Waste heat recovery steel rolling heating furnace based on MILD oxygen-enriched combustion and heating method thereof

An oxygen-enriched combustion and waste heat recovery technology, which is applied in the combustion method, combustion chamber, burner, etc., can solve the problems of poor flame stability, uneven temperature distribution of oxygen-enriched combustion, and high safety hazards in the oxygen-enriched combustion method. Uniform and overcome the effect of increasing the theoretical combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

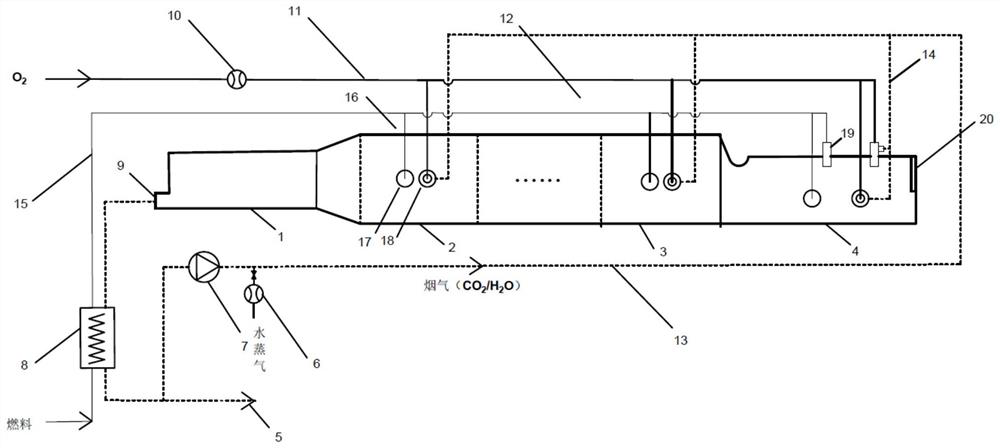

[0043] A kind of waste heat recovery steel rolling heating furnace based on MILD oxygen-enriched combustion, its structure diagram is as follows figure 1 As shown, it includes a preheating section 1, a heating section and a soaking section 4, which are connected in sequence, an oxygen main pipe 11, a flue gas main pipe 13, a fuel main pipe 15, the 5-flue gas outlet, 6-water vapor adjustment device, 7- - Fan, 8- Flue gas recuperator, 9- Flue gas outlet of preheating section, 10- Flow control device, 16- Fuel branch pipe, 17- Fuel burner, 18- Oxidant burner, 19- Soaking section flat Flame burner, 20-exit furnace door. The heating section is provided with several sections, including heating section 2, heating section 2, . . . , and heating n section 3.

[0044] The preheating section 1 is provided with a preheating section flue gas outlet 9, and the soaking section 4 is provided with an outlet furnace door 20;

[0045] Both the heating section and the soaking section are provid...

Embodiment 2-8

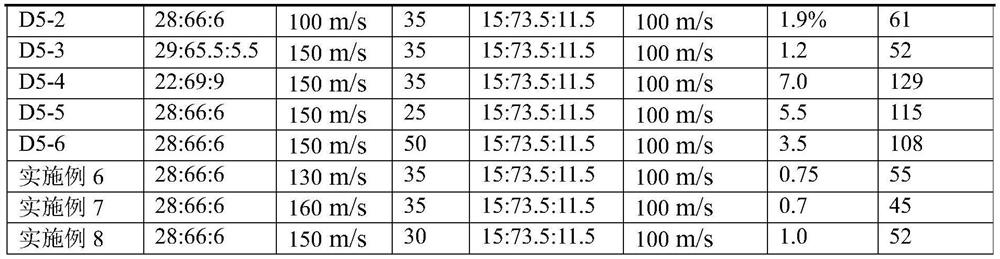

[0059] The same as Example 1, the difference is that the values of technical parameters in the soft combustion stage, the nitrogen oxide formation concentration during the heating and calcining process of the billet and the oxidation burning loss of the final billet are different, and the difference parameters are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com