Rich oxygen or pure oxygen supply high-temperature air combustion system

A lean-oxygen combustion, oxygen-enriched technology, applied in burners, combustion methods, combustion types, etc., can solve the problems of increasing the amount of flue gas and reducing thermal efficiency, and achieve the effect of reducing nitrogen content, improving heating efficiency, and improving parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

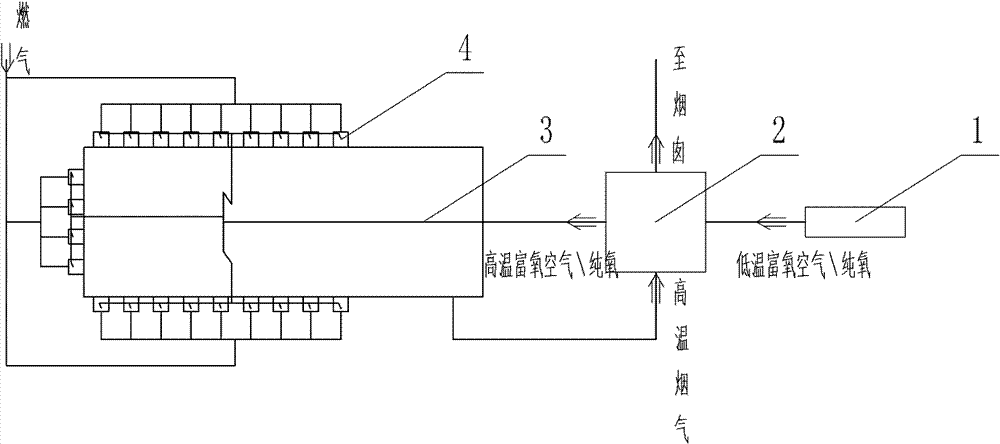

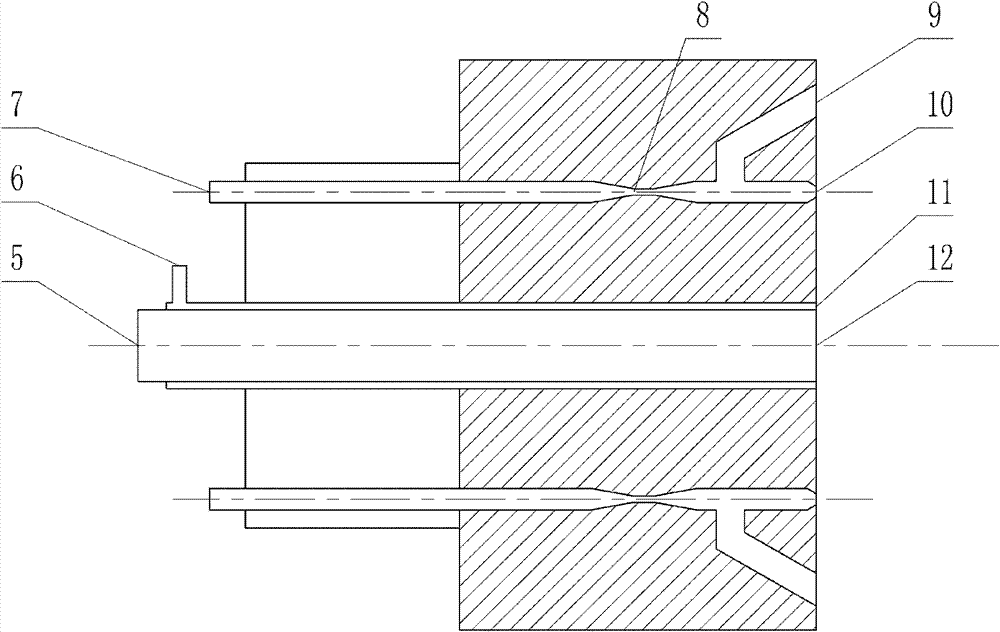

[0015] The present invention includes an oxygen-enriched or pure oxygen device 1, a continuous waste heat recovery device 2, a heating furnace 3, and a high-temperature oxygen-poor burner 4. The oxygen-enriched or pure oxygen device 1 is connected to the continuous waste heat recovery device 2 through a pipeline, and the continuous waste heat recovery device 2 is located in the flue of the heating furnace. The outlet of the continuous waste heat recovery device 2 is connected to the oxygen-enriched or pure oxygen inlet of the high-temperature oxygen-poor burner 4 . The high-temperature oxygen-poor burner 4 is installed on the furnace wall of the heating furnace 3 . The continuous waste heat recovery device 2 is placed in the flue of the heating furnace 3, the pressure obtained from the oxygen-enriched or pure oxygen device 1 is 6000Pa ~ 7000Pa, and the oxygen-enriched air or pure oxygen with an oxygen content greater than 21% enters the continuous waste heat placed in the flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com