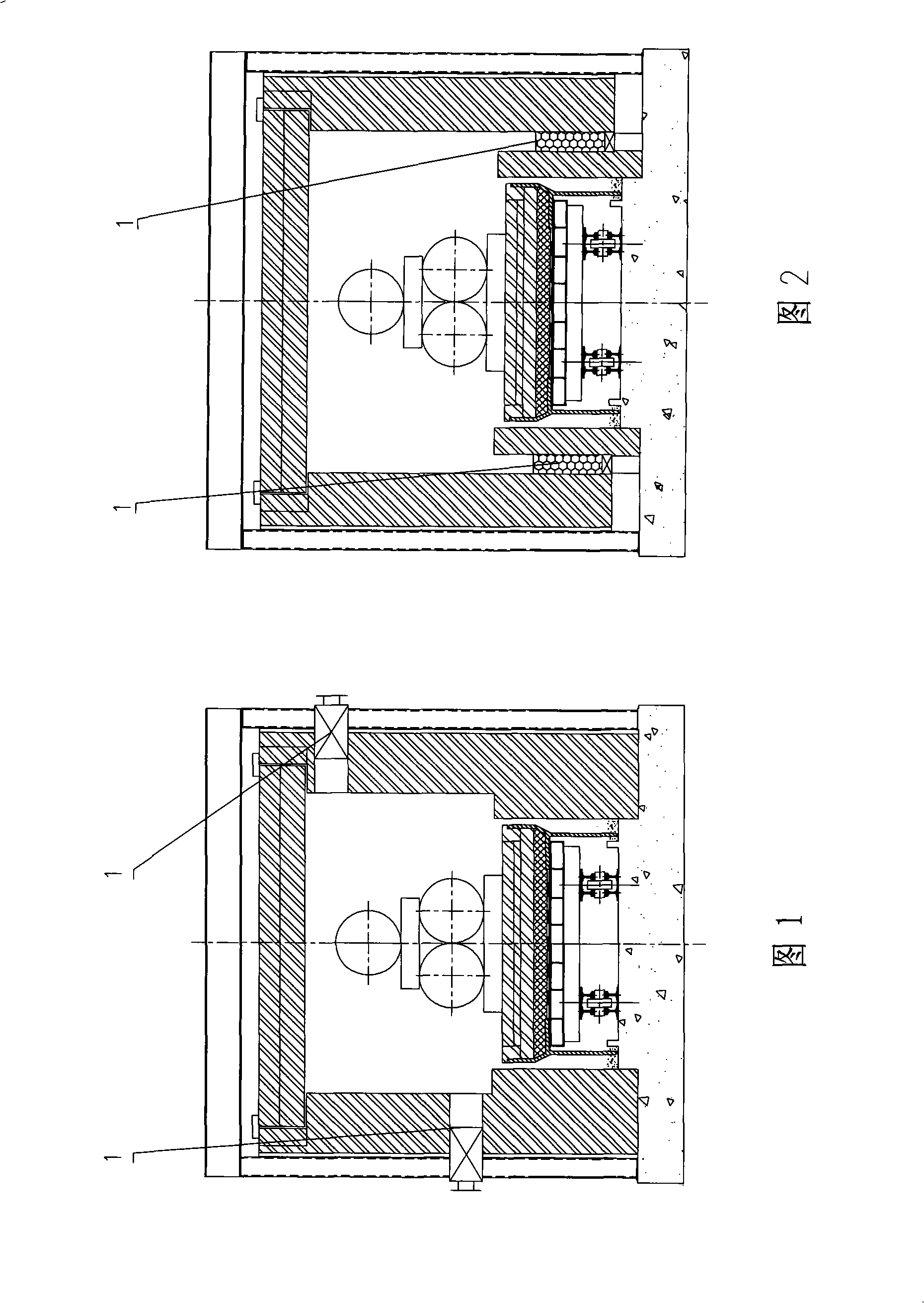

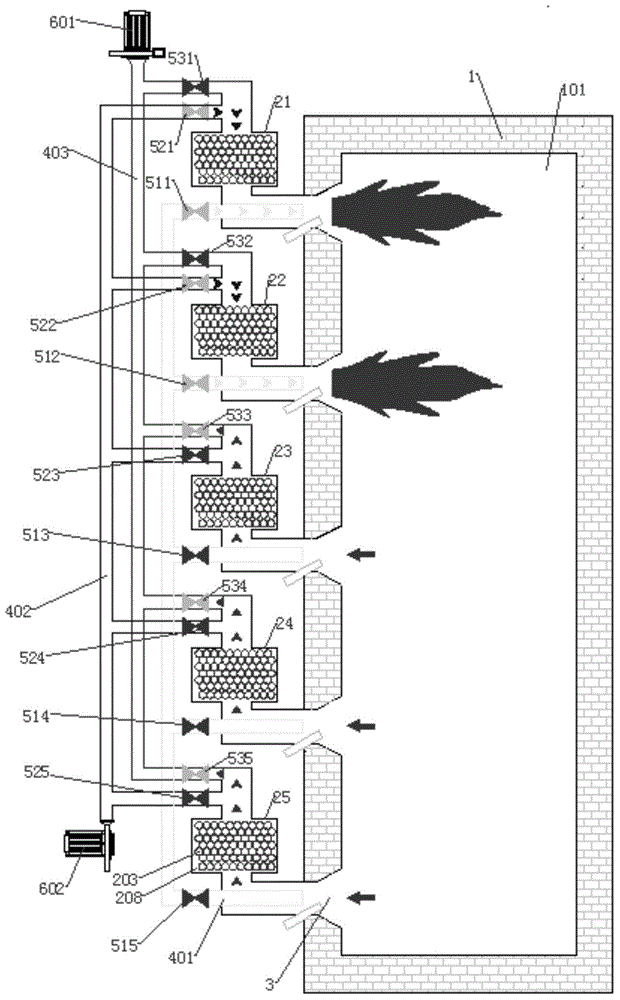

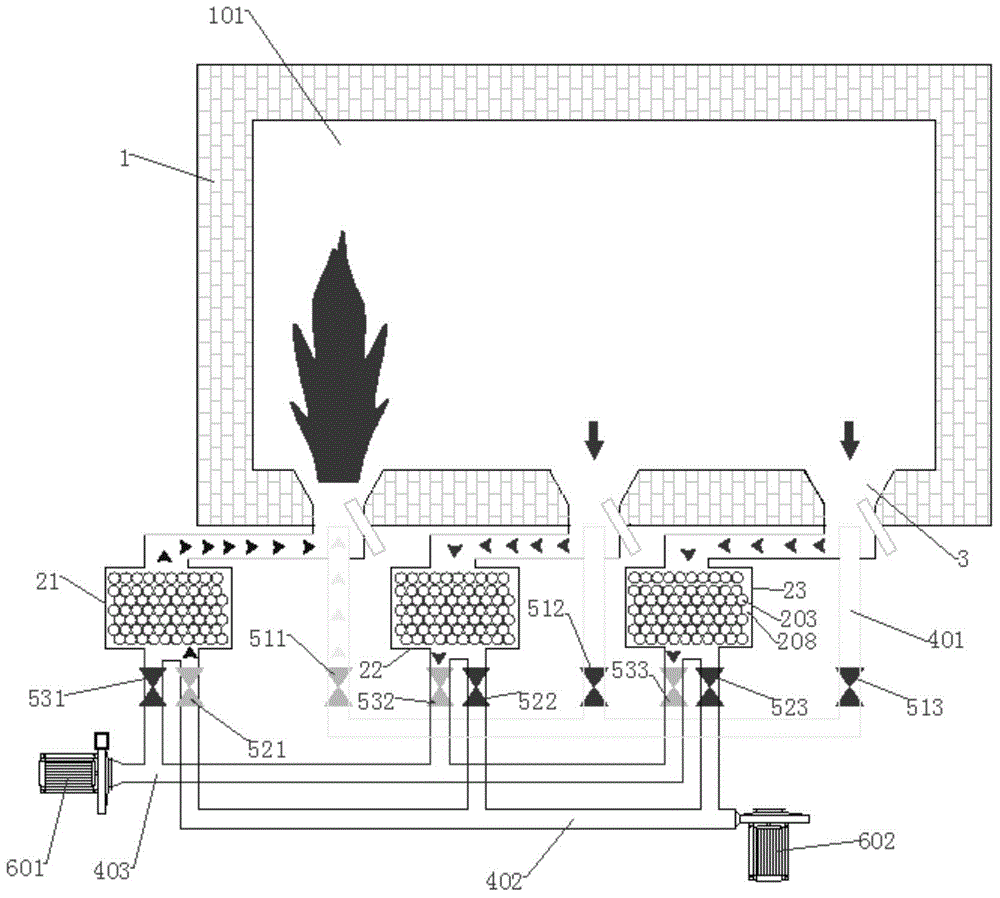

Cell-type car-type heating stove highly effective combustion system

InactiveCN101261089AImprove uniformitySolve easy blockageMechanical apparatusFurnace componentsFurnace temperatureHigh energy

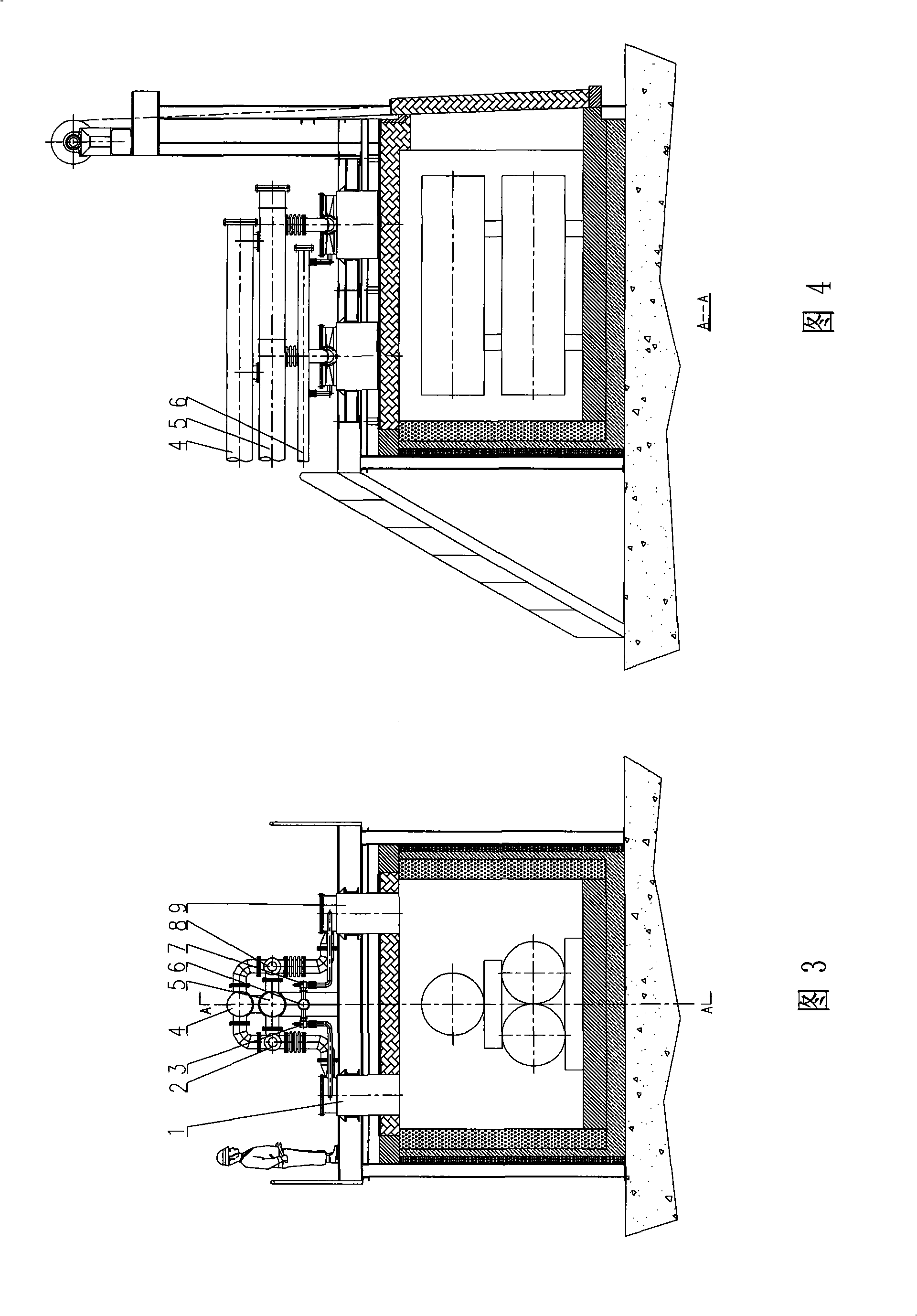

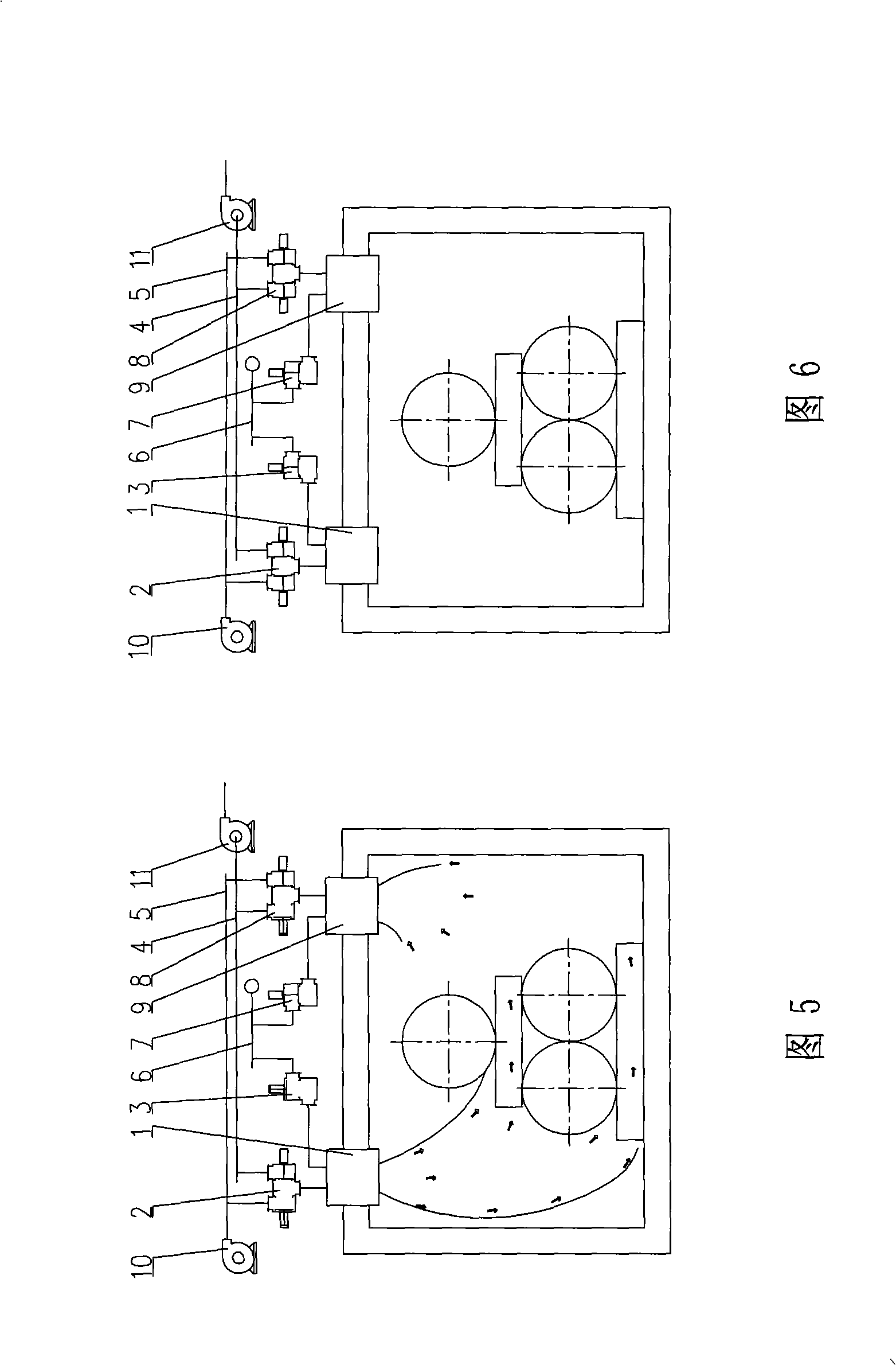

The invention relates to an efficient combustion system of a chamber and car bottom heating furnace, belonging to the energy-saving and environment-protecting heating furnace technique field. The invention comprises a plurality of pairs of heat accumulating left and right sides combustion nozzles which are arranged on the two sides of the furnace top of the heating furnace, wherein, the heat accumulating left side combustion nozzles are connected with a smoke pumping main and an air main through a left side reversing valve and are connected with a gas main through a left side gas quick-switch valve; the heat accumulating right side combustion nozzles are connected with the smoke pumping main and the air main through a right side reversing valve and are connected with the gas main through a right side gas quick-switch valve; the air main is connected with a combustion air fan; the smoke pumping main is connected with a smoking machine. The efficient combustion system forms the high kinetic energy U-shaped air steam inside the furnace, thereby improving the uniformity of the furnace temperature; all the flue gas generated by the combustion of half of the combustion nozzles of the whole furnace is discharged from the other half of the combustion nozzles, thereby abolishing the tail gas duct with high energy consumption and complicated structure of the prior chamber and car bottom heating furnace; the energy consumption is reduced by 40 to 60 percent and the furnace output and the blank heating quality are improved.

Owner:WUXI LONGSHAN TECH

Monitoring method of heating time and heating temperature of heating furnace

InactiveCN103045847APrevent increased oxidative burning lossAvoid oxidation burnFurnace typesHeat treatment process controlLoss rateHeating temperature

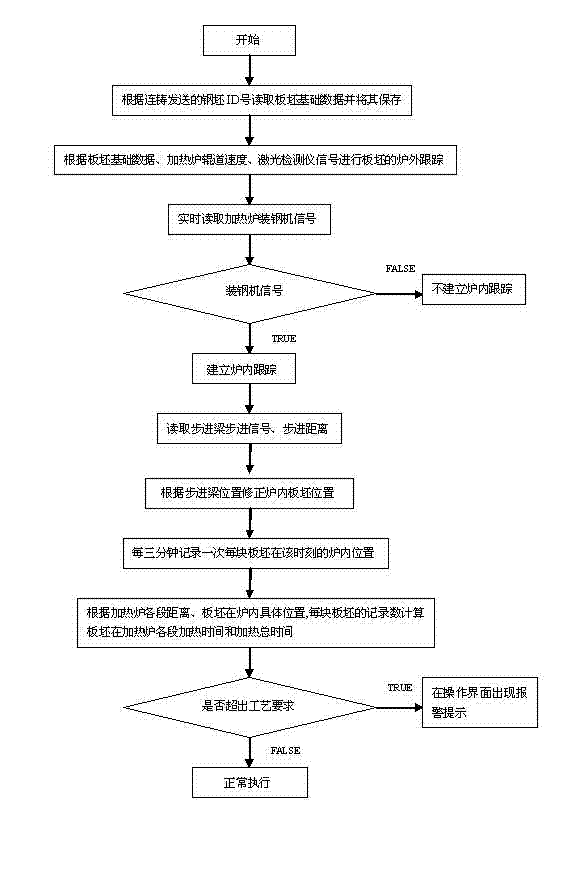

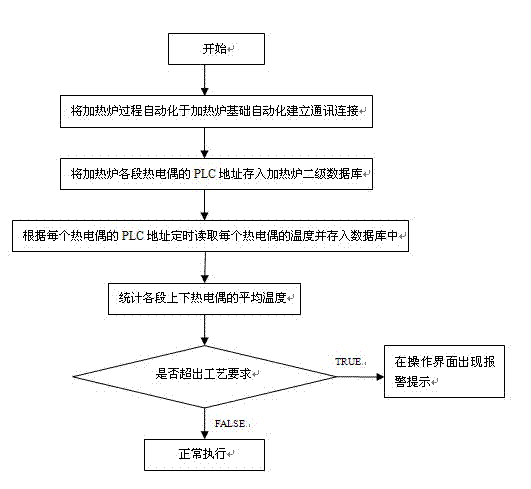

The invention relates to a monitoring method of the heating time and the heating temperature of a heating furnace on a hot rolling production line, and belongs to the field of automation of the metallurgical hot rolling production line. According to the technical scheme, the method comprises the following steps: reading steel billet ID (Identification) signals sent to PLC (Programmable Logic Controllers) at the first stage in the heating furnace continuously; establishing a tracking of steel billets in the furnace by tracking the positions of the steel billets on a roller bed outside the furnace; reading the position of each steel billet in the heating furnace every three minutes from a secondary database of the heating furnace and accumulating the reading results; calculating the heating time of the steel billets at each stage in the heating furnace; contrasting the heating time with a technological requirement and alarming if the heating time exceeds the time specified by the technological requirement; storing the PLC address of each thermocouple in the heating furnace in the secondary computer database of the heating furnace; reading an average value of the temperature at each stage in the heating furnace; and finally, contrasting the heating temperature with the technological requirement and alarming if the heating temperature exceeds the temperature specified by the technological requirement. With the adoption of the method provided by the invention, the occurrence of inferior-quality products caused by an incomplete phosphorus removal on the surface of strip steel due to the long heating time and the high heating temperature at each stage in the heating furnace is avoided; the oxidation burning loss rate is decreased; the yield is increased; the cost of the steel per ton is reduced; and therefore the economic benefit is improved.

Owner:TANGSHAN GUOFENG IRON & STEEL

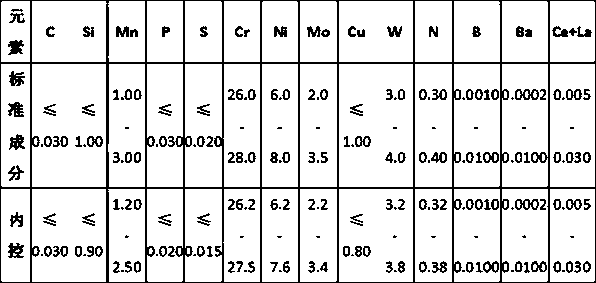

Super advanced double-phase stainless steel smelting process method of CD3MWN material

ActiveCN108823348AIncrease contentReduce precipitationProcess efficiency improvementHydrogenDouble phase

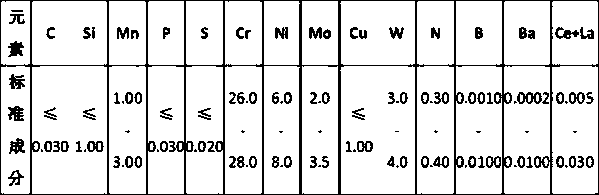

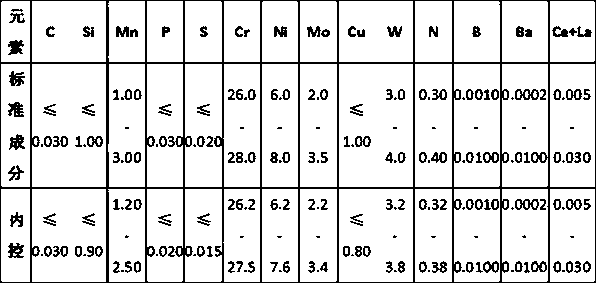

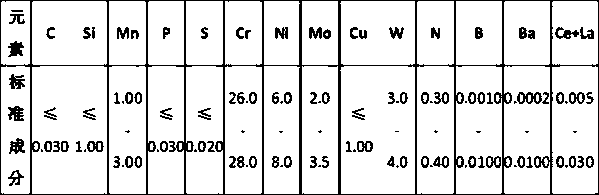

The invention relates to a super advanced double-phase stainless steel smelting process method of a CD3MWN material. According to the invention, internal control components during double-phase stainless steel smelting is designed, wherein C is less than or equal to 0.030 wt%, Si is less than or equal to 0.90 wt%, Mn is 1.20-2.50 wt%, P is less than or equal to 0.020 wt%, S is less than or equal to0.015 wt%, and Cr is 26.2-27.5 wt%, Ni is 6.2-7.6 wt%, Mo is 2.2-3.4 wt%, Cu is less than or equal to 0.80 wt%, W is less than or equal to 0.80 wt%, N is 0.32-0.38 wt%, B is 0.0010-0.0100 wt%, Ba is0.0002-0.0100 wt%, and Ce+La is 0.005- 0.030 wt%; and %Cr+3.3 (%Mo+0.5%W)+16%N is less than or equal to 45, the content of trace elements B, Ba, Ce, and La can be precisely controlled; the N content is increased to 0.30% or more, and at the same time, nitrogen holes in the casting can be avoided; and the content of harmful elements such as sulfur, oxygen, hydrogen and the like is minimized to improve the purity of the molten steel. The cast casting has high strength and excellent corrosion resistance. In the stainless steel, a ferrite phase and an austenite phase are close to 50%, the castinglife is prolonged. the production costs are greatly reduced, and purposes of energy saving and environmental protection can be realized.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

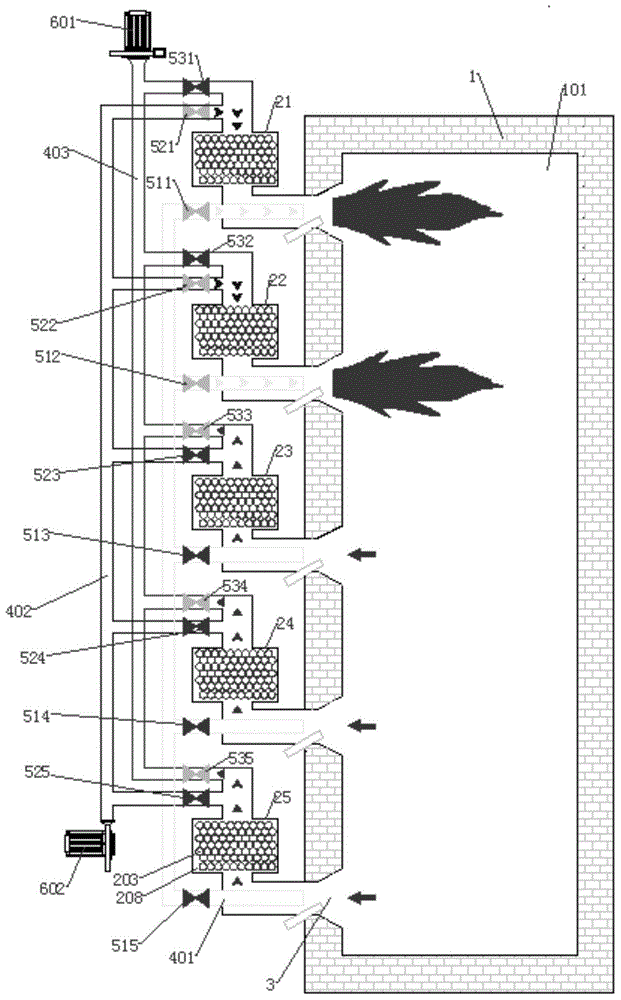

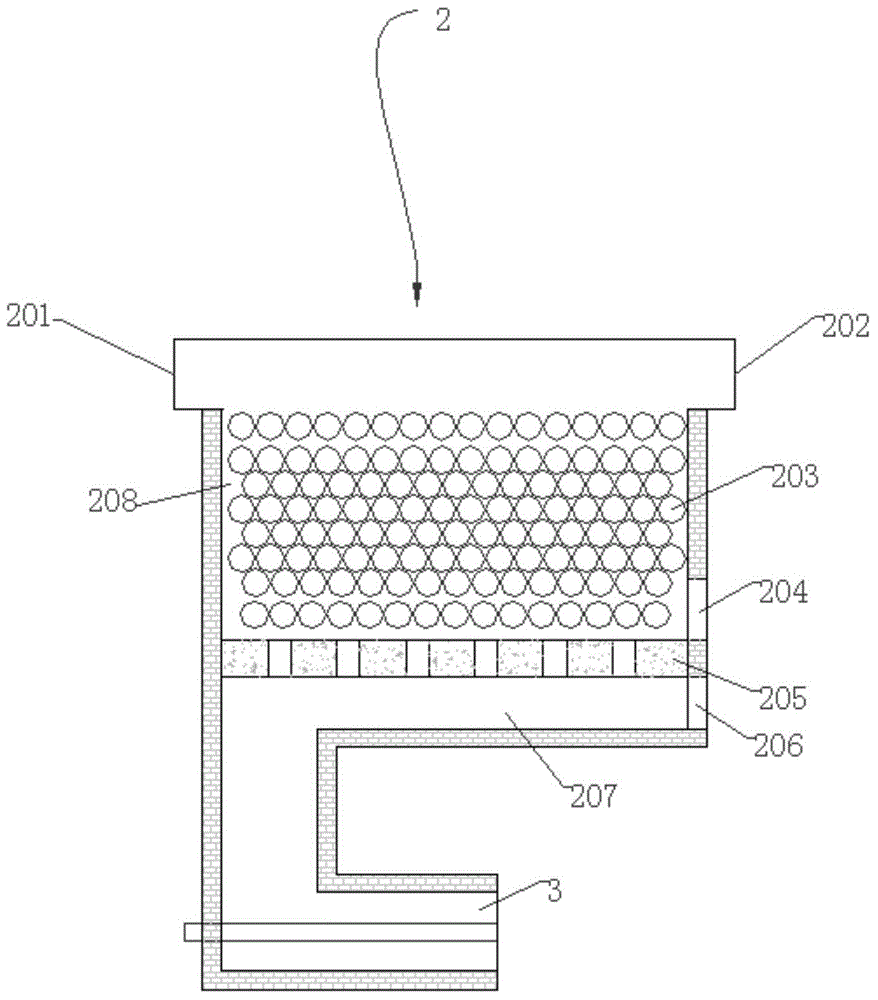

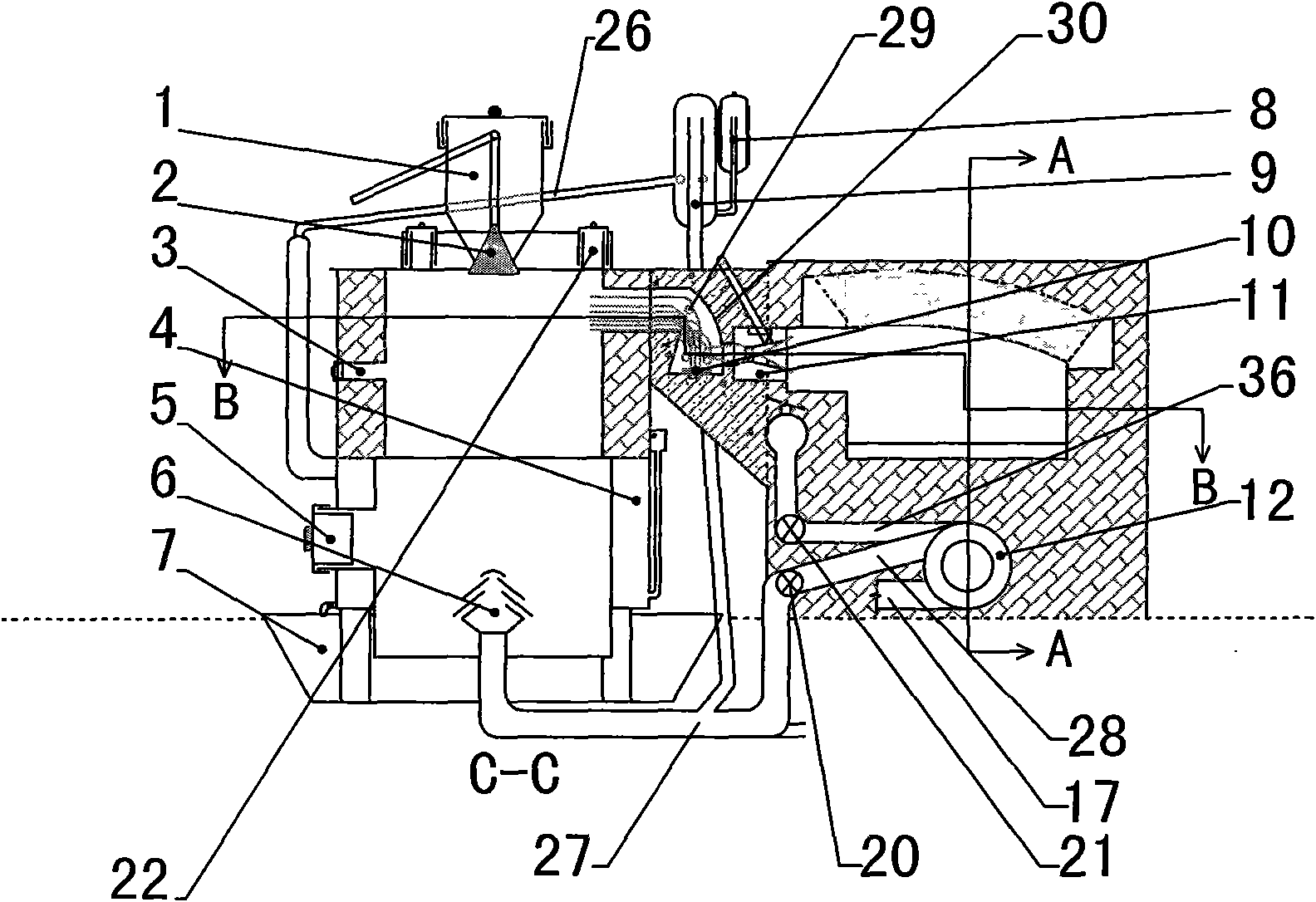

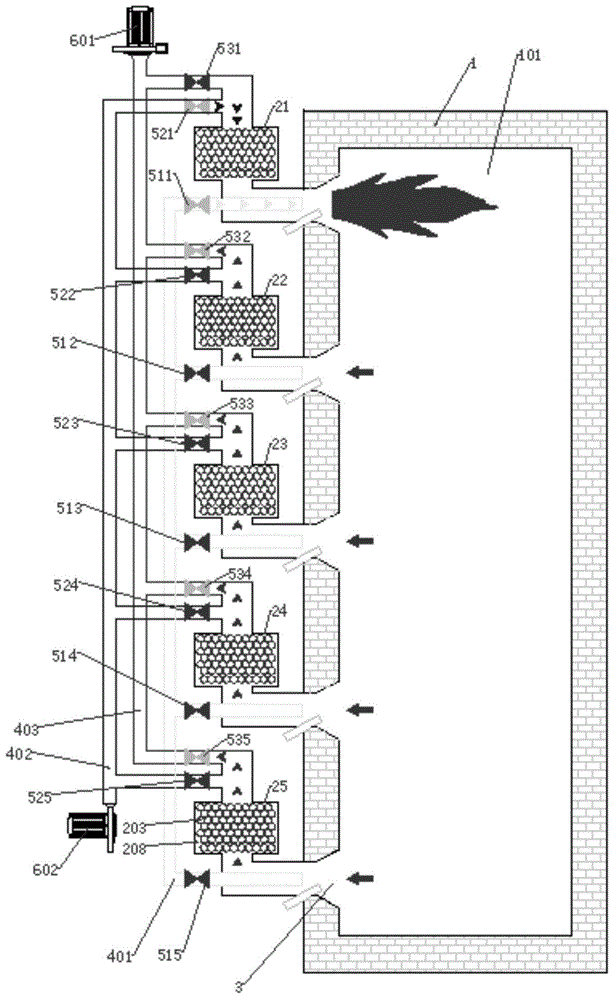

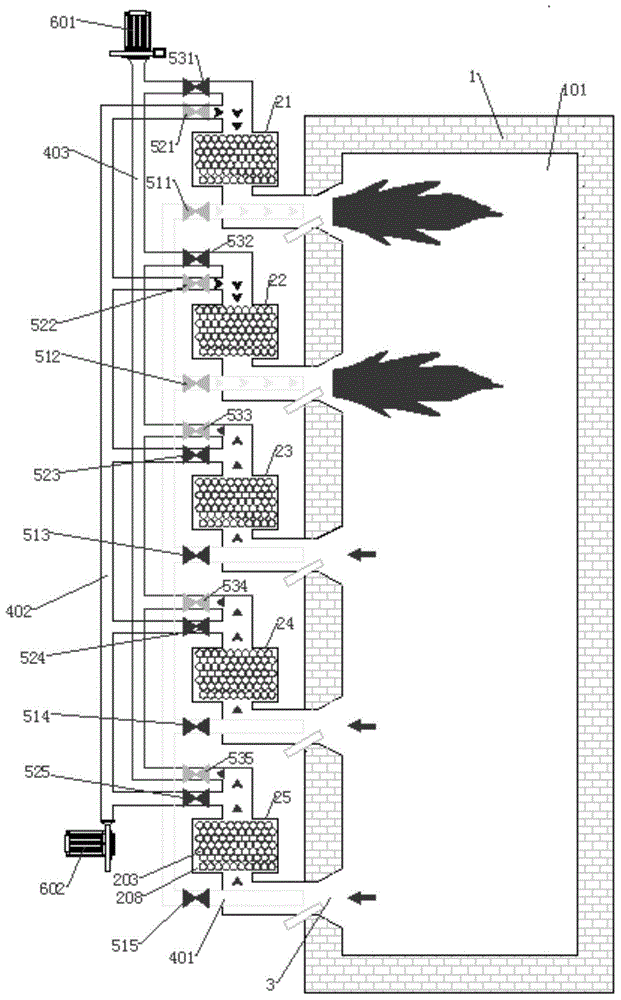

Progressive switchover heat storage type combustion device

InactiveCN104456569ADischarge in timeSmooth exhaustEnergy industryIndirect carbon-dioxide mitigationDetonationCombustor

The invention relates to a progressive switchover heat storage type combustion device. The progressive switchover heat storage type combustion device comprises at least five heat storage type combustors connected with a hearth and a controller capable of controlling the heat storage type combustors. The controller switches over the heat storage type combustors, so that the heat storage type combustors are alternately used for combustion or smoke exhaust, and the number of the heat storage type combustors used for smoke exhaust is made to be larger than that of the heat storage type combustors for combustion at any moment; in combustion production, when the controller switches over any heat storage type combustor, at least another heat storage type combustor maintains combustion work. Compared with the prior art, in the steering process of the device, the phenomena of detonation and furnace blast are effectively avoided, the safety performance is better, and the energy-saving effect is more obvious.

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

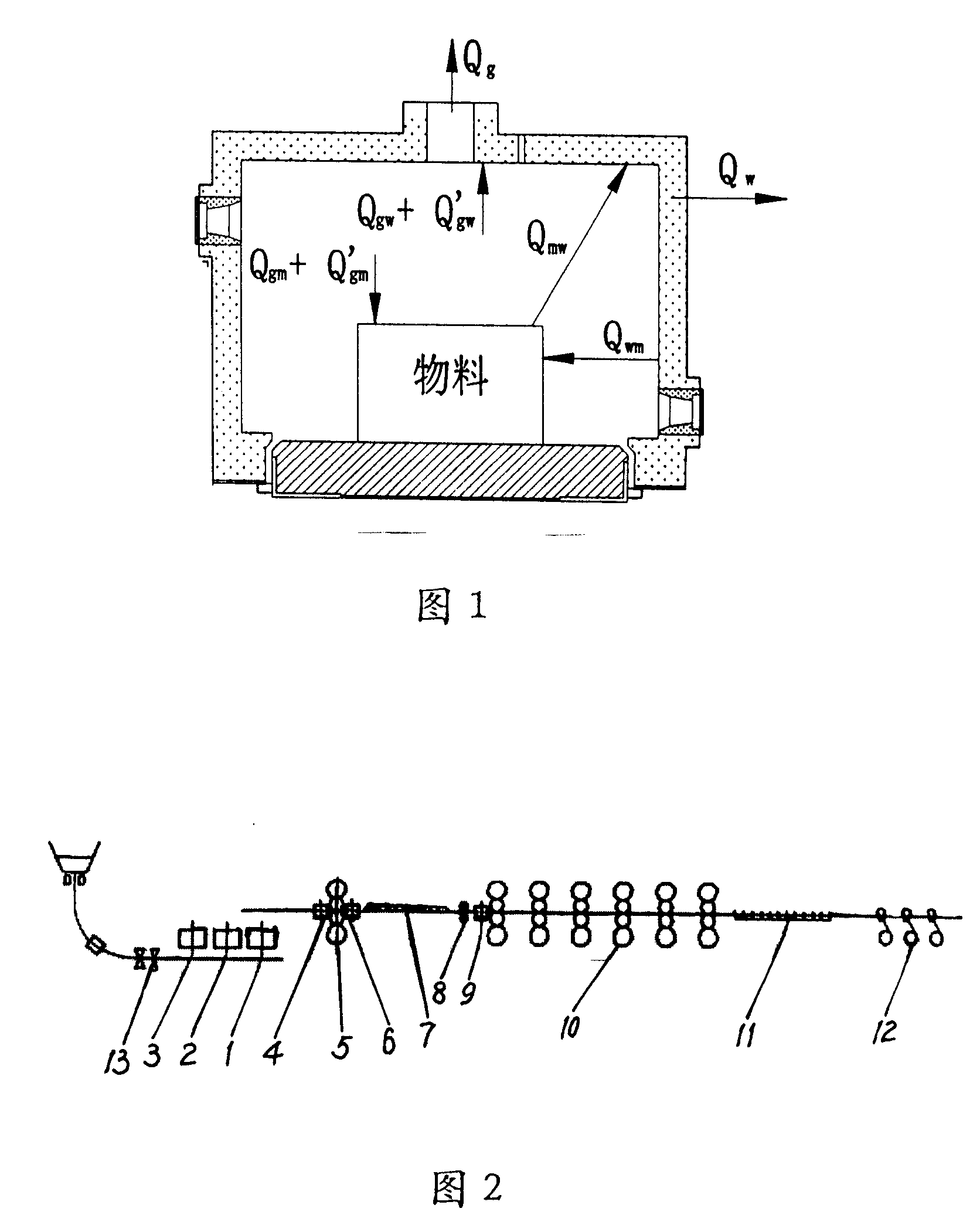

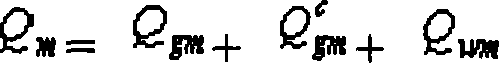

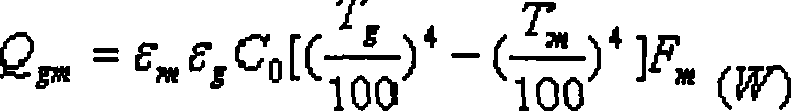

Metal strengthening heat transmission protection method in metal workpiece heating techniqiue

The invention relates to a method for protecting metal and intensifying heat diffusion in the technology for heating metal objects, the technology for heating metal materials or workpieces comprises a heating furnace and a rolling line, wherein a paint spraying system is additionally arranged in front of the heating furnace, and the process of the technology comprises: firstly, coating paint on metal billets or the workpieces, secondly, heating the metal billets or the workpieces in the furnace, thirdly, taking the metal billets or the workpieces out of the furnace, fourthly, removing a coating layer of the metal billets or the workpieces, and fifthly enabling the metal billets or the workpieces to enter into the rolling line. The method is a new method, namely, the workpieces are put on coat and then heated, which plays the role of protecting the metal and intensifying the heat diffusion. According to the method of the invention, heated metal workpieces is coated with functional paint on the surface and then heated, which has the advantages that the metal oxidization ratio is lowered, the trace element loss rate in the metal is lowered, the heating speed is increased, the existing heating equipment output and the production rate are increased, and the like.

Owner:BAOSTEEL ENG & TECH GRP

Air-fuel ratio detection device

InactiveCN106766974AGuaranteed working temperatureGood furnace temperatureControl devices for furnacesSimultaneous control of multiple variablesExhaust gasOperating temperature

The invention belongs to the technical field of meter detection, and discloses an air-fuel ratio detection device. The air-fuel ratio detection device comprises a combustion furnace, a resistance wire, an oxygen measurer and a data processing control center, wherein the combustion furnace comprises a combustion furnace shell and a furnace pipe accommodated in the combustion furnace shell; the resistance wire is wound on the furnace pipe; the data processing control center is used for controlling the resistance wire to be in a working state or an idling state, so that the temperature in the combustion furnace can be kept at working temperature; the oxygen measurer is connected to the combustion furnace and is used for detecting the residual oxygen content of exhaust gas in real time and transmitting detected residual oxygen content data to the data processing control center; and the data processing control center processes the residual oxygen content data to obtain a complete combustion air-fuel ratio with a fuel gas heat value in a changing state, so that the air-fuel ratio of each furnace section of an industrial kiln is corrected according to an excessive air coefficient required by the furnace section, and the combustion efficiency of the industrial kiln is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

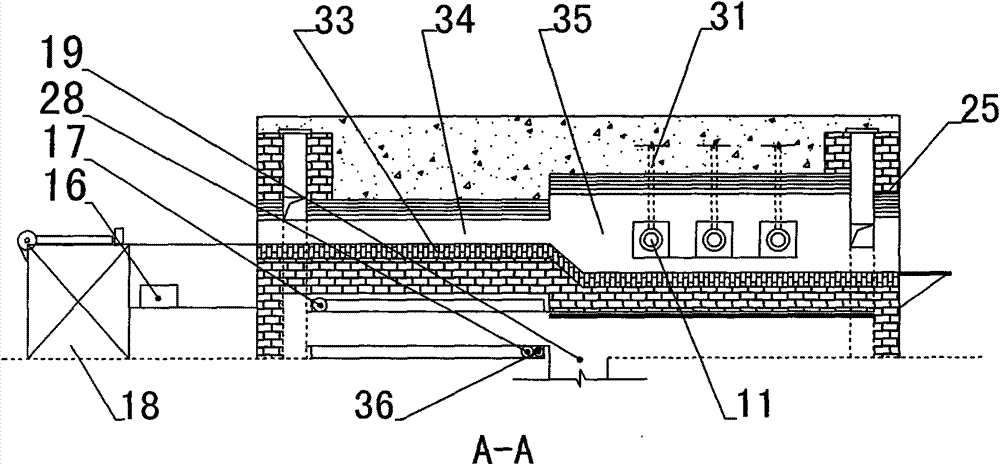

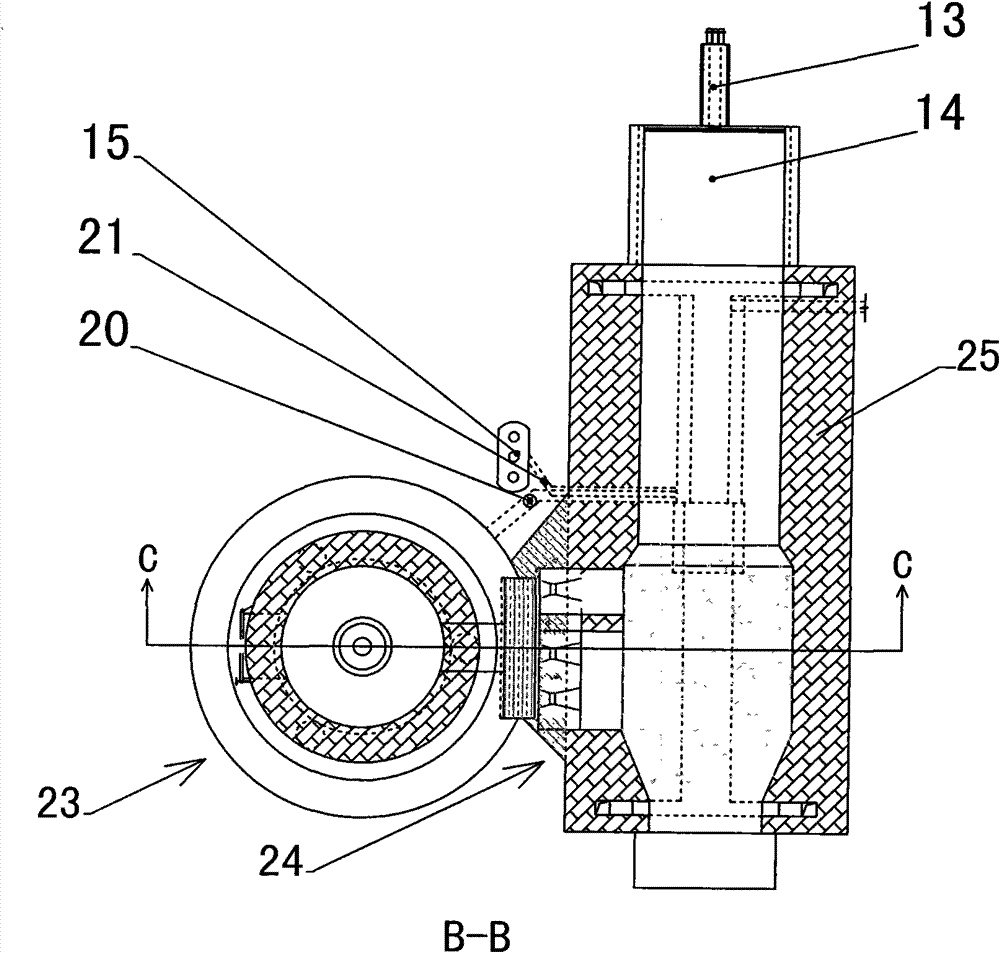

Gasification forging continuous reheating furnace

InactiveCN101920303AExtended service lifeDistinguished high and low temperatureForge furnacesProcess engineeringHearth

The invention relates to a gasification forging continuous reheating furnace, comprising a coal gas producer and a forge piece blank heating furnace; wherein the two are connected by a laryngeal chamber. The bottom of the forge piece blank heating furnace is in stepped structure, and a high temperature region and a low temperature region are formed in the hearth. Three burners are arranged in thehigh temperature region in the hearth, the gas inlet of the three burners is fixedly connected with the three gas outlets of the laryngeal chamber, and the gas inlet of the laryngeal chamber is connected with the gas outlets of the gas producer. The flue of the forge piece blank reheating furnace is internally provided with a spiral preheating device, and waste heat of the reheating furnace is utilized to heat the air which enters into the gas producer, thus achieving the aim of energy conservation. The invention adopts optimal short water jacket to directly supply hot gas for gas conversion,fuel and steam consumption is reduced, environmental pollution can be reduced, and forging quality can be greatly improved.

Owner:瓦房店世强轴承制造有限公司

Anti-oxidation decarburization protective agent and preparation method thereof and heat treatment process of H13 mold

ActiveCN106191400AImprove oxidation resistanceReduce oxidation burn rateFurnace typesHeat treatment furnacesOxidation resistantBoron nitride

The invention discloses an anti-oxidation decarburization protective agent. The anti-oxidation decarburization protective agent comprises the following raw materials in parts by weight: 0.4-0.6 part of aluminum oxide, 0.85-1.2 parts of zirconium oxide, 1.8-2.2 parts of magnesium oxide, 1.8-2.2 parts of chromic oxide, 9-11 parts of borax, 0.1-0.3 part of carbon-contained matter, 0.2-0.4 part of boron nitride, 0.5-1.5 parts of boron oxide, 18-23 parts of bismuth oxide, 0.3-0.5 part of zinc oxide, 1.8-2.5 parts of silicon dioxide, 5-10 parts of curing agents, 35-45 parts of water, and 40-45 parts of auxiliaries. The anti-oxidation decarburization protective agent is not limited by the mold size and shape; and a H13 mold coated with the anti-oxidation decarburization protective agent is obvious in anti-oxidation effect, reduces the oxidation burn loss by above 91% after annealing and tempering, and reaches the hardness of 48-52 HRC.

Owner:河南中轴福漫锻造有限公司

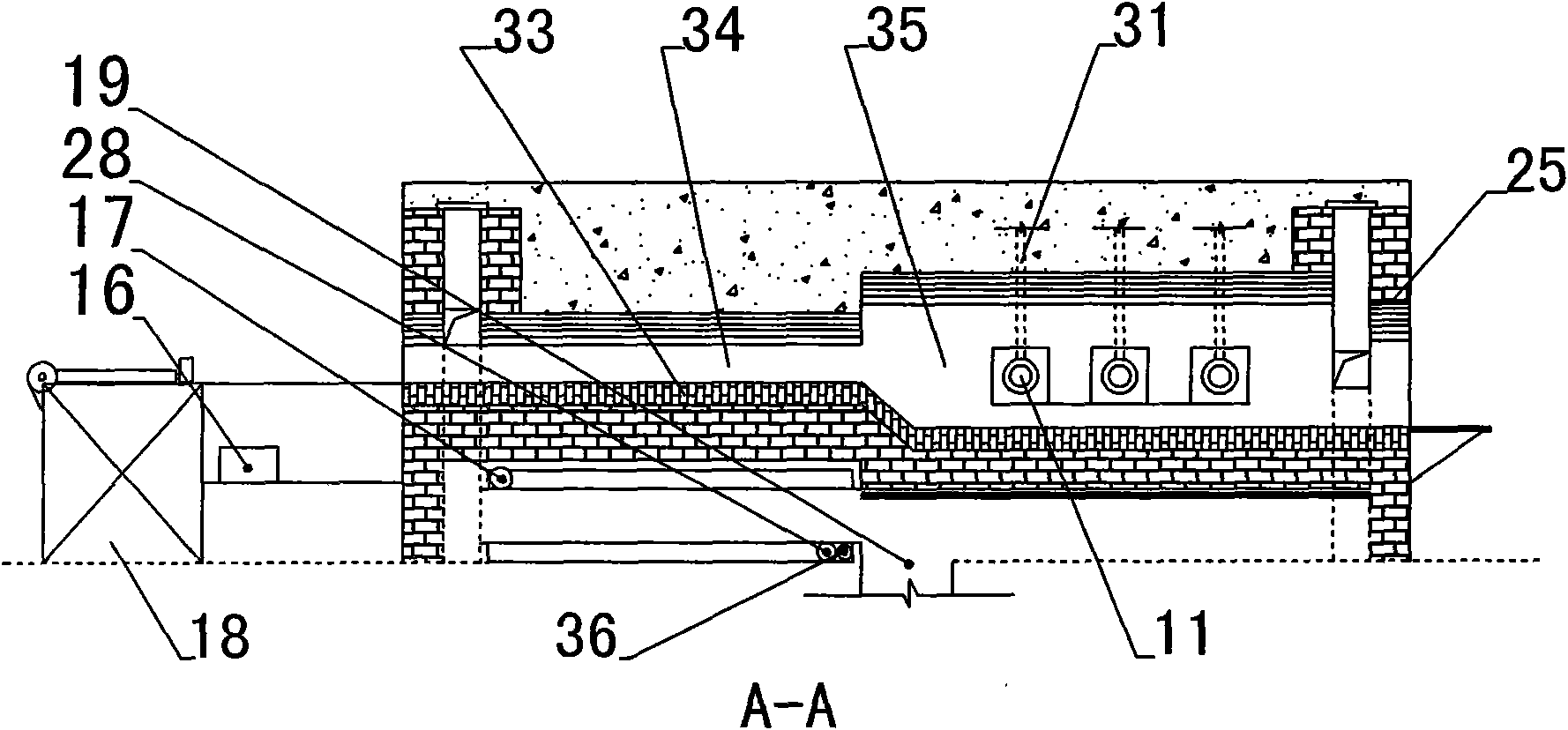

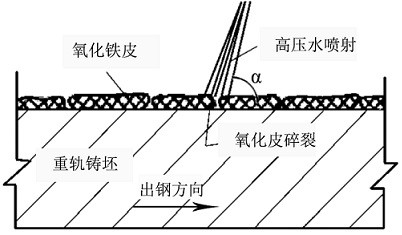

Method for improving billet descaling effect

PendingCN112718889AAvoid Surface Quality IssuesReduce oxidation burn rateWork heating devicesMetal rolling arrangementsSurface oxidationHigh pressure water

The invention discloses a method for improving the billet descaling effect. After a billet is taken out of a heating furnace, oxide scales on the surface of the casting billet are removed through high-pressure water descaling and high-pressure water inclined spraying, the inclination angle alpha between the high-pressure water spraying direction and the surface of the casting billet ranges from 30 degrees to 60 degrees, and the high-pressure water pressure ranges from 15 MPa to 22 MPa. The thickness range of oxide scales on the surface of the casting billet discharged from the furnace is controlled to be 0.5 mm-1.5 mm, the oxidation burning loss rate of the surface of the casting billet is greatly reduced by 50% or above, the oxide scales on the surface of the casting billet are removed through high-pressure water inclined spraying, the phosphorus removal effect reaches 90%-98% and is improved by 13%-15% compared with a traditional phosphorus removal method, the steel rail surface quality problem caused by incomplete phosphorus removal is greatly solved, and the high-speed heavy rail phosphorus removal effect is obviously improved.

Owner:HANDAN IRON & STEEL GROUP +1

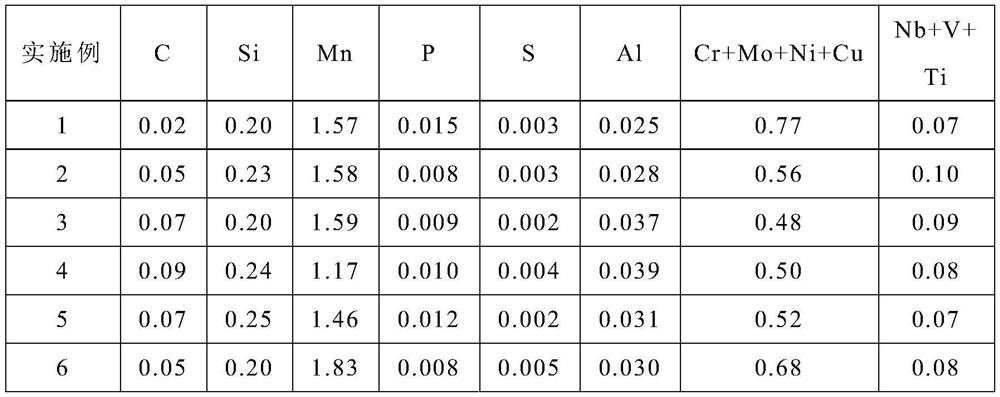

Method for improving yield of low-carbon high-microalloyed steel

ActiveCN112146458AReduce oxidation burn rateFurnace typesControl devices for furnacesHeating furnaceAir–fuel ratio

The invention discloses a method for improving a yield of low-carbon high-microalloyed steel. Sectional heating is adopted in a heating furnace, a preheating section conducts heating at a heating rateof 5.80-24.87 DEG C / min, a first heating section conducts heating at a heating rate of 3.41-11.78 DEG C / min, a second heating section conducts heating at a heating rate of 0.53-7.54 DEG C / min, and asoaking section conducts heating at a heating rate of 0.08-1.44 DEG C / min. An oxidation burning loss rate of the low-carbon high-microalloyed steel is reduced by performing sectional heating in the furnace, setting the heating rate of each section in the furnace and a tapping temperature range of steel billets, reasonably adjusting an air-fuel ratio of each section of the heating furnace, determining the optimal control range of the air-fuel ratio of each section and the like, so that the yield of the low-carbon high-microalloyed steel is equal to or greater than 98%.

Owner:武汉钢铁有限公司

High-temperature-resisting nanometer anti-oxidization isolating agent for oriented silicon steel billet and production method and application method of high-temperature-resisting nanometer anti-oxidization isolating agent

InactiveCN108070696AImprove loose structureReduce surface oxidation burning lossSuspending AgentsImpurity

The invention provides a high-temperature-resisting nanometer anti-oxidization isolating agent for an oriented silicon steel billet and a production method and application method of the high-temperature-resisting nanometer anti-oxidization isolating agent. The high-temperature-resisting nanometer anti-oxidization isolating agent comprises, by weight percent, 5%-10% of carbon powder, 20%-30% of magnesium aluminate spinel powder, 10%-20% of an inorganic binder, 5%-10% of a suspending agent, 5%-10% of an inorganic reagent and the balance magnesite clinker micro powder and inevitable impurities. Compared with the prior art, the formula of the isolating agent is adjusted, a proper production process is adopted, and the high-temperature-resisting nanometer anti-oxidization isolating agent for the oriented silicon steel billet and with stable high temperature stability is obtained; and after a production test, according to the isolating agent, the performance of an oriented silicon steel product is influenced, and meanwhile the burning loss is reduced by 80% or above. The isolating agent has the advantages of being simple in preparing, low in cost and stable in high temperature stability.

Owner:MAANSHAN IRON & STEEL CO LTD

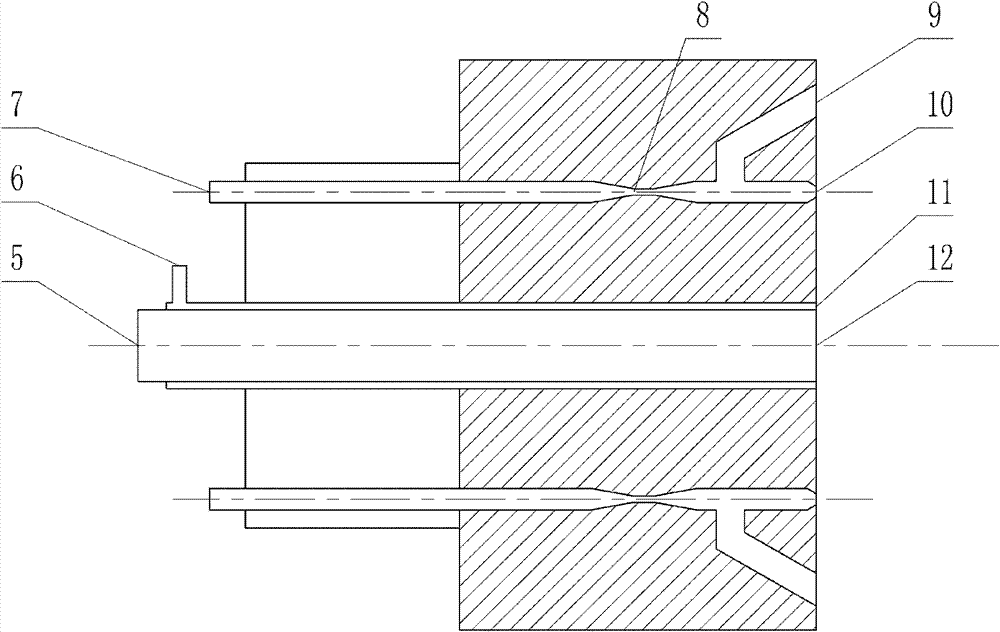

Double heat accumulation type high-temperature oxygen-deficient combustor with oxygen-enriched air supply

InactiveCN102095200AHigh blacknessEnhanced radiation heat transferIndirect carbon-dioxide mitigationGaseous fuel burnerHeat transfer efficiencyBurning out

The invention relates to a double heat accumulation type high-temperature oxygen-deficient combustor with oxygen-enriched air supply, belonging to the technical field of combustors. The combustor provided by the invention comprises a gas inlet / flue gas outlet, an oxygen-enriched air inlet / flue gas outlet, an oxygen-enriched air heat accumulator box, an oxygen-enriched air nozzle brick, a gas nozzle brick, a gas heat accumulator box, a gas nozzle, a flue gas circulating channel, an oxygen-enriched air and flue gas mixture nozzle, a flue gas reflux inlet and a flue gas reflux nozzle brick. The invention has the advantages that oxygen-enriched air is utilized to supply air, thereby reducing flue gas to bring waste heat and enhancing the heat transfer efficiency in a furnace; a heat accumulator is utilized to recycle the waste heat of the flue gas, thereby preheating combustion air and gas; simultaneously, high-temperature oxygen-deficient combustion conditions are realized through a special structural design; the oxidizing atmosphere in an industrial furnace is weakened to greatly reduce the oxidizing burn-out rate of a heated material, thereby solving the problems of high energy consumption, low yield and low emission of nitrogen oxides of the industrial furnace; and non-flammable fuel can be fully combusted.

Owner:北京沃克能源科技有限公司

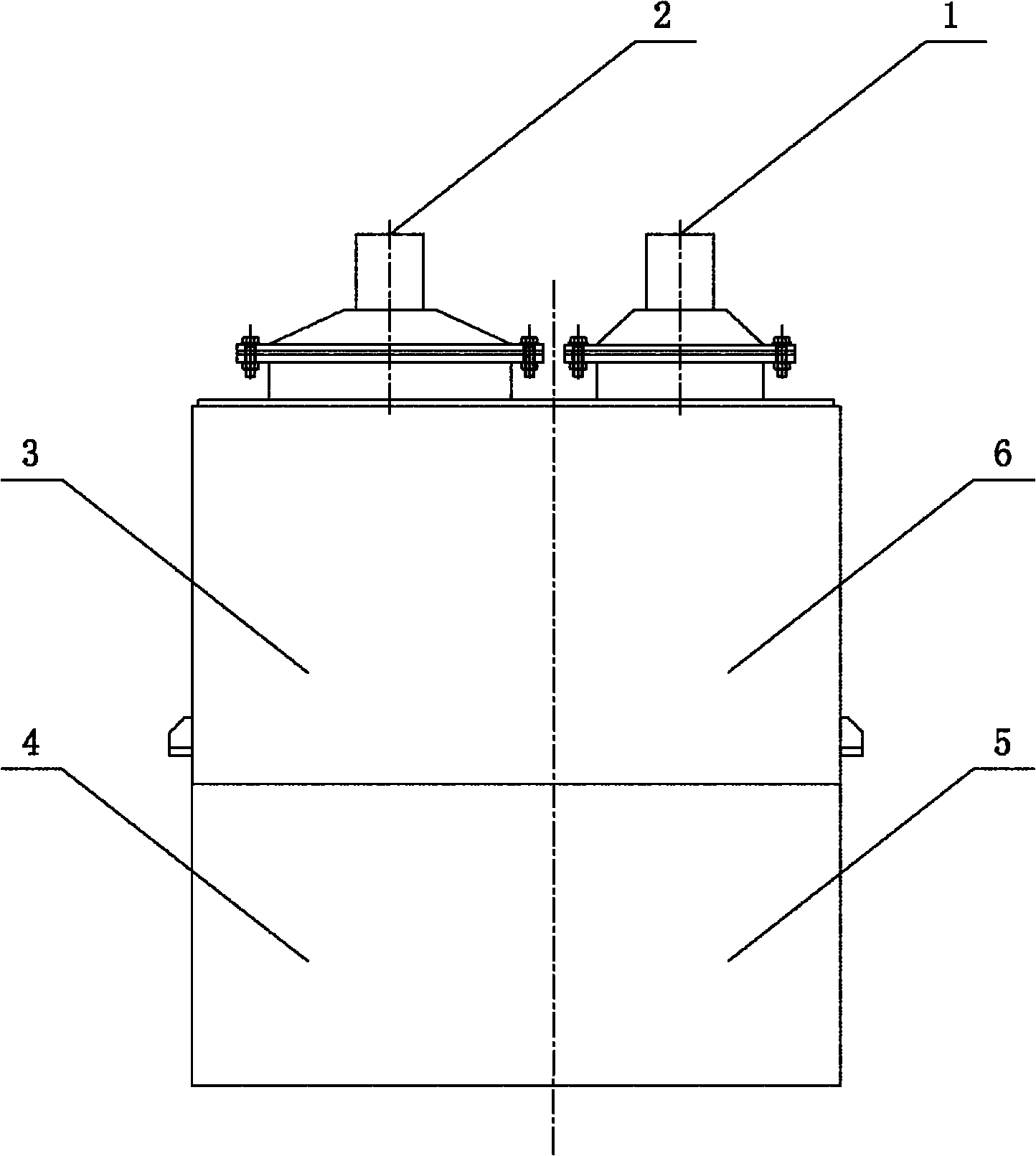

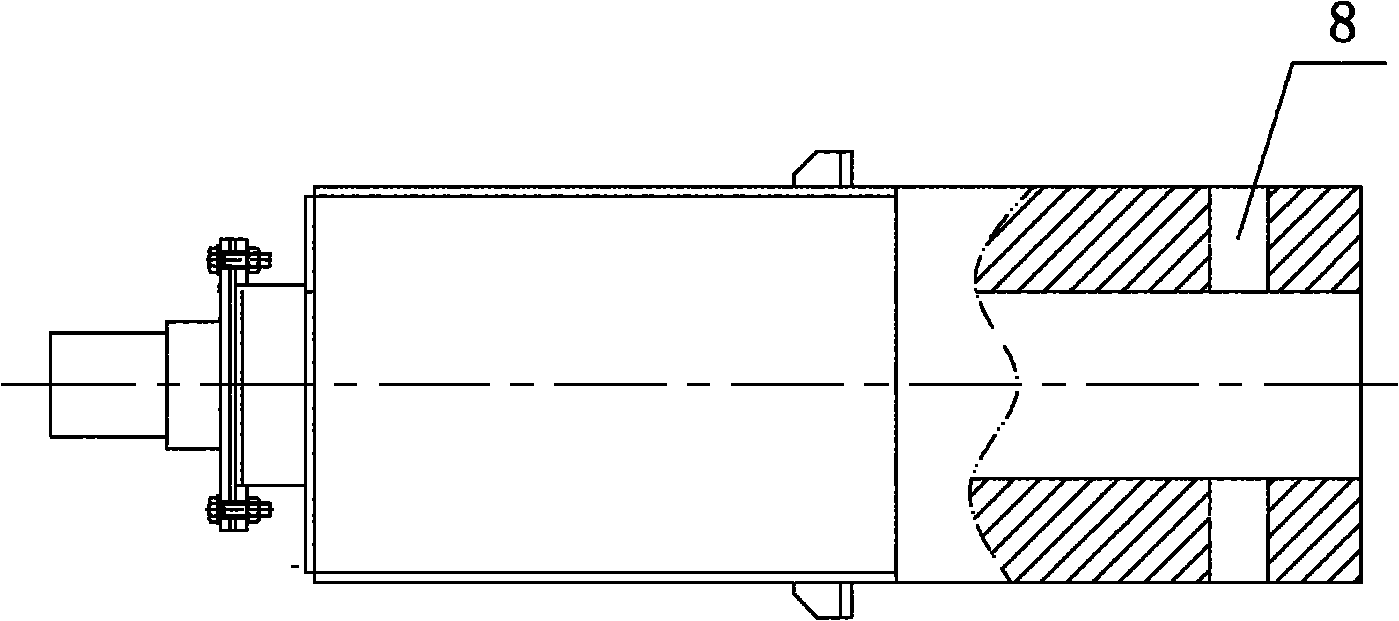

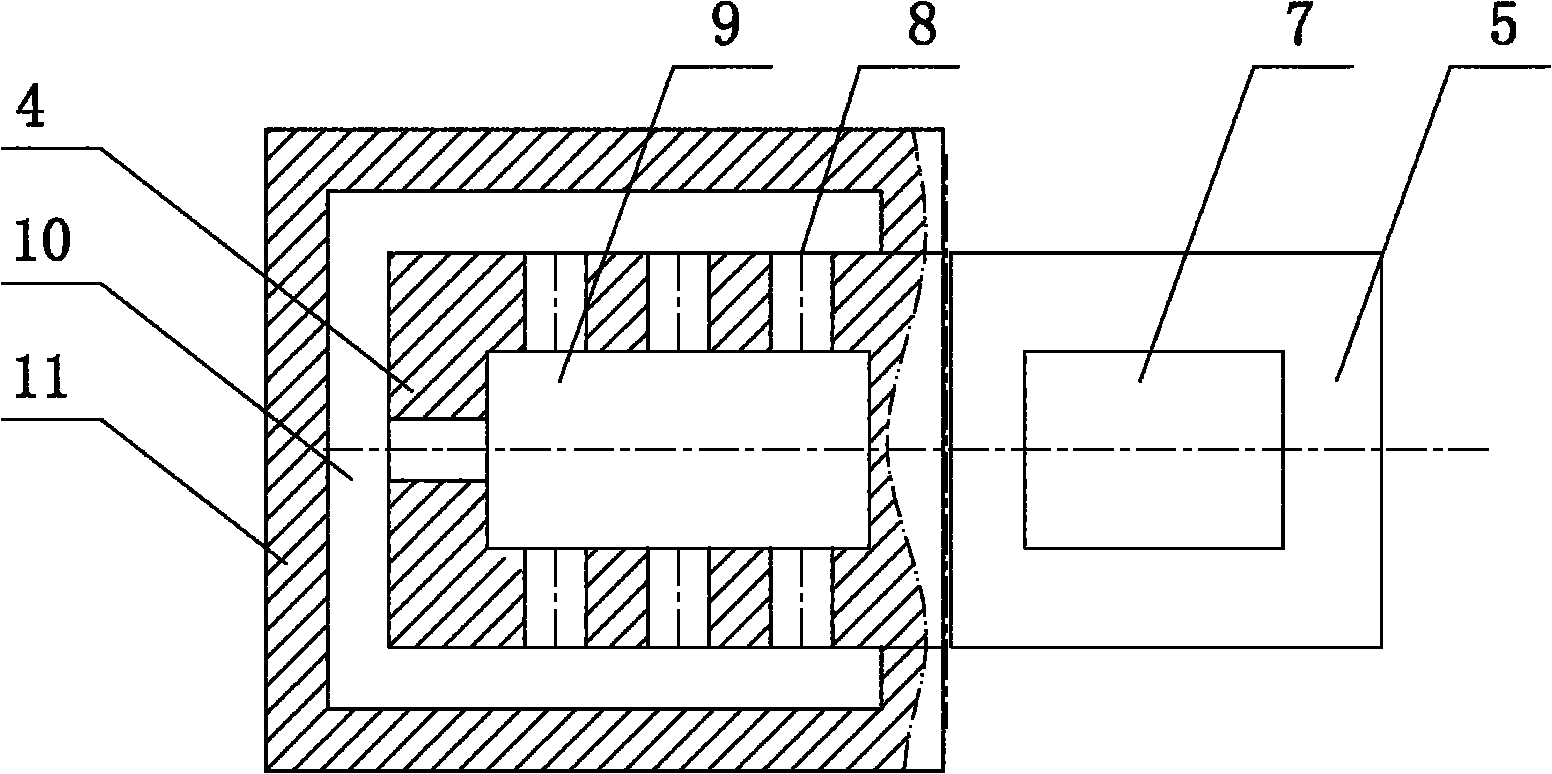

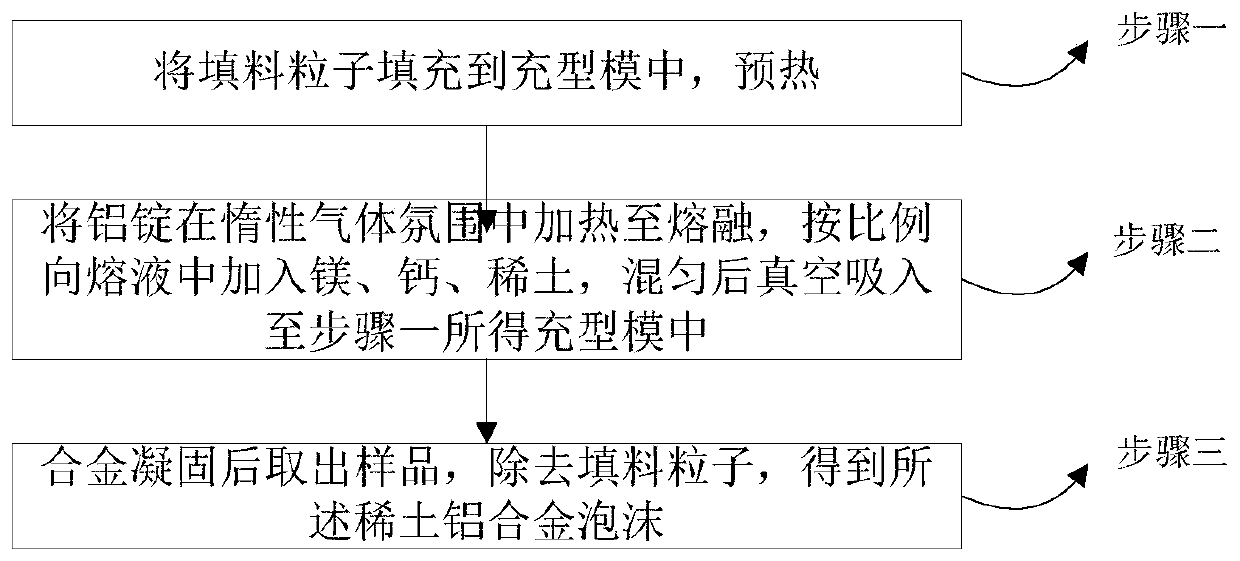

Rare earth aluminum alloy foam and preparation method thereof

The invention discloses rare earth aluminum alloy foam and a preparation method thereof, and relates to the technical field of alloy. A vacuum infiltration casting method is adopted, and the preparation method comprises the following steps of filling a filling mold with filler particles, and preheating; heating an aluminium ingot in an inert gas atmosphere until melting, adding magnesium, calciumand rare earth in a melt proportionally, uniformly mixing, and then performing vacuum suction in the filling mold in the step 1; and after the alloy is solidified, taking out a sample, and removing the filler particles, thereby obtaining the rare earth aluminum alloy foam. In the obtained rare earth aluminum alloy foam, a rare earth element and a magnesium element have lower oxidation burn out rate, and meanwhile, the rare earth aluminum alloy foam prepared according to the preparation method has excellent corrosion resistance.

Owner:CENT SOUTH UNIV

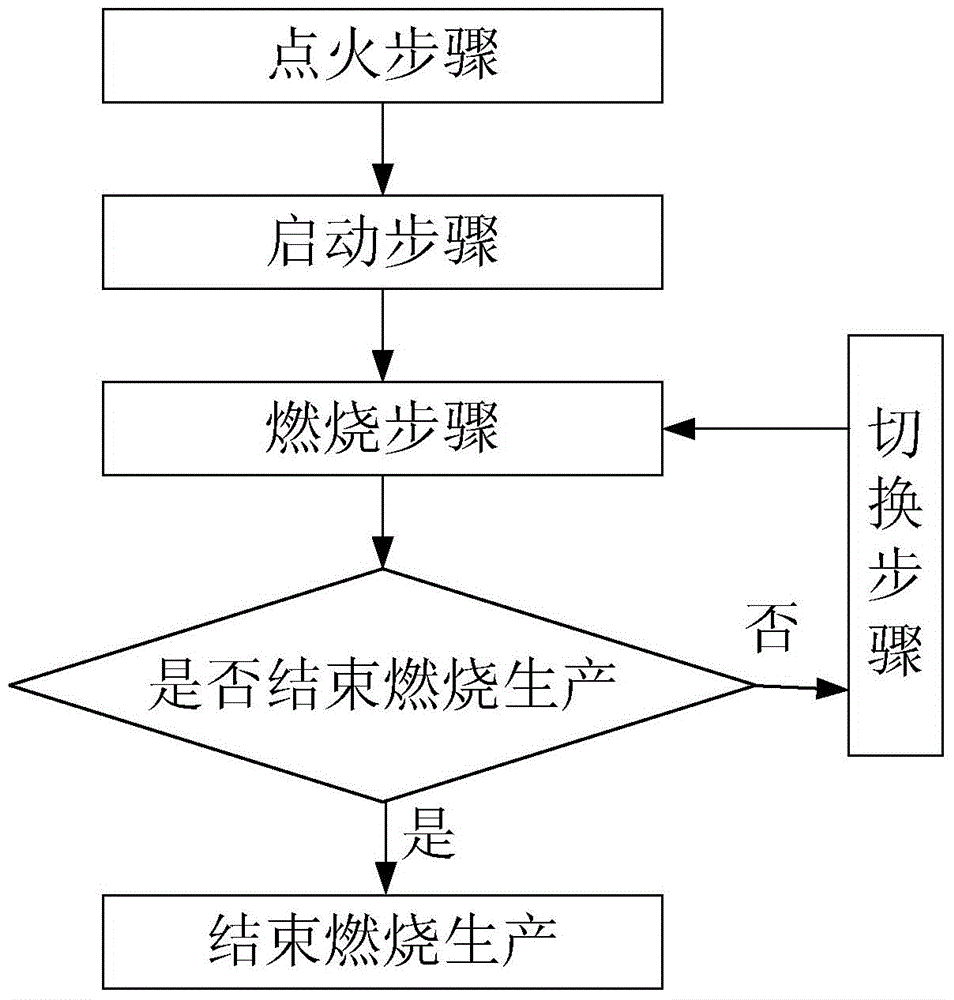

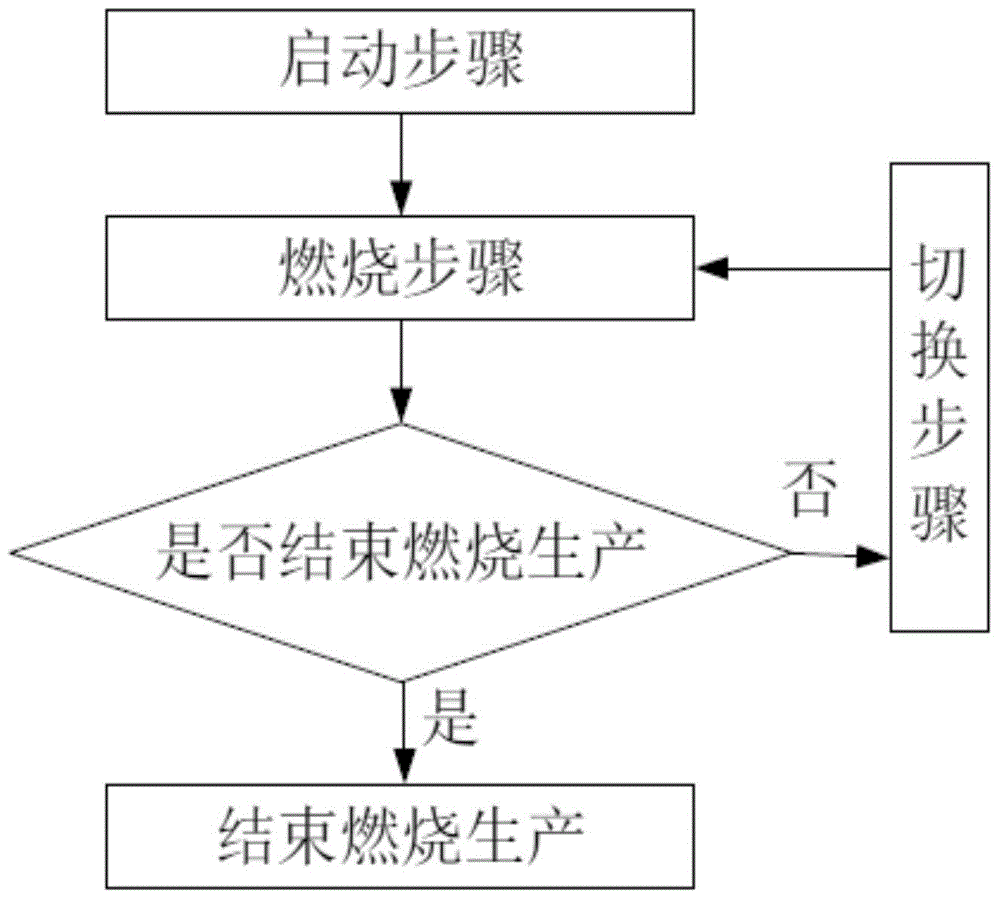

Control method of regenerative combustion equipment

ActiveCN104456616ADischarge in timeSmooth exhaustEnergy industryIndirect carbon-dioxide mitigationDetonationCombustion

The invention provides a control method of regenerative combustion equipment. The method includes an igniting step, a starting step, a combustion step and a switching step. The method overcomes the technical bias that the regenerative combustion equipment is controlled in pairs with a traditional method and achieves an unexpected energy-saving technical effect, and the phenomena that in an existing high-temperature air combustion technology, detonation and furnace explosion happen easily in the reversing process, and fuel waste is serious are effectively avoided.

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

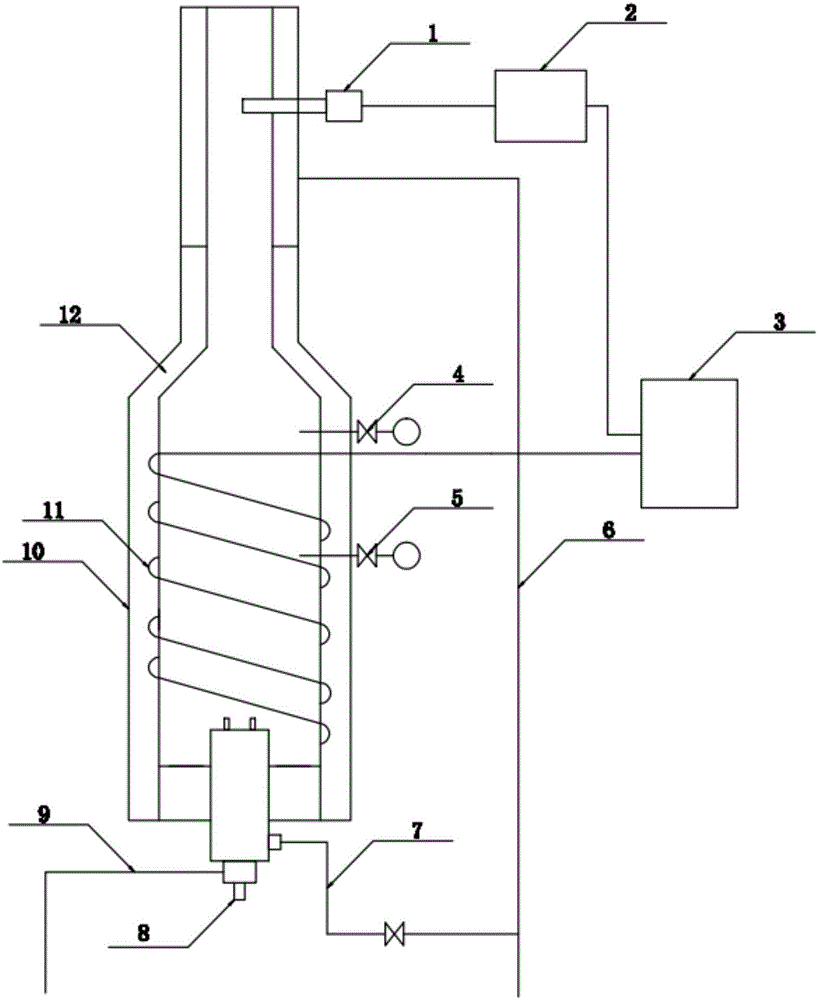

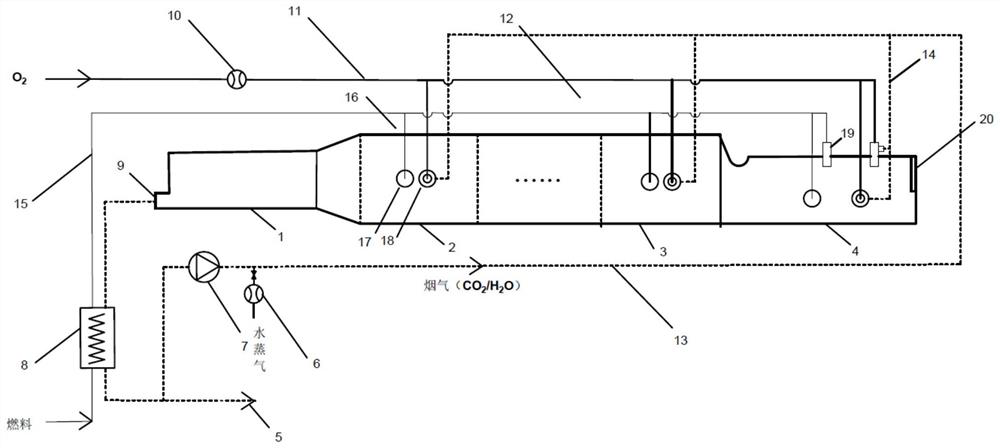

Waste heat recovery steel rolling heating furnace based on MILD oxygen-enriched combustion and heating method thereof

ActiveCN114838595AOvercome temperatureOvercoming thermal NO <sub>x<</sub> Liquid fuel feeder/distributionFuel supply regulationNitrogen oxidesFlue gas

The invention discloses a waste heat recovery steel rolling heating furnace based on MILD oxygen-enriched combustion and a heating method of the waste heat recovery steel rolling heating furnace, and belongs to the technical field of metallurgical heat energy engineering. The steel rolling heating furnace comprises a preheating section, a plurality of heating sections, a soaking section, an oxygen main pipe, a smoke main pipe, a fuel main pipe and a water vapor adjusting device, the heating sections comprise the first heating section, the second heating section,... and the n heating section, and the oxygen main pipe, the smoke main pipe and the fuel main pipe are connected with the preheating section, the heating sections and the soaking section correspondingly. And the water vapor adjusting device is arranged on the flue gas main pipe. MILD oxygen-enriched combustion is achieved through heating furnace transformation, the side-burning oxygen-blowing staged combustion mode is adopted, the oxygen matching amount is flexibly adjusted, the oxygen-enriched combustion technology and soft combustion are combined and applied to the steel rolling heating furnace, the advantages of energy conservation and emission reduction of the oxygen-enriched combustion technology can be fully played, and the defects of the oxygen-enriched combustion technology can be overcome. And the generation concentration of nitric oxide in the billet heating process and the oxidation burn-out rate of the heated billet are greatly reduced.

Owner:NORTHEASTERN UNIV

Dispersing agent for anti-oxidation coating for heating silicon steel plate blank and preparation method thereof

A dispersing agent for anti-oxidation coating for heating a silicon steel plate blank is prepared by the following steps: mixing 100 parts of a mixture of crylic acid, 2-acrylamide group-2-methyl propane sodium sulfonate, acrylic ester and water to prepare a component A; mixing 10-15 parts of ammonium persulfate and the water to prepare a component B; placing 8-10 parts of sodium hypophosphite and the water in a reaction still, stirring and rising temperature to 80 DEG C, then simultaneously dropping the component A and the component B, controlling the temperature to be 70-95 DEG C, and enabling the component A and the component B to completely and simultaneously drip off in 2-4 hours; and continuously reacting for 1 hour, cooling and adjusting a pH value to obtain the needed dispersing agent. A small quantity of the dispersing agent is added in a slurry mixed by powder coating and the water, viscosity of the slurry is reduced, mobility of the slurry is improved to be favorable for spraying and coating, the powder coating is even in dispersion and not easy to deposit, a slurry suspension system is stable, a coating layer forming on the surface of a silicon steel plate blank is even, tight and not easy to drop, the anti-oxidation efficiency of the coating layer is improved, and an oxidation burn out rate of the silicon steel plate blank is reduced.

Owner:湖北海力环保科技股份有限公司

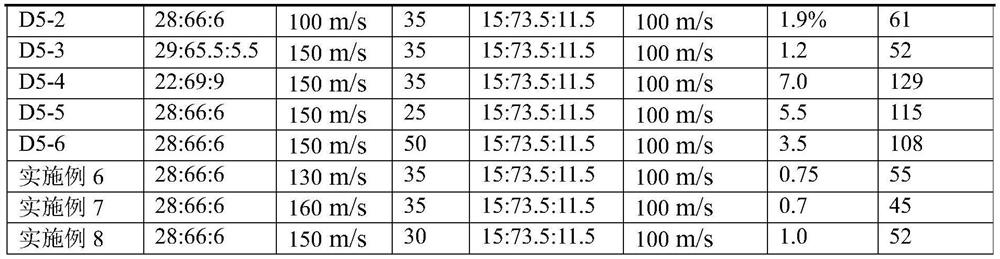

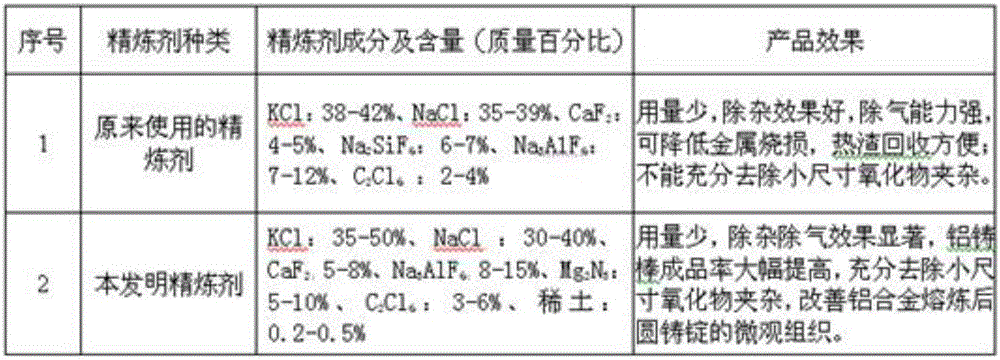

Aluminum Alloy Refining Agent

The invention relates to an aluminum alloy refining agent, which is characterized in that it consists of KCl, NaCl, CaF 2 、Na 3 AlF 6 , Mg 2 N 3 、C 2 Cl 6 Composed of rare earth and rare earth, the above-mentioned components are respectively by mass percentage, 35-50%: 30-40%: 5-8%: 8-15%: 5-10%: 3-6%: 0.2-0.5%, the present invention The aluminum alloy refining agent has the characteristics of good impurity removal effect and stronger degassing ability, especially the ability to remove small-sized alumina inclusions; it can also reduce metal burning loss and improve the microstructure of round ingots after aluminum alloy smelting.

Owner:ALNAN ALUMINIUM CO LTD

Control method of regenerative combustion device

ActiveCN104456617ASmooth exhaustStable furnace pressureEnergy industryIndirect carbon-dioxide mitigationCoordination typePollutant emissions

The invention provides a control method of a regenerative combustion device. The method includes a starting step, a combustion step, a switching step and a circulation step. Compared with the prior art, the method has the outstanding technical effects of being smooth in smoke exhaust, stable in furnace pressure, small in temperature difference, good in heating quality, remarkable in energy-saving effect and little in pollutant discharge. Thus, the method belongs to an environment coordination type regenerative combustion technology.

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

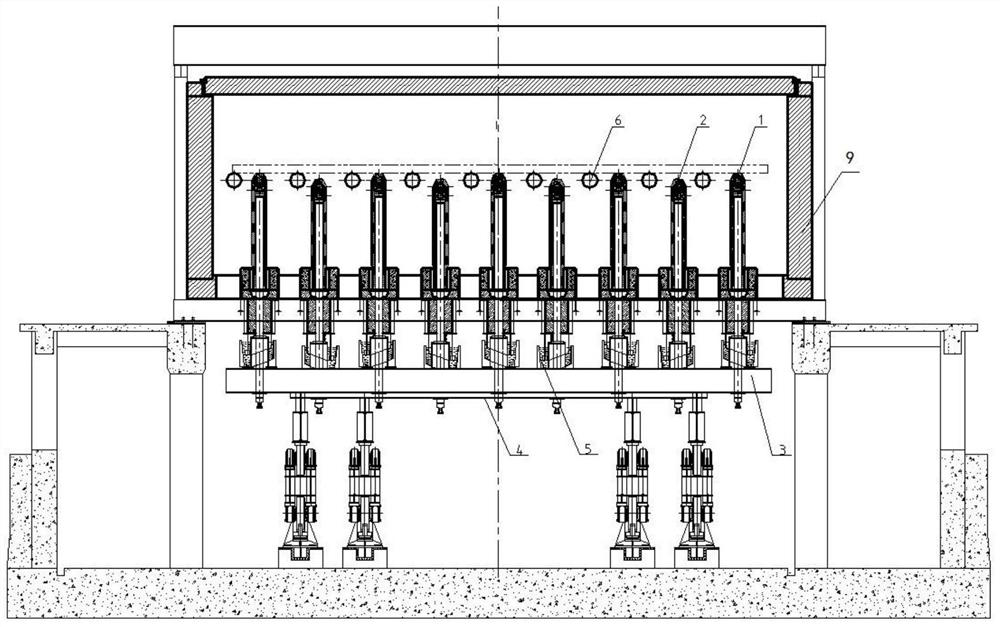

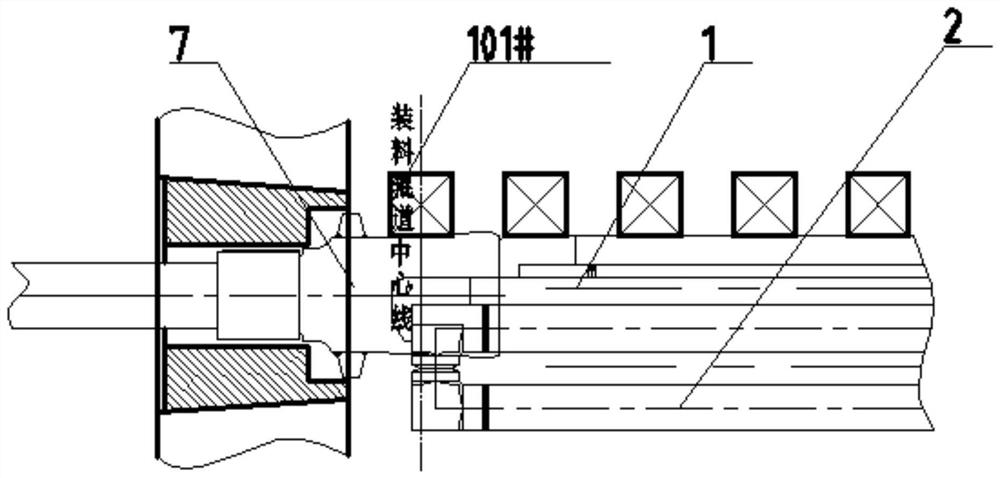

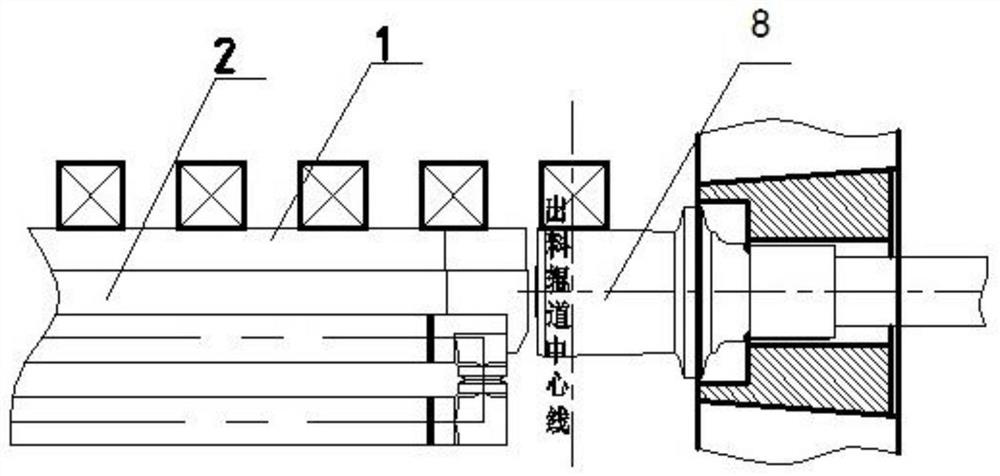

Stepping type heating furnace with double movable supporting devices for fast-paced production and machining method of stepping type heating furnace

PendingCN112595104AReduce oxidation burn rateImprove tapping efficiencyFurnace typesHeat treatment furnacesPhysicsHot work

The invention belongs to the technical field of hot working equipment in the iron and steel metallurgy industry, and particularly relates to a stepping type heating furnace with double movable supporting devices for fast-paced production and a machining method of the stepping type heating furnace. The heating furnace comprises a furnace body, a feeding device, a discharging device, a first stepping movable unit and a second stepping movable unit. The first stepping movable unit comprises a first stepping movable supporting device, the second stepping movable unit comprises a second stepping movable supporting device, the feeding device is arranged on the feeding side of the furnace body, the discharging device is arranged on the discharging side of the furnace body, and the first steppingmovable supporting device and the second stepping movable supporting device are arranged in a staggered mode. The two ends of the first stepping movable supporting device and the two ends of the second stepping movable supporting device are in butt joint with the feeding device and the discharging device separately. According to the stepping type heating furnace with the double movable supportingdevices for the fast-paced production and the machining method of the stepping type heating furnace, the supporting devices in the heating furnace are all movable supporting devices, so that a blank is always in an advancing state, and the tapping efficiency is doubled.

Owner:李坤鹏

Gasification forging continuous reheating furnace

Owner:瓦房店世强轴承制造有限公司

A method for smelting ultra-advanced duplex stainless steel made of cd3mwn

ActiveCN108823348BIncrease contentReduce precipitationProcess efficiency improvementSmelting processSS - Stainless steel

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Refining agent for aluminum alloy melting

ActiveCN103695687BGood effect of removing impuritiesStrong degassing abilityGraphiteMaterials science

The invention relates to a refining agent for smelting an aluminum alloy. The refining agent is characterized by comprising the following components by mass percent: 35% to 45% of NaCl, 25% to 35% of KNO3, 3% to 8% of CaF2, 6% to 10% of Na2SiF6, 7% to 12% of Na3AlF6, 5% to 10% of graphite and 0.5% to 1.5% of rare earth. The refining agent has the characteristics of good refining effect, strong degassing capacity and the like, and cannot generate noxious gas during a production process.

Owner:COSCO W M J ALUMINUM DEV CO LTD

Heat treatment method for improving room-temperature ductility of high-silicon electrical steel

ActiveCN102382963BReduce orderImprove room temperature plasticityHeat treatment process controlElectrical steelMetallic materials

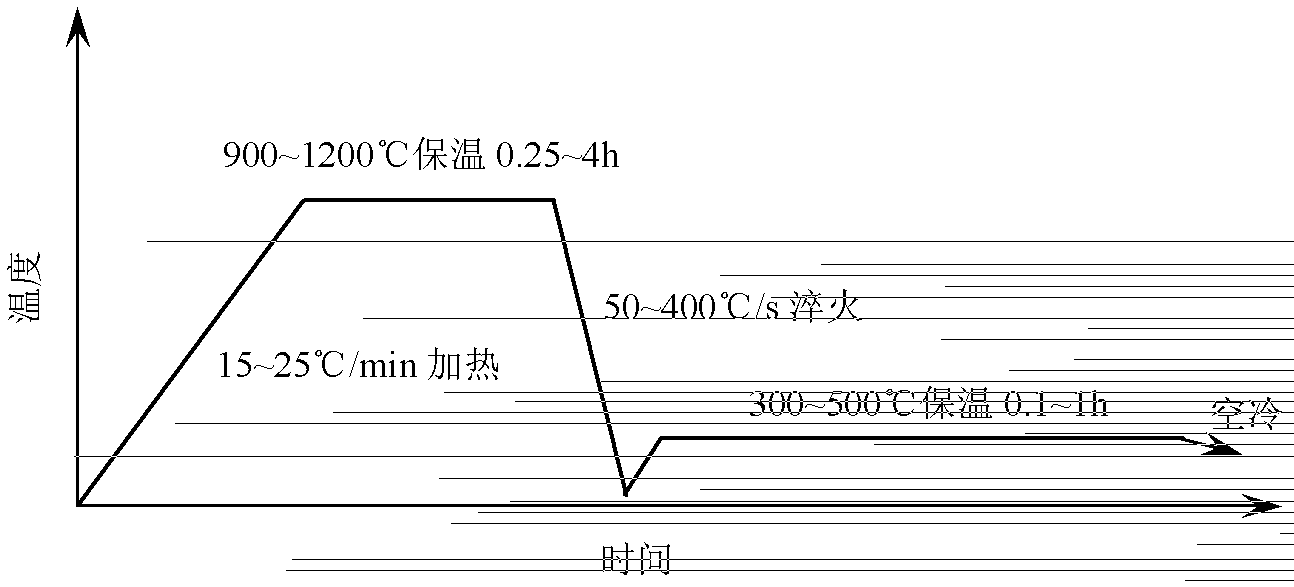

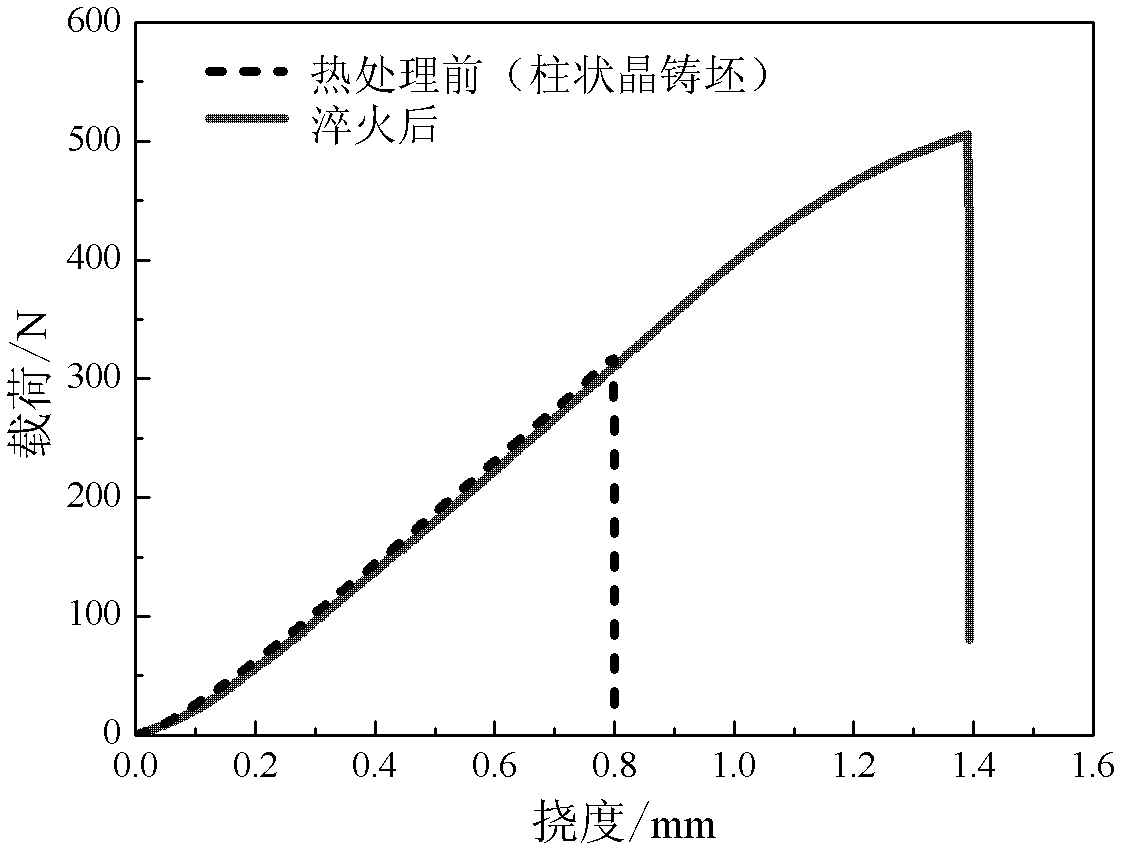

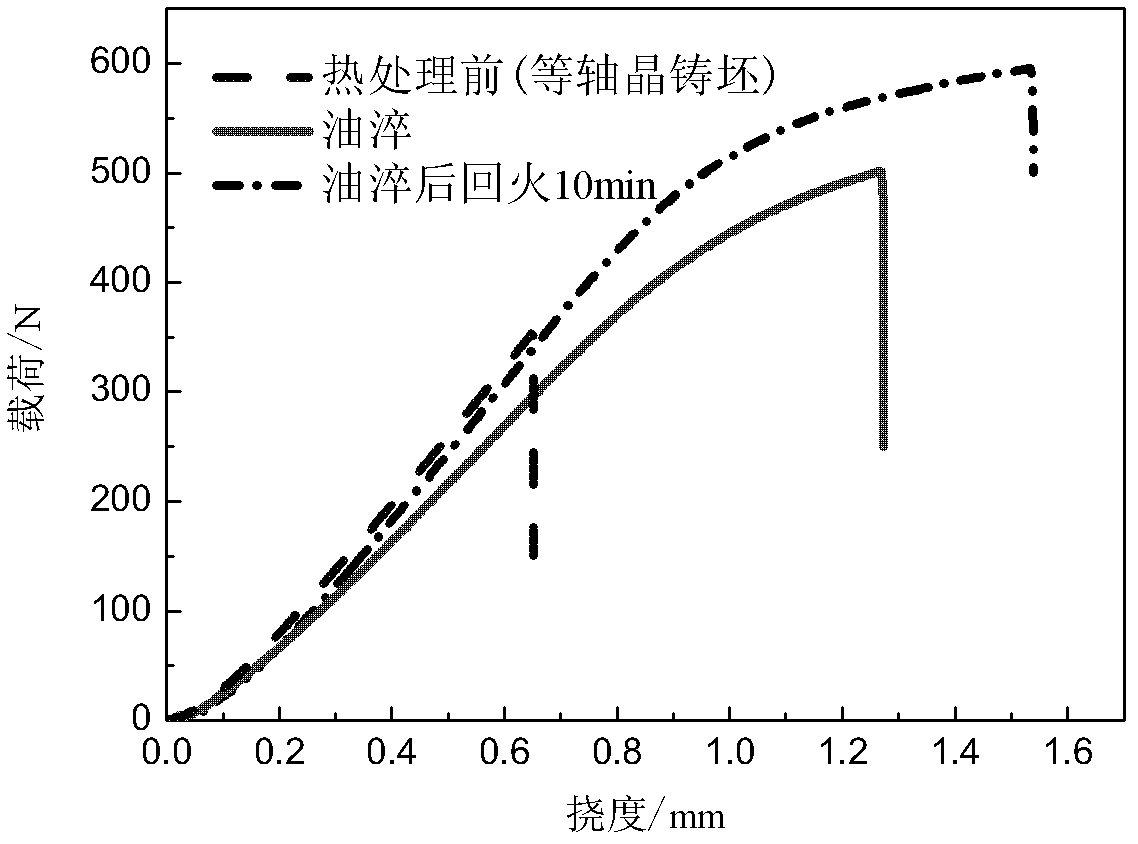

The invention discloses a heat treatment method for improving room-temperature ductility of high-silicon electrical steel, which is mainly applicable to treating Fe-Si (6.5 percent of Si by weight) high-silicon electrical steel, and belongs to the technical field of metal material heat treatment. A main process flow of the heat treatment method comprises four steps of: heating; preserving heat; cooling; and performing stress relief annealing; and the heat treatment method is particularly characterized by comprising the following steps of: heating a high-silicon electrical steel casting blank to 900-1,200 DEG C at the speed of 15-25 DEG C / minute; preserving heat for 0.25-4 hours at the temperature of 900-1,200 DEG C; cooling to room temperature at the cooling speed of 50-400 DEG C / second; and then reheating to 300-500 DEG C, preserving heat for 0.1-1 hour, then performing air cooling, and performing stress relief annealing, wherein the influences of degree of order, particularly factors such as precipitated phase, residual stress and the like, on the room-temperature ductility of the high-silicon electrical steel are comprehensively considered in the process flow. After the high-silicon electrical steel casting blank is treated by using the method, the room-temperature ductility of the high-silicon electrical steel casting blank is obviously improved.

Owner:UNIV OF SCI & TECH BEIJING

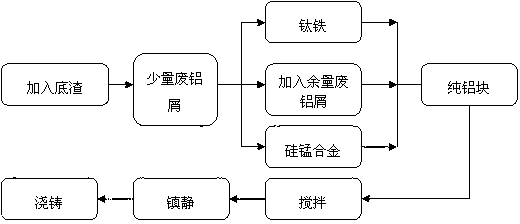

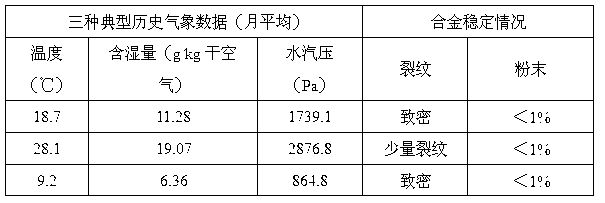

Preparation method of manganese-based MnAlSiTi alloy with high titanate content

The invention discloses a manganese-based MnAlSiTi alloy with high titanate content. The MnAlSiTi alloy contains the following chemical components in percent by mass: 40-55% of Mn, 12-18% of Al, 13-22% of Si, 1-2% of Ti and the balance of Fe and impurity elements. The preparation method comprises the following steps of: weighing aluminium scraps, ferrotitanium, pure aluminium, a silicon manganese alloy and a slag former according to the requirement of simple substance elements, sequentially adding the aluminium scrap, the ferrotitanium, the pure aluminium, the silicon manganese alloy and the slag former into an induction furnace to be smelted; and solidifying by adopting a slow-fast-slow way. The alloy prepared by the invention has high manganese content and high titanate content, the range of charging content of raw material carbon and other impurity elements can be widened, and the cost is low; and the prepared alloy can be stored under various weather conditions with stable structure and without pulverization. The alloy has the advantages of high deoxidizing capacity, high impurity removing rate, good alloying effect, high fatigue resistance and high earthquake resistance.

Owner:重庆中盛裕康冶金有限公司

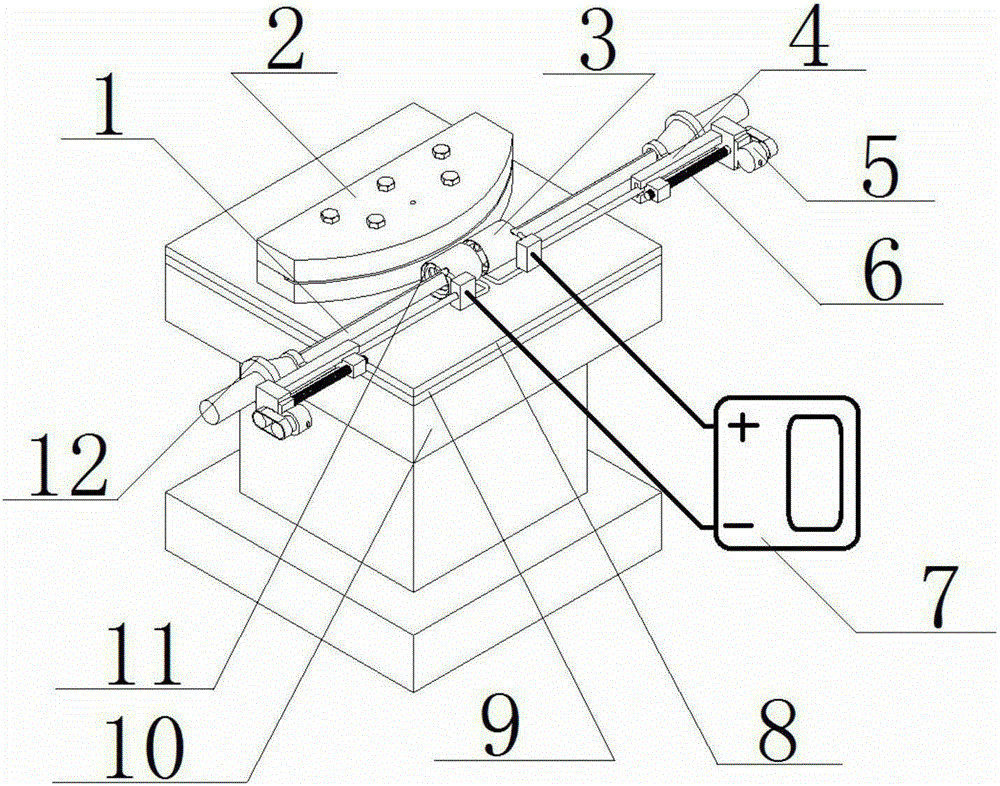

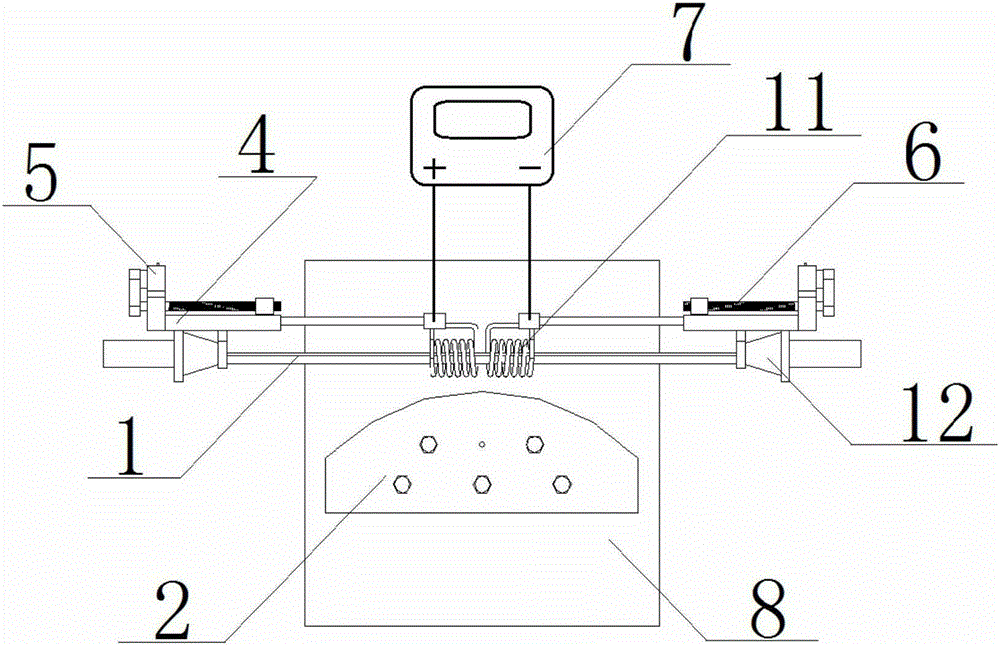

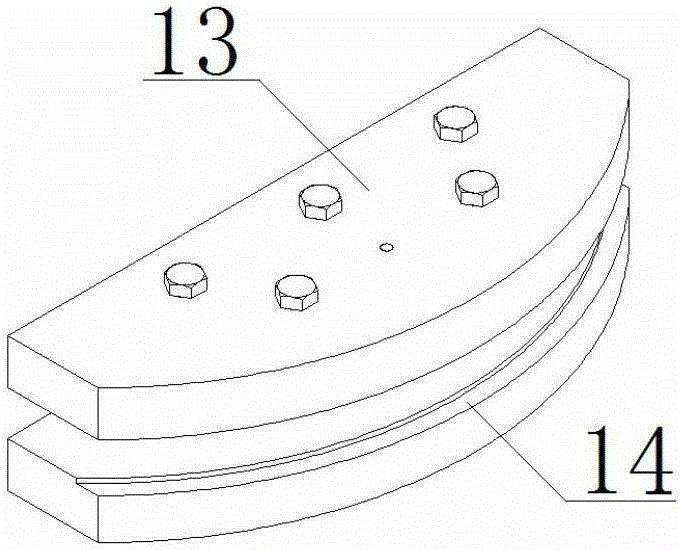

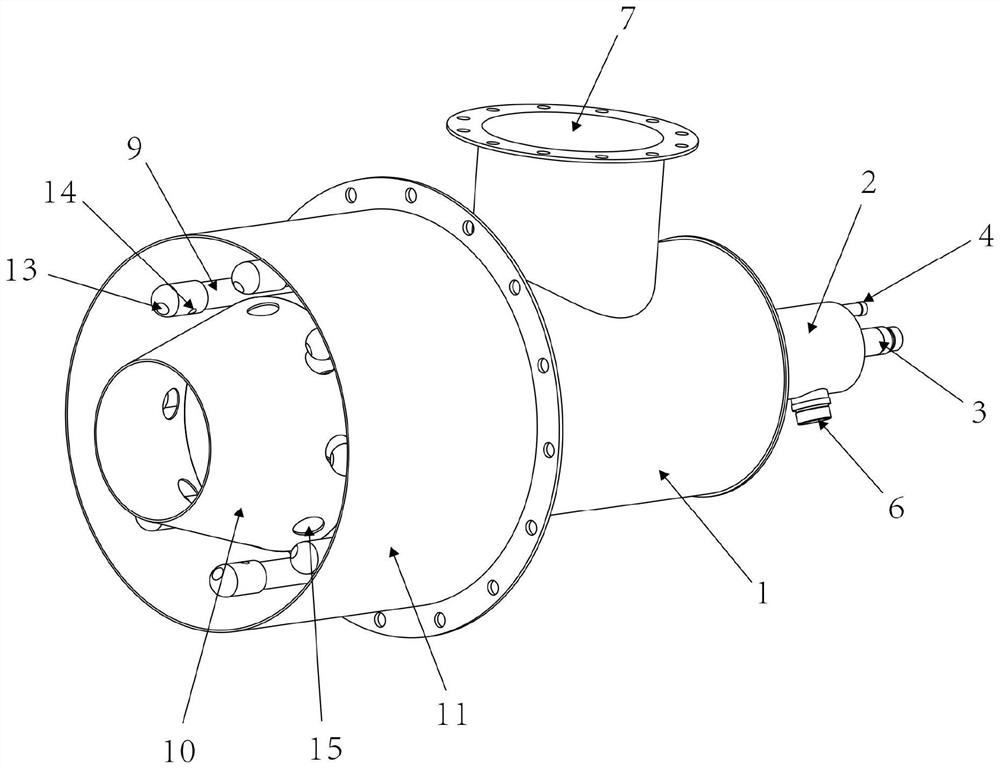

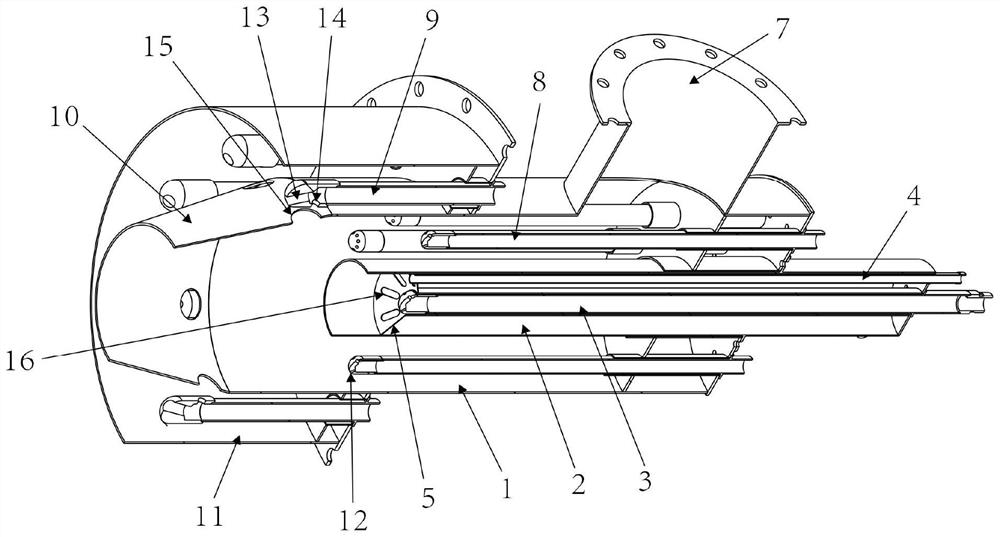

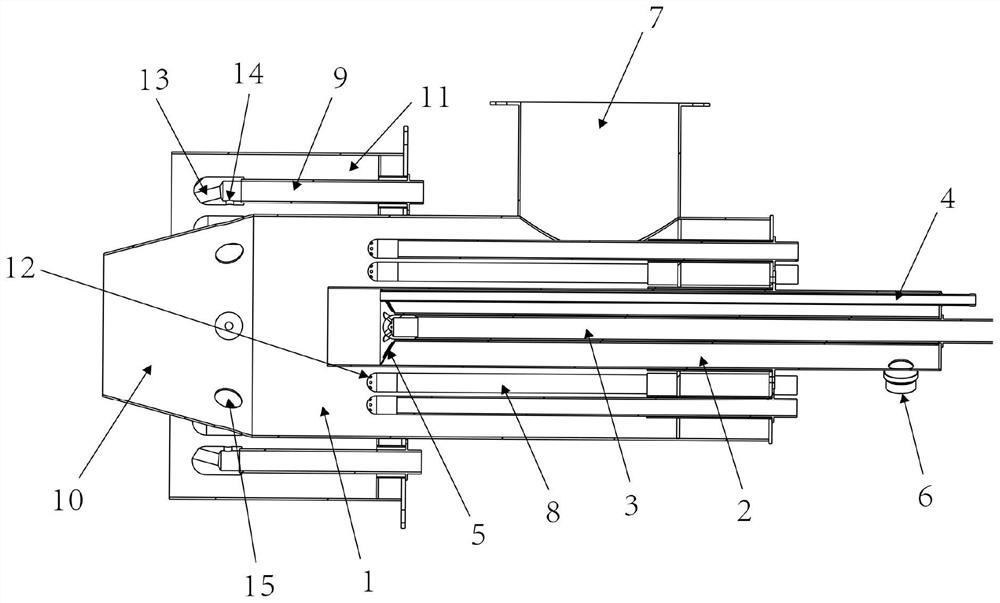

An induction heating stretch bending forming device for aircraft profiles

The invention discloses an induction heating stretch-bending forming device for aircraft sectional materials. The device comprises a stretch-bending mold, an induction heating system, a coil feeding mechanism and an insulation cushion layer, wherein the insulation cushion layer is used for the insulation treatment between the stretch-bending mold and a working table; the stretch-bending mold is mounted on the insulation cushion layer; the induction heating system is positioned at the outer side of the stretch-bending forming device; induction coils are positioned at the outer sides of the sectional materials; a magnetic field is generated around the induction coils after the electrification; the sectional materials are positioned in the magnetic field; the temperature rises through cutting magnetic lines of force; the coil feeding mechanism is mounted on a chuck of a stretch bender for finishing the feeding movement of the induction coils; a temperature sensor adopts a non-contact temperature sensor for measuring the temperature of the sectional materials in real time; and the output power of a power supply is adjusted according to temperature feedback signals so as to stabilize the heating temperature of the sectional materials. The forming device realizes thermal stretch-bending formation of the aircraft sectional parts, improves the forming precision and the structure stability, and guarantees the surface quality of the formed parts.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

High-speed low-nitrogen combustor for heating furnace and combustion method of high-speed low-nitrogen combustor

PendingCN114234187AReduce nitrogen oxidesFlame temperature and shape stabilityGaseous fuel burnerAutomotive engineeringNitrogen oxides

The high-speed low-nitrogen combustor comprises a lower straight barrel, a center gun is arranged in the lower straight barrel, a center fuel gun and an ignition gun are arranged in the center gun, the front end of the center fuel gun and the front end of the ignition gun are both arranged on a flame stabilizing device, and the flame stabilizing device is arranged at an opening in the front end of the center gun. A first air inlet is formed in the side face of the center gun, a second air inlet is formed in the side face of the lower straight barrel, a plurality of first fuel guns are arranged in the lower straight barrel and evenly and annularly distributed on the periphery of the center gun, and ports of the lower straight barrel, the center gun, the center fuel gun and the first fuel guns are located on the same side. According to the scheme, the nitrogen reduction strategy of staged combustion is adopted, combusted mixed gas is divided into three stages to be combusted in the axial direction, flames diverging from the center to the outer layer are formed, and therefore the combustor has the effects of reducing the oxidation burning loss rate, reducing generation of thermal nitrogen oxide and improving the steel billet yield.

Owner:北京瑞晨航宇能源科技有限公司

Temperature Control Method of Large Gas Pit Furnace

ActiveCN104654819BHigh energy saving rateHigh control precisionControl devices for furnacesTemperature controlProcess engineering

The invention discloses a temperature control method of a large fuel gas furnace, and relates to the technical field of steel rolling. The temperature control method comprises a plurality of FBT (Furnace Box Temperature) control areas; each temperature control area is provided with a temperature sensor, a glue gas sampling probe, an electromagnetic fuel gas control valve and an electromagnetic air control valve, wherein the temperature regulator controls the opening degrees of the electromagnetic fuel gas control valve and the electromagnetic air control valve; the initial air input and the initial fuel gas input of each temperature control area are determined according to the following formula: n is equal to (1-4)m, when O2 (Oxygen) is less than 2.5% and CO (Carbon Dioxide) is less than 20ppm; n is equal to (0.99-0.90) (1-4)m, when O2 is less than 2.5%; n is equal to (1.01-1.10) (1-4)m when CO is more than 20ppm. According to the temperature control method provided by the invention, the problems that the continuity and the waste of fuel gas can affect the production in the process of copper bar profiles can be solved.

Owner:LIUZHOU IRON & STEEL +1

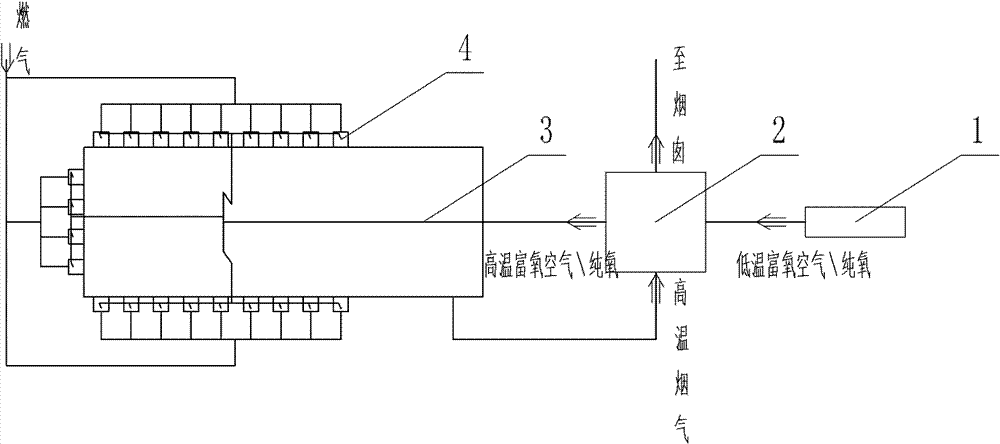

Rich oxygen or pure oxygen supply high-temperature air combustion system

InactiveCN102175038BReduce nitrogen contentReduce waste heatIndirect carbon-dioxide mitigationGaseous fuel burnerNitrogen gasTriatomic molecule

The invention discloses a rich oxygen or pure oxygen supply high-temperature air combustion system, belonging to the technical field of heating furnaces and comprising a rich oxygen or pure oxygen device, a continuous residual heat recovering device, a heating furnace and a high-temperature air combustor, wherein the oxygen enrichment or pure oxygen device is connected with the continuous residual heat recovering device through a pipeline, the continuous residual heat recovering device is positioned in a flue of the heating furnace, an outlet of the continuous residual heat recovering device is connected with a rich oxygen or pure oxygen inlet of the high-temperature air combustor, and the high-temperature air combustor is arranged on the furnace wall of the heating furnace. The inventionhas the advantages of realizing rich oxygen or pure oxygen supply under different heating capacities, reducing content of nitrogen in smoke, and increasing content of triatomic molecules in furnace gas, thereby reducing residual heat carried away by the smoke and improving heat exchange efficiency in the furnace.

Owner:北京沃克能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com