Stepping type heating furnace with double movable supporting devices for fast-paced production and machining method of stepping type heating furnace

A technology of walking heating furnace and movable support, which is applied in the field of walking heating furnace and processing, heating furnace before rolling or heat treatment furnace, and can solve the problem that the steel tapping rate cannot be improved well, and the billet movement frequency cannot be increased, etc. problem, achieve the effect of reducing oxidation burning loss rate and improving tapping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

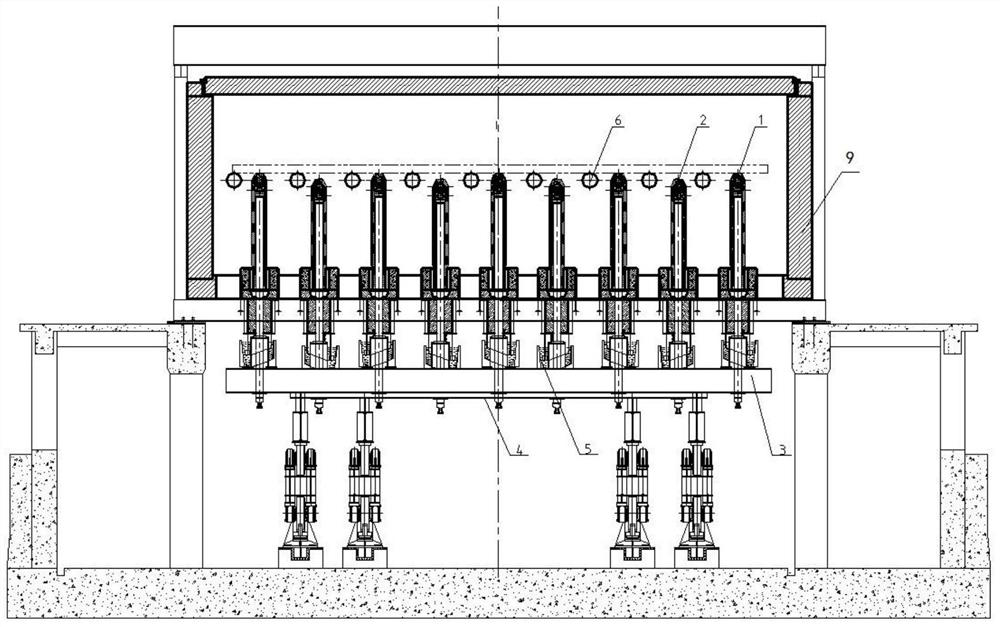

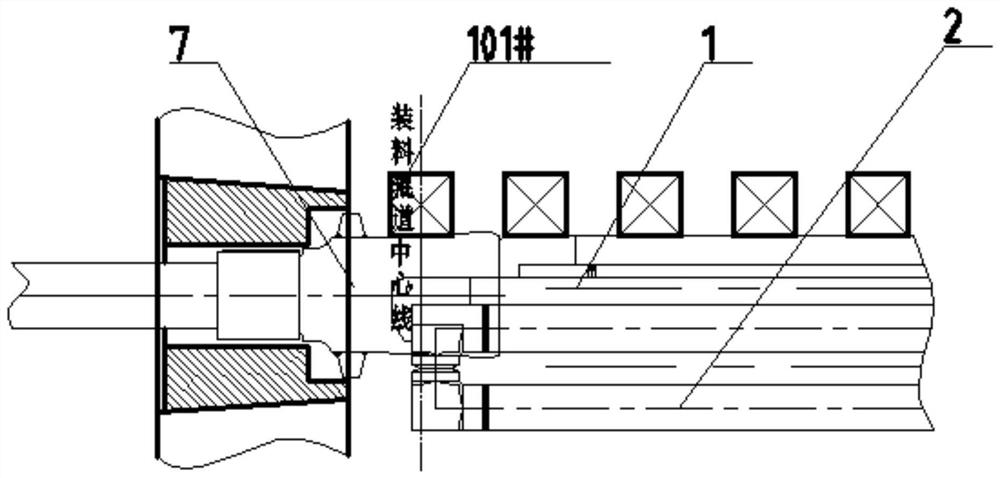

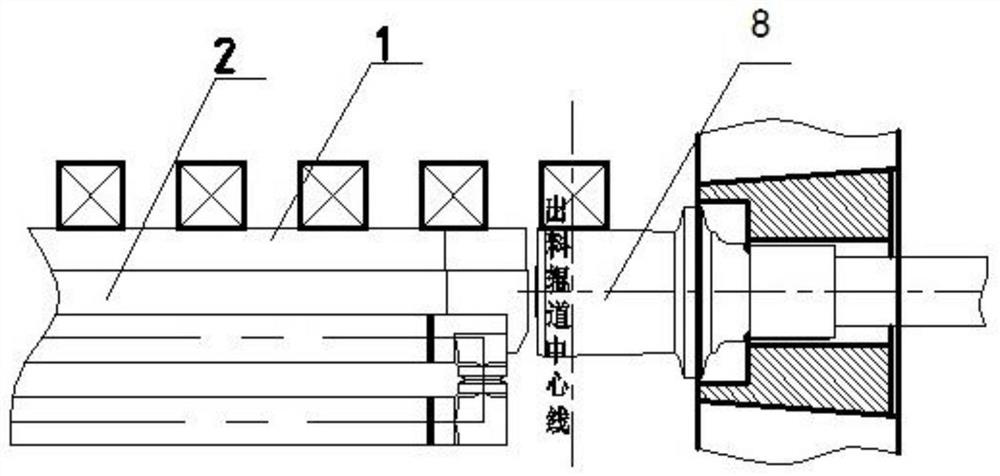

[0033]referencefigure 1 ,figure 2 withimage 3 In this embodiment, the present embodiment provides a stepping heating furnace produced by a dual movable support device, including a furnace body 9, a feed device 7, an discharge device 8, a first step-to-action unit, and a second stepped movable unit. The first stepped movable unit includes a first stepped moving support device, and the second stepped movable unit includes a second stepped moving support device, and the feed device 7 is disposed on the feed side of the furnace body 9, and the discharge device 8 is disposed. The discharge side of the furnace body 9, the first step into the movable support device, and the second stepped moving support device, and the first stepped movable support device and the second step of the second step-of-end moving support device are respectively The device 7 and the discharge device 8 are connected.

[0034]In the present embodiment, the first stepped movable support device is a first stepped movabl...

Embodiment 2

[0047]referenceFigure 5 withFigure 6Different from the first embodiment, the method of processing, the method provided in this embodiment includes the steps of:

[0048]201) The first target blank 101 is positioned to the feed plane 20 via the feeder 7, the first stepped moving beam 1 located in the front high, the second stepped active beam 2 is located at the low low, the feed plane 20 between high and low;

[0049]202) The second step of the active beam 2 rises to the feed plane 20. After the first target blank 101 rises to the post-high position, the first step is moved forward, and the first step into the active beam 1 is completed, and the retreat, and the rise is connected The bobbal billet continues to rise to the post-high position, continue to accelerate the forward to the second step in the active beam 2 speed;

[0050]203) The first stepped active beam 1 passes through the first target blank 101, with the second target blank continues to move forward, the second step into the act...

Embodiment 3

[0053]This embodiment provides a stepping furnace of fast-paced production, including a furnace body 9, a feed device 7, an discharge device 8, a first step-to-action unit, and a second stepped movable unit, the first step The unit includes a first stepped movable support device, and the second stepped movable unit includes a second stepped movable support device, and the feed device 7 is disposed on the feed side of the furnace body 9, and the discharge device 8 is disposed in the furnace body 9. The material side, the first step-in moving support device and the second stepped movable support device are interleaved, and the first stepped movable supporting device and the second step of the active support device are respectively with the feed device 7 and the discharge, respectively. Device 8 is connected.

[0054]In the present embodiment, the first stepped movable support device is a first active final, the second stepped movable support device being a second actuette, and the heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com