Method for preparing thermosensitive alternate laminar drug release composite material

A composite material and alternating layer technology, which is applied in the field of preparation of temperature-sensitive alternating layered drug release composite materials, can solve the problems of poor biocompatibility of monomers, difficult control of single-layer structure and interlayer compounding, and harsh preparation conditions , to achieve good biocompatibility, easy hot-melt processing, and weaken the effect of burst release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

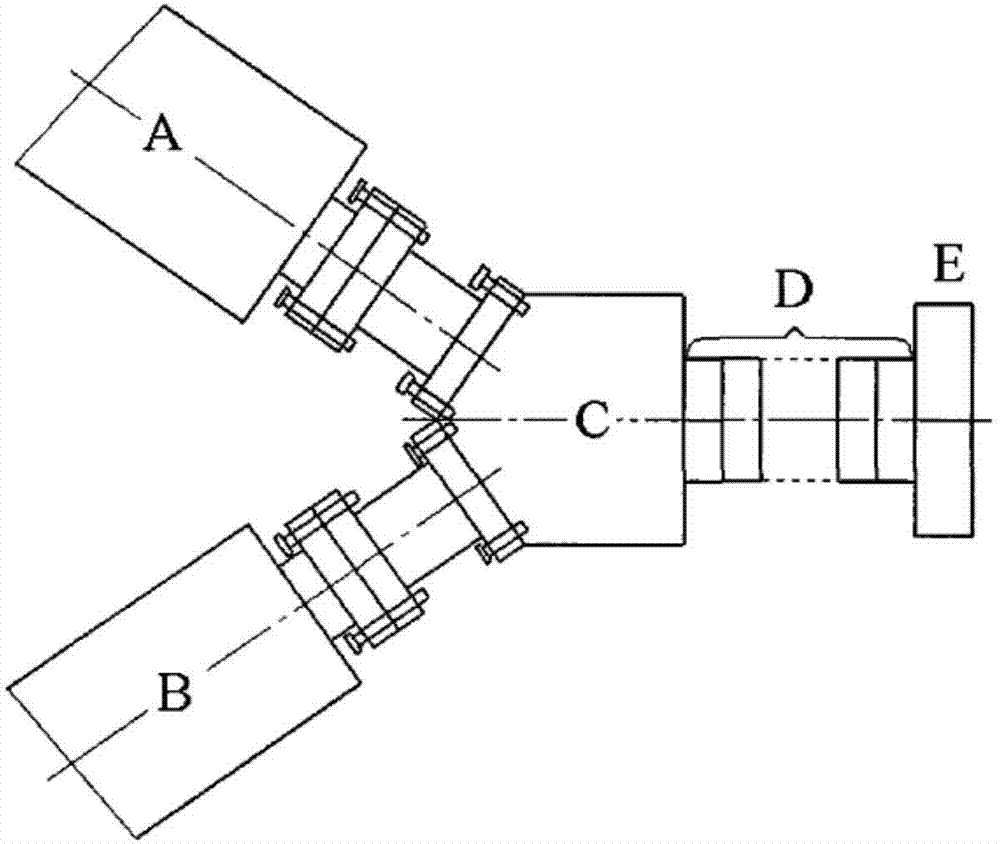

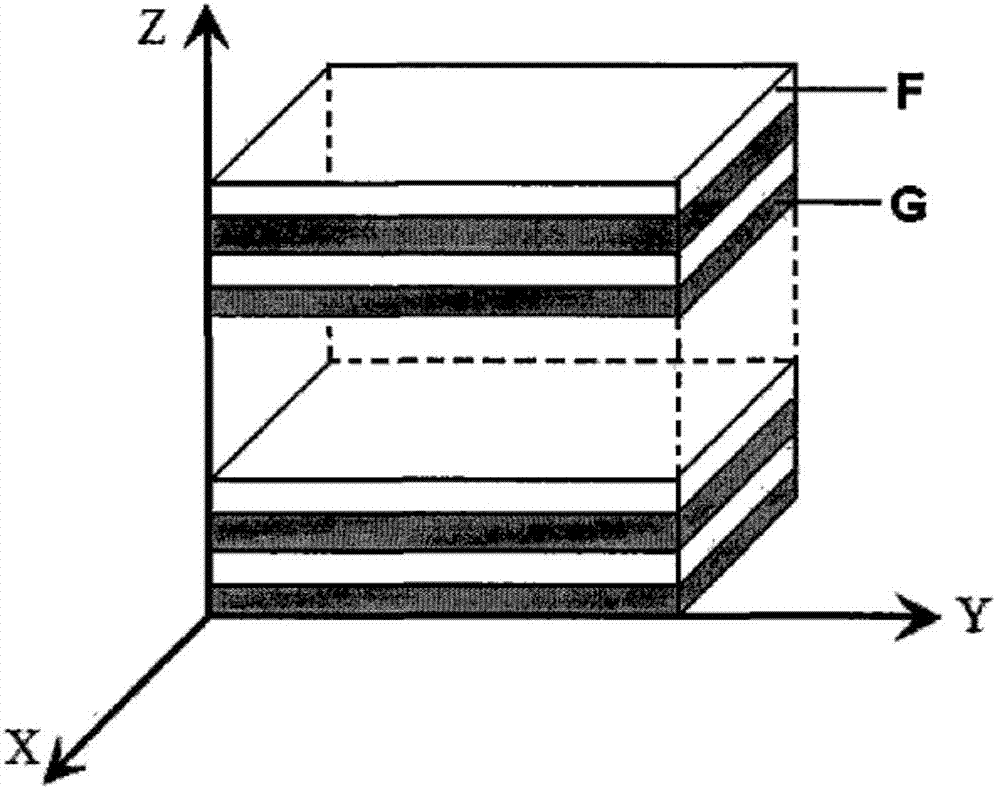

Method used

Image

Examples

Embodiment 1

[0048] A polycaprolactone (drug-loaded layer matrix)-polyethylene glycol (drug-loaded layer dispersed phase)-diclofenac sodium (drug) / polycaprolactone (temperature-responsive layer matrix)-glycerol trilaurate (temperature-responsive Layer temperature response functional phase) The raw materials of the temperature-sensitive alternating layered drug release composite material include the following components and contents in parts by weight:

[0049] Polymer-based drug-loaded layer component distribution ratio parts by weight

[0050] Polycaprolactone (for the drug-loaded layer matrix) 90

[0051] Polyethylene glycol (for the dispersed phase of the drug loading layer) 10

[0052] Diclofenac sodium (as a drug) 5

[0053] Polymer-based temperature-responsive layer composition ratio Parts by weight

[0054] Polycaprolactone (as the temperature response layer matrix) 90

[0055] Glyceryl trilaurate (for the temperature response layer temperature response functional phase) 10

[...

Embodiment 2

[0065] A polycaprolactone (drug-loaded layer matrix)-polyethylene glycol (drug-loaded layer dispersed phase)-diclofenac sodium (drug) / polycaprolactone (temperature-responsive layer matrix)-glycerol trilaurate (temperature-responsive Layer temperature response functional phase) The raw materials of the temperature-sensitive alternating layered drug release composite material include the following components and contents in parts by weight:

[0066] Drug-loaded layer component distribution ratio parts by weight

[0067] Polycaprolactone (as the drug-loaded layer matrix) 80

[0068] Polyethylene glycol (for the dispersed phase of drug loading layer) 20

[0069] Diclofenac sodium (as a drug) 10

[0070] Temperature-responsive layer group distribution ratio parts by weight

[0071] Polycaprolactone (as the temperature response layer matrix) 85

[0072] Glyceryl trilaurate (for the temperature response layer temperature response functional phase) 15

[0073] Note: The drug-load...

Embodiment 3

[0082] A polybutylene succinate (drug-loaded layer matrix)-polyethylene glycol (dispersed phase of the drug-loaded layer)-metoprolol tartrate (drug) / polybutylene succinate (temperature-responsive layer Matrix)-glycerol tristearate (temperature-responsive layer temperature-responsive functional phase) The raw materials of the temperature-sensitive alternating layered drug release composite material include the following components and contents in parts by weight:

[0083] Drug-loaded layer component distribution ratio parts by weight

[0084] Polybutylene succinate (as the drug loading layer matrix) 80

[0085] Polyethylene glycol (for the dispersed phase of drug loading layer) 20

[0086] Metoprolol tartrate (as drug) 10

[0087] Temperature-responsive layer group distribution ratio parts by weight

[0088] Polybutylene succinate (substrate for temperature responsive layer) 85

[0089] Glycerol tristearate (for the temperature response layer temperature response functional...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com