Patents

Literature

57results about How to "Product quality indicators are stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

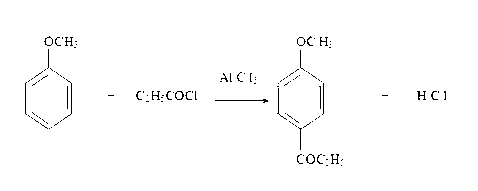

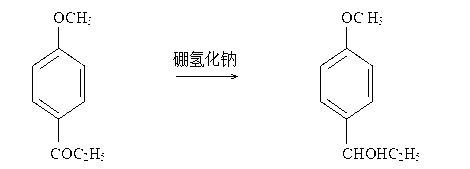

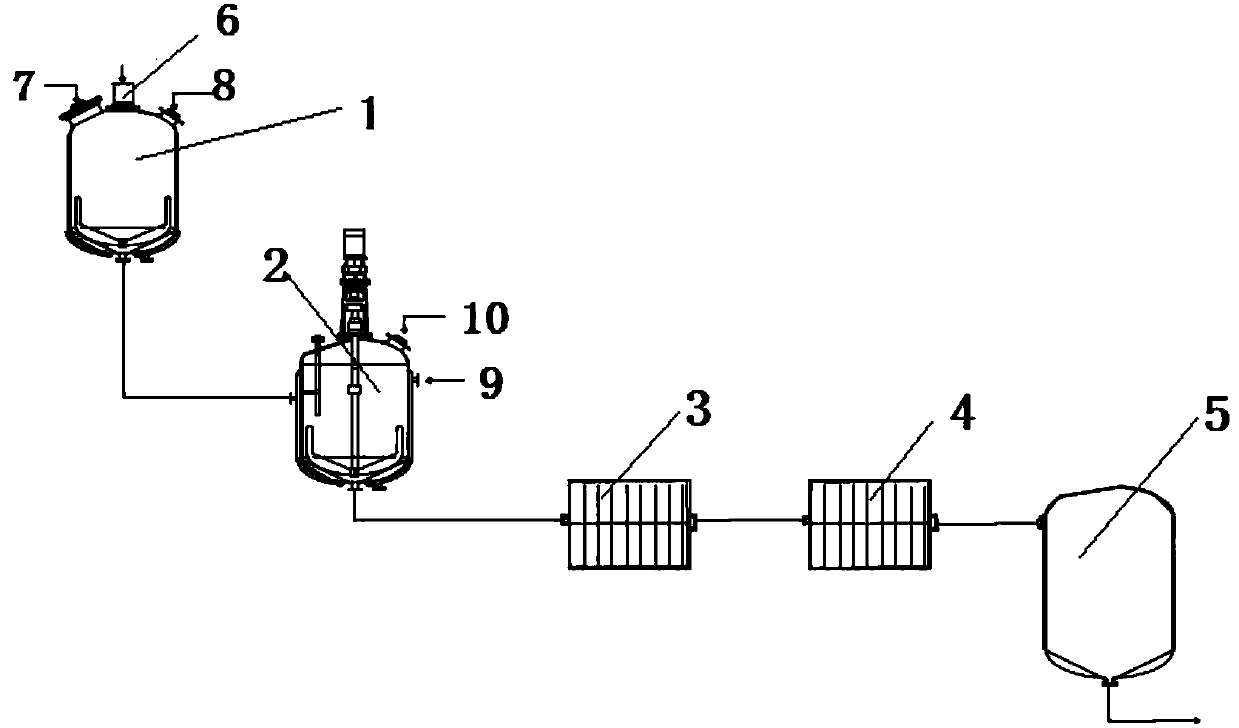

Synthetic method of anethole

InactiveCN103058835AReduce lossesLow costOrganic chemistryOrganic compound preparationSolventSide reaction

The invention discloses a synthetic method of anethole. Anisole and propionyl chloride serve as starting raw materials, are subjected to a friedel-crafts acylation reaction, then are restored through sodium borohydride, and then are catalyzed and dehydrated through organic acid and acid inorganic salt, and finally the anethole is manufactured through rectification. Side reaction is low through the adoption of acylation and reduction, a middle body is not needed to be purified and can be directly put into the next reaction, purification loss and purification cost of the middle body are reduced, yield coefficient is improved, and energy consumption is reduced. A chemical reduction method is utilized to replace a catalytic hydrogenation method, selectivity is high, response speed is fast, side reactions are small in number, and reduction yield coefficient can reach above 98%. Double catalysts are adopted to carry out ordinary pressure low temperature dehydration in dissolvent with a low boiling point, and compared with a negative pressure continuous dehydration method, dehydration time can be shortened by 90%, and the energy consumption is greatly reduced. The total yield coefficient of the method can reach 75%. A product quality index is higher than that of a natural product standard.

Owner:HUAIAN WAN BANG SPICE IND CO LTD +1

Preparation method of medium-viscosity cellulose acetate butyrate

The invention discloses a preparation method of medium-viscosity cellulose acetate butyrate. The preparation method comprises the following steps of pulverizing wood pulp; uniformly spraying a mixture of acetic acid and butyric acid into the pulverized wood pulp, and activating for 1h to 6h at the normal temperature; cooling a mixture of acetic anhydride, butyric anhydride, butyric acid and a liquid acid catalyst to minus 5 DEG C to minus 20 DEG C for standby use; slowly throwing the activated wood pulp into the well-cooled mixture, and maintaining the temperature to be less than or equal to 65 DEG C; adding magnesium acetate solution into the reacted system, and adding 200 to 500 parts by weight of acetic acid with the mass percentage of 50 to 70 percent for hydrolysis, wherein the system temperature is controlled at 60 to 70 DEG C, and the hydrolysis time is 2h to 5h; continuing adding magnesium acetate to neutralize the liquid acid catalyst, and adding the material into water for chromatographic solid-liquid separation; washing the separated CAB (cellulose acetate butyrate) solids with water until the acid value is less than 300ppm, and drying the CAB solids to obtain the CBA finished product. Through the method, a method for preparing medium / high-viscosity CAB is developed, and the content of butyryl in CAB is 36 to 40 percent; the power viscosity is 400cps to 1000cps.

Owner:JIANGSU RUICHEN CHEM

Method for removing residual formic acid in epoxidized fatty acid methyl esters or epoxidized soybean oil by use of eutectic solvent

ActiveCN103272407ASimple process operationLow costLiquid solutions solvent extractionSolventFormic acid

The invention belongs to the field of chemical technology and specifically relates to a method for removing residual formic acid in epoxidized fatty acid methyl esters or epoxidized soybean oil by the use of a eutectic solvent. The method provided by the invention comprises the following specific steps: sending crude epoxidized fatty acid methyl esters or crude epoxidized soybean oil which contains 0.2-15wt% of formic acid and is obtained by a epoxidation process through a formic acid method into an extraction kettle, adding a certain amount of an extractant under the condition of stirring, stirring for a period of time, standing for layering, sending a material on the upper layer into a vacuum dehydration kettle for further dehydration and refining, pouring an extract on the lower layer into an extractant regeneration kettle; heating under the condition of pressure reduction to distill formic acid in the extract, recycling the formic acid steam after being condensed in a condenser, and sending residual extractant left in the extractant regeneration kettle into the extraction kettle for recycling. The method provided by the invention has advantages of no discharge of waste water, high formic acid removal rate, simple technological operation, environmental protection, safety and low cost, and is suitable for both small-scale device and large-scale device production.

Owner:石家庄搏澳增塑材料科技有限公司

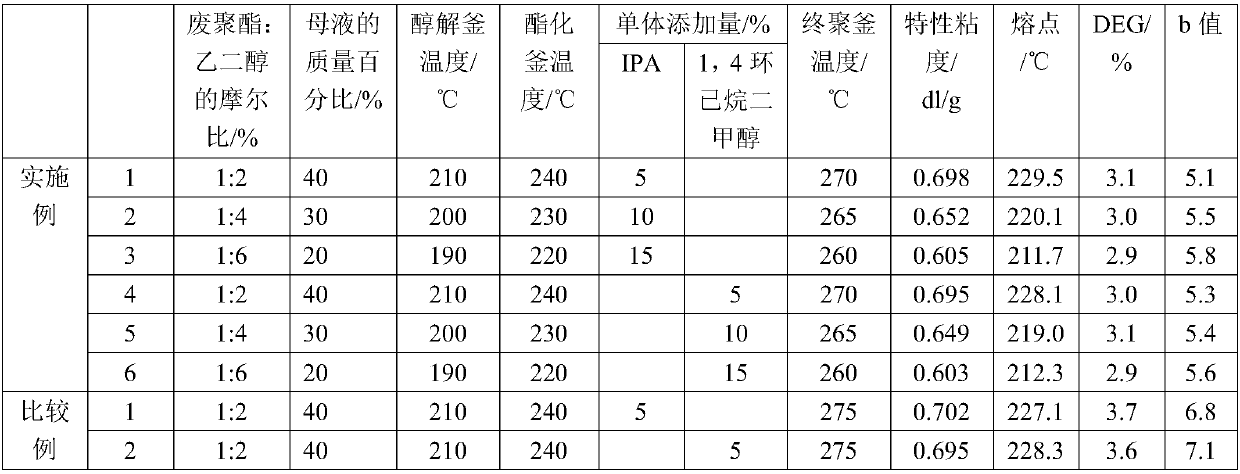

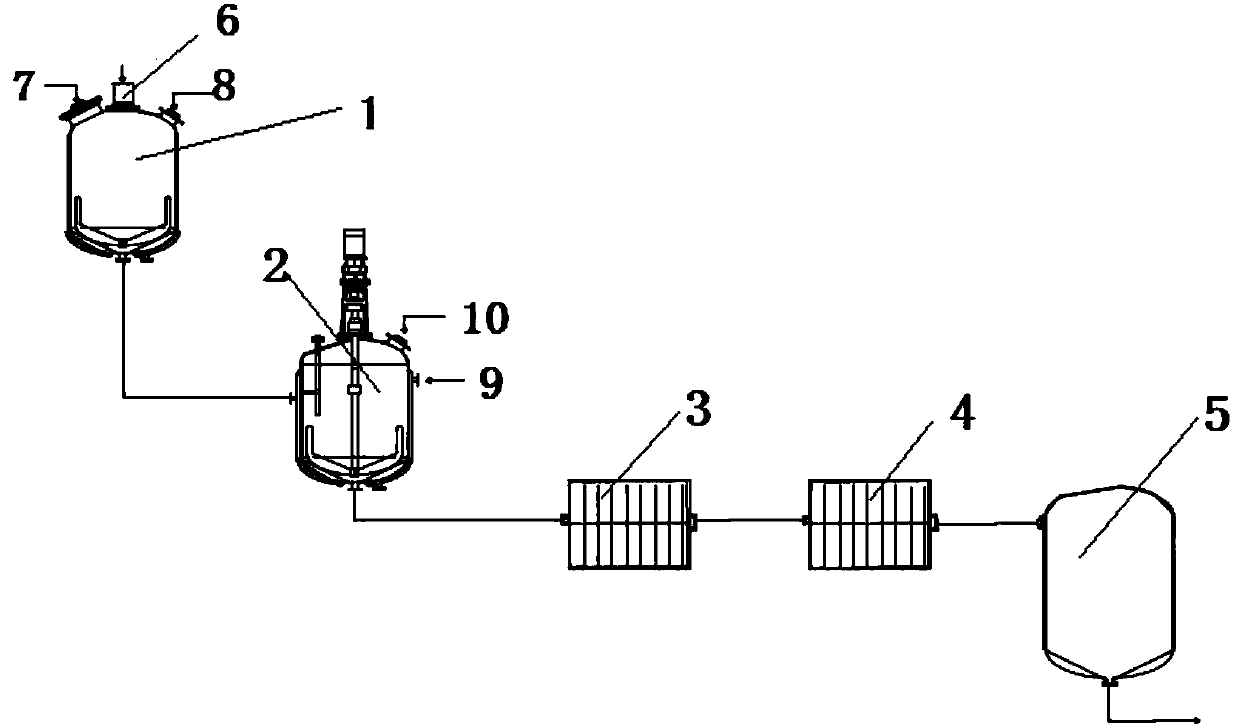

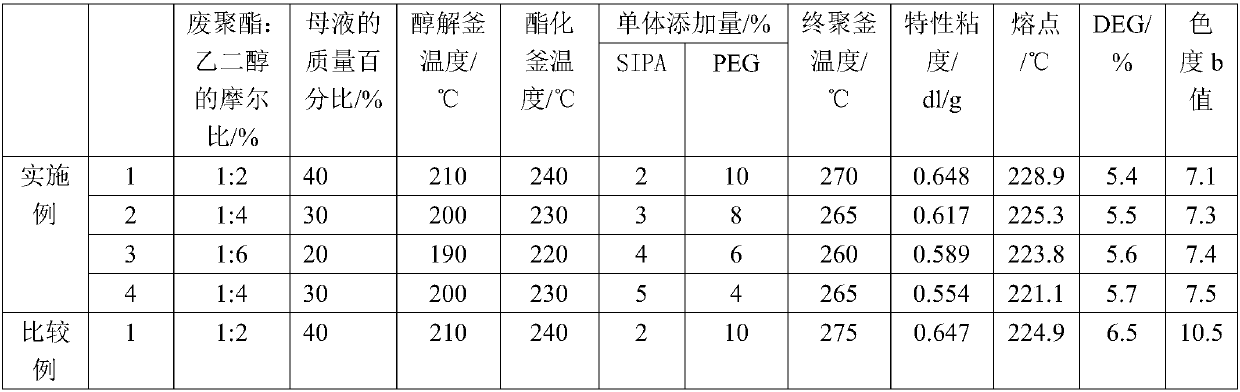

Method for preparing regenerated high-shrinkage polyester by waste polyester alcoholysis method

ActiveCN107793560AQuality improvementProduct quality indicators are stablePlastic recyclingPolyesterCyclohexanedimethanol

The invention discloses a method for preparing regenerated high-shrinkage polyester by a waste polyester alcoholysis method. The method comprises the following steps: (1) pretreatment of waste polyester, (2) alcoholysis of the waste polyester, (3) quality regulation and control of ester and addition of isophthalic acid or 1,4-cyclohexanedimethanol comonomer, and (4) polycondensation and preparation of sections. The intrinsic viscosity of the finally obtained regenerated high-shrinkage polyester is 0.60-0.70 dl / g, the melting point is 210-230 DEG C, the content of diethylene glycol is 3.0+ / - 0.3%, and a chroma b value is less than 6. The prepared regenerated high-shrinkage polyester can be used for preparation of high-shrinkage polyester filaments, short fibers and high-shrinkage polyesterfilms; and high-valued recycling of the waste polyester is realized.

Owner:ZHEJIANG SCI-TECH UNIV

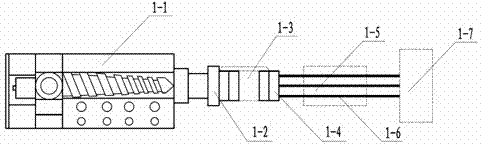

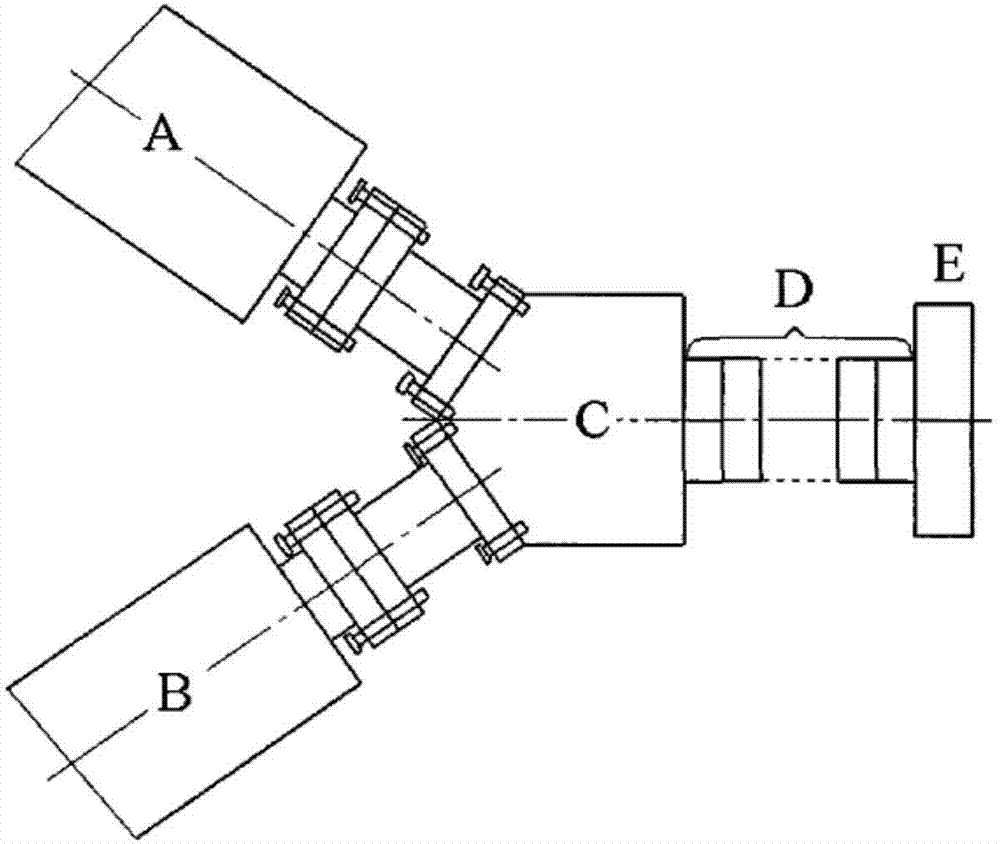

Preparation method of macromolecular multi-layered hydrogel drug sustained-release material

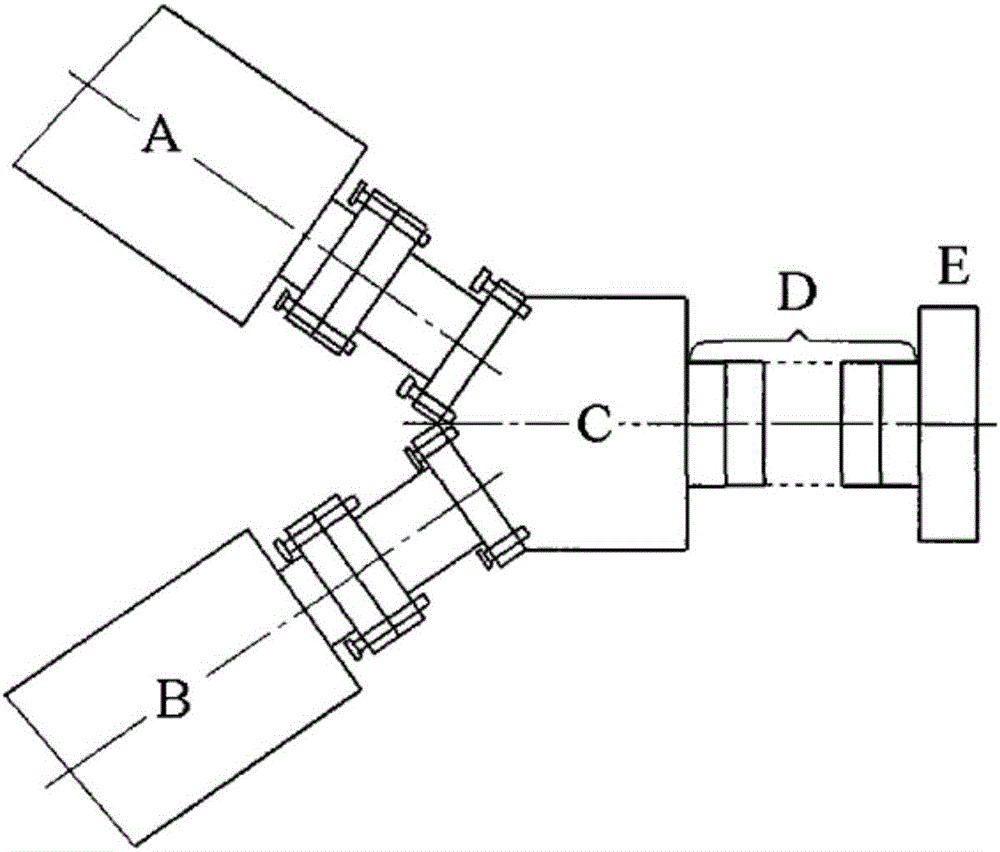

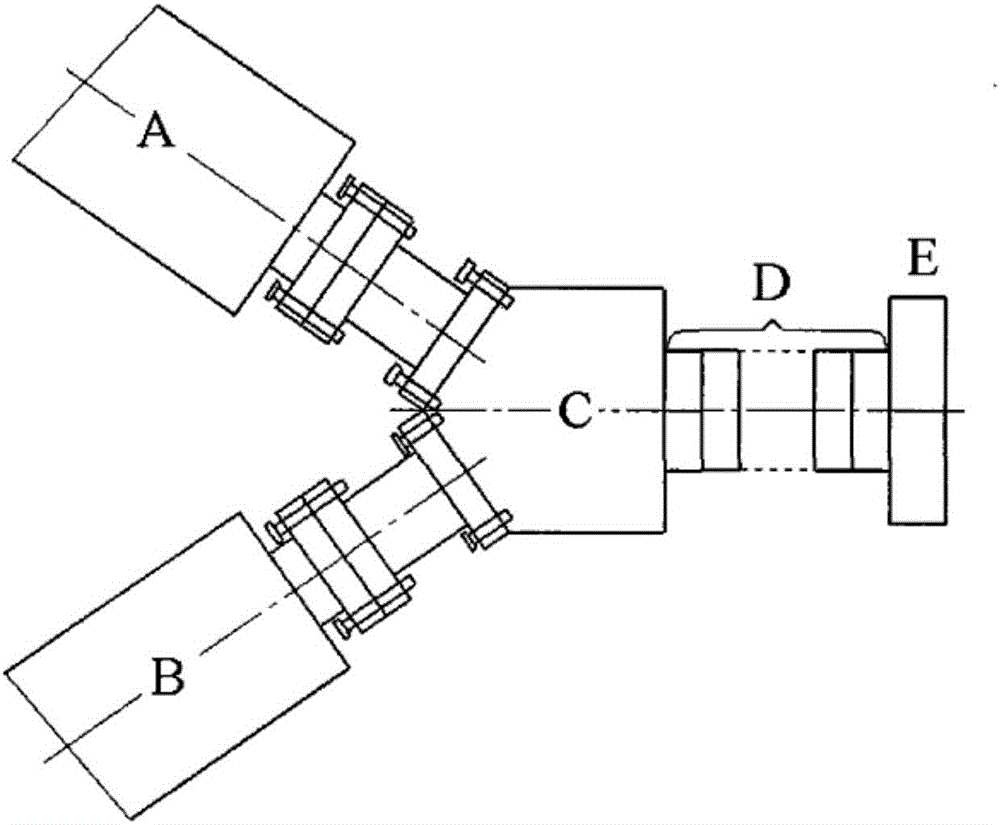

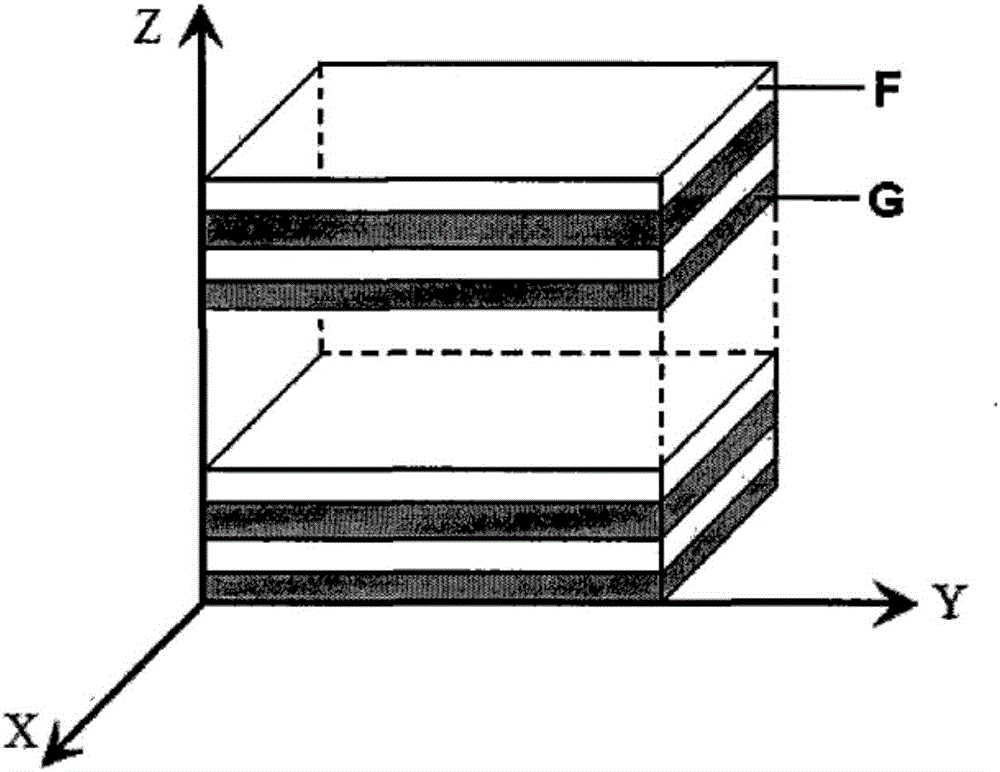

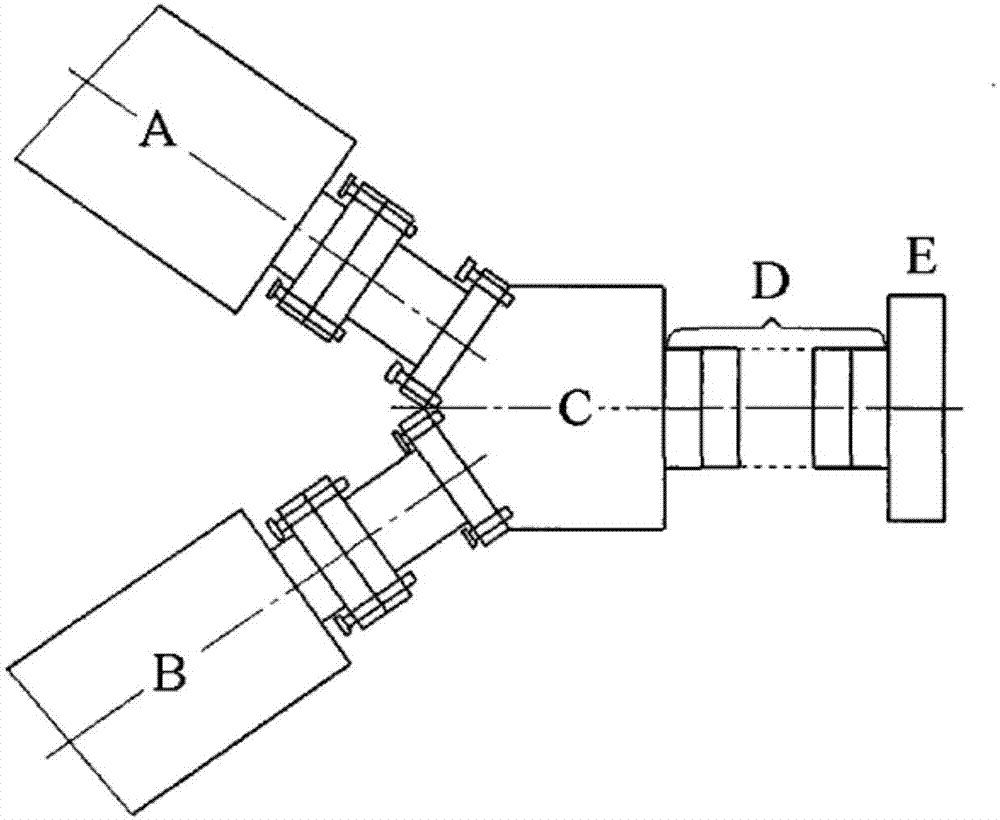

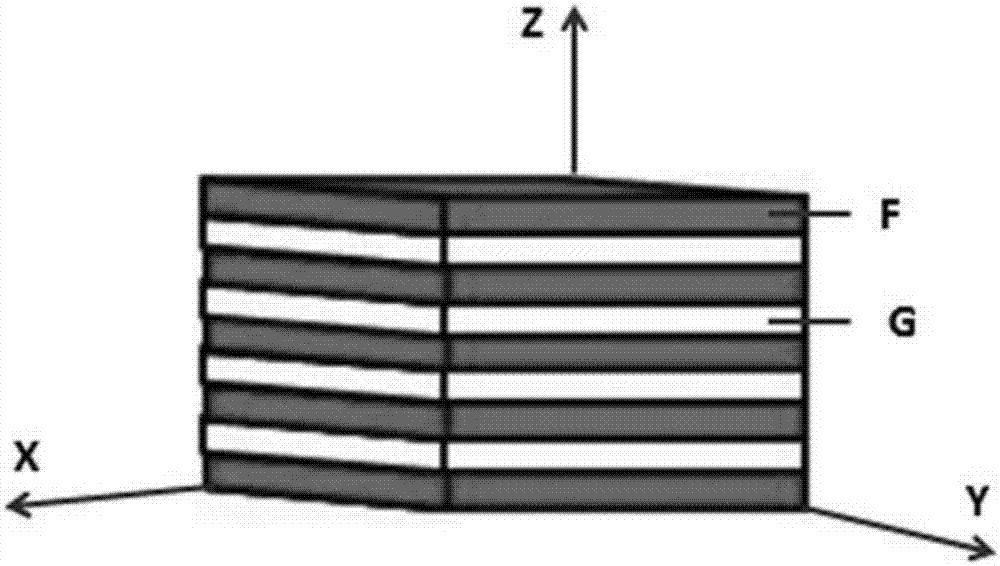

ActiveCN106344497AEasy to achieve alternate layer laminationFlexible control of sustained releaseAerosol deliveryOintment deliveryPolyelectrolyteSuperimposition

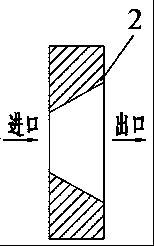

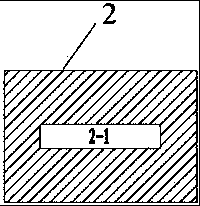

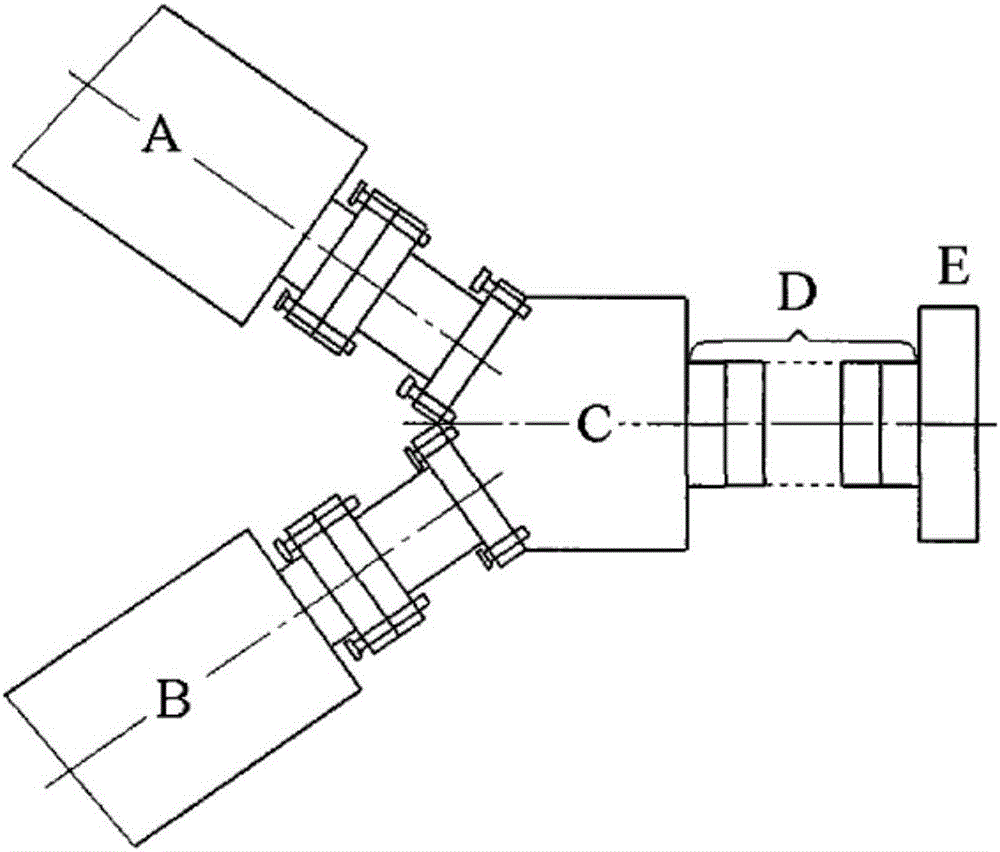

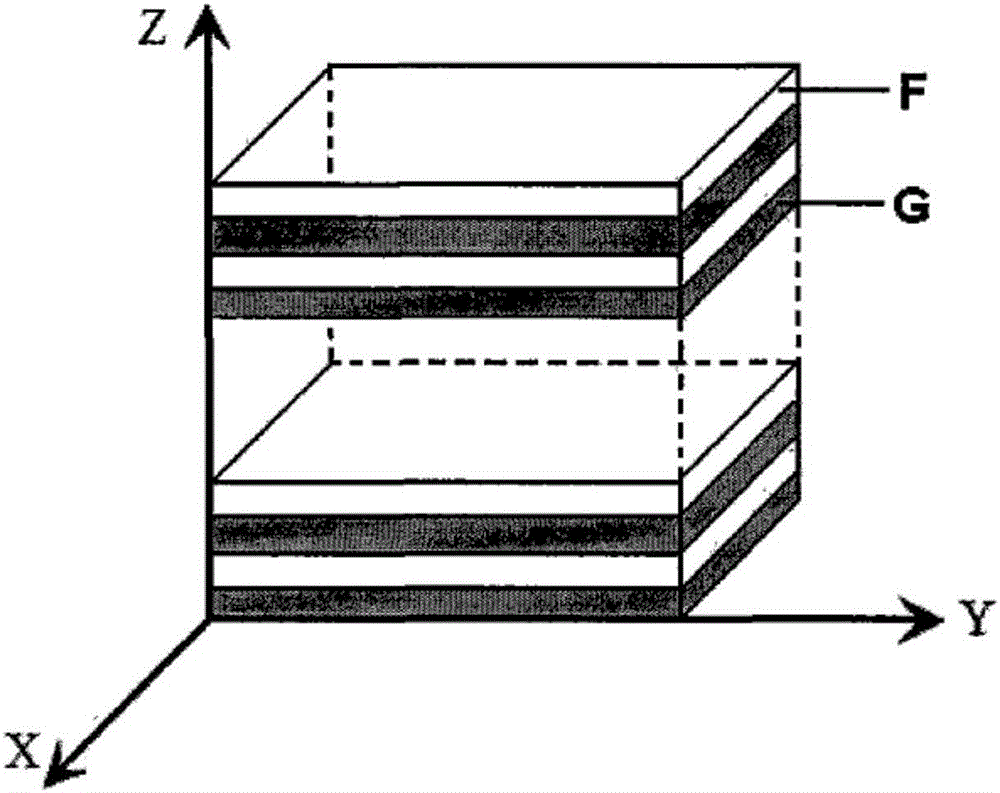

The invention relates to a preparation method of a macromolecular multi-layered hydrogel drug sustained-release material. The preparation method mainly includes steps of performing laminar superimposition function on the proper mixture ratio and composition of polyanion macromolecular blended solution A and polycation macromolecular blended solution B through a micro-bedding co-extruding device, sealing and placing the solution A and solution B to make them crosslink slowly and completely to realize structuring of macromolecular polyelectrolyte loaded with drugs, and to prepare a macromolecular polyelectrolyte hydrogel drug loading system with flexible and controllable drug form distribution, flexible and controllable drug sustained-release performance and having alternative multilayered structure, so as to meet different drug sustained-release demands. Compared with the traditional method of preparing the macromolecular multi-layered hydrogel drug sustained-release material by superimposition layer by layer, the method is a continuous production method, and good for improving the production efficiency; the technique is simple, and product quality index between different batches is stable; the preparation can realize the large-scale industrial production, is wide in application scale and has wide industrial and market prospect.

Owner:SICHUAN UNIV

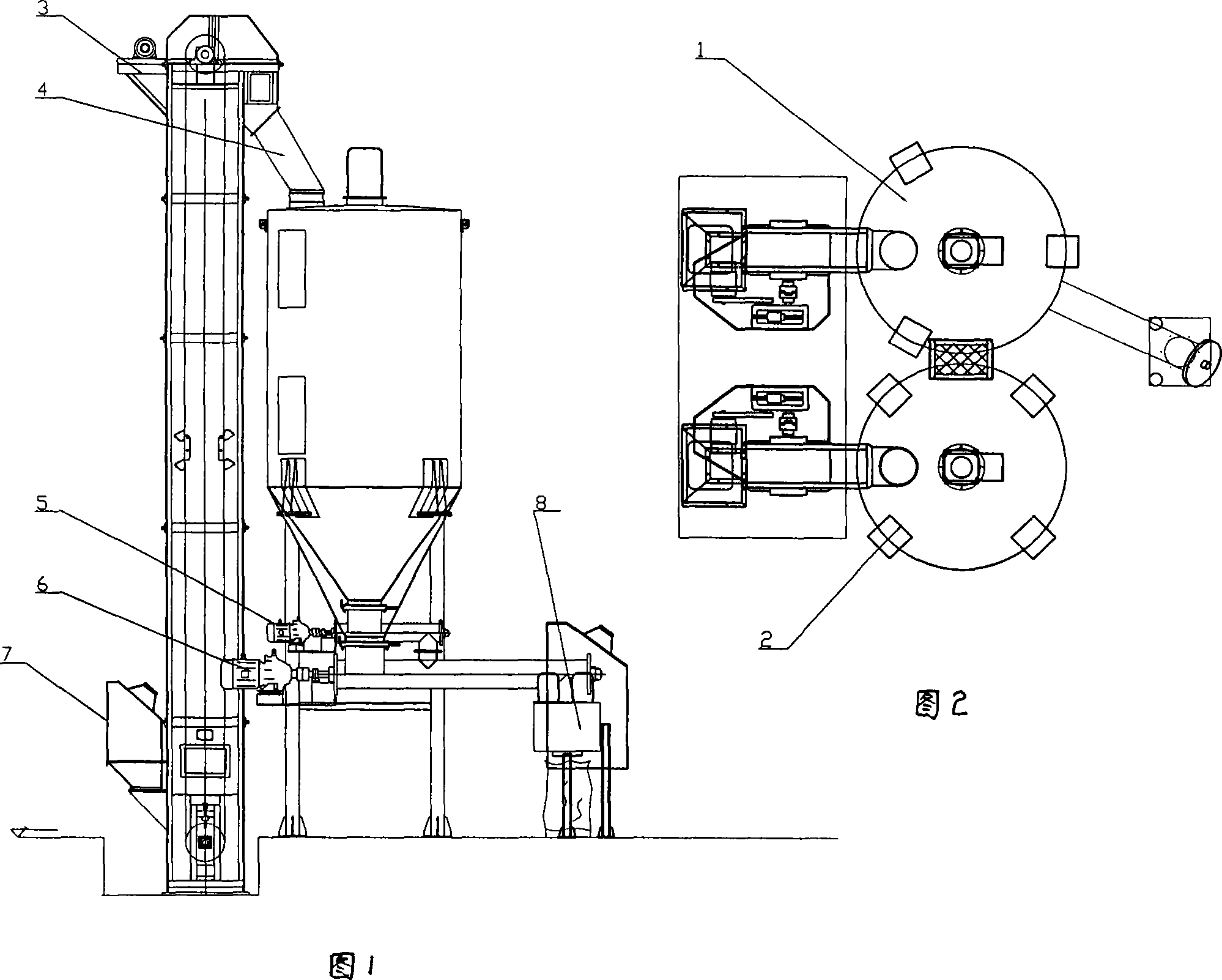

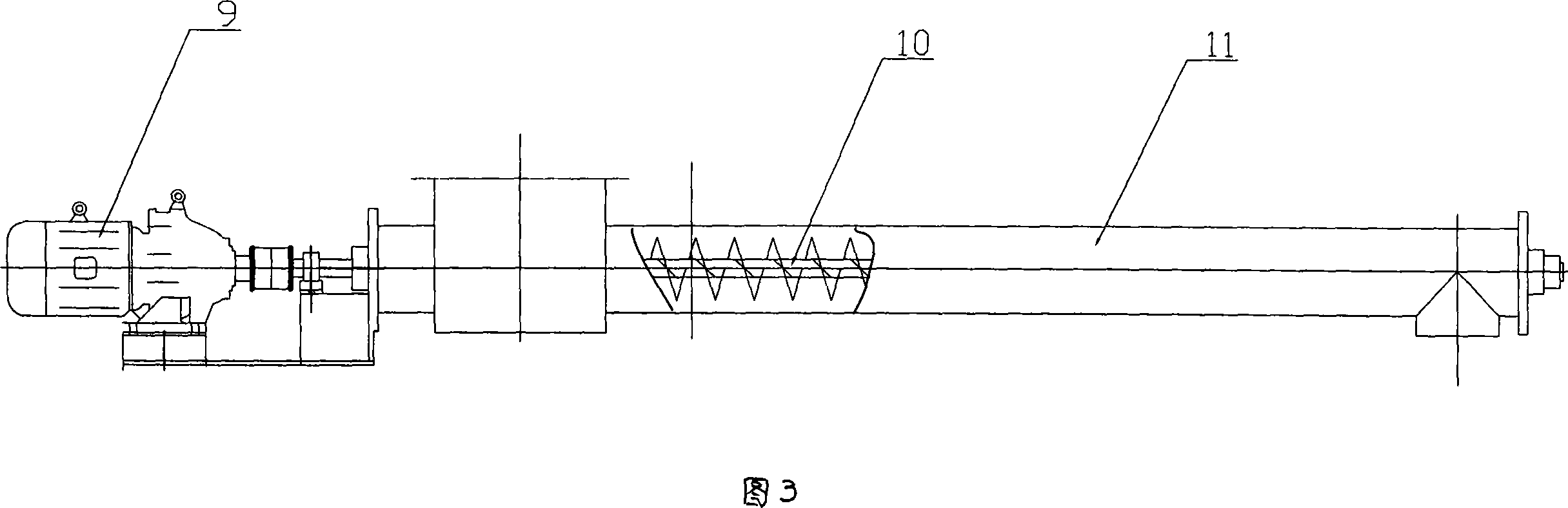

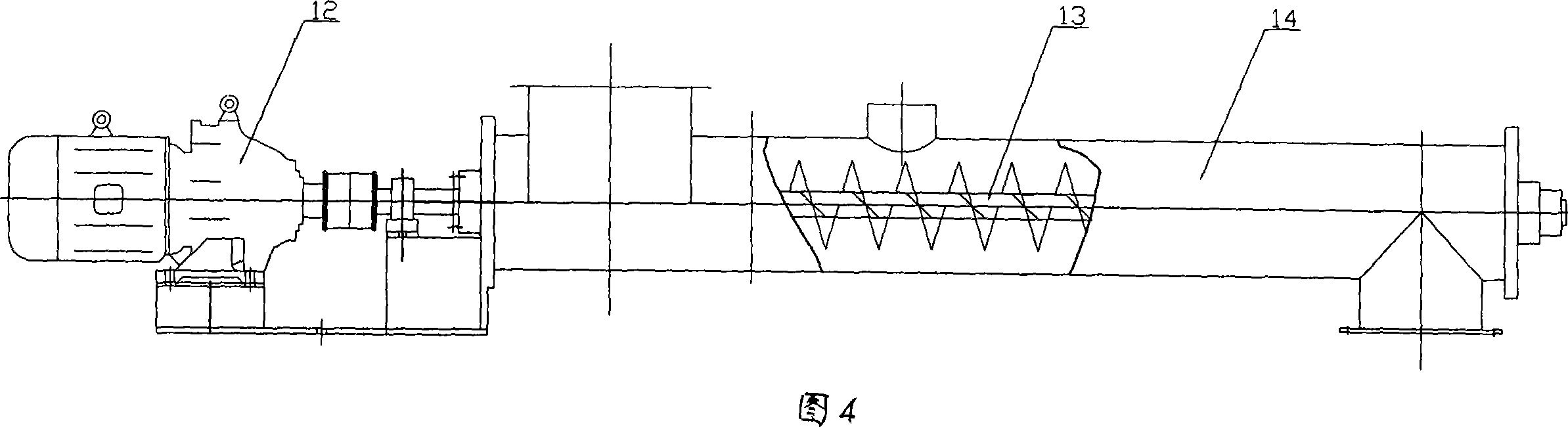

Continuous producing technology and device for thermal insulation dry powder mortar

InactiveCN101058217ASolve easy segregationSolve for uniformityClay mixing apparatusSold ingredients supply apparatusThermal insulationMaterials science

The invention relates to a heat-insulating mortar production process and device, mixing the powder and inorganic light aggregate into various barn, materials in both barns feeding to the spiral mixer continuously. The device comprises the feeder, hopper, feeding device, mixer, and packing machine. The two parallel barns have hoppers opposite to each other, feeder at the outlet of one barn, mixer at the outlet of a feeder, the other barn having a feeder mixer, and the packing machine setting at the outlet of the mixer. It realizes continuous production, low in labor, high in production efficiency, fine in product quality.

Owner:上海曹杨建筑粘合剂厂

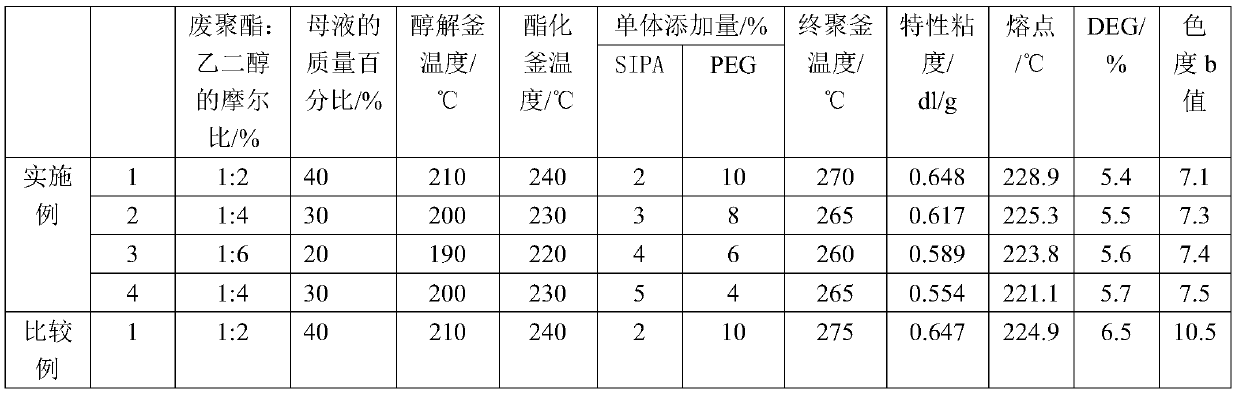

Method for preparing regenerative cationic-dye dyeable polyester with waste-polyester alcoholysis method

ActiveCN107652422AQuality improvementAchieve productionPlastic recyclingMonocomponent polyesters artificial filamentPolyesterFiber

The invention discloses a method for preparing regenerative cationic-dye dyeable polyester with a waste-polyester alcoholysis method. The method includes the steps of 1), pretreatment of waste polyester; 2), alcoholysis of the waste polyester; 3), quality regulation of esters and adding of isophthalic acid-5-sodium and polyethylene glycol as a comonomer; 4), polycondensation and slicing preparation, wherein the cationic-dye dyeable polyester finally obtained is 0.55-0.65dl / g in intrinsic viscosity, 220-230DEG C in melting point, 5.5+ / -0.3% in content of diglycol and smaller than 8 in chroma value of b. The obtained regenerative cationic-dye dyeable polyester is applicable to preparation of cationic-ion dyeable poester filaments and short fiber, and high-value recycling of the waste polyester is realized.

Owner:ZHEJIANG SCI-TECH UNIV

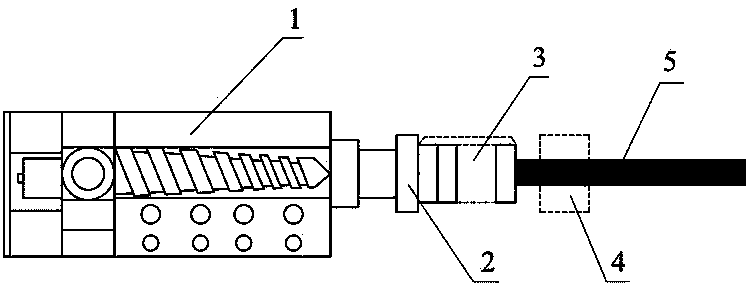

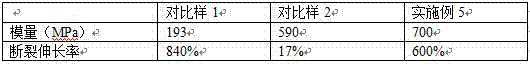

Method for preparing polymer/inorganic filler composite material

The invention discloses a method for preparing a polymer / inorganic filler composite material. The method for preparing the polymer / inorganic filler composite material is characterized by comprising the following steps: carrying out mixing granulation on polymers and inorganic fillers according to a certain proportion, conveying by an extruder in a bidirectional stretching melt mixing and molding integrated device, plasticizing and melting, thereby obtaining particles or sheets of the polymer / inorganic filler composite material with the inorganic fillers with good dispersibility and excellent performances under the bidirectional stretching-shearing acting force of bidirectional stretching melt mixers. According to the invention, inorganic filers are distributed more uniformly in a polymer matrix, and have few aggregates; moreover, the dispersion morphology and the dispersion degree of the inorganic fillers can be regulated and controlled by changing the number of the bidirectional stretching melt mixers. The polymer composite material obtained by the method provided by the invention has favorable mechanical performance, favorable thermal stability, favorable electric conductivity and favorable flame retardance. The method for preparing the polymer / inorganic filler composite material, which is provided by the invention, can be used for continuous production, is convenient to operate and control, is stable in quality, is high in production efficiency, and has wide application prospect.

Owner:SICHUAN UNIV +1

Method for preparing heat-conductive composite material

The invention discloses a method for preparing a heat-conductive composite material, wherein a crystalline polymer and a heat-conductive filling material are used as the raw materials; the crystalline polymer and the heat-conductive filling material are mixed according to the weight ratio of (50-80):(50-20); in the event of processing, polymer melt flows through a strong-shearing flow field; the dispersed state of the filling material in a polymer matrix is improved; more mutual contact heat-conductive network structures including the heat-conductive filling material, polymer crystal and the heat-conductive filling material are formed, and therefore, the heat-conductive coefficient of the composite material can also be greatly increased. On the basis of the existing traditional extrusion equipment, a bidirectional tensile mixer is additionally arranged; and the method for preparing the heat-conductive composite material prepared by the invention has the advantages of being simple to operate, continuous for production, convenient for operation control, steady in quality and high in production efficiency and has wide industrialization and market prospects.

Owner:SICHUAN UNIV

Preparation method of macromolecular laminar drug-loaded hydrogel with controllable drug distribution

ActiveCN106344496AAchieve decentralizationRealize alternate laminationAerosol deliveryOintment deliveryPolyelectrolyteSuperimposition

The invention discloses a preparation method of macromolecular laminar drug-loaded hydrogel with controllable drug distribution. The preparation method mainly includes steps of performing multiple times of laminar superimposition on polyanion macromolecular blended solution A with appropriate proportion and composition and polycation macromolecular blended solution B with appropriate proportion and composition through a microlayer co-extrusion device, and sealing and placing to allow the solution A and the solution B to crosslink slowly and completely to realize structuring of drug-loaded macromolecular polyelectrolyte so as to prepare a macromolecular hydrogel drug loading system with flexible and controllable drug form distribution and drug release performance and with an alternative multilayered structure to meet different drug release demands. Compared with a traditional method using layer-by-layer superposition to prepare the macromolecular laminar drug-loaded hydrogel, the method has the advantages that the method is a continuous production method and beneficial to the improving of production efficiency; the method is simple in process, the product quality indexes of different batches of produces are stable, and the method is capable of achieving large-scale industrial production, wide in application range and promising in industrialization and market prospect.

Owner:SICHUAN UNIV

Method for manufacturing carvacrol by carvone composite foot oil

ActiveCN103058829AImprove product quality indicatorsMild reaction conditionsOrganic chemistryOrganic compound preparationSulfonateHydrogen

The invention discloses a method for manufacturing carvacrol by carvone composite foot oil. The method comprises the steps of enabling sodium hydrogen sulfite and carvone of the composite foot oil to be subjected to an additive reaction, generating water-soluble alpha-hydroxy sodium sulfonate, separating insoluble organic impurities, then heating the alpha-hydroxy sodium sulfonate together with alkali, hydrolyzing the alpha-hydroxy sodium sulfonate and the alkali to be the carvone, isomerizing and rectifying the carvone, and obtaining the carvacrol. The alkali is sodium hydroxide. The method for manufacturing the carvacrol by the carvone composite foot oil has the advantages of being temperate in reaction condition, convenient to operate and prone to industrialization. Waste water generated in various steps of the reaction is neutral. A sulfuric acid solution can be repeatedly used. A recovery rate of the carvone of the composite foot oil is more than 80 percent. The manufactured carvacrol is more than 9.5 percent in content and product quality indexes are higher than the perfume grade standard.

Owner:HUAIAN WAN BANG SPICE IND CO LTD

Method for preparing medicament sustained-release material

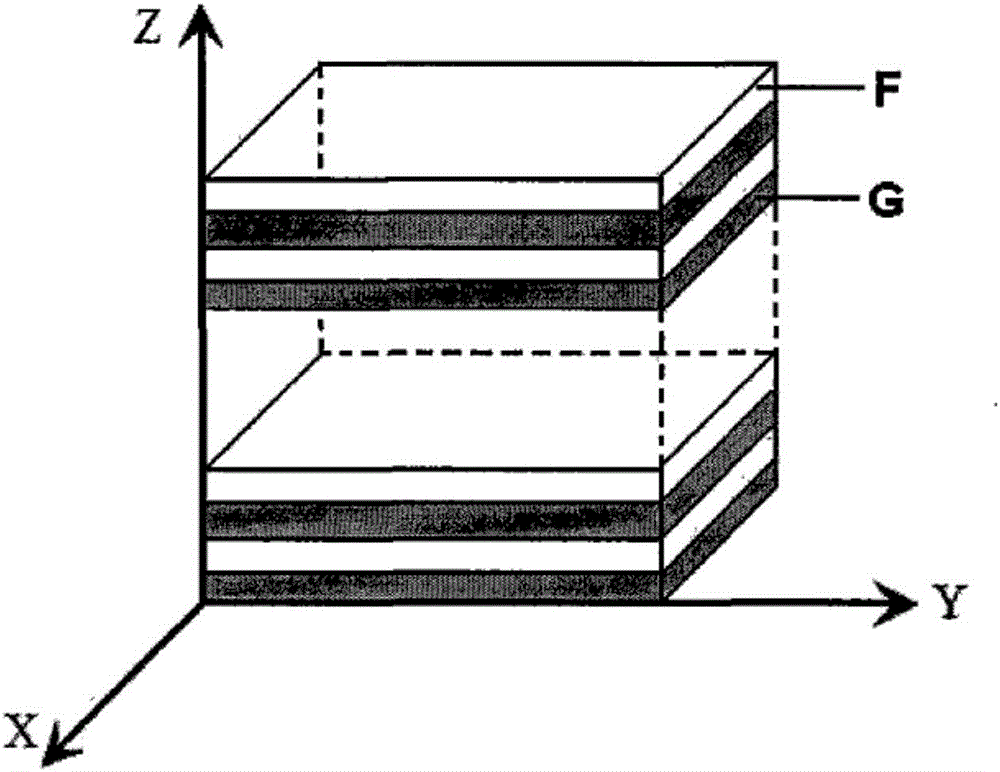

ActiveCN103735490AHigh aspect ratioChange orientationPharmaceutical delivery mechanismPharmaceutical non-active ingredientsPolymer scienceEngineering

The invention discloses a method for preparing a medicament sustained-release composite material. In the method, biodegradable high polymers are taken as a substrate and a dispersed phase, and 50-99 percent by weight of a biodegradable high polymer substrate, 50-1 percent by weight of a biodegradable high polymer dispersed phase, and a medicament of which the amount is 0.01-40 percent based on the total weight of a biodegradable high polymer mixture are fused and mixed by using an extruding machine of a multi-stage bilateral stretching, mixing and pelletizing integrated device, so that structuring of a drug-loading biodegradable high polymer blend is realized, a high polymer drug-loading substrate with flexibly-controllable releasing performance is prepared, and different medicament releasing demands are met. By adopting a continuous production process in the method, the production efficiency is increased, the process is simple, and the quality indexes of different batches of products are stable. The method can be applied to large-scale industrial production, is wide the application range, and has wide industrial and market prospects.

Owner:SICHUAN UNIV

Method for preparing alternate lamellar bio-degraded polymer drug controlled-release composite

ActiveCN106421799AImprove mechanical propertiesImprove phase morphologyOrganic active ingredientsPharmaceutical non-active ingredientsControlled releaseDrug release

The invention provides a method for preparing an alternate lamellar bio-degraded polymer drug controlled-release composite. The method mainly includes the steps that polymer-based drug quick release layers and polymer-based drug slow release layers with different release behaviors are alternately and orderly arranged in a melt co-extrusion mode, polymers deform and are oriented in the extrusion process through the shear and stretching effects of a layer multiplier during multiple times of lamellar overlapping, drug diffusion and release channels are improved, and the obtained alternate lamellar bio-degraded polymer drug controlled release composite has the reasonable initial release concentration and required long-term release rate and achieves controllable, flexible and effective release of drugs to meet different drug release requirements. The alternate lamellar bio-degraded polymer drug controlled release composite is controllable in form and adjustable in formula; the mechanical property is excellent; continuous volume production can be achieved, and the production efficiency can be improved; the application range is wide, and wide industrial and market prospects are achieved.

Owner:SICHUAN UNIV

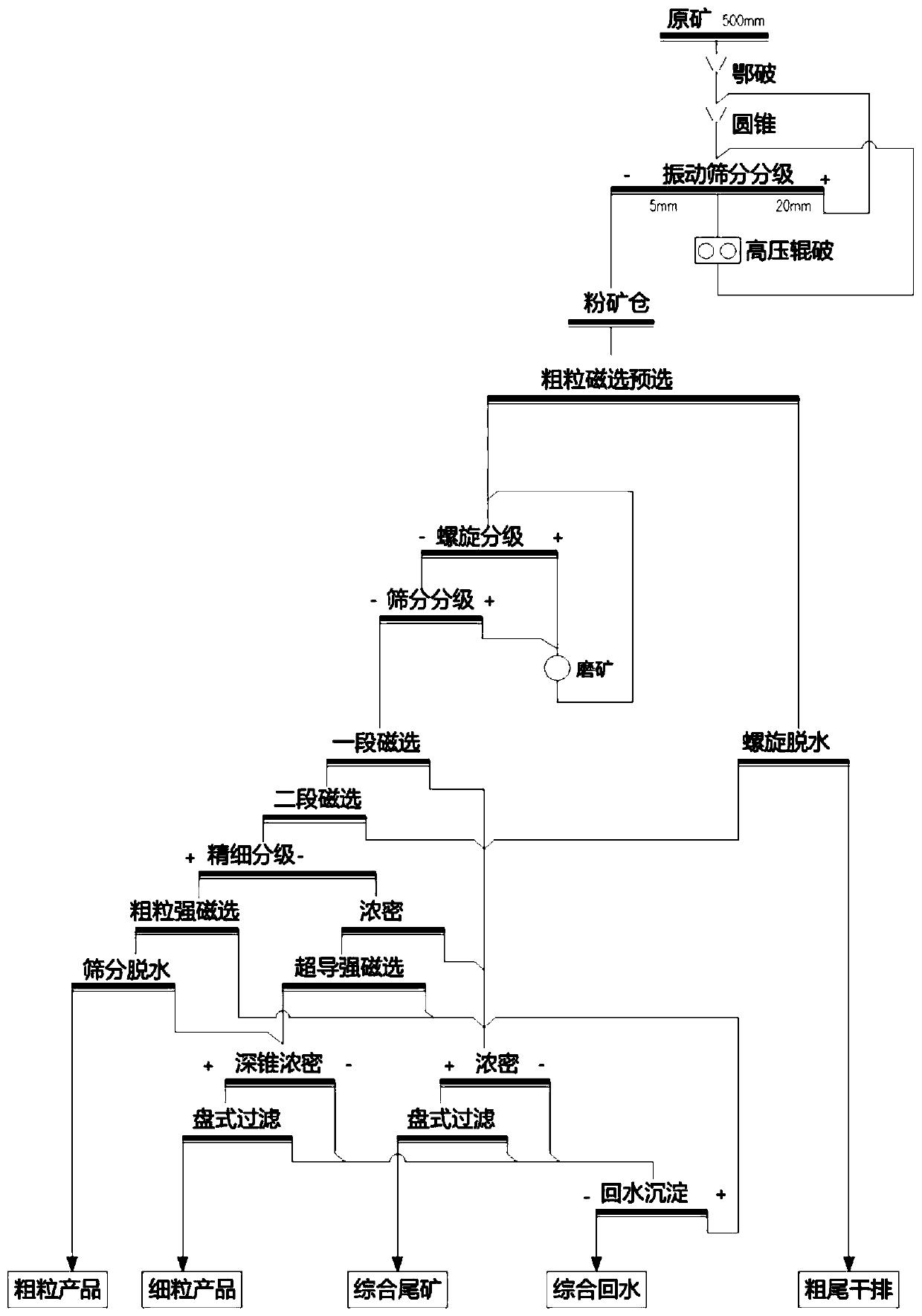

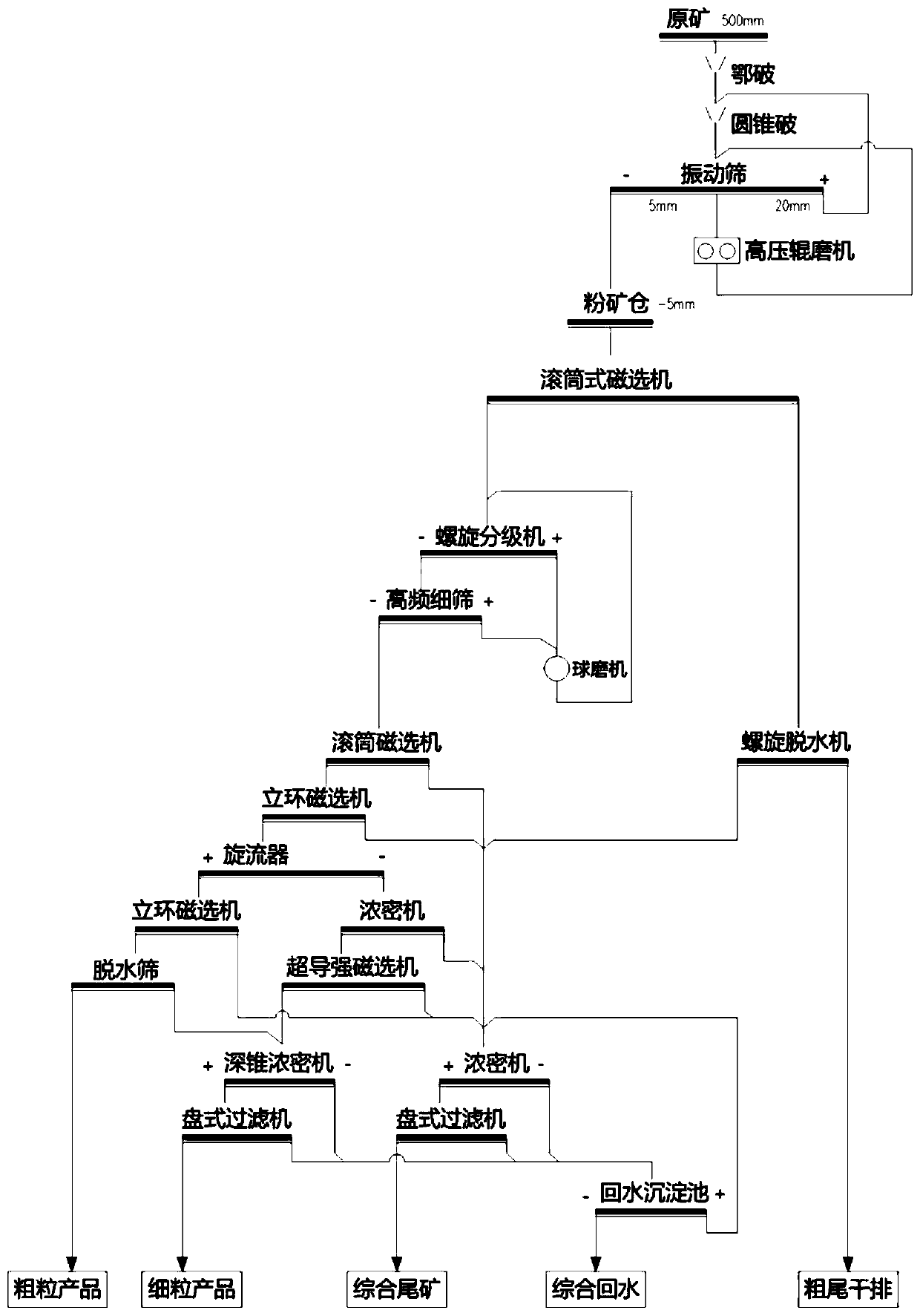

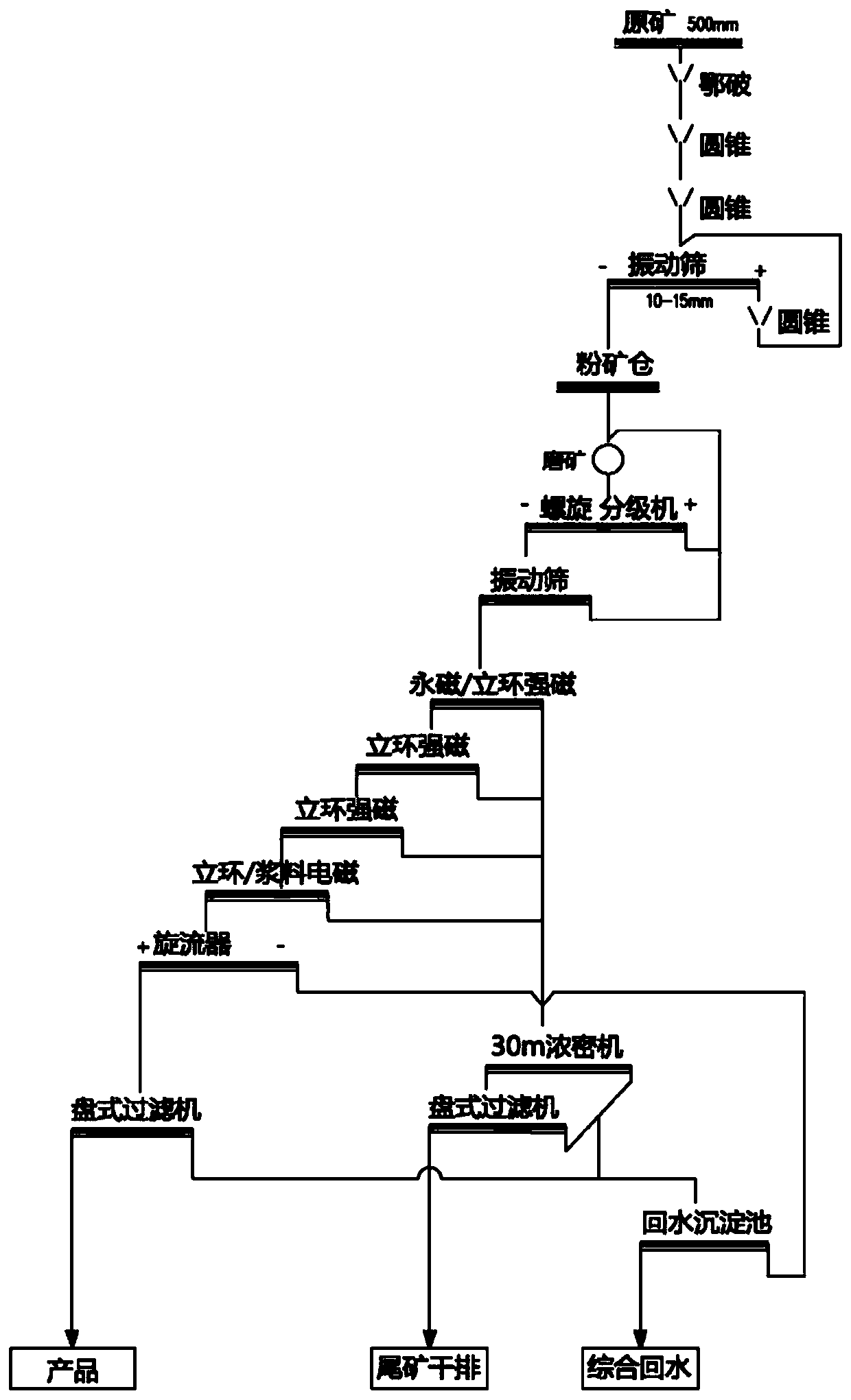

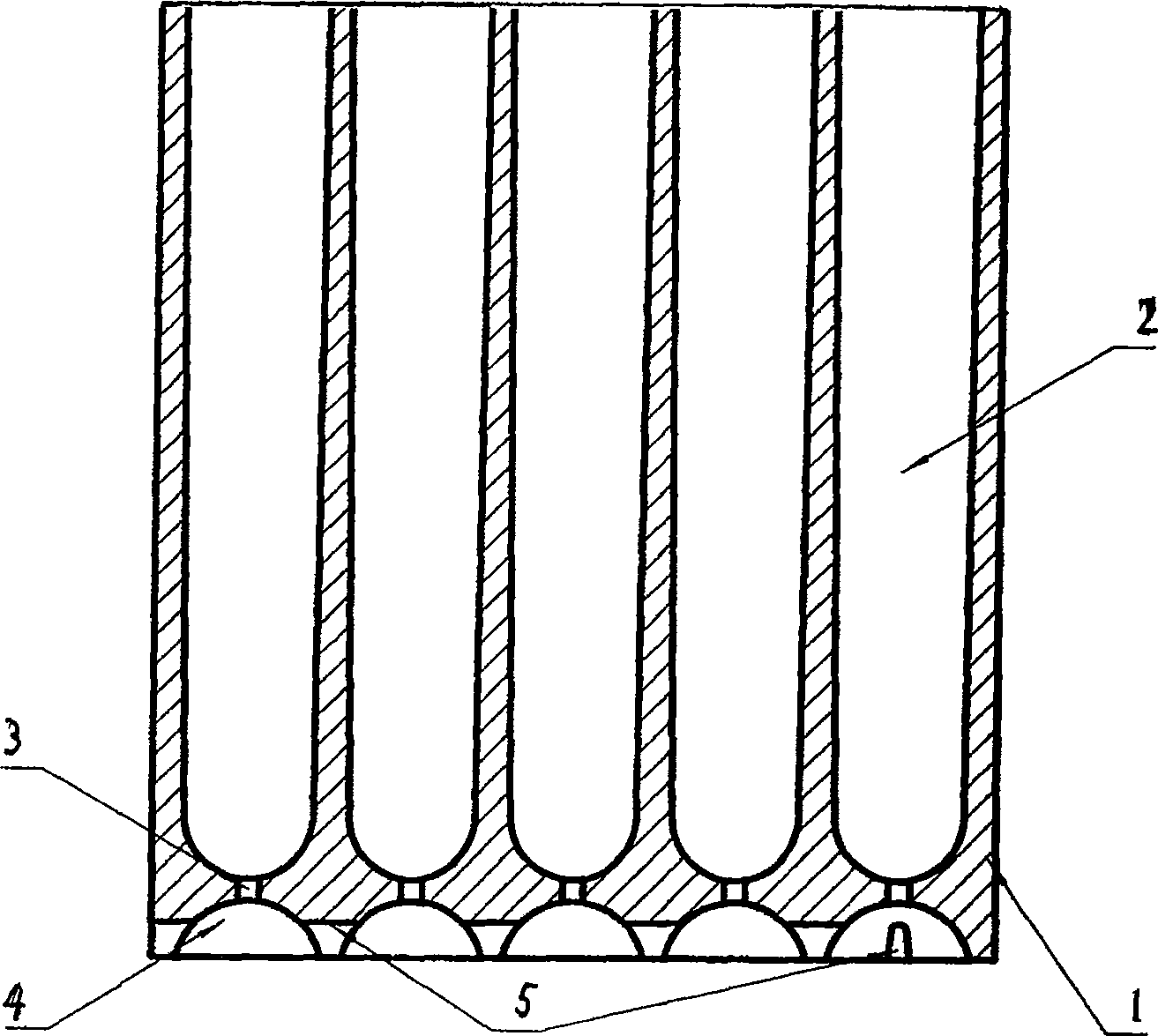

Method for improving quality, reducing cost and improving efficiency of ceramic raw materials prepared from granite stone waste rocks

ActiveCN110743684AImprovement of comprehensive technical and economic indicatorsIncrease throughputMagnetic separationGrain treatmentsMachining processGlass-ceramic

The invention provides a method for improving quality, reducing cost and improving efficiency of ceramic raw materials prepared from granite stone waste rocks. The method comprises the following steps: multi-stage crushing, laminated crushing, coarse grain pre-selection, pre-grading, partial ore grinding, multi-stage magnetic separation, grading separation, superconducting strong magnetic separation, grading dehydration and the like. The method is a pollution-free and environment-friendly physical technology in the whole process; compared with a traditional process, the comprehensive technicaland economic indexes are obviously improved, high-quality glass and ceramic raw materials with the K2O content of 6-10wt%, the Na2O content of 0.5-3.5wt%, the SiO2 content of 65-74wt% and the Fe2O3 content of 0.15wt% and the whiteness of 60-68 are obtained, the whiteness of the product is improved from 50-53 to 60-68 degrees, the yield is improved from 51-55% to 65-72%, and the treatment capacitycan be improved by 13-18%; the product structure is refined and diversified, and a proper product is provided for material homogenization, energy conservation and consumption reduction in the downstream glass and ceramic industry machining process.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Firework touch off base material taking amylum as base and method for preparing

InactiveCN100543401CHigh strengthReduce the possibility of bottoming outTextiles and paperFireworksFiberStearic acid

The invention provides a firework display base materials based on starch and the preparation method and relates to a preparation method of firework display base material and the base. The preparation method is that proper amount of water is poured after starch, grain powder or pulp are fragmented, part or all of release agent is added, then after being agitated uniformly, agitating while heating until the starch is totally gelatinized, slightly cooler, residual materials are poured in and mixed thoroughly into gray gunk. The gray gunk is filled into a die with a temperature of 150-280 DEG C, the die is closed to keep the heat until being dried, then a product is get after unloading from the die. The pulp is waste or new pulp or a market pulp board and the release agent is stearic acid, silicone oil or stearate. Based on the starch as the base material and supplemented by paper fiber, the invention has high strength and reduces possibilities of impacting the bottom when transmitting; a contour forging once-through shape craft is adopted which is very simple, the quality of the product is stable, and the individual difference is little without any deforming, moreover manpower is saved. By replacing the die, the invention can produce display shells, firework display tubes and various firework bases.

Owner:吕启晟

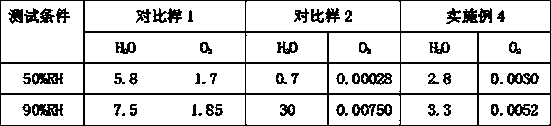

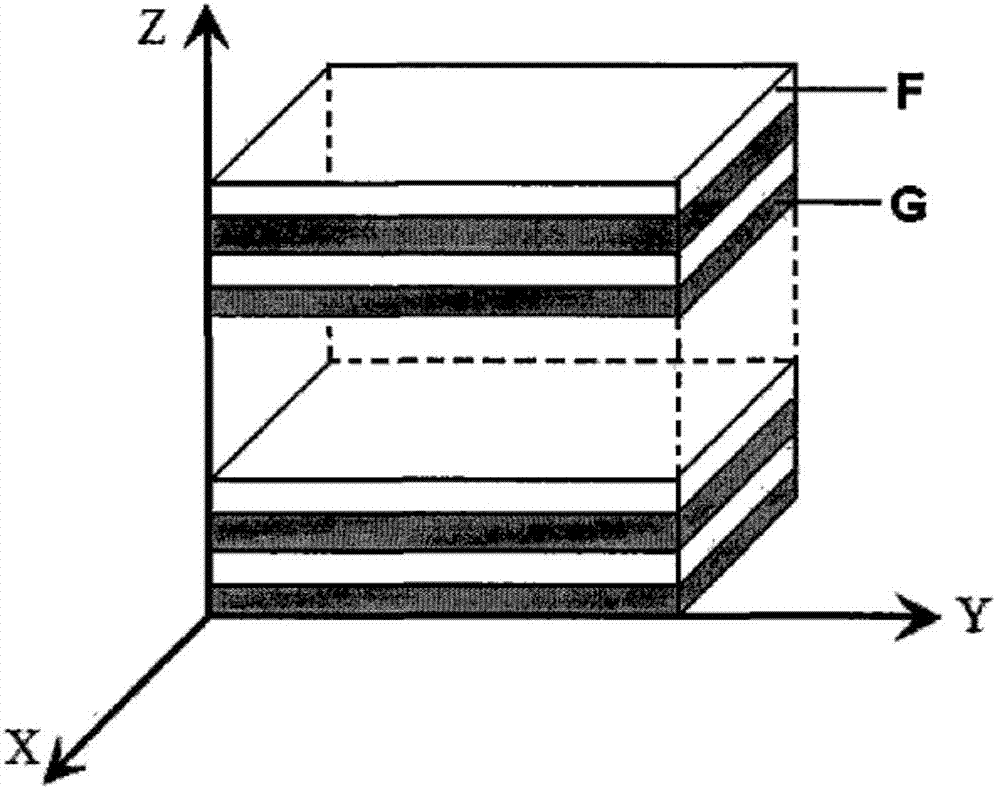

Method for preparing alternate layered biodegradable polymer barrier material with excellent water vapor and oxygen barrier properties

ActiveCN107286607AImprove hydrophobicityEffectively control the diffusion pathSynthetic resin layered productsLaminationWater vaporOxygen

The invention discloses a method for preparing an alternate layered biodegradable polymer barrier material with excellent water vapor and oxygen barrier properties. The method comprises the main content as follows: the water vapor barrier property and the stability of the barrier property on humidity are improved through adding hydrophobic substances to water vapor barrier layers, and the diffusion path of oxygen is increased to improve the oxygen barrier property through adding a filler with large specific surface area to an oxygen barrier layer; a multi-layer structure of which the water vapor barrier layers are arranged at the outmost layer and the internal oxygen barrier layer and the water vapor barrier layers are alternately arranged is designed by using a coextrusion system, thereby obtaining excellent water vapor and oxygen barrier properties and the stability of the properties on the humidity at the same time; dimensions and form structures of a disperse phase and the filler are optimized to further improve the barrier properties through stretching and shearing force fields in the coextrusion process, and meanwhile, the mechanical property is improved. The method is a continuous production process and is simple in process, products of different batches are stable in quality index, large-scale industrial production can be carried out, and the method has wide industrialization and market prospects, and is of great significance in theoretical research and application and development of a composite material.

Owner:SICHUAN UNIV

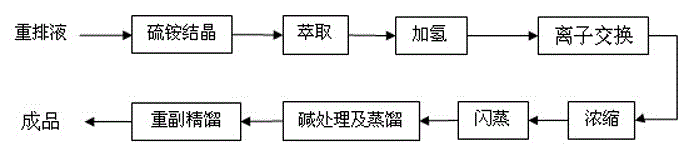

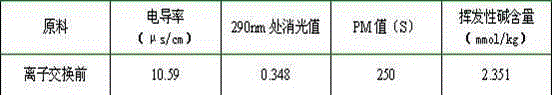

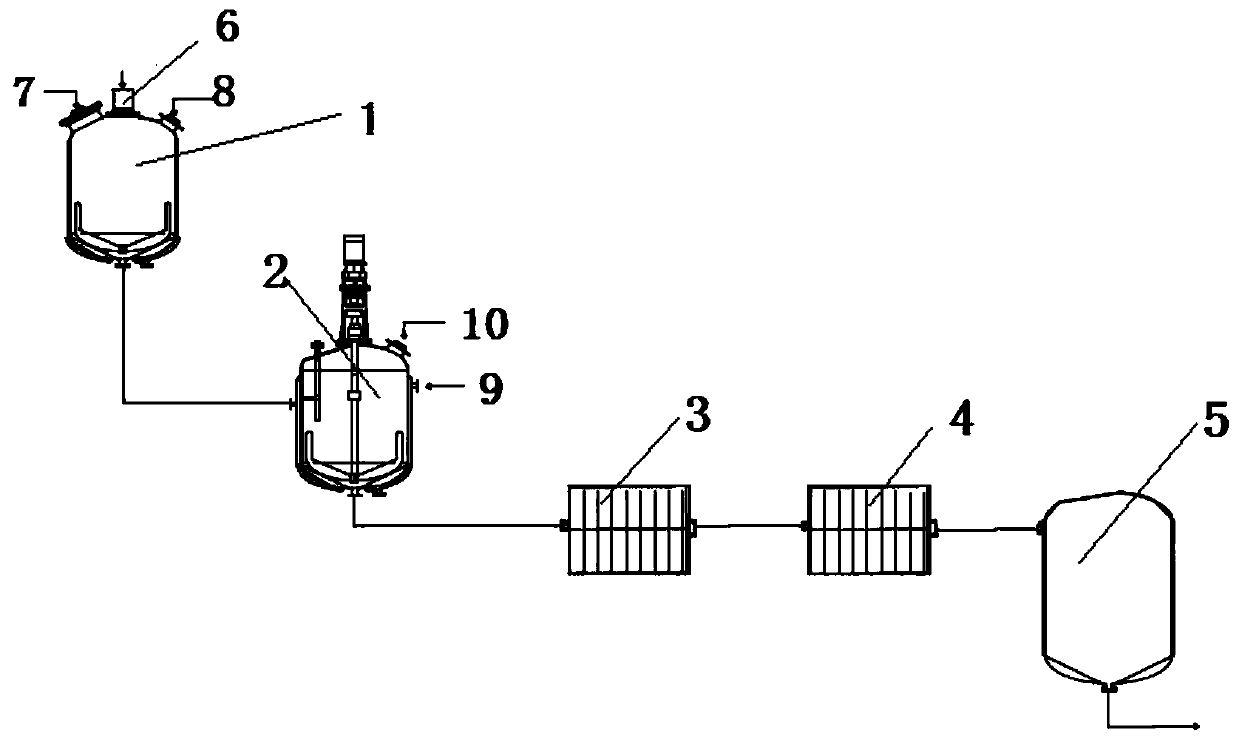

Process for refining caprolactam

InactiveCN105037233AReduce the number of regenerationsReduce use costLactams separation/purificationIon exchangeAqueous solution

The invention discloses a process for refining caprolactam. The process comprises the following steps: performing a hydrogenation reaction on a coarse caprolactam aqueous solution which is obtain after an extraction process; then, adsorbing by ion exchange; and further concentrating and distilling to prepare high-purity caprolactam. The process breaks through the convention of sequentially adsorbing and hydrogenating in the prior art, the extracted caprolactam aqueous solution is refined by adopting a process of sequentially hydrogenating and adsorbing by ion exchange, so that the content of impurities and inorganic salt which exist in coarse caprolactam and influence the product quality can be effectively reduced, and the coarse caprolactam can be purified. According to the process, the use cycle of ion exchange resin is prolonged, the number of regeneration times is reduced, massive wastewater generated by ion exchange resin regeneration is avoided, cost and resources can be reduced on the premise of improving the product quality, and pollution can be reduced.

Owner:XIANGTAN UNIV

A kind of method for preparing regenerated cationic dyeable polyester by alcoholysis of waste polyester

ActiveCN107652422BQuality improvementAchieve productionPlastic recyclingMonocomponent polyesters artificial filamentPolyesterFiber

The invention discloses a method for preparing recycled cationic dyeable polyester by alcoholysis of waste polyester, which comprises the following steps: 1) pretreatment of waste polyester; 2) alcoholysis of waste polyester; 3) quality of esterified product Regulation and addition of sodium isophthalic acid-5-sulfonate and polyethylene glycol as comonomers; 4) Polycondensation and preparation of slices; the intrinsic viscosity of the finally obtained regenerated cationic dyeable polyester is 0.55~0.65 dl / g, melting point 220~230℃, diethylene glycol content 5.5±0.3%, chroma b value less than 8. The regenerated cationic dye-dyeable polyester prepared by the invention can be used in the preparation of cationic dye-dyeable polyester filaments and short fibers, and realizes high-value recycling of waste polyester.

Owner:ZHEJIANG SCI-TECH UNIV

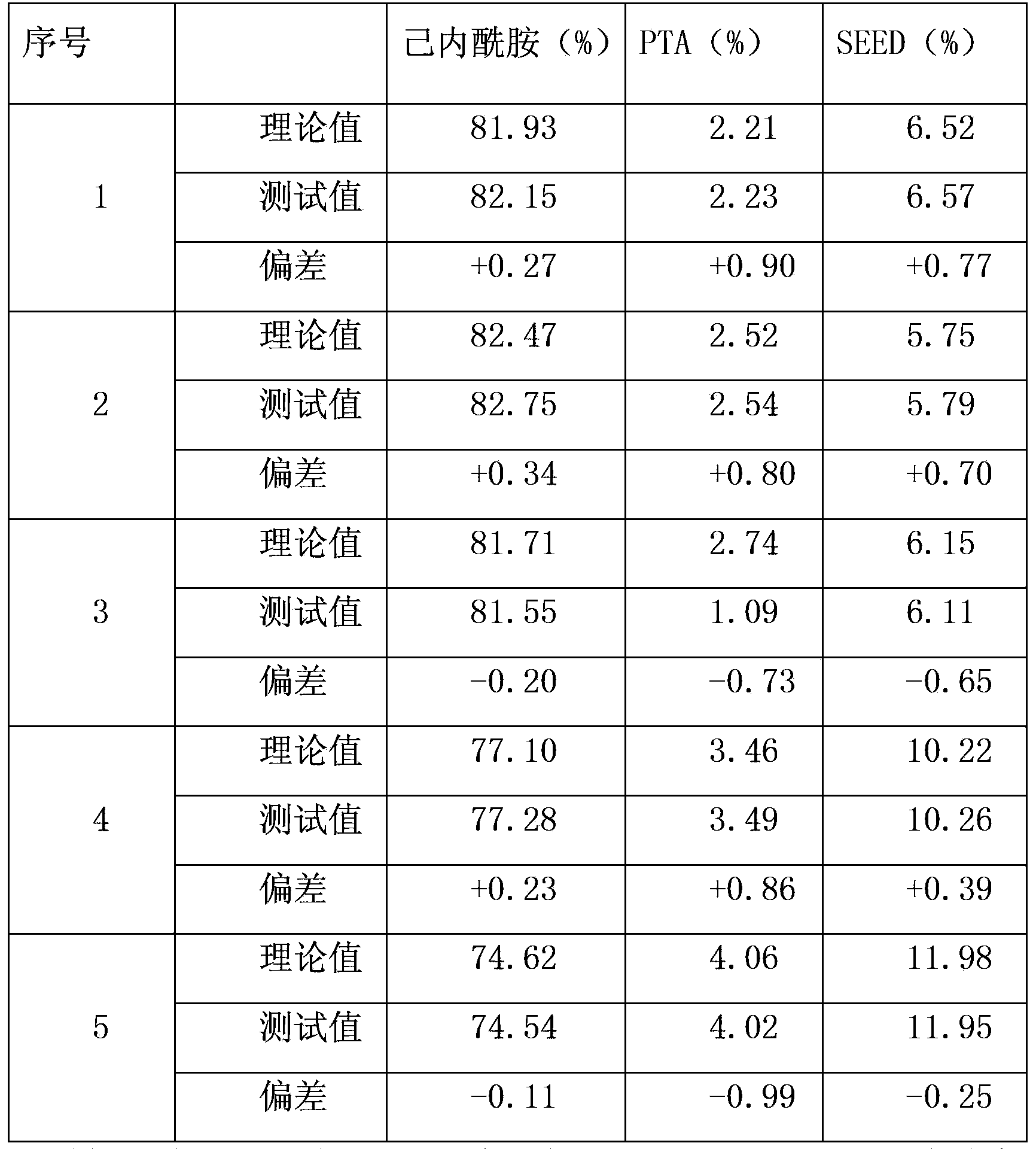

Quantitative test method for components of additives in PA6 producing process

InactiveCN103364369ADeployment quality controllableImprove product quality indicatorsColor/spectral properties measurementsSpectrogramChemistry

The invention provides a quantitative test method for components of additives in a PA6 producing process. The quantitative test method comprises the following steps: preparing PA6 additive solution samples with different component contents; collecting spectral data of multiple groups of samples by a Fourier near infrared spectrometer, to obtain a near infrared spectrogram of each sample, and constituting a calibration sample set; correlating the component contents of each group of samples with the spectrogram; establishing a quantitative analysis model for a solution component test; after assessment results meet requirements, testing components of a solution to be tested by the Fourier infrared spectrometer, to obtain component data of the solution to be tested. The quantitative test method has the beneficial effects that: the detection accuracy is up to 0.01%, the blending quality of acid additives can be controlled, the blending error of each batch is controlled within + / -0.2%, the blending accuracy of the additives is increased, and the stabilities of the product quality index, the spinning property and the dyeing uniformity are improved.

Owner:TIANJIN CHANGLU HAIJING GRP CO LTD

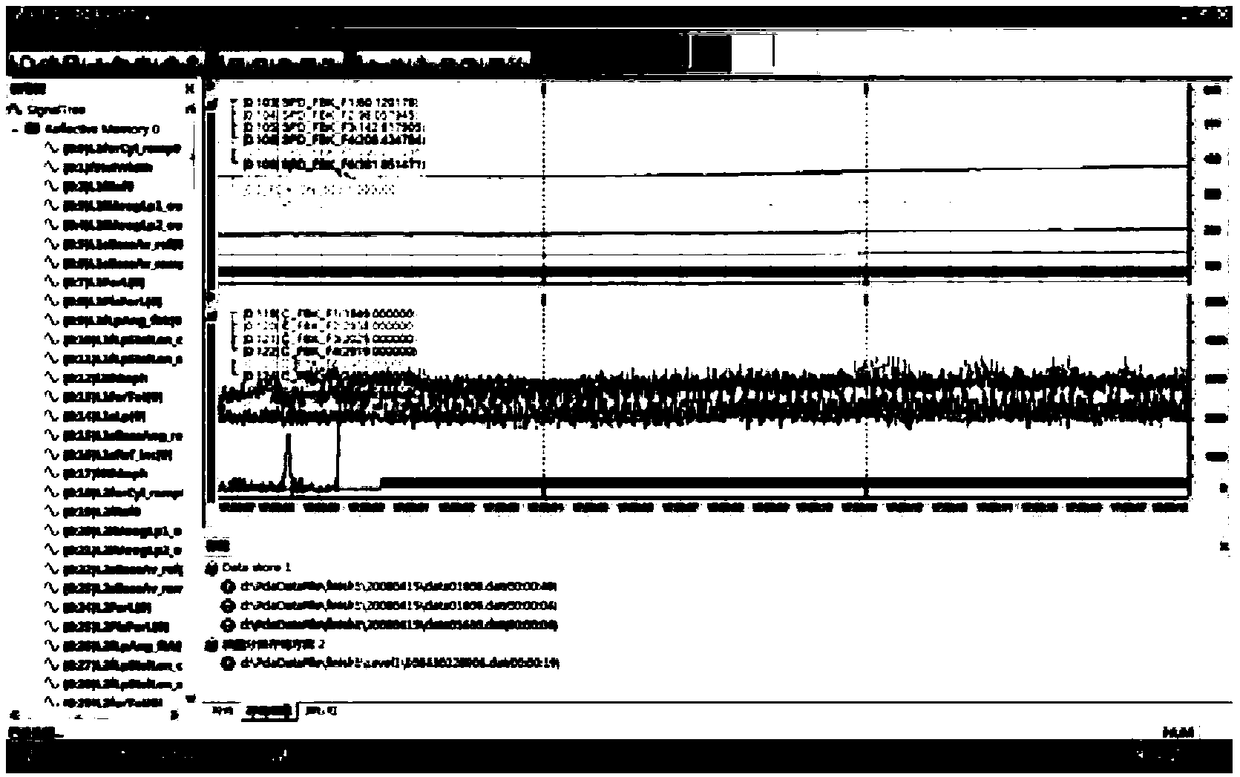

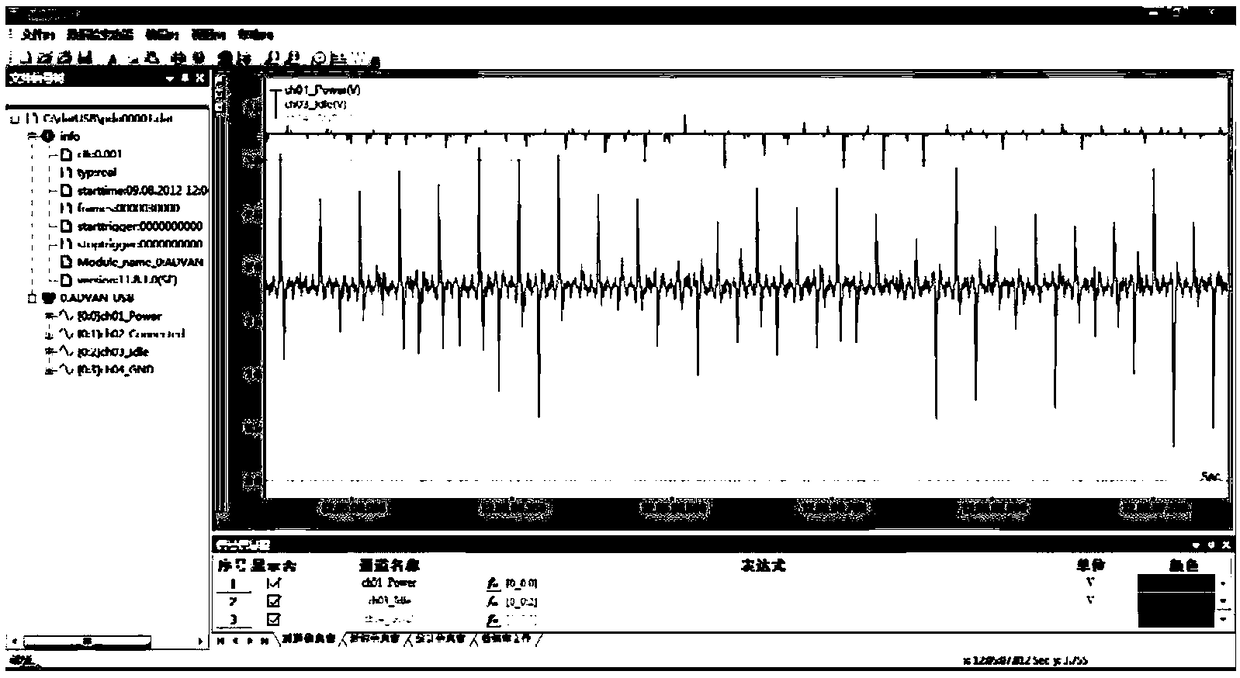

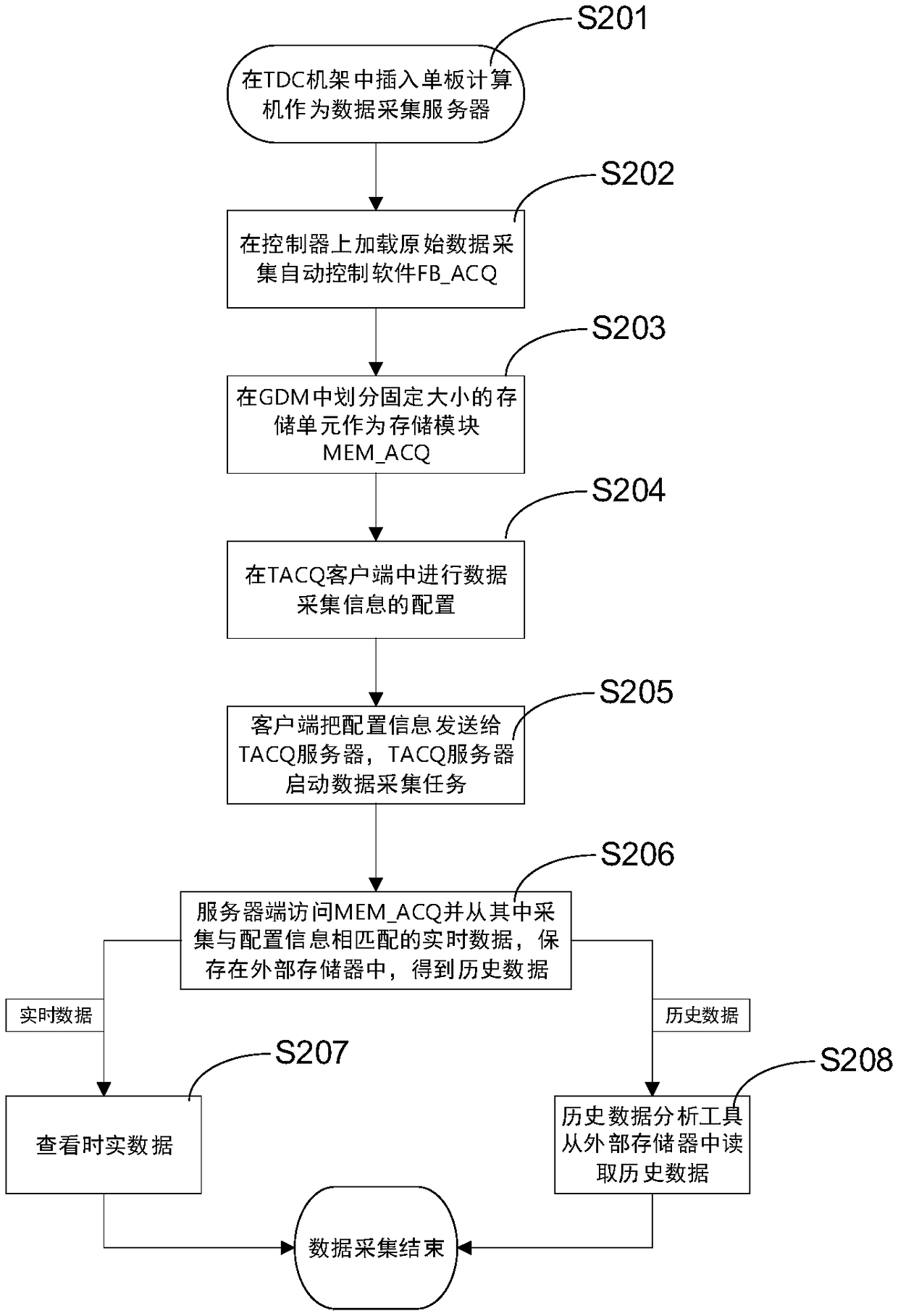

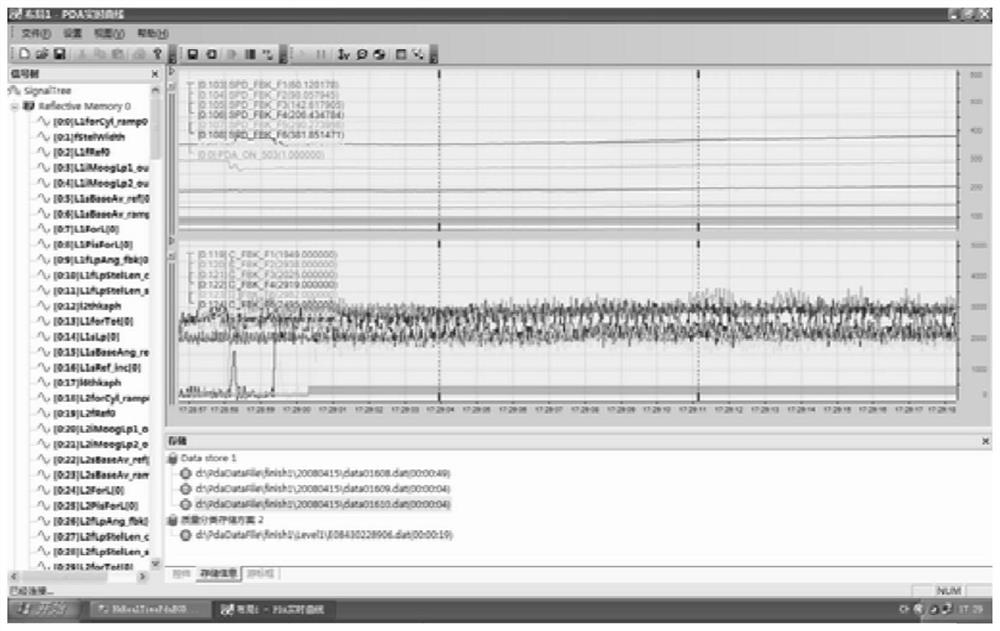

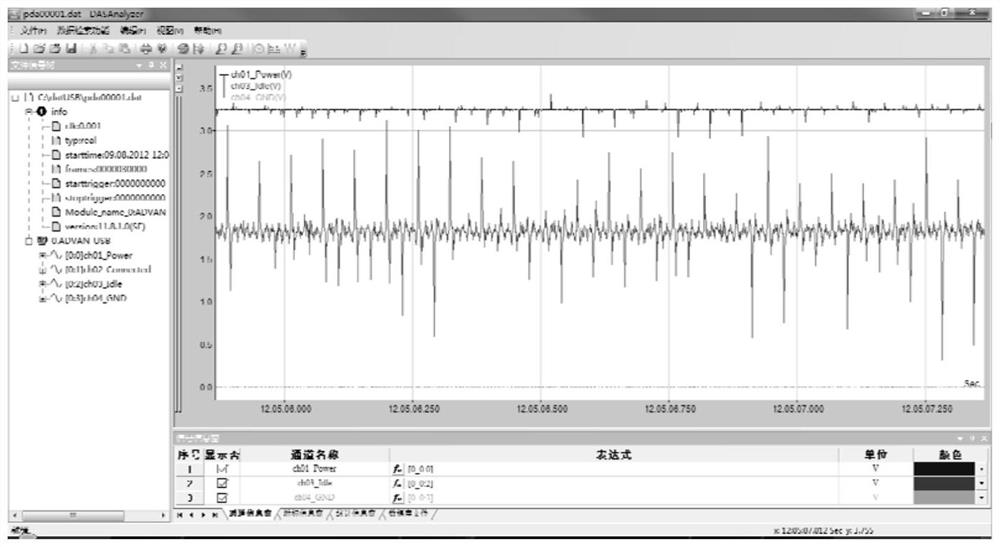

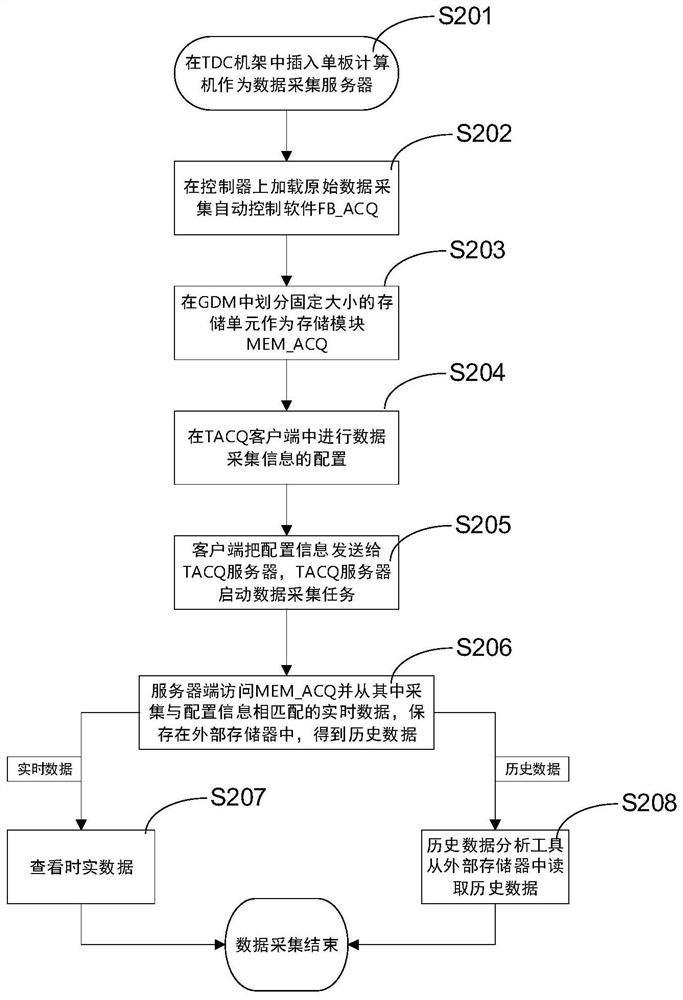

Embedded data acquisition system and method for GDM networks of SIMATIC TDC systems

ActiveCN109324573AEasy to configure and useData storage file is simpleTotal factory controlProgramme total factory controlAutomatic controlTime error

The invention provides an embedded data acquisition system and method for GDM networks of SIMATIC TDC systems, and aims at solving the problem that the data acquisition of TDC systems in the prior artmust be realized through GDM network cards. The system comprises automatic control software FB-ACQ, a memory module MEM-ACQ, a single board computer and data acquisition software TACQ. The FB-ACQ isoperated on a TDC system controller, completes data acquisition for the TDC system controller according a period configured for the acquisition and stores the acquired data in a specific area MEM-ACQof a GDM; and the single board computer is inserted into a TDC system rack in an embedded manner, and completes the acquisition of real-time data and historical data through operating the TACQ. The embedded data acquisition system and method are capable of realizing the high-speed acquisition of GDM data of the TDC systems, ensuring the time precision of data acquisition, and ensuring that the cumulative time error of every 10000 sample values does not exceed 1 ms; and the fastest sampling period can reach 1 ms, up to 50 pieces TDC controller data can be acquired at the same time, and up to 2048 channels can be acquired at the same time.

Owner:北京北科麦思科自动化工程技术有限公司

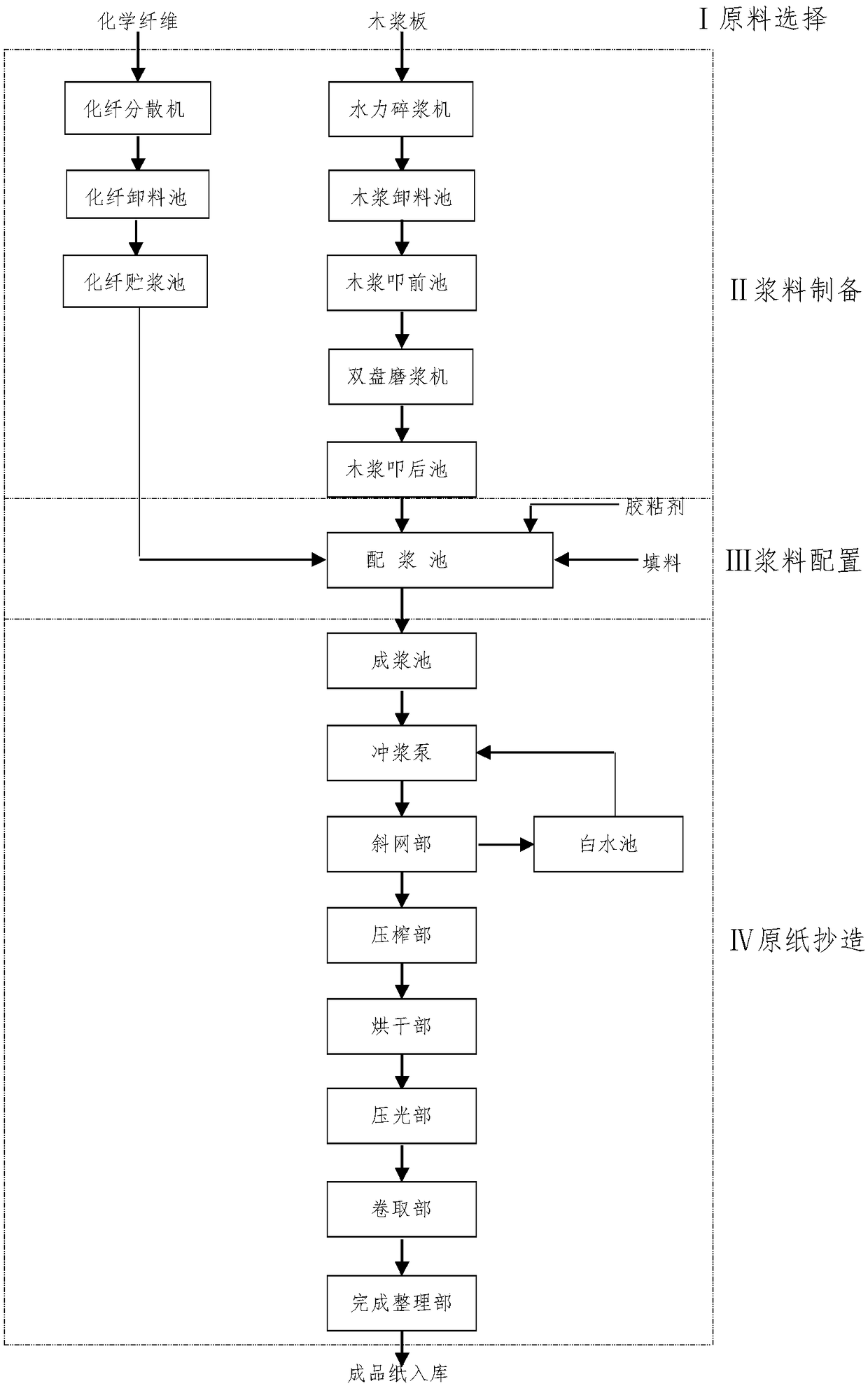

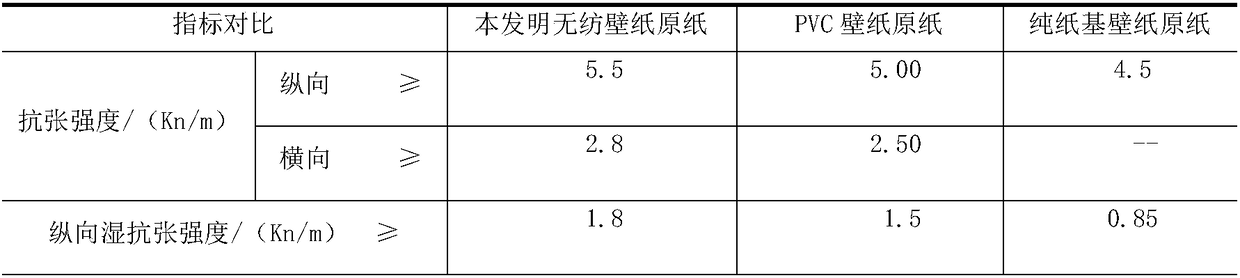

Environment-friendly non-woven wallpaper body paper and method for producing same

InactiveCN108425286AReduce pollutionImprove breathabilitySpecial paperPaper/cardboardFiberEnvironmental resistance

The invention discloses environment-friendly non-woven wallpaper body paper and a method for producing the same. The method includes four steps of (1), selecting raw materials including raw main production materials which are wood pulp boards and chemical fibers; (2), preparing slurry, to be more specific, defibering the wood pulp boards by the aid of hydraulic pulpers, carrying out grinding by the aid of double-disc grinding machines to obtain wood pulp slurry for standby application, washing the chemical fibers by the aid of hot water and dispersing the chemical fibers by the aid of dispersion machines to obtain chemical fiber slurry for standby application; (3), configuring the slurry, to be more specific, uniformly mixing the wood pulp slurry and the chemical fiber slurry, which are prepared at the step (2), according to certain proportions to obtain mixtures and adding adjusting materials and adhesive into the mixtures to obtain slurry; (4), manufacturing body paper with pulp, tobe more specific, diluting the slurry prepared at the step (3) until paper can be manufactured with pulp in an online manner, carrying out dehydration forming by the aid of oblique meshes of oblique-mesh papermaking machines, carrying out dehydration by the aid of squeezing portions, carrying out drying and finishing by the aid of drying portions and carrying out sorting by the aid of paper winding machines to obtain the environment-friendly non-woven wallpaper body paper. Compared with the prior art, the environment-friendly non-woven wallpaper body paper and the method have the advantages ofzero toxicity or harm and environmental friendliness.

Owner:NANJING FORESTRY UNIV

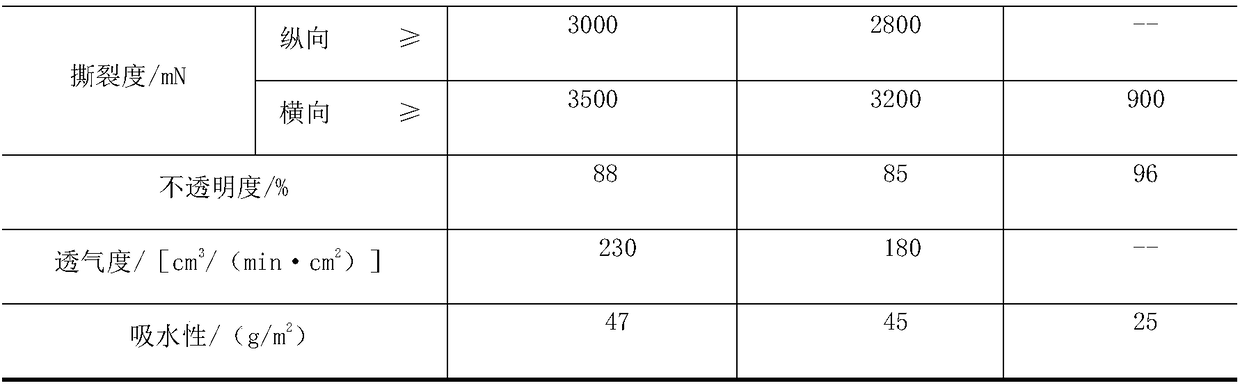

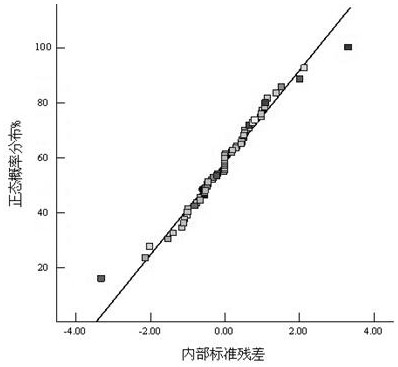

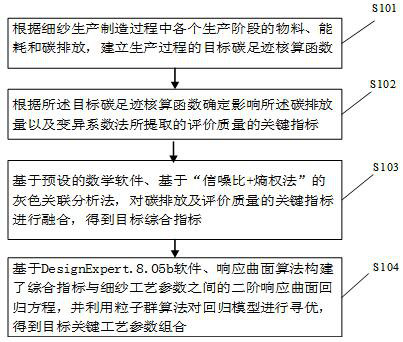

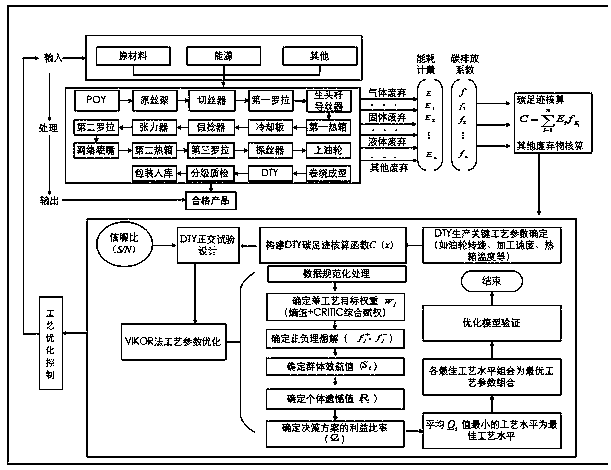

Spinning procedure process technological parameter optimization method based on carbon accounting

InactiveCN113947234AEmission reductionProduct quality indicators are stableForecastingTechnology managementYarnCarbon footprint

The invention discloses a spinning procedure technological parameter optimization method based on carbon accounting, and relates to the field of energy conservation, emission reduction and quality control in the spinning production process. The method comprises the following steps: firstly, selecting process parameter indexes which influence the carbon emission and the resultant yarn quality of a spinning procedure; extracting key quality indexes for evaluating resultant yarn quality according to a variable coefficient method; and constructing a relation model between the energy consumption of the spinning process and the quality of resultant yarn; establishing a target carbon footprint accounting function of the production process according to the spun yarn production flow; determining key indexes influencing the carbon footprint and the extracted evaluation quality according to the target carbon footprint accounting function; and based on preset mathematical software and a grey correlation analysis method of signal-to-noise ratio + entropy weight method, fusing the key indexes of carbon emission and evaluation quality to obtain a target comprehensive index. The purposes of reducing production energy consumption in the spun yarn production process, reducing carbon emission and improving the spun yarn quality are achieved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

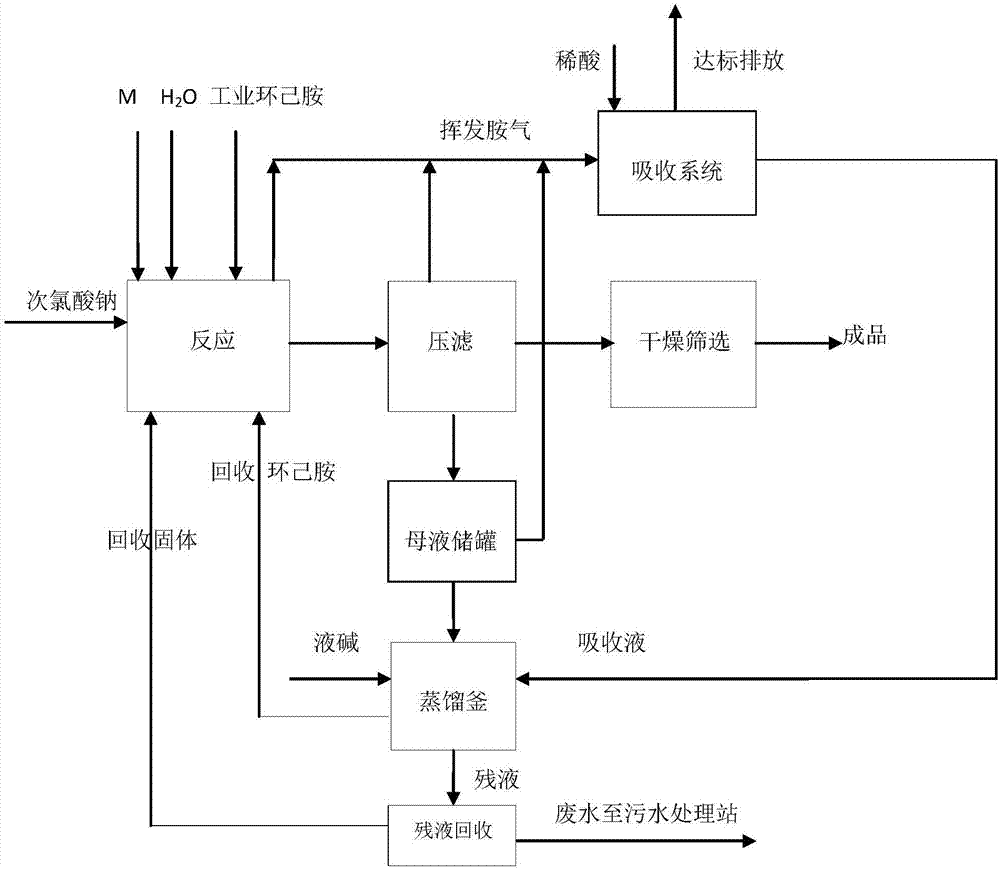

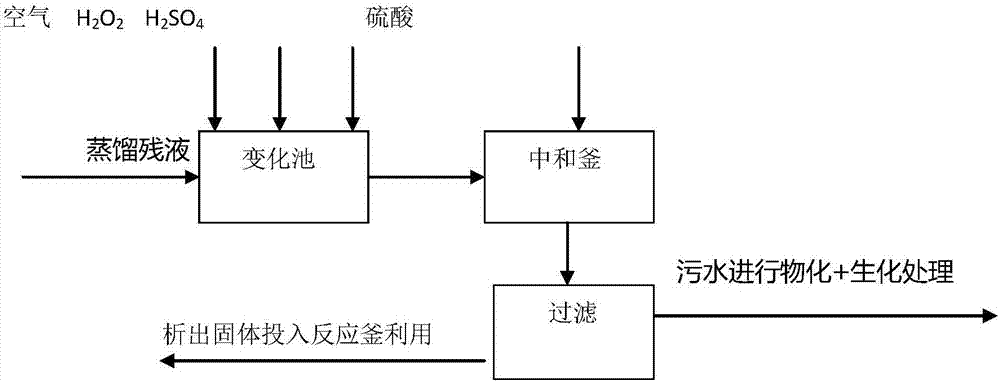

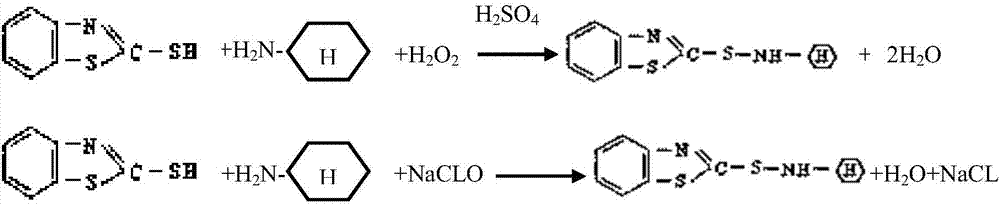

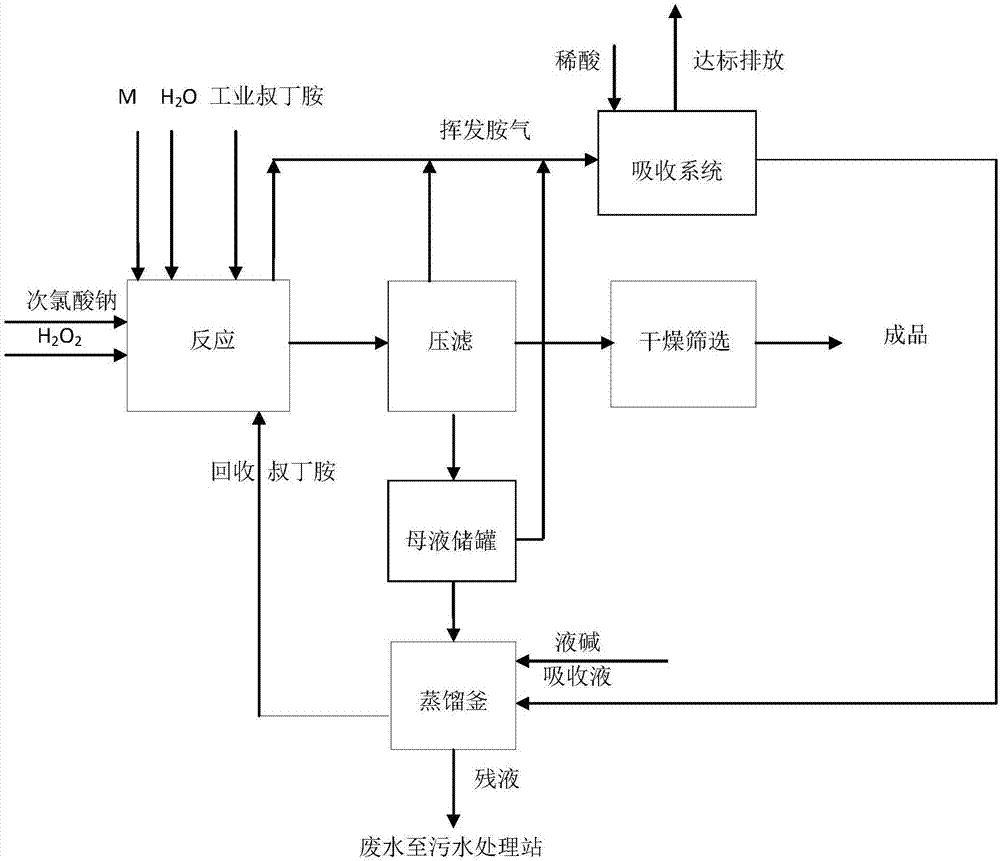

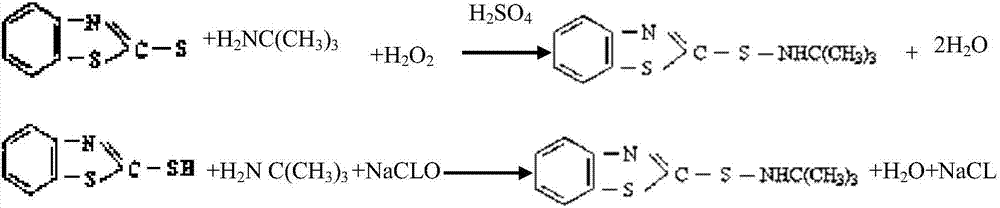

Method for using rubber accelerator M to synthesize sulfonamide accelerator CBS by solvent purification method

InactiveCN107445918AReduce chemical oxygen demand CODcrReduce generationOrganic chemistryPurification methodsReaction temperature

The invention discloses a method for using a rubber accelerator M to synthesize an sulfonamide accelerator CBS by a solvent purification method. The method comprises the following steps of: by adopting the rubber accelerator M and cyclohexylamine as materials, adopting hydrogen peroxide and sodium hypochlorite as oxidants, adopting sulfuric acid as a catalyst, reacting to synthesize the accelerator CBS, wherein the optimum production process conditions include: (1) the molar ratio between all the materials and the oxidants is as follows: n(M):n(cyclohexylamine) is equal to 1:2.2; n(M):n(20% hydrogen peroxide):n(15% sodium hypochlorite) is equal to 1:0.6:0.65-0.75; (2) the reaction temperature is 35-40 DEG C; and (3) the reaction time is 2.0-2.5 hours. The method disclosed by the invention has the advantages that the technical problem in using the rubber accelerator M to synthesize the sulfonamide accelerator CBS by the solvent purification method is comprehensively solved, the product quality index is higher than international level, the consumption index reaches lower industrial level, and the problem of treatment of waste water, solid wastes and odor pollutants is solved.

Owner:QINGDAO AUX CHEM

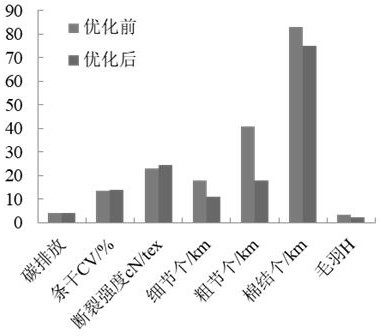

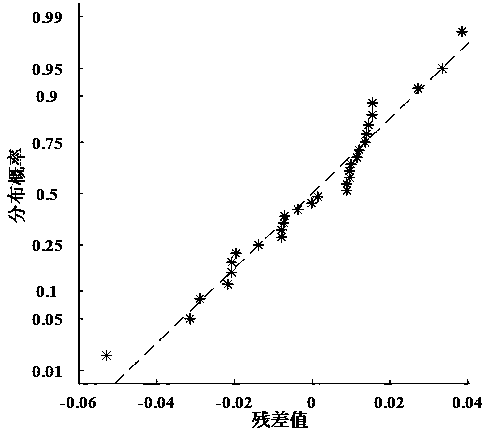

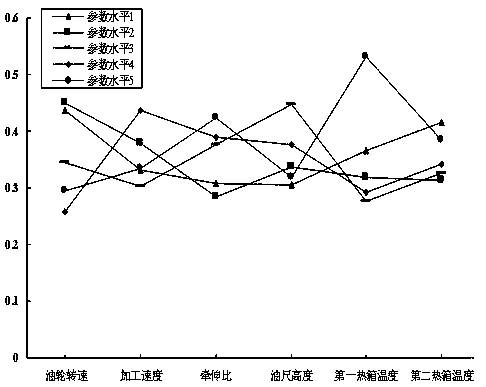

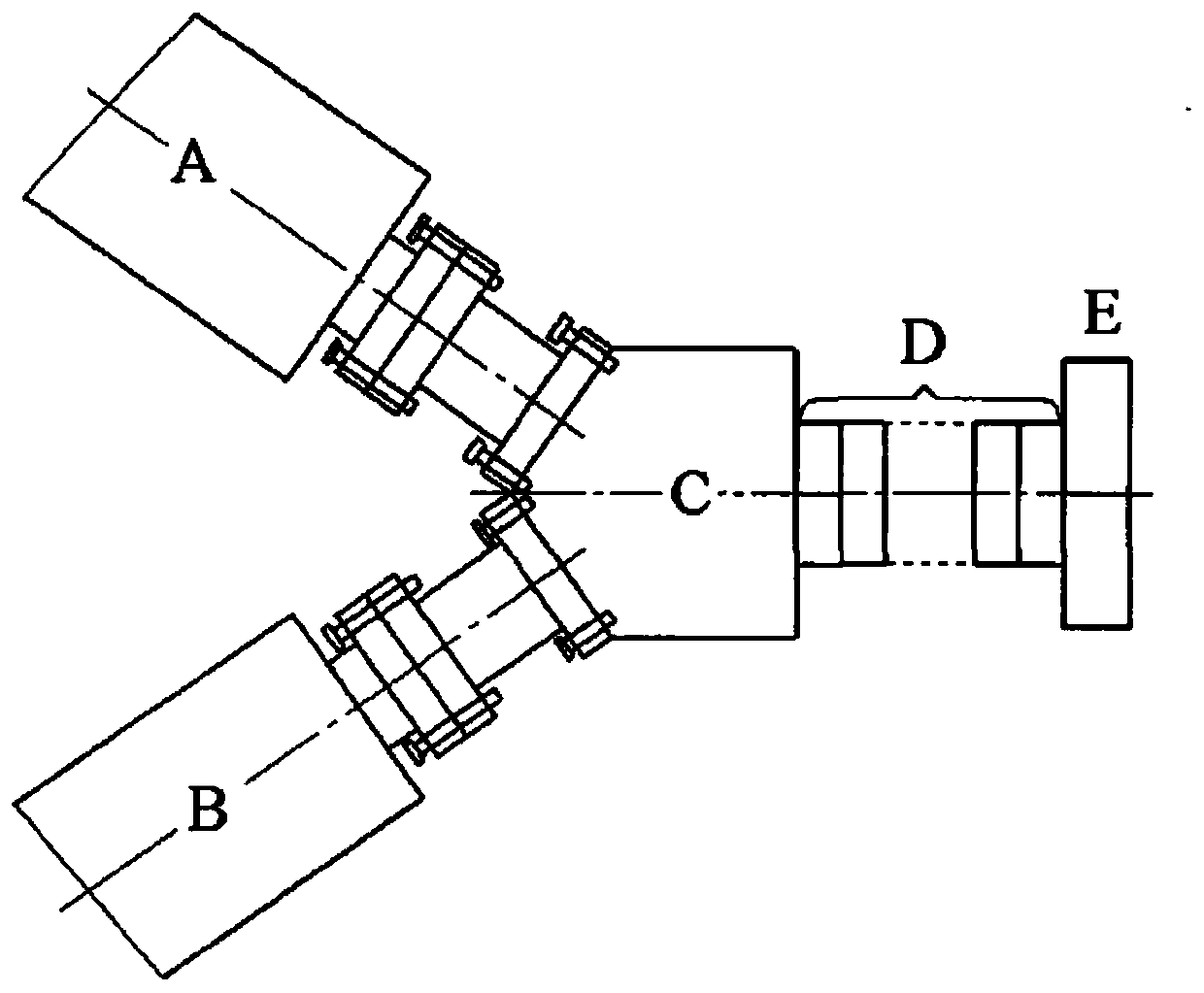

Polyester drawn textured yarn process optimization method

ActiveCN111324973AProduct quality indicators are stableEmission reductionDesign optimisation/simulationManufacturing computing systemsPolyesterYarn

The invention discloses a polyester drawn textured yarn process optimization method, and relates to the field of polyester drawn textured yarn production process energy conservation, emission reduction and quality control, and the method comprises the steps: building a target carbon footprint accounting function of a production process according to materials, energy consumption and carbon emissionof each production stage in the polyester drawn textured yarn production process; according to the target carbon footprint accounting function, determining key process parameters influencing the carbon footprint and influencing the quality characteristics of the polyester drawn textured yarn finished product; and optimizing the key process parameters based on preset mathematical software, an orthogonal test of a signal-to-noise ratio and a VIKOR method of'entropy + CRITIC 'comprehensive empowerment to obtain a target key process parameter combination. According to the method, the aims of reducing the production energy consumption in a data driving mode, reducing the carbon emission and improving the quality index of the polyester drawn textured yarn product in the production process of the polyester drawn textured yarn are achieved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

A method for preparing alternate layered biodegradable polymer barrier materials with excellent water vapor and oxygen barrier properties

ActiveCN107286607BImprove hydrophobicityEffectively control the diffusion pathSynthetic resin layered productsLaminationWater vaporMechanical property

The invention discloses a method for preparing an alternate layered biodegradable polymer barrier material with excellent water vapor and oxygen barrier properties. The method comprises the main content as follows: the water vapor barrier property and the stability of the barrier property on humidity are improved through adding hydrophobic substances to water vapor barrier layers, and the diffusion path of oxygen is increased to improve the oxygen barrier property through adding a filler with large specific surface area to an oxygen barrier layer; a multi-layer structure of which the water vapor barrier layers are arranged at the outmost layer and the internal oxygen barrier layer and the water vapor barrier layers are alternately arranged is designed by using a coextrusion system, thereby obtaining excellent water vapor and oxygen barrier properties and the stability of the properties on the humidity at the same time; dimensions and form structures of a disperse phase and the filler are optimized to further improve the barrier properties through stretching and shearing force fields in the coextrusion process, and meanwhile, the mechanical property is improved. The method is a continuous production process and is simple in process, products of different batches are stable in quality index, large-scale industrial production can be carried out, and the method has wide industrialization and market prospects, and is of great significance in theoretical research and application and development of a composite material.

Owner:SICHUAN UNIV

Method for preparing thermosensitive alternate laminar drug release composite material

InactiveCN107260654AAchieve releaseReduce burstOrganic active ingredientsPharmaceutical delivery mechanismTemperature responseCo extrusion

The invention discloses a method for preparing a thermosensitive alternate laminar drug release composite material. The method is mainly characterized by preparing the thermosensitive alternate laminar drug release composite material of which a polymer-based drug loading layer and a polymer-based temperature response layer are alternately and orderly arranged through fusion co-extrusion, regulating morphological structures of the polymer-based drug loading layer and the polymer-based temperature response layer through a shear tensile action under the action of a laminar overlay force field in an extrusion process, improving drug diffusion and temperature response release channels, enabling the obtained thermosensitive alternate laminar drug release composite material to have a reasonable initial drug release amount and a temperature response drug release property, realizing controllable, flexible and effective release of a drug, and meeting different drug release requirements. According to the thermosensitive alternate laminar drug release composite material prepared by the invention, the morphology can be structured, and the property can be designed; the thermosensitive alternate laminar drug release composite material can be biodegraded, is safe and non-toxic, is good in mechanical property, can be continuously produced, is flexible and controllable in drug release behavior, and has remarkable research value and remarkable application prospect in the field of drug response release.

Owner:SICHUAN UNIV

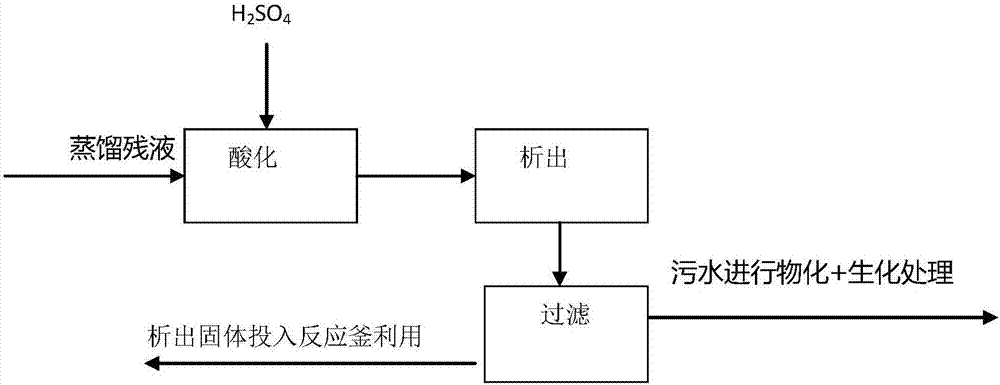

Method for synthesizing sulfenamide-like accelerator TBBS by using solvent purification method rubber accelerator M

InactiveCN107501206AReduce chemical oxygen demandReduce generationOrganic chemistryPurification methodsReaction temperature

The invention discloses a method for synthesizing sulfenamide-like accelerator TBBS (N-cyclohexyl-2-benzothiazolylsulfenamide) by using a solvent purification method rubber accelerator M. The accelerator TBBS is synthesized by using the rubber accelerator M and tert-butylamine as raw materials, by using hydrogen peroxide and sodium hypochlorite as oxidants and by using sulfuric acid as a catalyst; and the method comprises the following optimal production process conditions: (1) a molar ratio of the rubber accelerator M to the tert-butylamine is 1:2.4; and a molar ratio of the rubber accelerator M to the hydrogen peroxide to the sodium hypochlorite is 1:0.6:(0.55-0.65); (2) a reaction temperature is 55-60 DEG C; and (3) reaction time is 2.0-3.0h. The method disclosed by the invention comprehensively solves a technical problem of synthesizing the sulfenamide-like accelerator TBBS by using the solvent purification method rubber accelerator M, product quality indexes are higher than Chinese standard levels, consumption indexes achieve industry relatively-low standards, and the method solves treatment problems of pollutants including wastewater, solid waste and cacosmia.

Owner:QINGDAO AUX CHEM

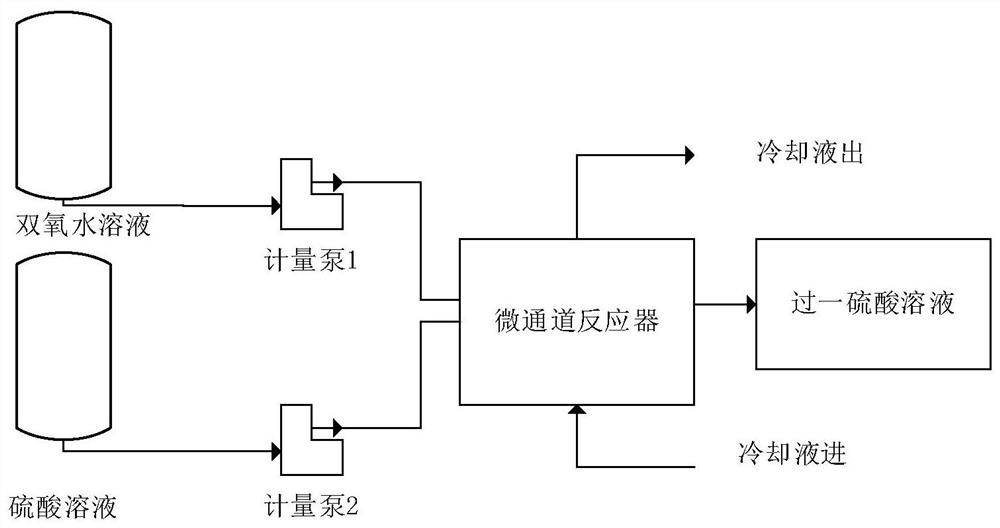

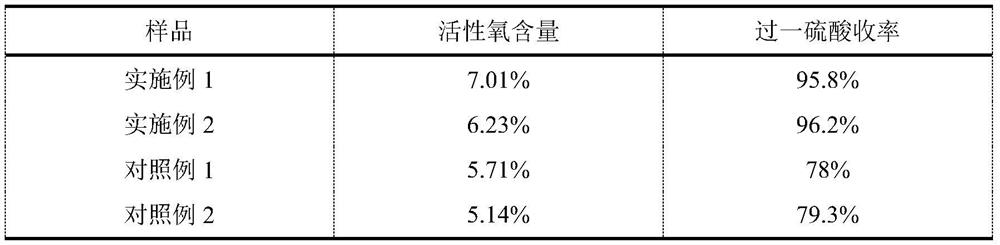

Method for continuously preparing peroxymonosulfuric acid by using microchannel reactor

PendingCN113845093AIntrinsically safePromote absorptionPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical/physico-chemical microreactorsReaction temperatureHeat transfer efficiency

The invention discloses a method for continuously preparing peroxymonosulfuric acid by using a microchannel reactor. The method comprises the following step: with hydrogen peroxide and sulfuric acid as raw materials, simultaneously and continuously conveying the raw materials into the micro-channel reactor, wherein a reaction molar ratio of the hydrogen peroxide to the sulfuric acid is controlled to be 1: (1.1-5), a reaction temperature is controlled to be -15 DEG C to 65 DEG C and reaction retention time is controlled to be 2 seconds to 10 minutes. According to the method, the peroxymonosulfuric acid is prepared by adopting the microchannel reactor, the mass transfer efficiency and the heat transfer efficiency of the microchannel reactor are very high; continuous reaction is adopted, so the time consumption of a working procedure can be effectively shortened, and production efficiency is improved; moreover, reactants can be in full contact, and the yield of the product peroxymonosulfuric acid is improved; and meanwhile, reaction heat can be removed more quickly, the temperature of a reaction system can be regulated and controlled in time, accurate control over the reaction temperature is achieved, the possibility of safety and quality accidents is reduced, and safe and efficient production is achieved.

Owner:ZHEJIANG JINKE CHEM

A kind of embedded data acquisition system and method for simatic TDC system GDM network

ActiveCN109324573BNo difficulty in getting startedOptimizationTotal factory controlProgramme total factory controlAutomatic controlReal-time data

The invention provides an embedded data acquisition system and method for GDM networks of SIMATIC TDC systems, and aims at solving the problem that the data acquisition of TDC systems in the prior artmust be realized through GDM network cards. The system comprises automatic control software FB-ACQ, a memory module MEM-ACQ, a single board computer and data acquisition software TACQ. The FB-ACQ isoperated on a TDC system controller, completes data acquisition for the TDC system controller according a period configured for the acquisition and stores the acquired data in a specific area MEM-ACQof a GDM; and the single board computer is inserted into a TDC system rack in an embedded manner, and completes the acquisition of real-time data and historical data through operating the TACQ. The embedded data acquisition system and method are capable of realizing the high-speed acquisition of GDM data of the TDC systems, ensuring the time precision of data acquisition, and ensuring that the cumulative time error of every 10000 sample values does not exceed 1 ms; and the fastest sampling period can reach 1 ms, up to 50 pieces TDC controller data can be acquired at the same time, and up to 2048 channels can be acquired at the same time.

Owner:北京北科麦思科自动化工程技术有限公司

Method for removing residual formic acid in epoxidized fatty acid methyl esters or epoxidized soybean oil by use of eutectic solvent

The invention belongs to the field of chemical technology and specifically relates to a method for removing residual formic acid in epoxidized fatty acid methyl esters or epoxidized soybean oil by the use of a eutectic solvent. The method provided by the invention comprises the following specific steps: sending crude epoxidized fatty acid methyl esters or crude epoxidized soybean oil which contains 0.2-15wt% of formic acid and is obtained by a epoxidation process through a formic acid method into an extraction kettle, adding a certain amount of an extractant under the condition of stirring, stirring for a period of time, standing for layering, sending a material on the upper layer into a vacuum dehydration kettle for further dehydration and refining, pouring an extract on the lower layer into an extractant regeneration kettle; heating under the condition of pressure reduction to distill formic acid in the extract, recycling the formic acid steam after being condensed in a condenser, and sending residual extractant left in the extractant regeneration kettle into the extraction kettle for recycling. The method provided by the invention has advantages of no discharge of waste water, high formic acid removal rate, simple technological operation, environmental protection, safety and low cost, and is suitable for both small-scale device and large-scale device production.

Owner:石家庄搏澳增塑材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com